Supply Chain Quiz 2

1/64

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

65 Terms

Legal Forms of Transportation (4)

Transportation service companies are classified

legally as either common, contract, exempt, or

private carriers

Common carriers

Contract carriers

Exempt carriers

Private carriers

Common Carriers

offer transportation services to all shippers at published rates between designated locations without discrimination.

Ex: Airlines (like Delta or American Airlines)

Bus companies (Greyhound)

Railroads/Amtrak

Shipping companies (FedEx, UPS, USPS)

Taxi services or ride-share drivers in many states

Contract Carriers

not bound to serve the general public. Contract carriers serve specific customers under negotiated contractual agreements.

Ex: A private trucking company that hauls products exclusively for Coca-Cola

*coke does not own the trucks! this is the difference between this and private

Exempt Carriers

exempt from federal economic regulation of services & rates & if they transport certain exempt products like unprocessed produce, livestock, coal, school buses

Private Carrier (air transportation)

not subject to economic regulation & typically transports goods for the company owning the carrier.

Ex: Walmart using its own trucks to deliver products to its stores.

*Walmart owns these trucks! thats the difference between this and contract

Where do airlines make most of their money?

Airline industry is very dependent on passenger revenue to maintain financial viability:

Passenger fares represents about 75% of revenue

Private

transport company’s freight and personnel in support of the primary business

For Hire carriers

businesses that transport passengers or cargo for compensation

Major Carriers

provide services between major population areas (New York, Chicago, Los Angeles, Miami, etc.)

Ex: United, Delta, Southwest,

American Airlines, US Airways, Alaska Airlines, AirTran

Majors are responsible for majority of passenger and freight activity

Major carriers do provide cargo transportation together with passengers

On passenger planes, cargo is being held in the “belly hold” under the passenger cabin

Cargo is typically consolidated into pallets

National Carriers

provide services between less- populated areas and major population centers

routes are relatively short

Examples of national carrier airlines: Frontier, Airlines, Midwest Express, jetBlue

Ex: JetBlue: Albany, NY → Boston, MA

Albany is smaller, Boston is a major hub. Short route, narrow-body jet.

Regional Carriers

Similar to National because they do short routes

Routes served are usually relatively short with smaller planes

They “feed” passengers from outlying areas to major airports served by majors

Operate within a particular region of the country

Examples of national carrier airlines: Piedmont Airlines, Atlantic Coast Airlines, Sky West Airlines

Ex: Atlantic Coast Airlines: Norfolk, VA → Washington D.C. (Dulles)

All Cargo Carriers

Transport Primarily Cargo

Examples: FedEx and UPS airlines, DHL (German logistics company), Atlas Air, Air Transport International

In 1977 cargo transportation was deregulated,

allowing all-cargo carriers to freely set the fees

and rates, enter and exit markets, and use any

size airplanes dictated by the market needs

Charter Carriers

transport people and freight

Use small- to medium-sized aircrafts

Have no set time schedule or designated route

Carrier charters the entire aircraft to transport people of freight between specified origin and destination

Big customer for charters is Department of

Defense (personnel and supplies)

Main Advantages/Disadvantages of Air transportation

Advantages:

Air transportation service is fairly reliable (except in adverse weather conditions)

Variations in transit times are small, flights are usually arriving on-time (+/- 15 min of scheduled time)

fast

Disadvantage:

poor accessibility

Passengers/cargo must be transported to/from airport, there is no door-to-door air delivery

It adds time and cost to the air services

expensive

Cost of Air tansportation

Most Expensive relative to other (surface) modes but fast

low transit time between given points

Cost of air transportation is

about 3 times higher than for motor carriers (trucks)

about 10 times higher than for rail

Hub-and-spoke sytem

Most air carriers use a hub-and-spoke system, routing flights through major hubs for connections.

Major hubs examples:

Delta: Atlanta, Cincinnati

United: Chicago, Denver, Washington-Dulles

American: Charlotte, Chicago, Dallas-Fort Worth

System can cause congestion of air traffic, ground operations, and passengers, increasing transit time and reducing reliability.

Dominant carriers at hubs can control time slots, limiting access for other airlines.

What types of goods are moved by air?

-Mail

- Electronics, communication equipment and parts

- Emergency shipments, time sensitive goods:

equipment components, spare parts,

radio pharmaceuticals, vaccines, donor organs

- Perishable goods: perishable food, live flowers

- Jewelry and luxury items (racehorses, high-end cars)

- Humanitarian aid: food, water, medical supplies

- Aerospace and defense components: military

equipment, aircraft engines, avionics

Motor Carriers

Trucking

Private carriers (Motor Carriers)

provides services to the company that owns or leases the vehicles

ex: Walmart’s fleet of trucks used to deliver products only to its own stores.

For Hire carriers (2 sub categories as well)

provides services to the public

and charges a fee for a serviceGeneral (common) freight carriers - serve general public upon demand, charge reasonable rates, without discrimination. Carry the majority of goods shipped

Specialized carriers transport petroleum products, agricultural commodities, refrigerated goods, building or hazardous materials, livestock, forest products.

