17 SQ: Primary Shaping

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

20 Terms

What is the main task for primary shaping processes?

Creating cohesions from shapeless materials

How can primary shaping be categorized?

According to nature of shapeless material (DIN 8580)

Nature:

Liquid

Plastic

Pulpy

Granular/Powdered

Splintered/Fibrous

Gaseous/Vaporous

Ionized

Primary Shaping by Welding

Primary Shaping by AM

Name advantages of casting processes

Complex geometries realizable

Near net-shape production (less post-processing and machining afterwards)

Wide range of materials

Wide range of parts (mass)

Economic

Circular economy

Name disadvantages of casting processes

Sometimes expensive systems

Sometimes bad surface qualities

Tradeoff between mass production and surface quality/precission/complexity of geometry

How can casting processes be categorized?

In permanent form and lost form

Lost form:

Sand Casting

Investment Casting

Lost Foam Casting

Permanent Form:

Die Casting

Mold Casting

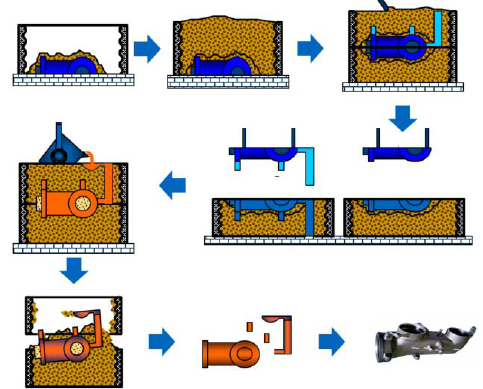

Sketch the sand casting process

Covering of one half of the mold with casting sand

Filling the box with coarse casting sand

Repeat for the other half

Join the two halves and add feeders and degassing pipes

Open boxes and take out the mold

Pour molten material and wait to solidifaction

Take part out, remove feeders, bur and degassing pipes

Why is sand casting or lost foam casting more suited for iron-based materials than mold casting or die casting?

Because mold and die casting require the material to be melted to a fully liquid phase, which is more energy expensive for ferrous alloys

Why are cooling rates for sand casting typically slower than for mold or die casting?

Due the higher heat capacity of sand when compared to metal

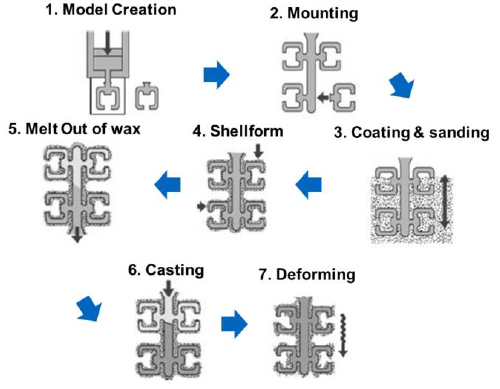

Give a process description of investment casting

Wax mold is created (and mounted together if the case)

Coating and sanding

Shellform completed with the sound around the wax positive mold

Wax is molten out

Casting

Deforming

What are the main advantages for investment casting?

High surface quality and precission

Small components realizable

Near net-shape production

What is the main difference between common sand casting and lost foam casting?

Sand casting leaves the mold used to do the form in sand untouched, while in lost foam casting the mold is burnt by the melts

What casting processes are suited for what types of materials?

All metals: sand casting, lost foam casting, investment casting

Low melting temp. alloys: die casting and mold casting

Name typical casting deffects

Undersize

Cavities

Warpage

Cold shut

Stress cracks

Inclusions

Gas porosity

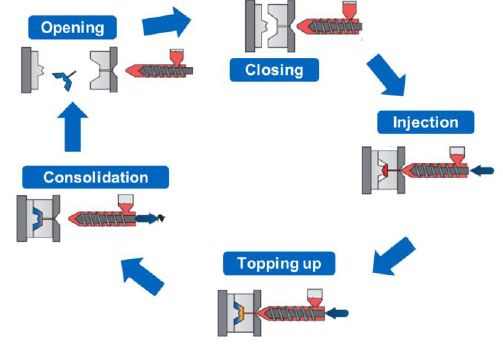

Name the process steps for injection molding

Closing

Injection

Topping up

Consolidation

Opening

What are the main differences between injection molding and extrusion?

Injection Molding: with a mold and higher pressures

Extrusion: without mold for linear components

Both of them use the same screw + temp principle

True or false? Extrusion is suited for manufacturing parts with complex geometries in all three spatial directions. Why?

False. Extrusion can only create complex geometries in 2 dimensions, since the third dimension is the extrusion direction an is therefore basically linear

What are the advantages and drawbacks for Additive Manufacturing?

Advantages:

Lightweight design

Funtional Integration

Mass customization and personalization

High complexity in geometry

Disadvantages:

Small series

Not yet standarized

Pre- and post-processing needed

Expensive systems

When does it make sense to used addtivie manufacturing as porduction process?

For small series with high mass customization and personalization needed

For lightweight design

For functional integration as extremely complex geometries

Name additive manufacturing processes used for aerospace industry

Selective Laser Melting

Electronic Beam Melting

(Fused Depositon Modelling and Stereolithography)

What are the main differences between EBM and SLM? How does this affect the production process?

SLM (Selective Laser Melting): layered melting of powdered material with laser and with no vacuum

EBM (Electronic Beam Melting): layered melting of powdered material with electron beam and with vacuum → more complex and expensive process due to vacuum but with better results