MEC316 - Renewable Energy

1/212

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

213 Terms

What are the advantages of wind power?

+ sustainable energy

+ clean energy

+ no fuel transportation or storage

+ free source

+ spatial dispersion of energy

What are the disadvantages of wind turbines?

- unpredictable

- cost of turbine (integration and installation)

- environmental impact (visual, noise, wildlife, radio interference)

Explain the effects of the atmospheric boundary layer on wind power generation.

wind speed increases with height in atmospheric boundary layer

What is the boundary layer power law?

(Uz/U10) = (Z/10)^a

where Uz and U10 are velocities at heights Z, 10 metres respectively.

a=0.15 for level grass with scattered trees, for rougher surfaces a>0.15

What is the Weibull distribution?

H = 8760 exp[-(V/C)^k]

H=hours/years during which V is exceeded

V = annual average wind speed

typically k=2, C=1.13V

What are the non-dimensional parameters that affect the wind turbine power coefficient?

power coefficient, tip speed ratio, solidity, Reynolds number.

Power Coefficient (Cp) equation

=power extracted from wind / power available in wind = P/E

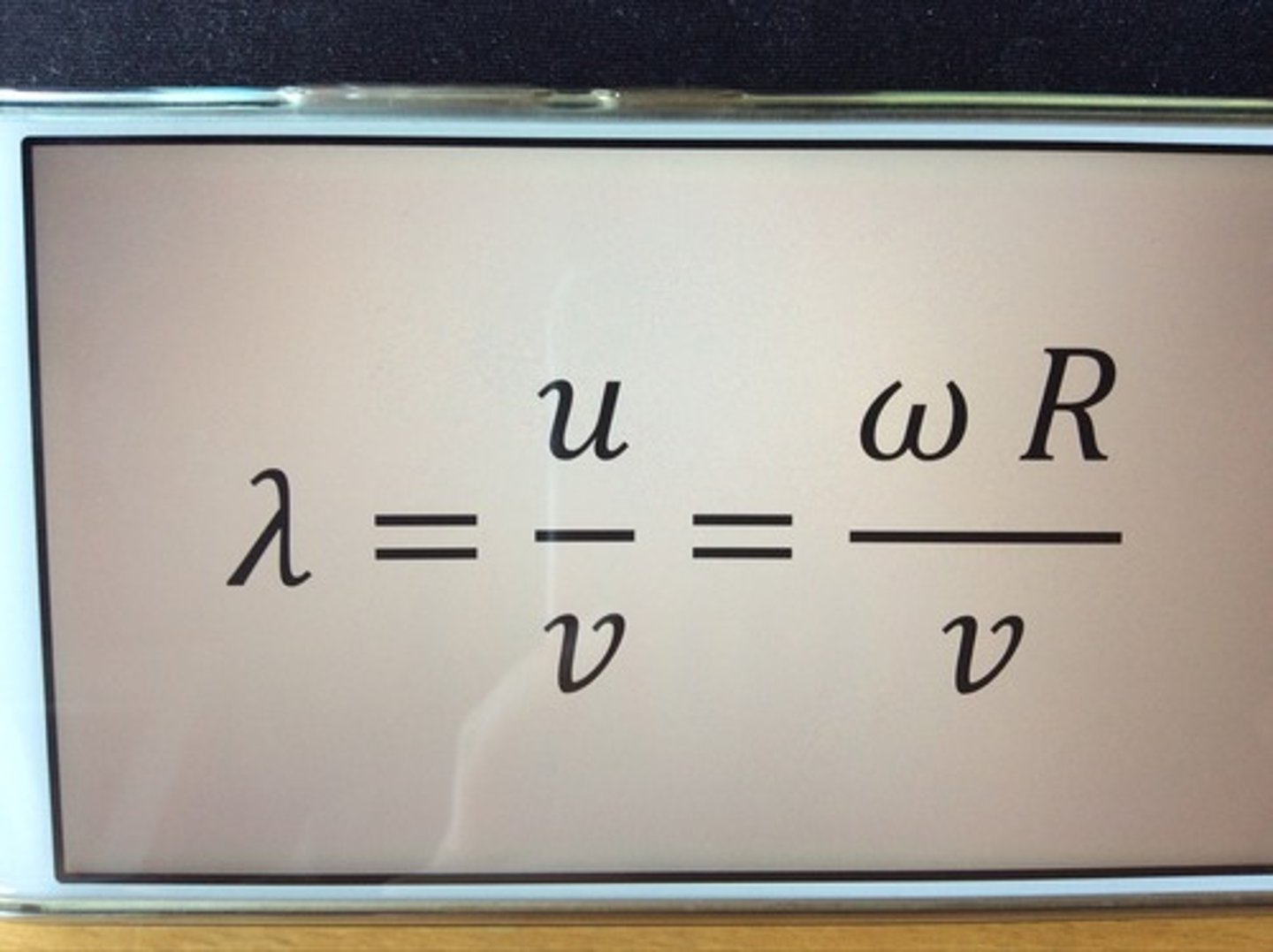

Tip speed ratio

= blade tip speed / wind speed

solidity

= total blade area/ flow area swept by rotor

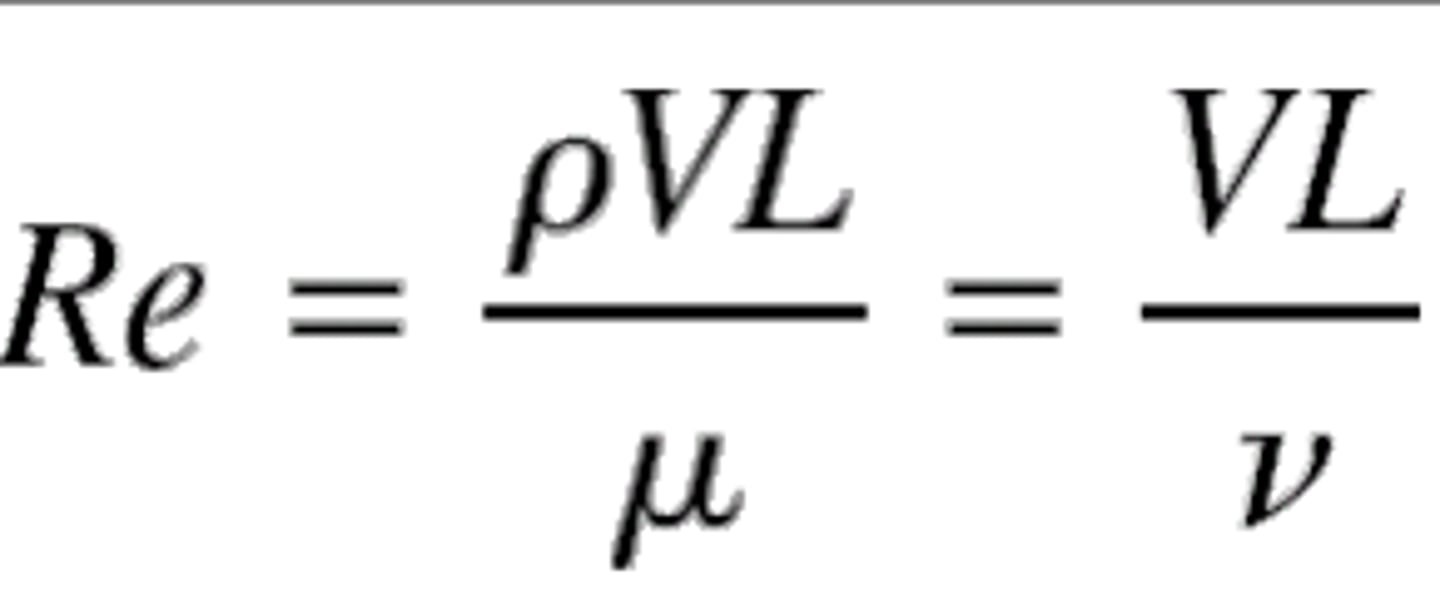

Reynolds number

What are the main difference of HAWTs and VAWTs?

