AOP-702 (1) Loss of Component Cooling Water

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

14 Terms

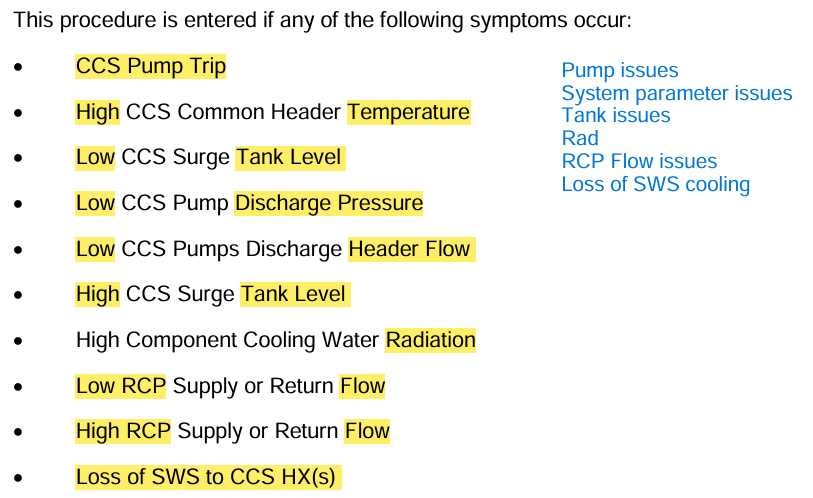

Entry Conditions

CCS Pump Trip

Basically any Header/Tank alarm

High/Low RCP Supply/Return flow

Loss of SWS to CCS Hx

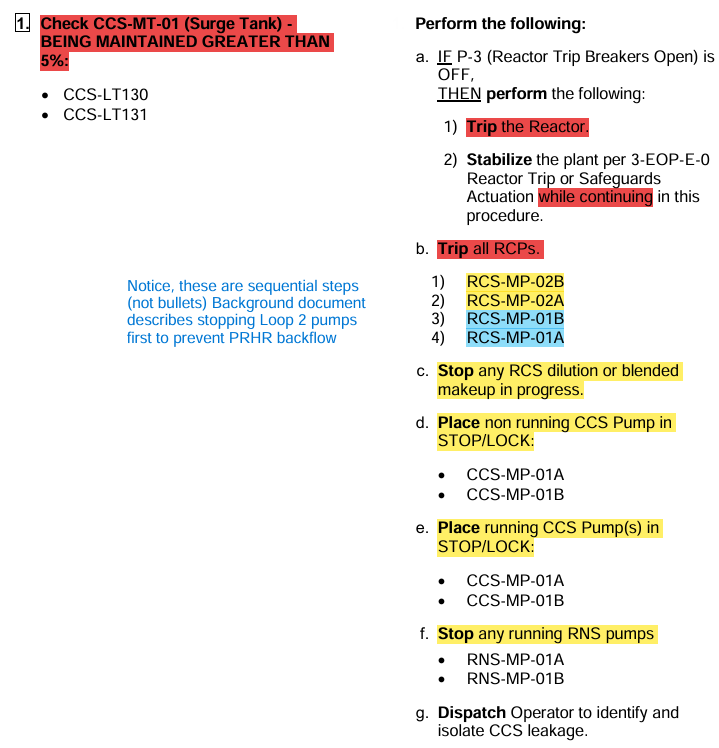

Actions if Surge Tank is Drained (<5%)

(Step 1 RNO)

Perform E-0

Trip all RCPs (Sequentially Loop 2s first)

