TOLERANCE QU

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

What is tolerances?

A tolerance is an

acceptable amount of

dimensional variation

that will still allow an

object to function

correctly.

What are three basic tolerances that occur most often in working drawing?

Limit dimensions, bilateral tolerance, and unilateral tolerance

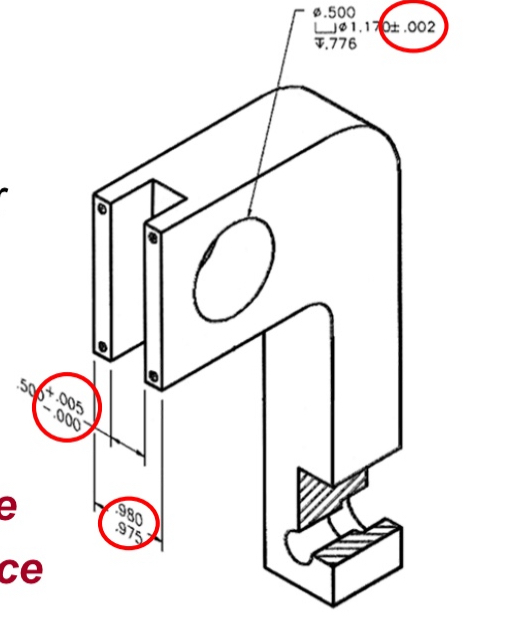

What is Limit Dimensions?

Provides an upper limit and lower limit for the dimension. Any size between or equal to the upper limit and/or lower limit is allowed.

What is bilateral tolerance?

Provides an equal allowable variation, larger and smaller. Uses a plus/minus (±) symbol to specify the allowable variation.

What does unilateral tolerance do?

Provides an allowable variation in only one direction (either larger or smaller). Uses separate plus (+) and minus (–) signs.

What is definitions?

Specified Dimension is the target dimension from which the limits are calculated.

What are Limits?

Limits are the maximum and minimum sizes shown by the toleranced dimension.

What is general tolerances?

Tolerances that are assumed if no specific tolerance is given for a dimension. Typically tolerances are specified based on the number of digits to the right of the decimal point in a dimension. It is shown on drawings.

What is a clearance fit?

Always a clearance between the axle and the opening.

What is a interference fit?

Always an interference between the axle and the opening.

What is a transition fit?

occurs when two mating parts can sometimes have a clearance fit and sometimes have an interference fit

What is Maximum material condition?

The condition of a part when it contains the largest amount of material.

The MMC of an external feature

the length of a plate, is the upper limit of the dimension

The MMC of an internal feature

the diameter of a hole, is the lower limit of the dimension

Least material condition

condition of a part when it contains the smallest amount of material

The LMC of an external feature

the length of a plate, is the lower limit of the dimension

The LMC of an internal feature

the diameter of a hole, is the upper limit of the diameter dimension

Allowance

the minimum clearance or maximum interference between parts

Define an engineer

A person who is trained in and uses technological and scientific knowledge to solve practical problems.

Define an engineers notebook

An engineering notebook is used to formally document, in chronological order, all of the work that a person performs related to a specific design project. It should be clear and complete so that someone unfamiliar with the work could take over the project without additional information.

What is the first step of the design process and what do you have to do

Define Problem - a valid and justifiable problem with no known solution or that can be improved

What is the second step of the design process and what do you have to do

Generate concepts - while often difficult due to indefinite solution paths, find one or a few solution paths

What is the third step of the design process what do you have to do

Develop solution - reach an optimal solution by creating a detailed design solution with a justifiable path

What is the fourth step of the design process and what do you have to do

Construct and test - construct a testable prototype, plan prototype testing, collect and analyze the data

What is fifth step of the design process and what do you have to do

if result of test indicates the design does not meet expectation, then start again. Evaluate the product effectiveness, make improvements if needed

What is the sixth step of the detain process and what do you have to do

Present design - Presentation must clearly state main points and precise details, and document the project.

Definitions of precision

The design and manufacturing of highly accurate and exact machines, tools, and components

What is the definition of accuracy

How close a measurement or calculation is to the true or accepted value

Definition of horizontal/vertical