What do motor carriers transport?

- Manufactured consumer goods

- Food

- Industrial goods

- Almost all of livestock: ship, lambs, cattle, hogs

- Grain (corn, soybean, wheat, rice, etc.)

- Fossil products: coal, oil, gasoline

- Cars

- Plastic, chemicals and rubber

- Construction materials: lumber, steel, stone, sand, gravel

Cost of Motor Carriers

Competes w/rail & air for short hauls (up to 250 miles) and medium hauls (up to 1000 miles).

Cheaper than air carriers (dry van rates are $2-$3 per mile).

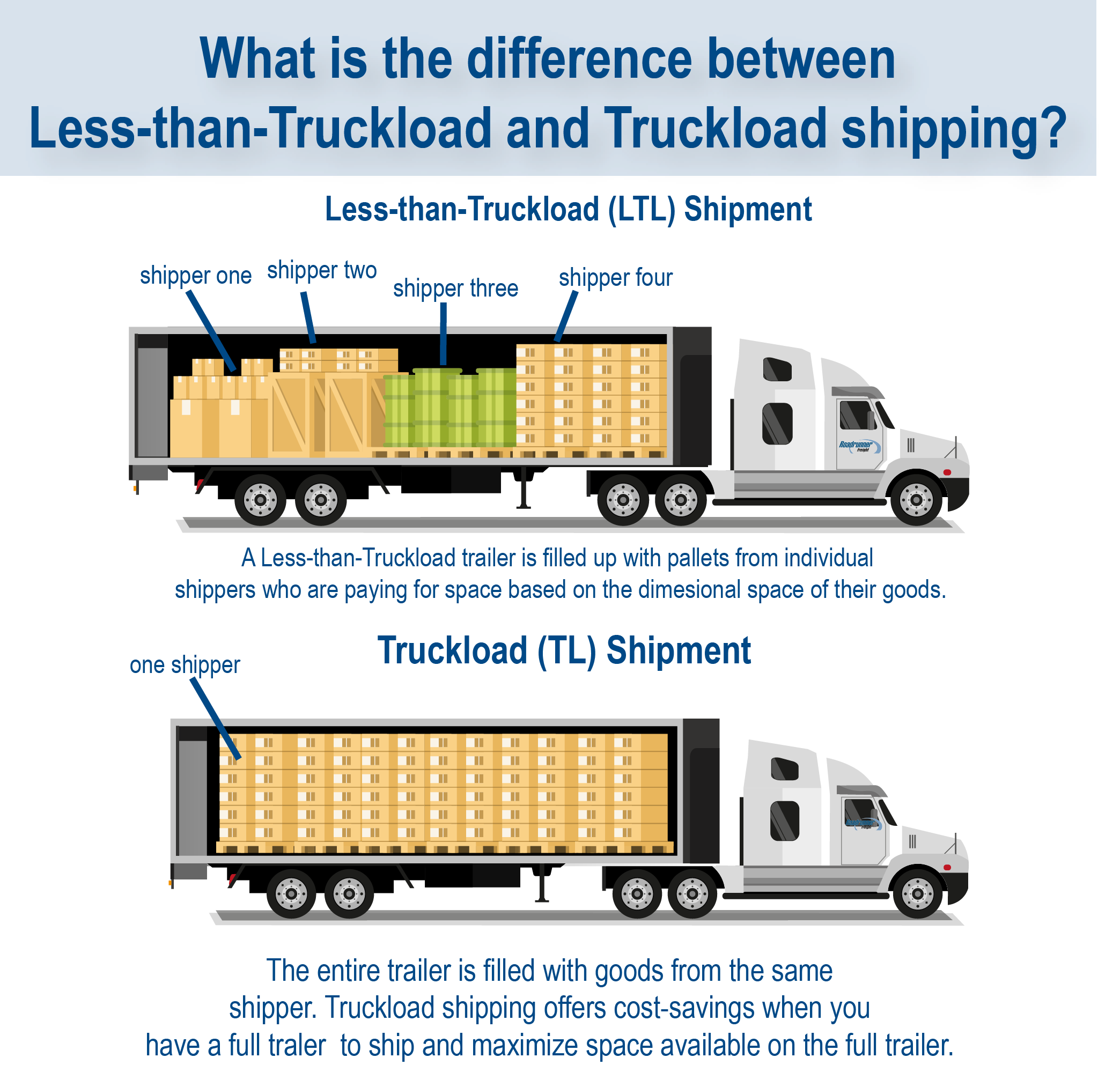

Truck Load (TL) Carriers

high-volume shipments, enough to fully utilize truck capacity.

Trailers dedicated to one shipper’s cargo - single pickup and drop-off points.

TL industry accounts for ~95% of total trucking industry revenue

Top TL carriers: Knight-Swift, JB Hunt, LandStar, Werner, Ryder Systems, Penske Logistics, Schneider National

Low barriers of entry – Start a motor carrier with $5–10K using a $100–250K truck as loan collateral.

ex: FedEx Freight TL service transporting a full truckload of electronics from a warehouse in Memphis, TN → a retail distribution center in Atlanta, GA.