-HAWTs face wind, VAWTs can use wind from any direction

-HAWTs more common

-HAWTs have rotor, gearbox etc at top, VAWTs don't

-VAWTs used in urban environments

-HAWTs used under streamline wind conditions

Give some examples of HAWTs.

1. high solidity, low speed:

-max running time more important than max power

-e.g. american traditional, wind pumps, windmills

2. low solidity/high speed

-look like aircraft propellers

-most popular

-max power per unit cost desired

-single,two or three -bladed

Give some examples of VAWTs.

-aerofoil blades

-Darrius/ Troposkein arc blades

-fixed straight blades H-type wind turbine

Give an example of drag type wind turbines

cup anemometer and savonius wind turbine

What are the advantages of VAWT?

+ generator, gearbox etc can be on the ground (easier to maintain)

+don't need yaw mechanism and control system to turn rotor against the wind, operates from any direction

+manufacturing cost lower

What are the disadvantages of VAWTs?

-oscillatory forces can cause vibration damage or fatigue

-not self-starting

-needs wires, can be impractical

-blade optimisation more challenging due to unsteady condition

-VAWTs are very difficult to mount high on a tower to capture the higher level winds. so use lower, more turbulent winds and produce less in possibly more damaging winds.

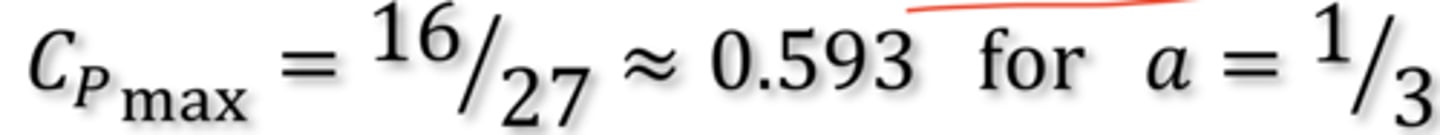

What is the theoretical upper limit of the energy that a wind turbine can extract from the kinetic energy in the wind.

59.3%

Betz limit

Betz limit assumptions

-homogeneous, incompressible, steady state flow

-flow uni-directional

-inviscid flow

-infinite number of blades represented by a disc

-uniform thrust over disc of rotor area

-rotor only (no hub or tower effects)

An empirical formula, E = 2.5 A (V_m ^3) , can be used to make a rough estimate of the annual electricity production in kWh. why is this different to the Betz limit?

(1) The Betz limit is a theoretical upper limit for wind turbines. It is normally less than 50% for operational wind turbines;

(2) The turbine availability is normally about 90% rather than 100% as assumed in the empirical formula.

Why is a drag-type VAWT not desirable for harvesting wind energy?

-very low efficiency

-maximum Cp only 11% for drag-type

Why is the performance of a drag-type VAWT much lower than lift-type WTs?

shape affects drag, aerofoil has much lower drag coefficient

Describe the process of blade stall in relation to aerofoil dynamics

stall is caused by boundary layer separation, occurs when flow suddenly leaves the suction side of the aerofoil (when the angle of attack becomes too large).

causes loss in lift and increase in drag. dangerous in planes but good in WTs.

Why is stall angle an important factor in wind turbine blade design?

-limiting the performance at high lift/ wind conditions

-can be used to control the rotor speed.

Which span section of the HAWT blade works hardest in extracting energy from the wind?

the outboard blade (force generated is much higher for the blade section near the tip than near the root.

Why is the blade chord reduced from the root to the tip for a typical large HAWT blade?

to limit the blade load near the tip for structural consideration

How does a bi-directional lift-type HAWT work?

zero pitch angle.

