higher business - operations

1/53

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

54 Terms

factors to consider when choosing a supplier

price, quality, location, lead time, reputation, discounts

inventory management system

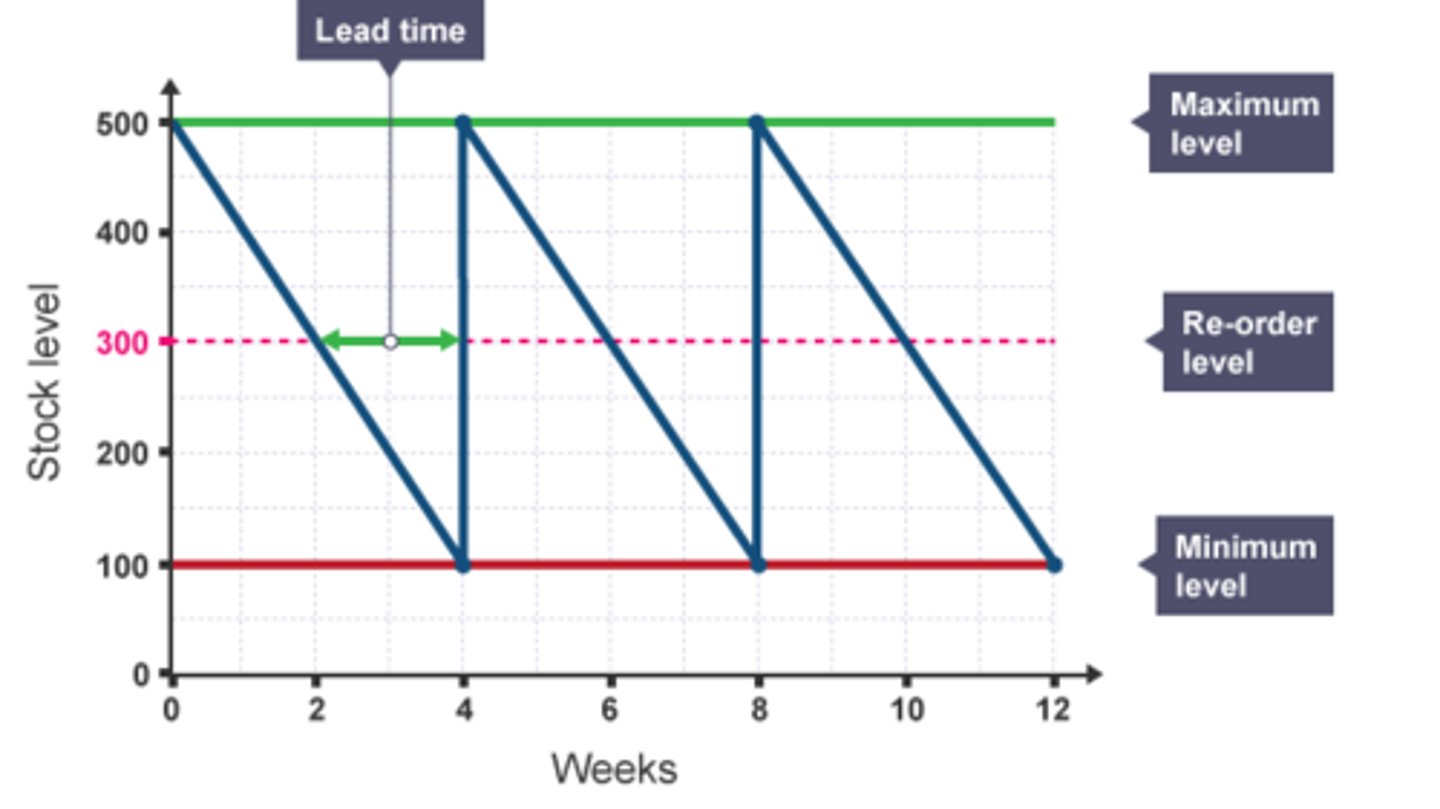

maximum inventory level

the largest amount of items to be stored on site

minimum inventory level

the lowest amount of items to be stored on site

re-order level

the level at which stock is re-ordered, epos links to system and automatically reorders

purpose of controlling stock

supplies could go out of date, supplies could go out of fashion, risk of theft, money tied up in stock

consequences of understocking

business may run out and hold up production, no bulk buying discounts, increased delivery costs, increased admin costs

factors affecting inventory levels

storage available, demand, lead time, skill of staff, finance

computerised inventory control disadvantages

costs a lot to set up, train staff to operate, breakdowns can halt production

computerised inventory control advantages

new stock automatically re-ordered, accurate monitoring or stock, allows for decisions on slow moving stock, highlights regional variations, theft deterrent