Less-than-truckload (LTL)

LTL consolidate multiple smaller shipments in

the TL quantity for inter-city movement and deliver small quantities at the drop-off points.Fees are higher compared to TL.

Accounts for about 5% of trucking industry revenue

LTL industry operates as a “hub-and-spoke” system

Shipment is brought to the consolidation facility

ex: UPS Freight LTL service shipping a small pallet of furniture from Chicago, IL → Detroit, MI.

Pick up and Delivery (PUD) Trucks

City straight trucks are used for in the city to provide pickup and delivery services (PUD)

PUD vehicles are normally smaller than line-haul vehicles and are single units

A typical PUD truck has a cargo unit

that is 15 to 20 feet long

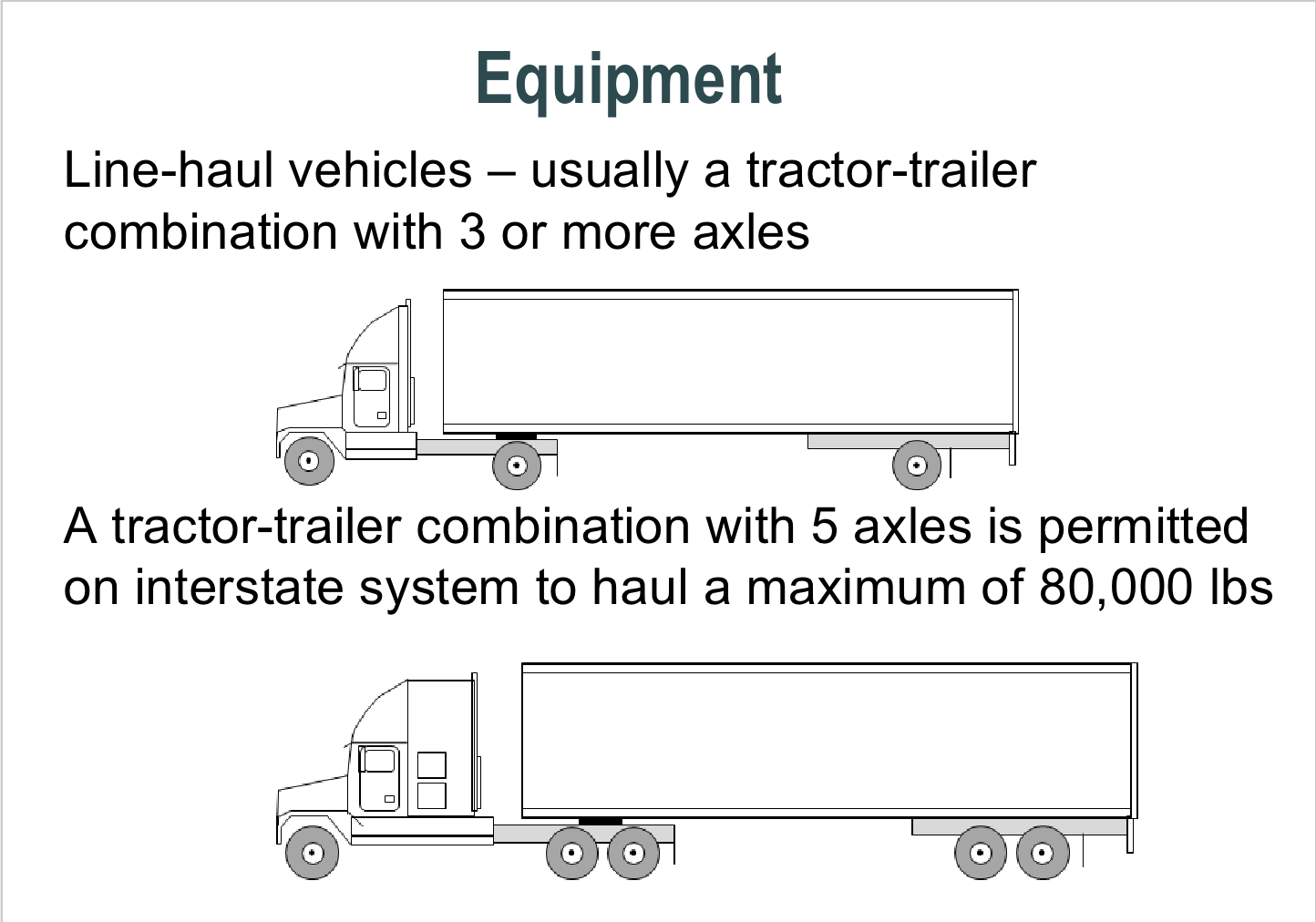

Motor Carrier Equipment pt 1

Line-haul vehicles – usually a tractor-trailer combination with 3 or more axles

A tractor-trailer combination with 5 axles is permitted on interstate system to haul a maximum of 80,000 lbs

Motor Carrier Equipment pt 2

Specialized vehicles:

- Dry van (standard trailer with all sides enclosed)

- Open top (allows loading/unloading through the top)

- Flatbed (used to haul commodities like steel, lumber)

- Tank trailer

- Refrigerated trailed (reefer)

Advantages and Disadvantages to Motor Carriers

Advantages of Motor Carriers

Flexibility/Accessibility: Can serve virtually any location, including remote areas.

