Waste water 9

1/40

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

41 Terms

What is the purpose of biological treatment?

- to oxidize the organic matter that escapes primary treatment

- to provide further removal of suspended solids

•Often includes treatment for nitrogen and phosphorous removal.

What is the biological process?

Where we design a reactor to grow micro-organisms (Biomass) on the incoming organic matter (Substrate) to remove biological oxygen demand (BOD) before discharge to the receiving environment (lake, river, coast).

Microbial Growth Kinetics (Monod)

The rate at which micro-organisms (Biomass) grow in the presence of organic matter (Substrate) is described by the Monod equation.

What are the two most common reactor designers?

1.Secondary treatment by suspended growth biological processes i.e micro-organisms are suspended in the fluid

2.Secondary treatment by attached growth biological processes i.e. where micro-organisms are grown on the surface of some rock or plastic media

What are two typical suspended growth systems?

1.Oxidation ponds (waste stabilisation ponds)

2.Activated sludge process (ASP)

What are the four types of oxidation ponds?

Four major types of ponds:

1.Aerobic ponds

2.Anaerobic ponds

3.Facultative ponds

4.Aerated ponds

Characteristics of an aerobic pond

•Shallow ponds, less than 1 m in depth.

•Light penetrates to the bottom maintaining algal photosynthesis during daytime.

•Dissolved O2 is maintained throughout the pond mainly by photosynthetically derived O2.

•Surface reaeration by wind mixing.

•Organic waste degradation mainly through the action of aerobic bacteria.

characteristics of anaerobic ponds

•Deep ponds (2-5 m) that receive high organic loadings.

•O2 consumption rate is much higher than O2 production rates, which creates the anaerobic conditions.

•Anaerobic bacteria break down the organic matter, releasing methane and carbon dioxide. Sludge is deposited on the bottom.

•Typical BOD reduction efficiency is of the order of 50-70%.

Characteristics of facultative ponds

•1-2 m deep

•BOD reduction by aerobic bacteria at the pond surface and by anaerobic bacteria at the bottom.

•The soluble BOD is aerobically stabilized and suspended and colloidal BOD tend to settle and is decomposed by anaerobic bacteria.

•BOD reduction: 70-85%.

characteristics of Aerated ponds

•Mechanical diffused aerators provide oxygen and allow for a greater proportion of organic material to remain suspended.

•Suspended solids and organic colloidal materials (BOD) settles to the bottom to form a sludge layer that undergo anaerobic decomposition.

Stabilisation Basins/Ponds

The rate at which micro-organisms (Biomass) consume the organic matter (Substrate); the substrate utilisation rate can be shown to be given by:

Activated Sludge Process

•Microorganisms are mixed thoroughly with the organic compounds present in wastewater.

•As the microorganisms grow and are mixed by the agitation of air, the individual organisms flocculate to form an active mass of microbes called activated sludge.

Activated Sludge Process

Activated sludge processes include:

1.Conventional activated sludge

2.Step aeration activated sludge

3.Contact stabilisation

4.Complete mix activated sludge

5.Extended aeration

6.Oxidation ditch

7.Nutrient removal (Nitrogen and Phosphorus)

For now, we'll consider the fundamentals of conventional ASP.

Components of activated sludge process

1. Aeration tank

•Long, rectangular basin.

•Aerated for 4-8 hours.

Keeps microbes in suspension

2.Settling tank

•Separates the sludge from the effluent most of which is returned into the aeration tank (RAS).

3.Waste activated sludge

•A portion of the sludge is wasted (WAS) everyday to maintain the proper amount of microbes to efficiently oxidise the biodegradable organics.

Food to Micro-organism ratio (F/M)

•The food to micro-organism ratio F/M describes the degree of starvation of the biomass in the aeration tank

•It can be designed to operate the system at different microbial growth rates for different removal processes such as carbon removal only or combined carbon and nitrogen removal

Attached Growth Biological Processes

•Utilise films of microorganisms attached to inert carrier to treat wastewater.

•Microorganisms form a film on a bed, disk or other support material (plastic materials, stones) over which wastewater is applied.

•Wastewater components and oxygen diffuse into the biofilm.

•End products diffuse out of biofilm into bulk water.

•Flow from the attached growth process may be passed through a sedimentation basin (humus tank).