JIT production

producing what is needed when needed and nothing more

advantages of JIT

less storage space needed, respond to changes in demand, close relationship with suppliers built

disadvantages of JIT

depends on reliability of supplier, production halted if delays in supplies, sales lost if demand not met

features of effective warehousing

large buildings, central locations, ground level only, large loading bays

centralised storage

large buildings in a central location that store inventory and distribute raw materials to factories or finished goods to retail outlets

advantages of centralised storage

cheaper for one large warehouse than many small, easy for suppliers to deliver, economies of scale consistent procedures

disadvantages of centralised storage

inventory has to be dispersed eventually causing delays, wastage of theft, expensive for specialist stock and equipment

decentralised storage

storing stock in many locations in smaller warehouses or storerooms

decentralised storage advantages

inventory always close at hand, more responsive to local needs, no consequences of understocking

decentralised storage disadvantages

inventory has to be delivered to multiple locations, expensive for multiple locations, inconsistency in procedures

logistics management

ensure the right materials are delivered to the right location on time for a low of a cost as possible

role of the logistics manager

ensure delivery, order correct resources adhere to production budgets, give out instructions to warehouse staff, motivate staff

capital intensive production

producing products that mostly utilise machinery

automation

fully automatic, use of robotics controlled by CAM

mechanisation

involves humans and machinery working together to produce products

automation advantages

robots are consistent and accurate, robots can do dangerous jobs, robots can work 24/7, low wage costs

automation disadvantages

huge investments, breakdowns bad, no human touch, demotivated workforce

mechanisation advantages

improves accuracy and speed over hand made, some human touch

mechanisation disadvantages

human error still possible, cant work 24/7

labour intensive advantages

no high capital set up costs, human touch, motivated workforce

labour intensive disadvantages

human error, workers need breaks and holidays, costs for training

factors affecting the method of production

quantity of goods, skills of workforce, cost of labour, finance available, technology available

methods of controlling quality

quality control, quality assurance, quality circles, quality standards, mystery shoppers, bench-marking

quality control

a method of inspection, checking the product only at then end of the manufacturing process

quality assurance

method of prevention, checking the product throughout the manufacturing process

quality control advantages

ensures faulty products aren't sold, avoids bad PR

quality control disadvantages

not lean, wasteful, reworking takes time

quality assurance advantages

leaner than quality control, can spot where faults occur

quality assurance disadvantages

can still lead to waste, many check points can slow down production

quality circles

groups of workers who meet to discuss ways of improving products or processes

quality circles advantages

increases motivation, lowers staff turnover, good suggestions

quality circles disadvantages

lost working time, strong personalities can sway a discussion

quality standards

established specifications used to measure the degree of excellence of a good or service

quality standards advantages

proves the product has met a good standard, can be used as a marketing tool, higher prices can be charged, less complaints

quality standards disadvantages

lengthy process, agreed standards need to be maintained, requires thorough checks and audits

mystery shoppers

researchers posing as customers who gather observational data about a store

mystery shoppers advantages

keeps staff on their toes, no bias is shown, can improve service without complaints being made

mystery shoppers disadvantages

staff may resent the shoppers and take feedback personally, not a full evaluation could be an off day, businesses need to pay mystery shoppers

benchmarking

method of ensuring quality by coping the best in the business, the market leader

benchmarking advantages

can create a good target for staff, aiming to be the best is motivating

benchmarking disadvantages

may be hard to find trade secrets, only ever as good as the benchmark

continuous improvement

ongoing small, incremental improvements in all parts of an organization

quality management

a total commitment by everyone in an organization to improve the quality of procedures and products by reducing waste, errors, and defects

requirements for quality management to be effective

high quality inputs, rigorous selection, high quality training