Place CCS Pumps in STOP/LOCK

Stop any running RNS Pumps

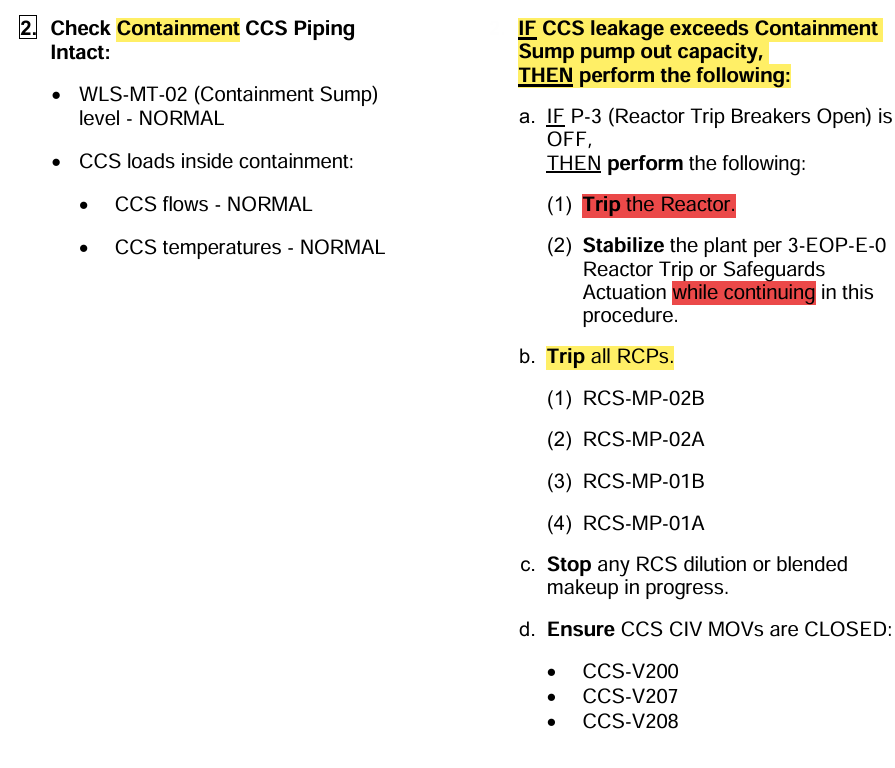

CCS Leak inside Containment

(Step 2)

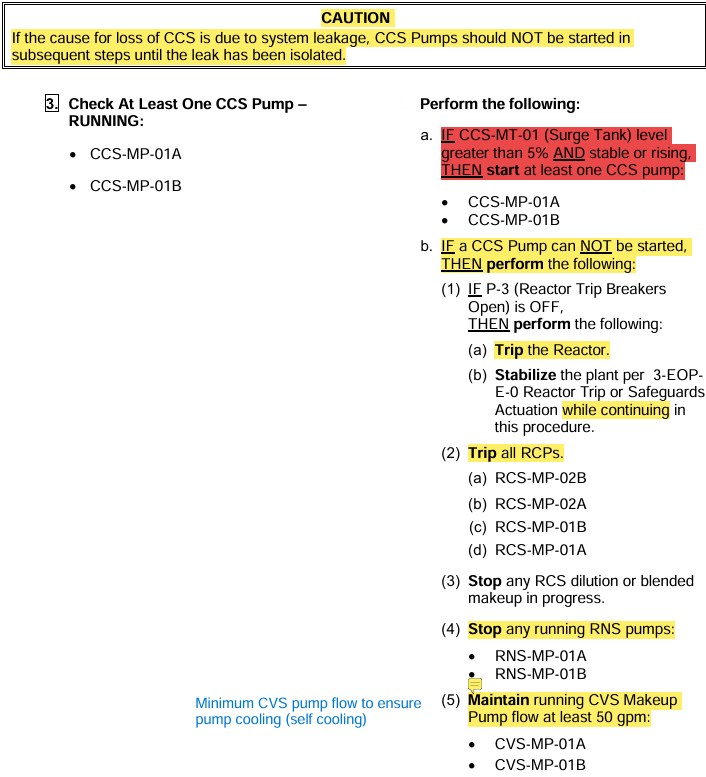

Condition to start a CCS Pump

(Step 3 RNO if NO CCS pumps are running)