Attached Growth Biological Processes types

1.Trickling Filter

2.Rotating Biological Contactor (RBC)

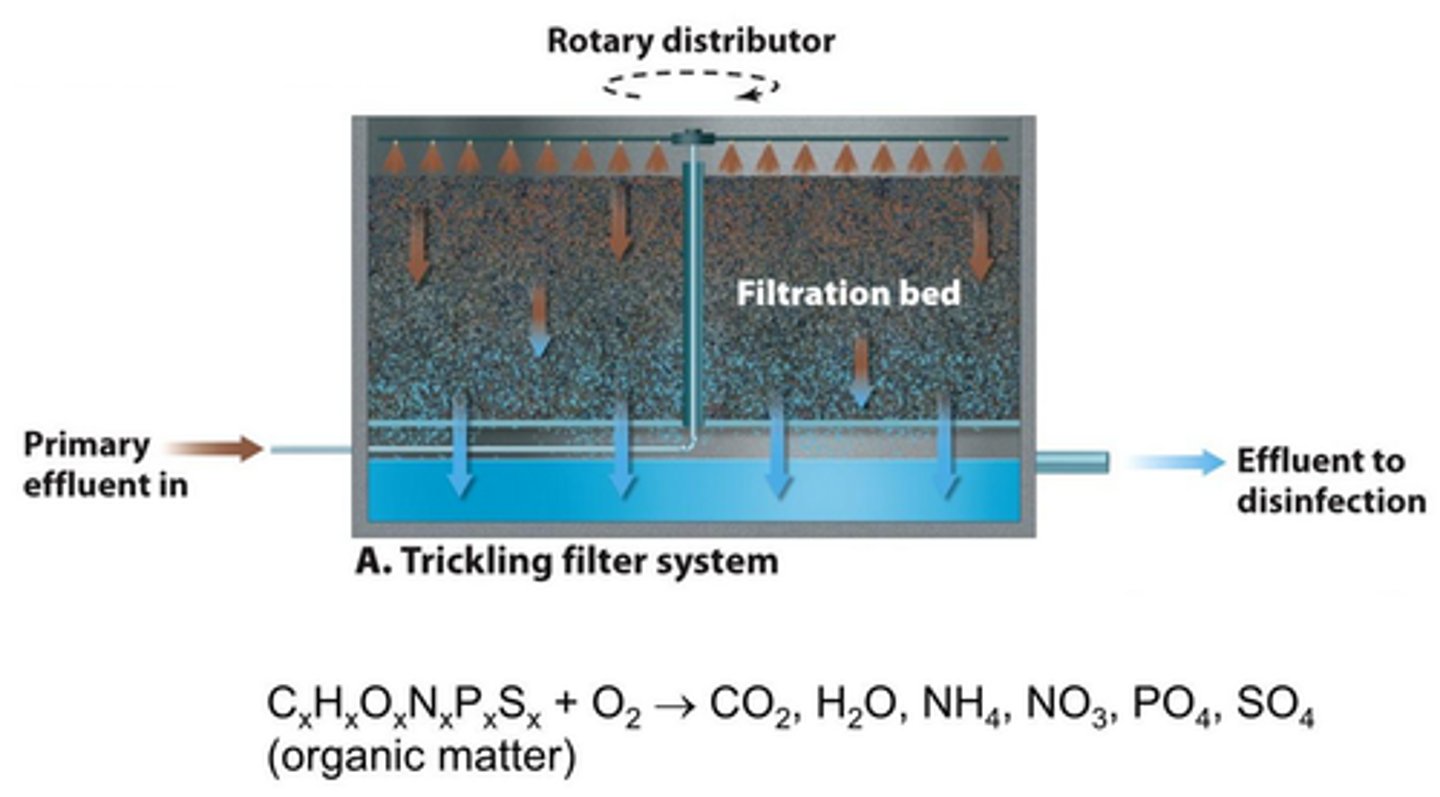

Trickling Filter

•Wastewater trickles through a bed of coarse stones (1-2m deep) or plastic material (3-12 m deep).

•A rotating arm distributor evenly distributes the wastewater from above the bed.

•The microorganisms in the wastewater attach themselves to the bed and grow into a thin biofilm layer on the surface.

•Organics/substrate and oxygen diffuse into the biofilm

•Waste products diffuse out of the biofilm.