Speed for Short Hauls: For distances under 1,000 miles, trucks can pick up and deliver cargo faster and cheaper than air carriers.

Versatility: Flatbed trailers can transport standard ocean containers, allowing competition with railroads.

Disadvantages of Motor Carriers (based on general knowledge from ChatGPT)

Higher cost for long hauls compared to rail or water transport.

Limited capacity: Trucks carry less cargo than trains or ships.

Vulnerability to traffic, weather, and road conditions.

Rail Carriers

Companies that transport goods and sometimes passengers via trains on a network of railroad tracks, typically used for bulk, heavy, or long-distance shipments.

Each railroad serves a specific geographic region

Class 1 railroads

Class 1 railroads: companies with revenue of over $504M

In 1920 there were 186 Class 1 railroads. There are 7 now:

- BNSF (Burlington-Northern Santa Fe)

- Union Pacific

- CSX

- Norfolk Southern

- Canadian National Railway

- Canadian Pacific Kansas City

- Amtrak

Seven class 1 railroads generate 94% of railroad revenue

Regional Railroads

Regional railroads have revenue of $40-$504 Million

Local Railroad

Local railroads have revenue of under $40 Million

Goods carried by railroad

Goods carried by railroads are heavyweight low-value commodities or bulk products

Coal (hauled primarily by rail)

- Building and construction materials (lumber, pipes, metals, asphalt, paper, bricks)Farm products and food (grain, packaged and canned

food)Beverages (beer, wine, orange juice, soft drinks)

Liquids (ethanol, diesel fuel, gas, crude oil)

Chemicals (soda ash, sulfuric acid, plastic pellets)

Bulky items (transformers, military vehicles, machinery,

wind turbines)Vehicles (cars, trucks, SUVs, auto parts)