Surge tank must be >5% AND stable/rising

If unable to start pump, take same actions as if empty surge tank with the addition of maintaining running CVS MU flow >50gpm

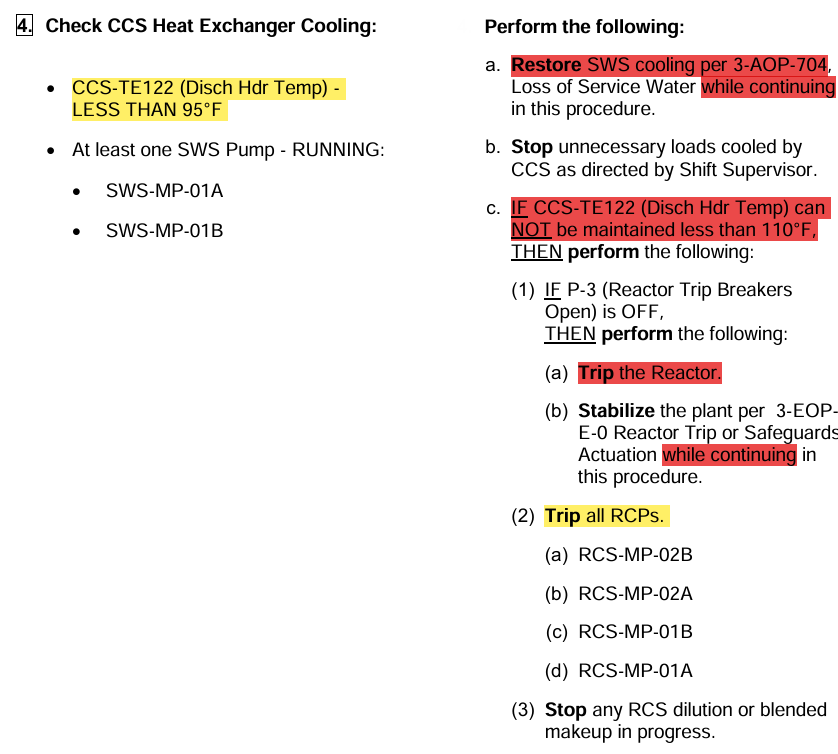

Check CCS HX Cooling

(Step 4)

Normal CCS Discharge Header Temp is <95°F

Anything higher is indication of loss of cooling

RNO:

Restore SWS per AOP-704 While Continuing

*E-0 Action: Cannot maintain <110°F

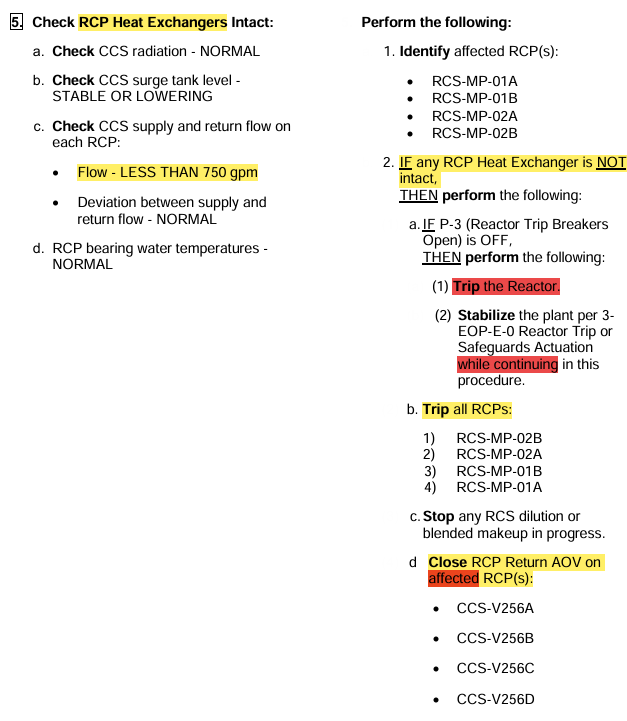

Indications of a Non-Intact RCP Heat Exchanger

(Step 5)