Trickling Filter advantages & disadvantages

Advantages

•Simplicity of operation

•Resistance to shock loads

•Low biosolids yield

•Low power requirements

Disadvantages

•Relatively Low BOD Removal (85%)

•High Suspended Solids in the effluent ("sloughing" of biofilm)

•Very little operational control

Types of Trickling Filters

Two major types:

1.Standard or low rate trickling filter

•Single stage rock media units

•Loading rates: 1-4 m3 wastewater/m2 filter area-day

•Large area required

2.High rate trickling filter

•Single stage or two-stage rock media units

•Loading rates: 10-40 m3 wastewater/m2 filter area-day

•Re-circulation ratio: 1-3

•Plastic media 25-50m3/m2/day, deep bed 3-12m

•Re-circulation ratio : 1-6

Rotating Biological Contactor (RBC)

•Consists of closely spaced discs (light weight, 3-3.5 m diameter) mounted on a horizontal shaft.

•The discs are rotated while about ½ of their surface area is immersed in wastewater.

•Microbes in wastewater adhere to the rotating surfaces and forms a biofilm.

•Oxygen is supplied to the attached biofilm from the air when the film is out of the liquid.

•As the biofilm passes through the wastewater they absorb organic compounds for oxidation.

Rotating Biological Contactor (RBC) disk purposes

The discs serve three main purposes:

•They provide media for the build up of attached microbial growth.

•They bring the biofilm into contact with wastewater.

•They aerate the wastewater and the suspended microbial growth in the reservoir.

Advantages of RBC

•Simple operation, short retention time due to large active surface, low power, minimal odour, and low sludge production.

Factors affecting RBC performance

Factors affecting RBC performance

•Number of stages

•Organic loading

•Hydraulic loading

•Recirculation rate

•Submergence

•Rotational speed

•Oxygen levels

What are the 5 stages of treating at the WWTP?

- Preliminary treatment (screens and grit removal)

- Primary treatment (clarifcation/sedimentation)

- Secondary treatment (biological)

- Tertiary treatment

-Disinfection

What are the three purposes of preliminary treatment?

- Removal of untreatable solid materials

- Protection of susbsquent treatment units

- Improvement of the performance of subsequent units

- Removal of untreatable solid materials

- Protection of susbsquent treatment units

- Improvement of the performance of subsequent units

- bar racks/ screens

- mechnical device to shred or grind the solids and return them to the flow

What are the 3 common devices used to grind coarse solids in WWT?

- Comminutors

- Macerators

- Grinders

What are the 3 purposes of grit removal?

- protect the downstream mechanical equipment from abrasion and wear

- Reduce the formation of deposits in channels, tanks and pipelines

- Reduce the frequency of digester cleaning that is required due to accumulated grit

What are the 3 major types of grit removal systems?

\- Horizontal-flow (square or rectangular)

- aerated (Rectangular)

- Vortex-flow

What are the 3 major types of grit removal systems?

stationary horizontal screen, to intercept solids and a rotating or oscillating cutting bar to shear the material

What are Macerators?

Slow-speed grinders that use two sets of counter-rotating blade assemblies

What are grinders?

Pulverise the solids by a high apeed rotating assembly

What is grit?

materials that have a settling velocity greater than organic material in waste water (sand, gravel, broken glass)

What are the 2 horizontal-flow grit chamber charateristics?

Velocity-controlled channel, designed to allow sufficient detention time for particles to settle

What controlls the velocity flow for horiozntal- flow grit chamber?

- dimensions of channel

- Special influent distribution gates

- Special weir sections at the effluent end

What are the characteristics of aerate grit chamber?

- wastewater flows through the chamber in a spiral

- air is introduced along one side of the chamber

- heavier particles settles to the bottom

- lighter organic particles remain suspended and are carried out of the tank

- quantity of air is adjusted to provide the roll

What are the characteristics of vortex grit chamber?

- Wastewater enters the chamber tangentially

- Grit settles by gravity into the bottom of the tank

- Effluent exits at the top of the tank

- Outlet is wider than the inlet (lower exit velocity, stops grit from being drawn into the effluent flow)

- Airlift pump removes the grit from the grit sump

What is the purpose of flow equalisation?

Create costant flow for WWTP

What are the two configuration flow equalisers?

- In-line equalisation

- Off-line equalisation

Flow equalisation types (sketch)

More info on flow equalisation (Read)