Fundamentals of Welding 1

1/26

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

Joining

welding, brazing, soldering, and adhesive bonding

Assembly

mechanical methods of fastening

Welding definition

joining process in which two or more parts are coalesced at their contacting surfaces by application of heat/pressure

Welding Importance/Pros

Provides a permanent joint, is economically stable, not restricted to a factory environment

Limitations of Welding

Performed manually and labor cost are expensive, High energy and inherently dangerous, welded joints do not allow for convenient disassembly, difficult detection of defects

Two Categories of Welding Processes

Fusion welding, Solid State welding

What is Fusion Welding? What is Autogenous welding?

Joining processes that melts the base metal. Fusion welding with no addition of a filler metal.

List Three Fusion Welding Processes

Arc, resistance, oxyfuel gas

What is Arc Welding + Basics?

Melting of metals is done by electric arc. 1. before the weld 2. during the weld base metal melted and filler meal is added to molten pool 3. the completed weldment

Fusion: What is Resistance Welding?

Melting accomplished by heat from resistance to an electrical current between faying surfaces held together under pressure

Fusion: What is Oxyfuel gas welding?

melting is accomplished by an oxyfuel gas such as acetylene

What is Solid State Welding?

Joining processes in which coalescence results from application of pressure alone or a combination of heat and pressure

Solid State: Describe Diffusion Welding

coalescence by solid state fusion between two surfaces held together under pressure at elevated temperature

Solid State: Define Friction Welding

coalescence by heat of friction between two surfaces

Solid State: Define Ultrasonic Welding

coalescence by ultrasonic oscillating motion in a direction parallel to contacting surfaces of two parts held together under pressure

Applications of Welding

Construction, piping, shipbuilding, aircraft, automotive, railroad

The welder controls…

the path or placement of the welding gun

Fitter…

Arranges the parts prior to welding

Safety Concerns

high temperatures of molten metals, gas fuels are hazardous, most processes use electrical power + shock is a hazard

Special Hazards

UV exposure (dark viewing helmet), sparks + spatters of molten, smoke and fumes

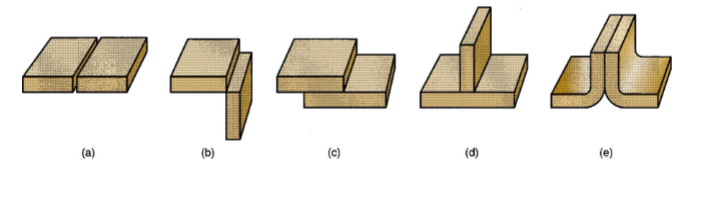

What are the five types of joints?

butt, corner, lap, tee, and edge

To accomplish fusion a source of __________ must be supplied to the _________.

high density het energy, faying surfaces

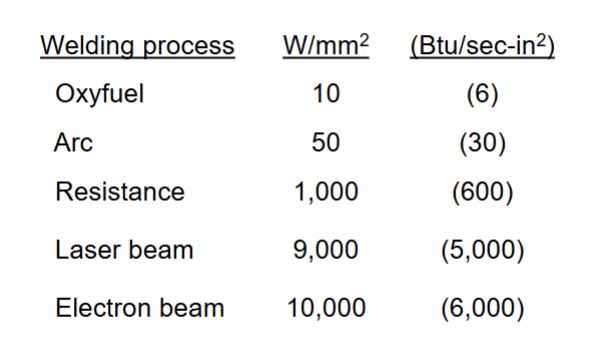

Power Density

Power transferred to work per unit surface area W/mm²

What happens when Power density is too low and when it is too high?

Low: heat is conducted into work so melting never occurs. High: localized tmeperatures vaporize metal in affected region

Power Densities for Welding Processes

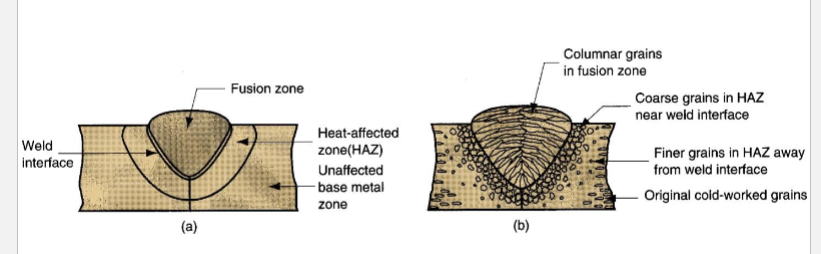

What are (a) and (b) in this fusion welded joint cross-section?

(a) principal zones, (b) typical grain structure

What is the Heat Effected Zone? What happens in this areas?

Metal experiences below melting but high enough for microstructural changes. The effect on HAZ is usually negative and welding failure often occurs here