CCS Radiation Abnormal

CCS Surge Tank RISING

CCS Supply and Return to each RCP:

Flow Greater than 750gpm

Deviation Alarm

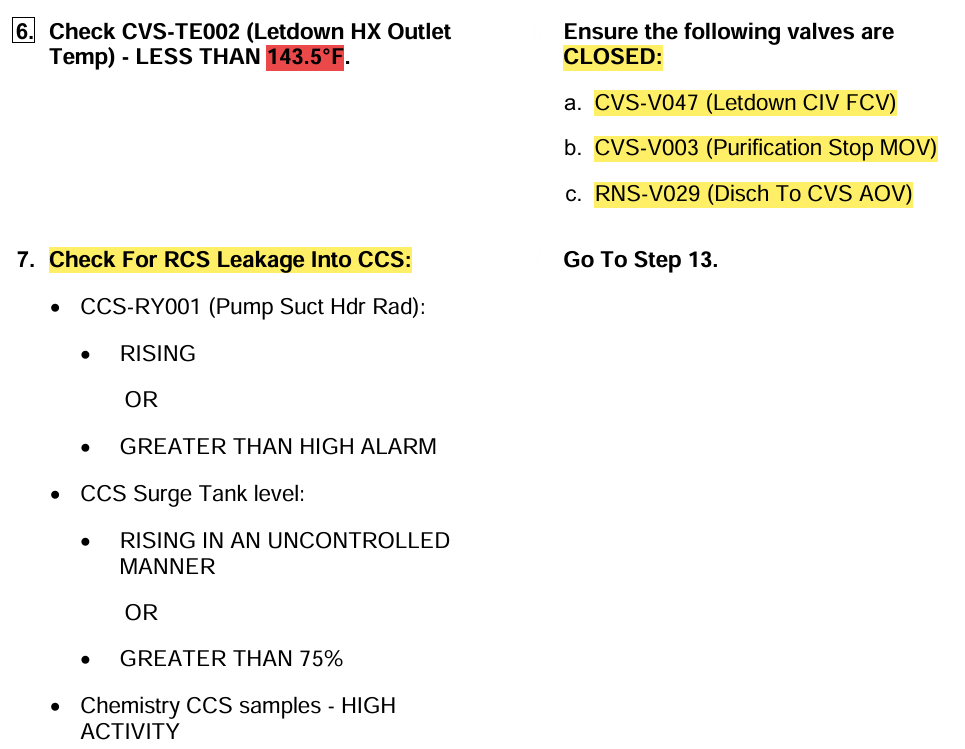

CVS LD Heat Exchanger Outlet Temperature

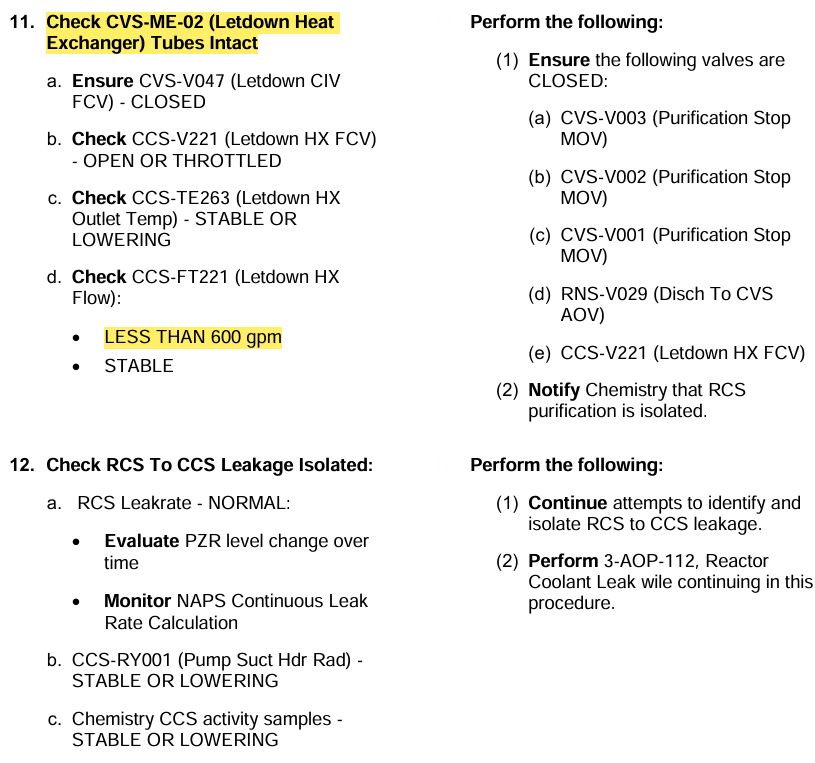