Intermodal containers

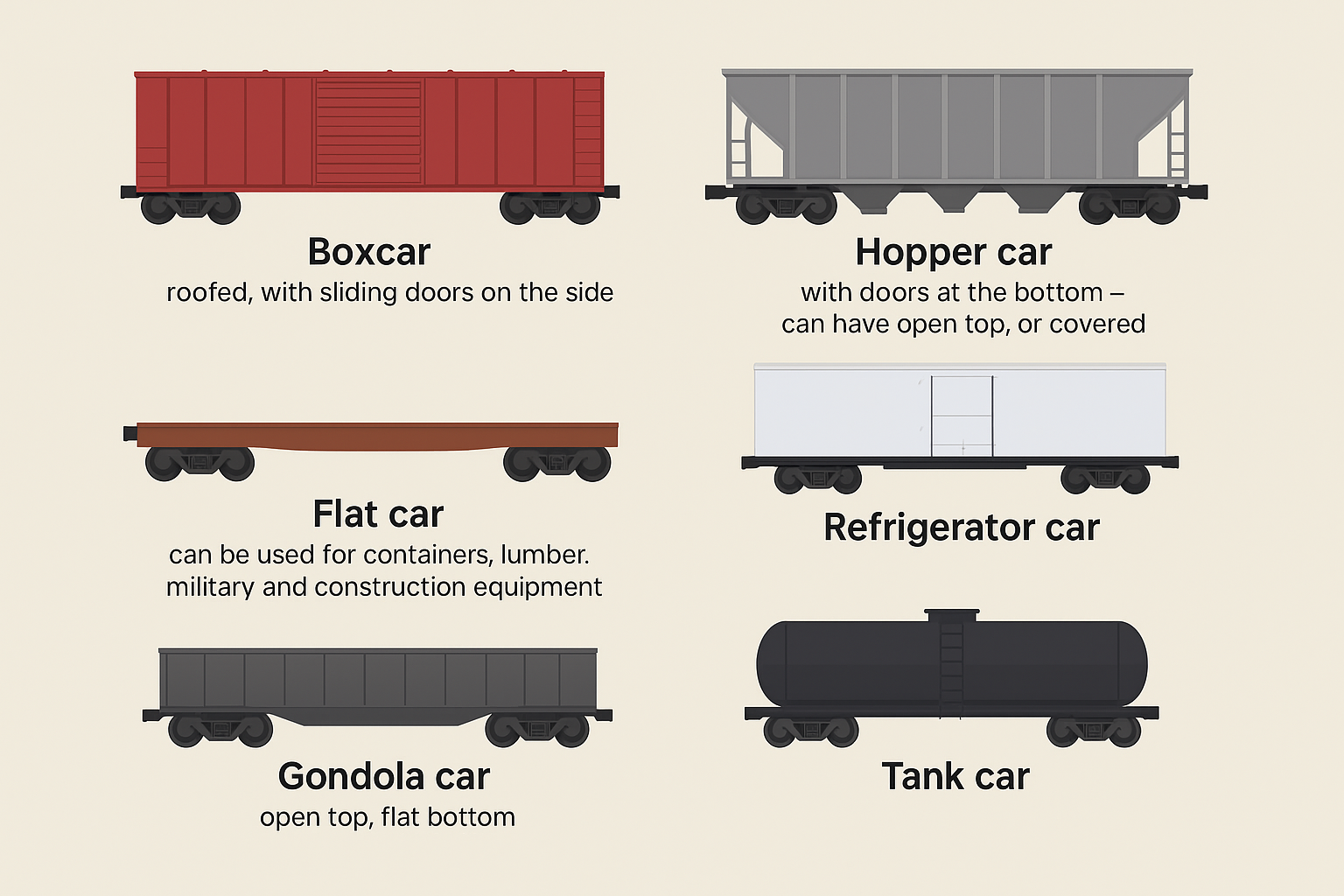

Rail Carriers Equipment

Basic unit of freight measure is carload

Carload varies in size and weight depending on the type of rail car used

In 2012 the average capacity per car is 102.7 tons

Trend is to increase car capacities, but bridge and track structure must handle the weight

Rail Car types

Boxcars (roofed, with sliding doors on the side) – used for general commodities

Hopper car with doors at the bottom – can have open top, or covered

Flat car (can be used for containers, lumber, military and construction equipment)

refrigerator car

Gondola car (open top, flat bottom)

Tank car

Advantages and Disadvantages to Railway

Advantages:

High capacity → lower cost per ton

Handles almost any commodity (variety of cars)

Flatcars carry containers → works with other transport

Disadvantages:

Fixed routes → less flexible

Slower than trucks/air

High infrastructure costs

Needs other transport for first/last mile

Intermodel Transportation

Trailer-on-Flatcar (TOFC) – Trucks’ entire trailers are loaded onto flat railcars. This lets trucks and rail work together; rail moves the long-haul part, trucks handle pick-up/delivery. Often called “piggyback service.”

Piggyback service is a distribution method that uses a combination of rail and truck transportation to move goods

Container-on-Flatcar (COFC) – Standard shipping containers are loaded directly onto flat railcars. This is the backbone of intermodal shipping, connecting ships, rail, and trucks efficiently.

Double stacking of containers allows for even higher efficiencies

Can be limited by heights of bridges (underpass clearances) and maximum carrying weights of bridges

How do freight yards work

Trains arrive at major hubs.

Cars are disconnected and sorted by destination.

Cars going to the same direction are reassembled into new trains.

Cargo waits in the yard while trains are rebuilt → main reason rail is slower (avg. ~40 mph).

Simple Version:

Trains broken → cars sorted → rebuilt → cargo waits → slows delivery (~40 mph).

Water Carriers

Inexpensive (cheaper than air, truck, rail), but slow & inflexible. Includes inland waterway, coastal & inter-coastal, & deep-sea.

one of the two modes of transportation used in international trade when carrying cargo over the water.

Water Carriers Cost

Cost: Very low per ton → cheapest for heavy, bulky goods.

Speed: Very slow → slower than rail, truck, or air.

Twenty-foot Equivalent Unit (TEU) and Forty-foot Equivalent Unit (FEU)

Has same dimensions, except length is twice of

TEU (40-feet).

1 FEU = 2 TEU

Two FEU’s stacked on two

TEU’s (for a total of 6 TEU’s)

Major Container Shipping Companies (6)

Mediterranean Shipping Company (Switzerland, 800 vessels, 5.7 million TEUs, 20% of the market)

A.P. Moller-Maersk Group (Denmark, 675 vessels, 4.2 million TEUs, 15% of the market)

CMA CGM (France, 624 vessels, 3.6 million TEUs, 13% of the market)

COSCO (China, 490 vessels, 3.1 million TEUs, 11% of the market)

Hapag-Lloyd (Germany, 266 vessels, 2 million TEUs, 7% of the market)

ONE (Japan, 231 vessels, 1.8 million TEUs, 6% of the market)

