Creep, Fatigue and Wear

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

What is creep?

A time/temperature dependent phenomenon for components under load for long periods of time, especially if at relatively high operating temperatures

If a material is loaded below its yield stress (elevated temperature) it can begin to plastically deform overtime

What temperature does creep usually ocur?

for materials operating at temperatures around or above 0.4Tm

In metals, how does crep occur?

due to the movement of dislocations (below yield stress) due to the high applied load and gradual diffusion of atoms at high temperature

In ceramics, how does creep occur?

complex movement at grain boundaries and by diffusion (crystalline), atoms slide past each other (amorphous ceramics, viscoelastic behaviour)

What are the consequences of creep?

Plastic strain of materials in service when under stress (e.g cables lengthening over time)

reduction in stress for constant displacement (e.g guitar strings require retightening)

what are the stages of creep?

Primary Creep: rate of creep is initially rapid but slows with time - dislocations climb and slip leading to work hardening

Secondary Creep: relatively steady state of creep where rate of dislocation climb = rate of work hardening

Tertiary Creep: increasing rate of deformation leading to failure - necking begins in the test piece, higher stress and leading to rapid failure

How can you increase the speed of creep?

Creep is faster at higher temperatures

Creep is faster with higher applied stress

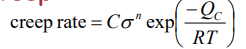

What is the equation for creep?

sigma = stress

R = gas constant

Q© = activation energy for creep

T = temperature

What is fatigue?

Repeated application and removal stress below its yield strength to a material → many cycles to failure of the sample

How does a failure cycle occur in fatigue?

Failure commences by the appearance of a tiny crack (often at the surface)

This crack propagates as the cycles of stress are continued until sudden failure

Does fatigue show signs of failure?

little warning of failure signs even in ductile metals - failure is typically perpendicular to the stress direction

What affects fatigue?

-Components with notches, scratches or indentations (stress raisers) are more prone to fatigue failure

-Fatigue is more rapid in high temperature environments

-A cyclical temperature change on a component can also cause fatigue through uneven expansion and contraction leading to uneven stress

Fatigue testing

Stress vs. number of cycles to failure (S-N curve) which depends on component shape and material

Design for fatigue

Can consider:

-fatigue limit (when stress vs. cycles levels out)

-fatigue strength (max stress for which fatigue won’t occur within a particular number of cycles)

-fatigue life (max number of cycles that can be applied of a particular load condition and stress level

how can fatigue be reduced?

-preventing the initiation of cracks

-reducing stress raisers by better component design

-reducing defects at the surface by surface treatments

What is wear?

when components that are ‘in contact’ are only truly in contact at a few points which carry the whole load and can be under high stress that may be greater than the yield stress

What are the different types of wear?

Adhesive wear: asperities are plastically deformed and welded together

abrasive wear: grit between the surfaces material to be removed

corrosive wear: chemical or electrochemical damage of the material surfaces combined with adhesive or abrasive wear

Surface fatigue: continual application and removal of load can lead to fatigue damage near the surface and the top layer of material can flake off

What factors are essential to consider during design?

type of load and the operating temperature