RCS Leakage into CCS

(Steps 6 & 7)

CVS LD Heat Exchanger Intact

(Step 11)

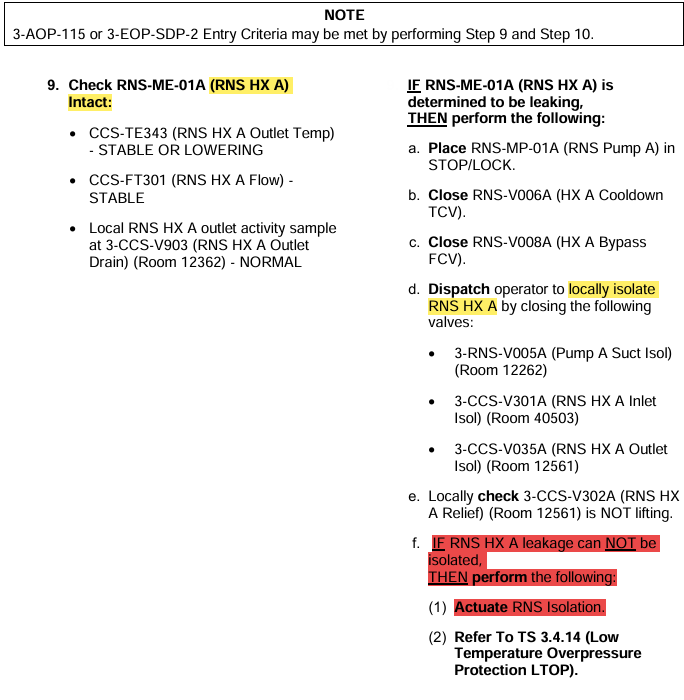

RNS Heat Exchanger Leaks

(Steps 9 & 10)

Step 10 RNS Hx B identical

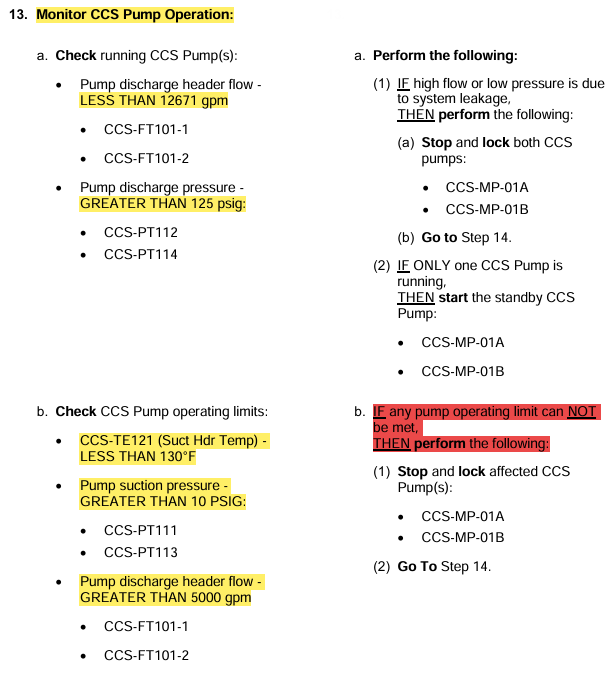

CCS Pump Operating Limits

(Step 13)