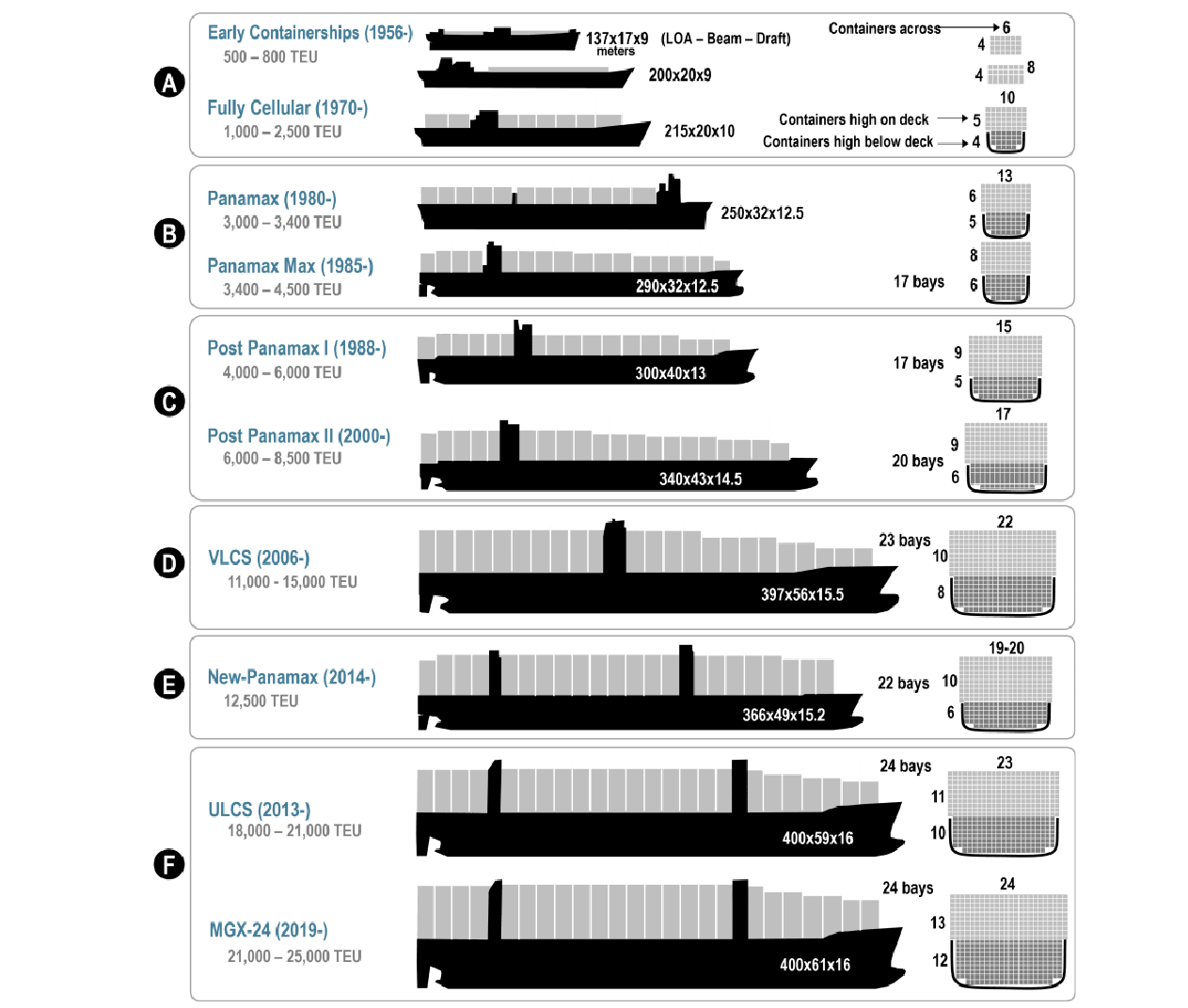

Evolution of Shipping Containers

Early: ~1,000 TEU, converted ships

Fully Cellular: 2,300+ TEU, faster, dedicated

Panamax: ~4,500 TEU, fits old Panama Canal

Post-Panamax: 6,600–8,000 TEU, wider than Panama Canal

VLCS: 11,000–14,500 TEU, few ports can handle

Neo-Panamax: ~12,500 TEU, fits expanded Panama Canal

ULCV: 18,000–24,000 TEU, limited routes

Future (Malacca Max): 27,000–30,000 TEU, for high-volume route

**Bigger ships = lower cost per TEU (economies of scale), but require larger ports, deeper drafts, stronger infrastructure.

Advantages and Disadvantages of Water Carrier

Advantages:

Economies of scale: Larger ships = lower cost per container.

High capacity: Can carry thousands of TEUs at once.

Efficient for long distances: Ideal for international shipping (e.g., China → LA).

Disadvantages:

Slow speed: 15–20 knots (~17–23 mph), trips can take 16–21+ days.

Weather-dependent: Storms and rough seas can delay shipments.

Port limitations for very large ships: Only certain ports can handle VLCS/ULCV vessels.

