SMP Test Prep

1/23

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

24 Terms

13 Main Obligations for Engineering Ethics

Support own’s professional society

Guard privileged information & data

Accept responsibility for own actions

Employ proper use of authority

Maintain own’s expertise in a state-of-art world

Build & maintain public confidence

Avoid improper gifts and/or gift exchange

Avoid conflict of interest

Apply equal opportunity employment

Maintain honesty in dealing with employers, co-workers, clients, vendors, government

Practice conservation of resources, pollution prevention, sustainability

Practice energy conservation

Practice safety, health, accident prevention & Management

P.A.S.S Acronym for operation of fire extinguisher

Pull the pin to allow the user to squeeze the lever to discharge the extinguisher.

Aim the hose at the base of the fire. Stand a safe distance away from the fire.

Squeeze the handle fully to discharge the fire extinguisher agent.

Sweep the hose from side to side.

Difference between Activity and Equipment Based Risk Assessment

Equipment based RA refers to the very general usage of the equipment itself without elaborating on what it is used for. Only the SWP for the equipment Is required. For example, usage of drying oven

Activity based RA includes everything and everything that is needed for the activity on top of the equipment being used. Requires knowledge of the SOP of the activity and SDS if chemicals are involved. More than one equipment can be used for a certain activity so SWPs are also included. Example, Conducting TSS experiment.

When should HAZOP be done?

When P&IDs are at ‘Approved for Design’ stage (final design HAZOP)

During construction site inspections ensure that recommendations arising from the HAZOP are being implemented.

At pre-commissioning safety reviews of plant procedures & safety audits to ensure that recommendations arising from the HAZOP are addressed.

HAZOP review at regular intervals (every 5 years) or when there are modifications to existing plant.

Format of HAZOP Table

Node | Process Parameter | Deviations (Guidewords) | Possible causes | Possible consequences | Existing Safeguards | Actions Required |

Purpose of HAZOP

Identify all possible deviations from design or normal operating conditions - to uncover all hazards and operability problems associated with the deviations.

When deviations arise that results in hazardous consequence or operability problems, actions are generated for team/design engineers to review and provide solutions - to eliminate hazards or reduce the risk to acceptable level

Define ‘Hazard’

Any deviation in operation that could cause:

a release of toxic, flammable or explosive chemicals

any action that could result in injury to personnel.

Define ‘Operability’

Any deviation in operation within the design envelop that would cause:

a shutdown

lead to a violation of environmental, health or safety regulations

negatively impact profitability.

Define ‘DEVIATION’

A way in which process conditions may depart from their INTENTION

Define ‘INTENTION’

Description of how process is expected to behave at the study line at design or normal operating conditions.

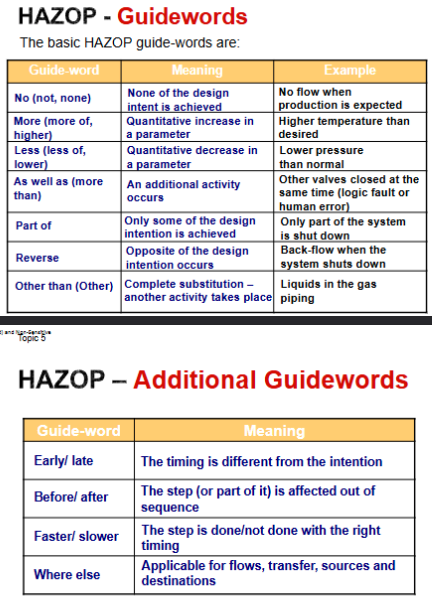

Define ‘GUIDEWORD’

A short word to create the imagination of a DEVIATION of the INTENTION used to identify unexpected yet credible DEVIATIONS from the INTENTION

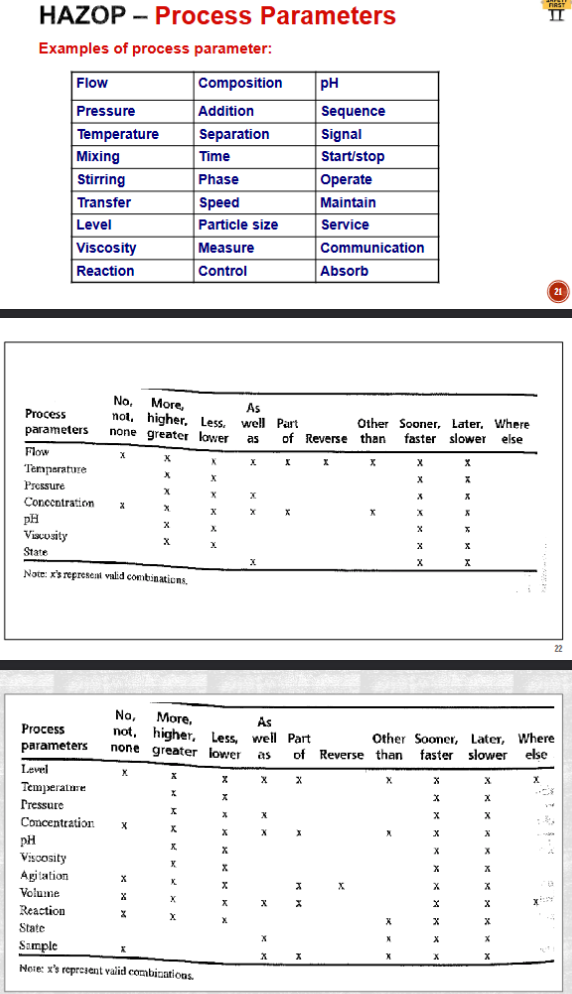

Process Parameters and combinations (to read)

How often should RA be reviewed?

All RA entries must be reviewed at least once every three years or

upon any accident, incident, near miss or dangerous occurence

when there is any significant change in work process or activity or legislation

when new information on WSH risks is made known

What to include in “Inventory of Work Activities” (Form A)

Department

Location

Process

Work Activity

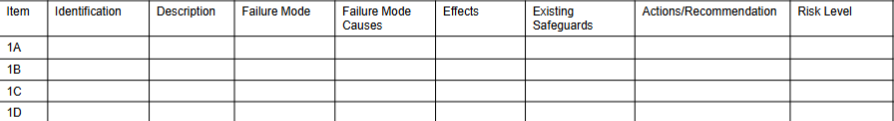

FMEA Format

Three main parts of RA

Hazard identification: identifying safety and health hazards associated with work.

Risk evaluation: assessing risks involved

Risk control: Prioritizing risk control measures to eliminate hazards or reduce risks to acceptable level.

What is Risk

The likelihood that a hazard will cause a specific bodily injury to any person

RA Prevention

Reduces likelihood of hazard but no impact on severity

RA Mitigation

Reduces severity

RA Elimination

Changes both likelihood and severity

RA Hierarchy of Control: Elimination (1st)

Total removal of worker’s exposure to hazards

Example: eliminate the risk of fall from height by doing the work at ground level

RA Hierarchy of Control: Substitution (2nd)

Involves substituting a process or product with a less hazardous one to mitigate the risk.

Example: Replace ladders with tower scaffolds

RA Hierarchy of Control: Engineering Controls (3rd)

Physical means to reducing likelihood or severity

Example: Machine guarding

RA Hierarchy of Control: Administrative Controls (4th)

Eliminates or reduces exposure to a hazard by adherence to procedures or instructions

Example: PTW, limiting exposure time to a hazardous task