Suction Header Temperature <130°F

Suction Pressure >10psig

Discharge Header Flow >5,000gpm

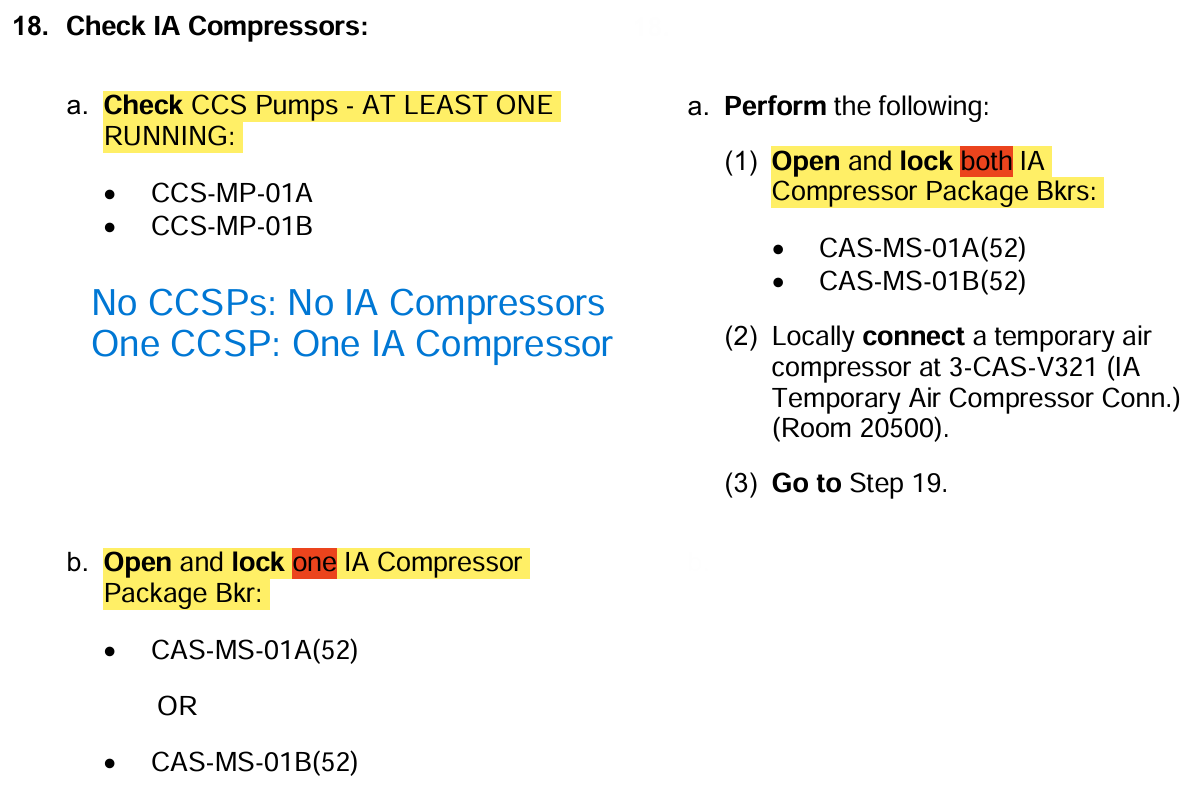

Instrument Air Compressor Actions

(Step 18)

If NO CCS Pump running:

Open and Lock BOTH compressor feeder breakers

Locally connect temporary air compressor (Room 20500)

If you have at least ONE Pump running:

Open and Lock ONE compressor feeder breaker

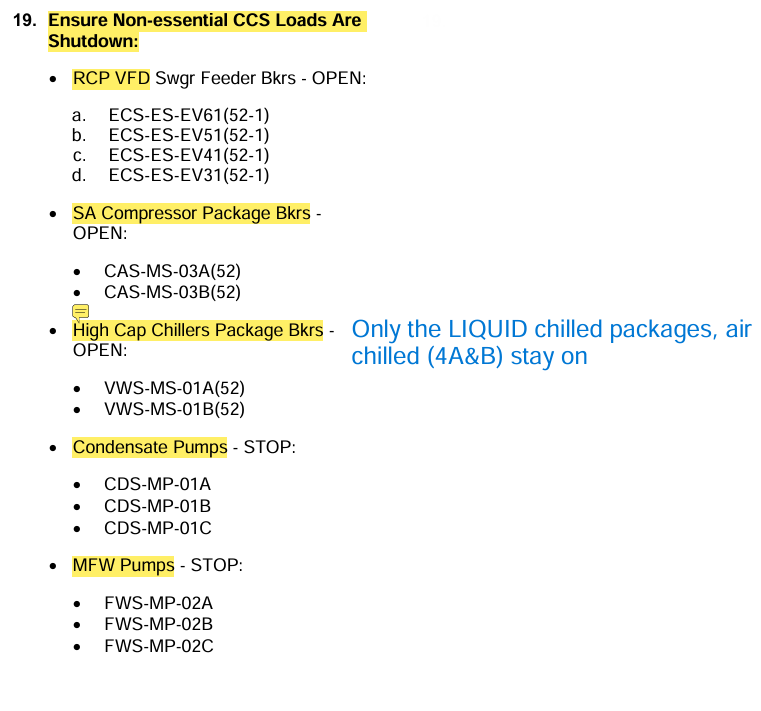

Non-Essential CCS Loads Shutdown per AOP-702

(Step 19)

RCP VFDs

SA Compressors

High Cap Chillers

Condensate Pumps

MFW Pumps

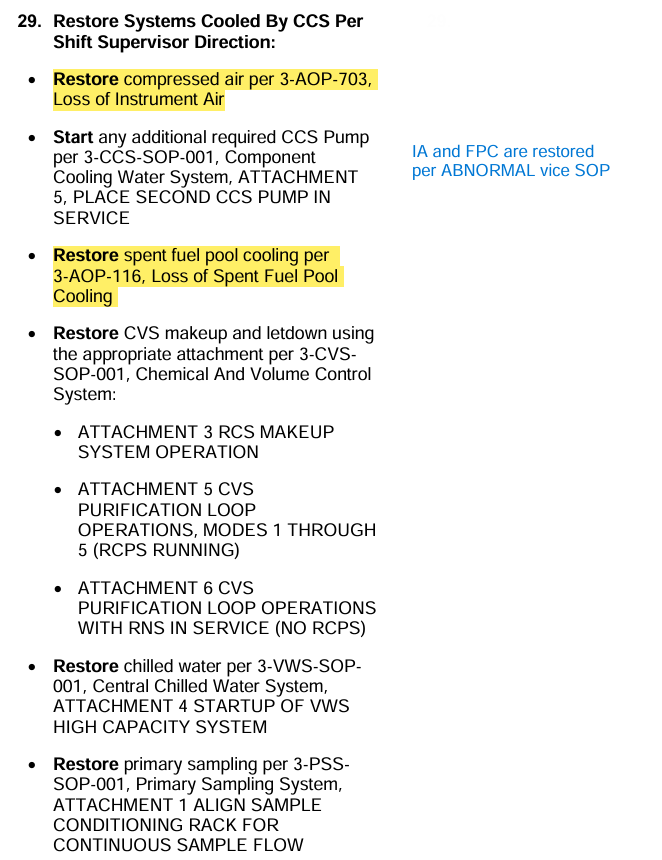

System Restoration Nuances

(Step 29)