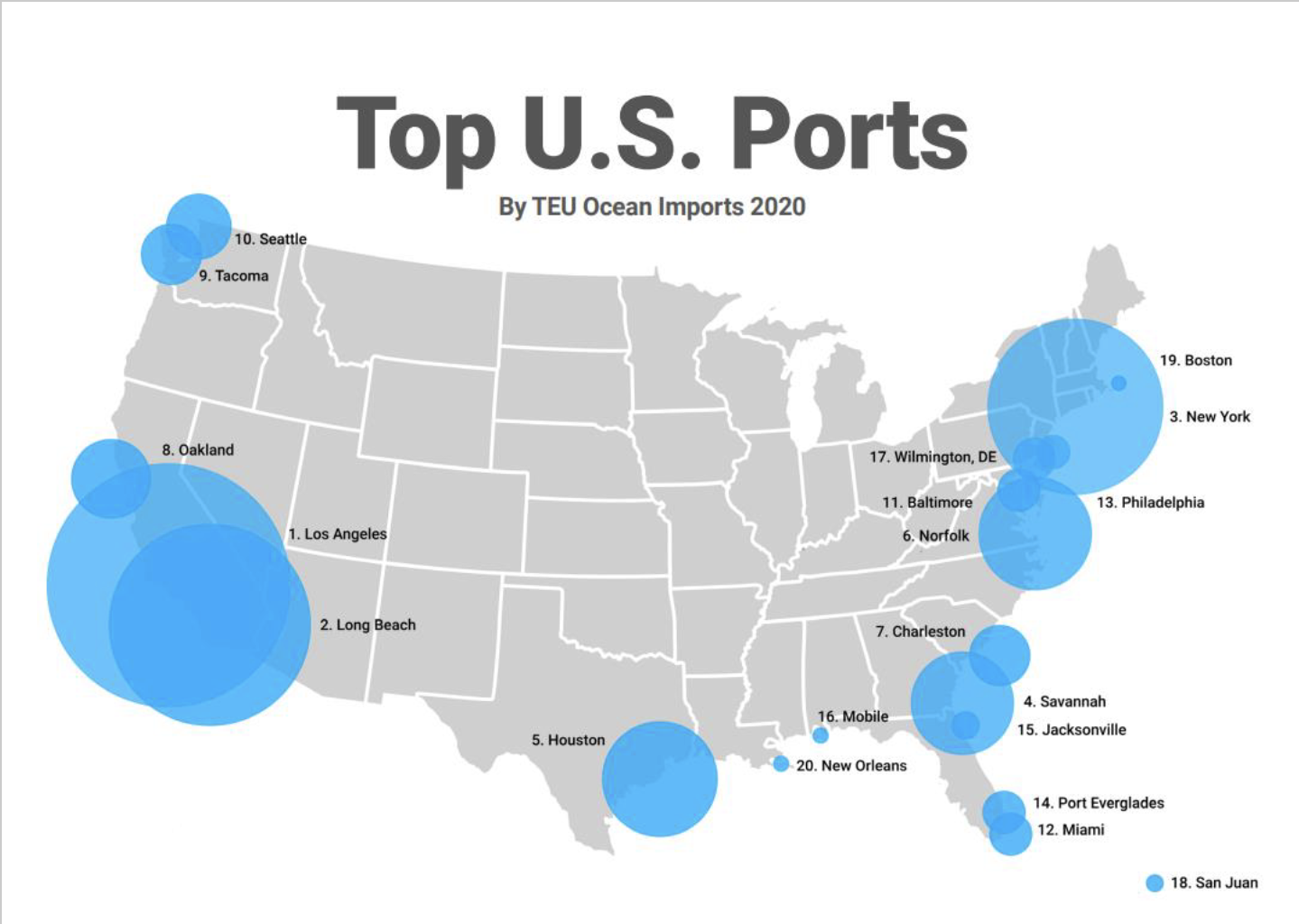

Top US ports for water carriers

Los Angeles

Long Beach

New York

Savannah

Houston

Norfolk

Charleston

Oakland

Tacoma

Seattle

Baltimore

Miami

Philly

Port Evergaldes

Jacksonville

Mobile

Wilmington, DE

San Juan

Boston

New Orleans

Dredging

removing dirt and debris from the bottom of shallow waters to make them more navigable by ships

Suez vs Panama Canal

Panama Canal: (this is all from chat)

Connects Atlantic ↔ Pacific.

Much shorter canal.

Smaller ship size limits (even after expansion) → Neo-Panamax (~12,500 TEU).

Cuts time for ships traveling between East Coast U.S. ↔ Asia or Caribbean ↔ Pacific.

Suez Canal:

Connects Mediterranean ↔ Red Sea (Europe ↔ Asia route).

No locks → handles much larger ships (ULCV up to ~20,000+ TEU).

Key route for Asia ↔ Europe.

Longer but allows massive ships that Panama cannot handle.

RoRo

RO-ROs or roll-on-roll-off cars, truck trailers & containers to be directly driven on & off the ship, without the use of cranes

RoPax

RoPax – “RoRo + Passengers” – ships capable of carrying passengers combined with RoRo capability

Consolidation warehouses

collect LTL shipments for transport in TL or CL quantities. Use of consolidation warehouses allows to realize transportation economies – consolidate and ship in TL or CL quantities.

Private Warehouses (idk if we need to know pros and cons)

Owned by the firm storing goods (majority of WH space in the US)

Pros:

Lower long-term cost

High control (labor, security, processes)

Choose location & equipment freely

Tax perks + can lease extra space

Cons:

High investment + financial risk

Low flexibility (hard to expand/move)

Only affordable for large firms

Insurance is harder/more costly

Public Warehouses

Owned by for profit orgs & leased out to other companies

Breakbulk- Breaks large shipments into customer-specific orders.

Includes repackaging, light assembly/customization, quality checks, material handling, and equipment/documentation support.

Offers short- or long-term storage.

Crossdocking

Receive → break down → repackage → ship out (to factories or stores).

Minimal storage (usually <24 hours).

Functions more like a distribution center, not a warehouse.

Warehousing

Goods are stored for days, weeks, or months.

Slower movement, more handling.