AOPs: Instrument Air (703) and Fuel Pool Cooling (116)

SOPs: CCS Pump, CVS, VWS, PSS

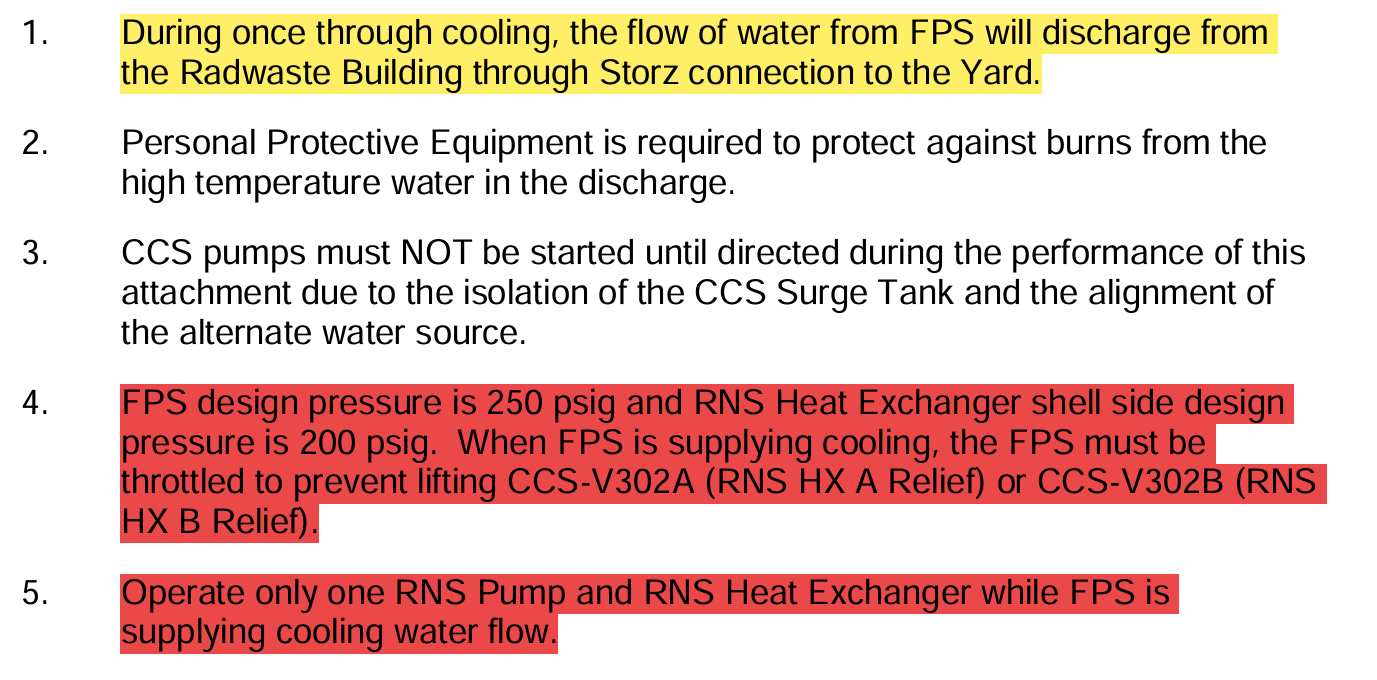

Attachment 1 Align Alternate Cooling to RNS

Precautions & Limitations

Attachment 1 Trigger:

Step 27 Check RNS - NOT REQUIRRED FOR:

RCS Cooling

SFP Cooling

IRWST Cooling

IRWST Injection

***If RNS is needed for any of the above reasons, FPS is aligned to cool RNS Heat Exchangers