Higher inventory + storage costs.

Best for products needing buffer stock or seasonal demand.

Distribution Centers and how they operate

Fast-flow facilities, not storage dungeons like traditional warehouses.

Goods arrive, are sorted, processed, and shipped out quickly—often within hours.

Handle cross-docking, order picking, repackaging, labeling, and light assembly if needed.

Designed for speed, accuracy, and minimal inventory sitting around.

Rely on tech + automation to track every item (scanners, conveyors, WMS systems).

*chat answer

Center of Gravity Model for facility location

we did this hand out in class

What is SAP

An enterprise-wide information system

Developed by a German company SAP AG (founded in 1972 in Weinheim, Germany)

Enables the companies to manage business operations, reporting, and relationships with customers and suppliers from the single database

Is highly customizable – can be configured to fit any business

– Smithfield Foods

– Huntington Ingalls

– CSX

Major ERP Systems providers

– Oracle

– Microsoft Dynamics 365

– Sage

– Epicor

– Infor

ERP Models

SAP is very “modular” – the company does not have to install the full SAP system, it may choose to install some modules that do only certain business processes

• Financial modules:

– FI (Financial Accounting)

– CO (Controlling, Cost Accounting)

– IM (Investment Management)

– TR (Treasury)

– EC (Enterprise Control)

Other modules include:

– MM (Material Management)

– SD (Sales and Distribution)

– PP (Production Planning)

– PDM (Product Data Management)

– QM (Quality Management)

– PM (Plant Maintenance)

– SM (Service Management)

– HR (Human Resources)

– WM (Warehouse Management)

Client-server architecture

SAP uses a centralized client–server setup.

The server is the main brain — it stores data, processes requests, and checks transactions.

Clients (users/computers) connect to the server and ask it to do things with data.

These actions are called CRUD: Create, Read, Update, Delete.

ERP Data organization

All ERP systems keep in the central database

three types of data

Organizational data- structure of the company

Master data- the permanent info about people/things

Transaction data- the activities the business performs

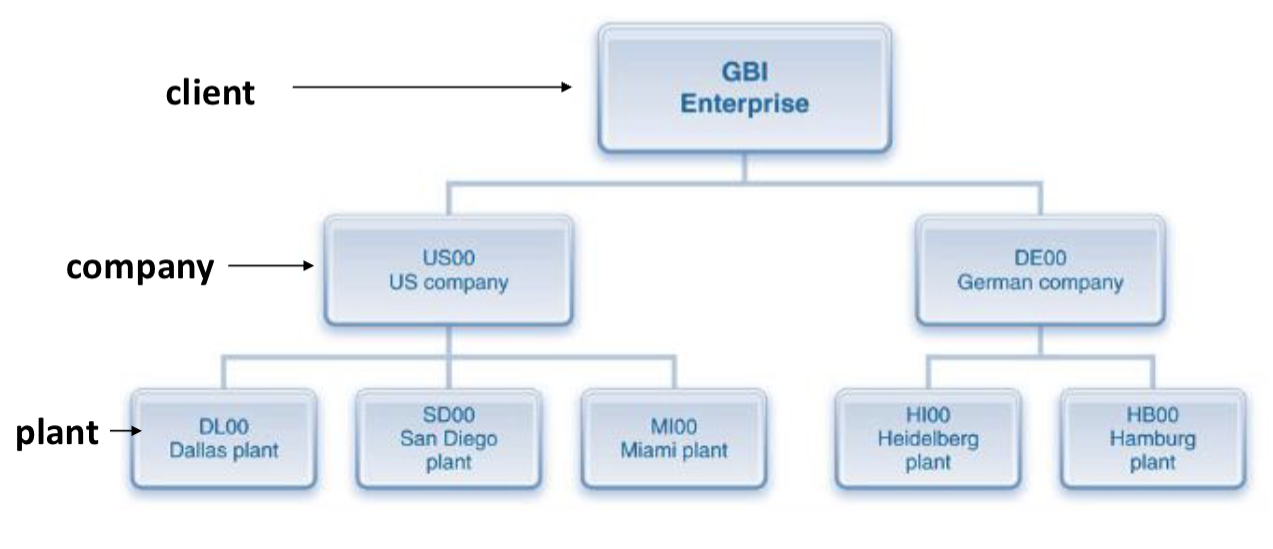

SAP Organizational Data

client- the highest level; represents the entire SAP environment (one database for one company group)

client can consist of companie

company/company code- legal entity that reports financials separately.

plant- a location where goods are produced, stored, or distributed

Most commonly used SAP material master data

Raw Materials (ROH)

Semi-Finished goods (HALB)

Finished goods (FERT)

Trading goods (HAWA)- purchased from vendors and resold to customers

Storage Location

A place within a plant where materials are kept until needed

A plant can have multiple storage locations

Locations range from small bins to entire buildings in size

Purchasing process and its major steps

Purchasing activities can be managed at the client, company, or plant level.

Most purchasing actions occur within a company code.

The plant is the location where materials are received, called the receiving plant.

Another key level for purchasing is the storage location, where goods are physically stored.