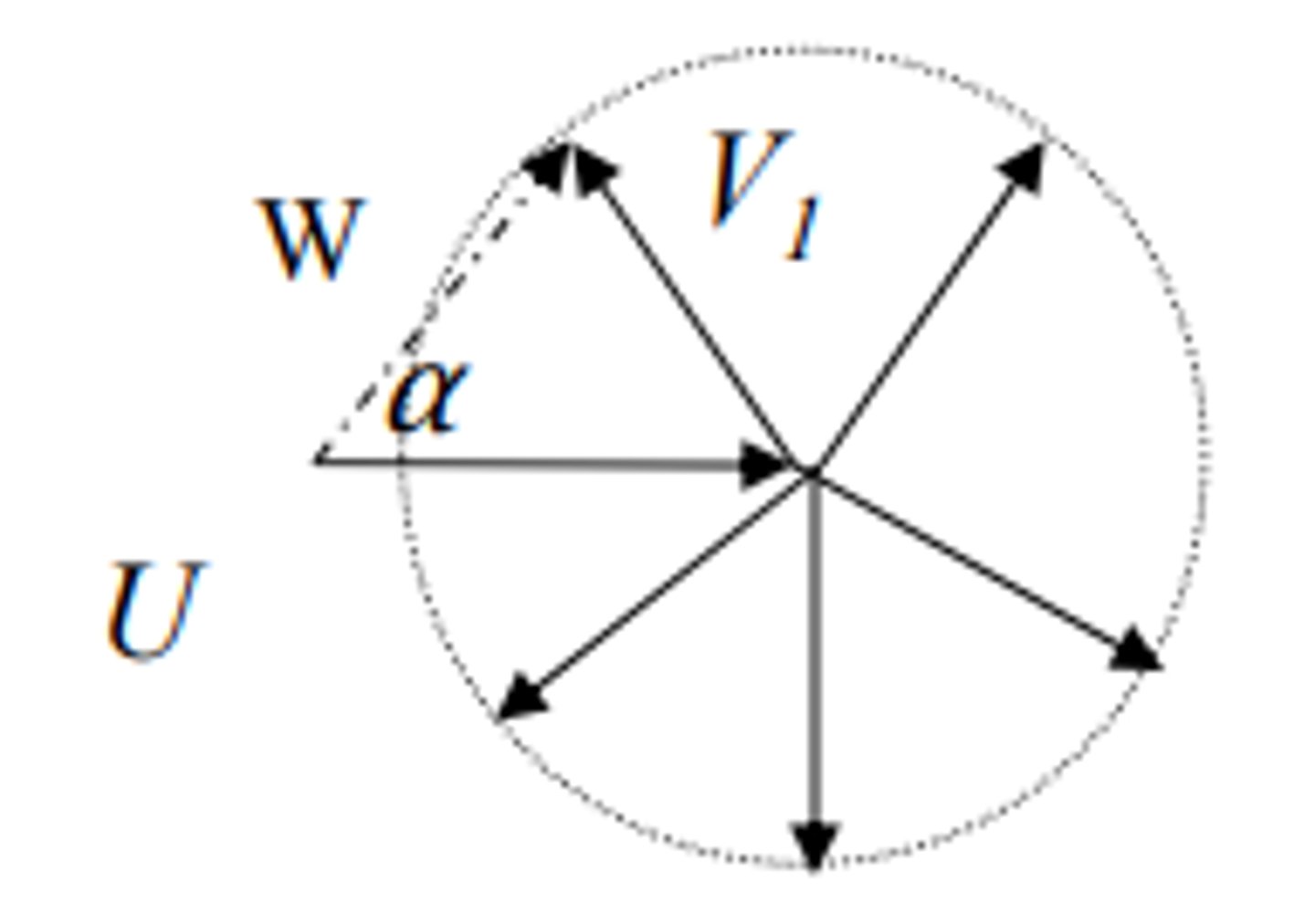

explain why VAWTs are prone to self starting problem

As the blade (U) rotates, α can become very large as it varies between ±90°, leading to blade dynamic stall. Hence the blades are stalled for most of the cycle, and so the rotor will not normally start by itself at low rotational speed.

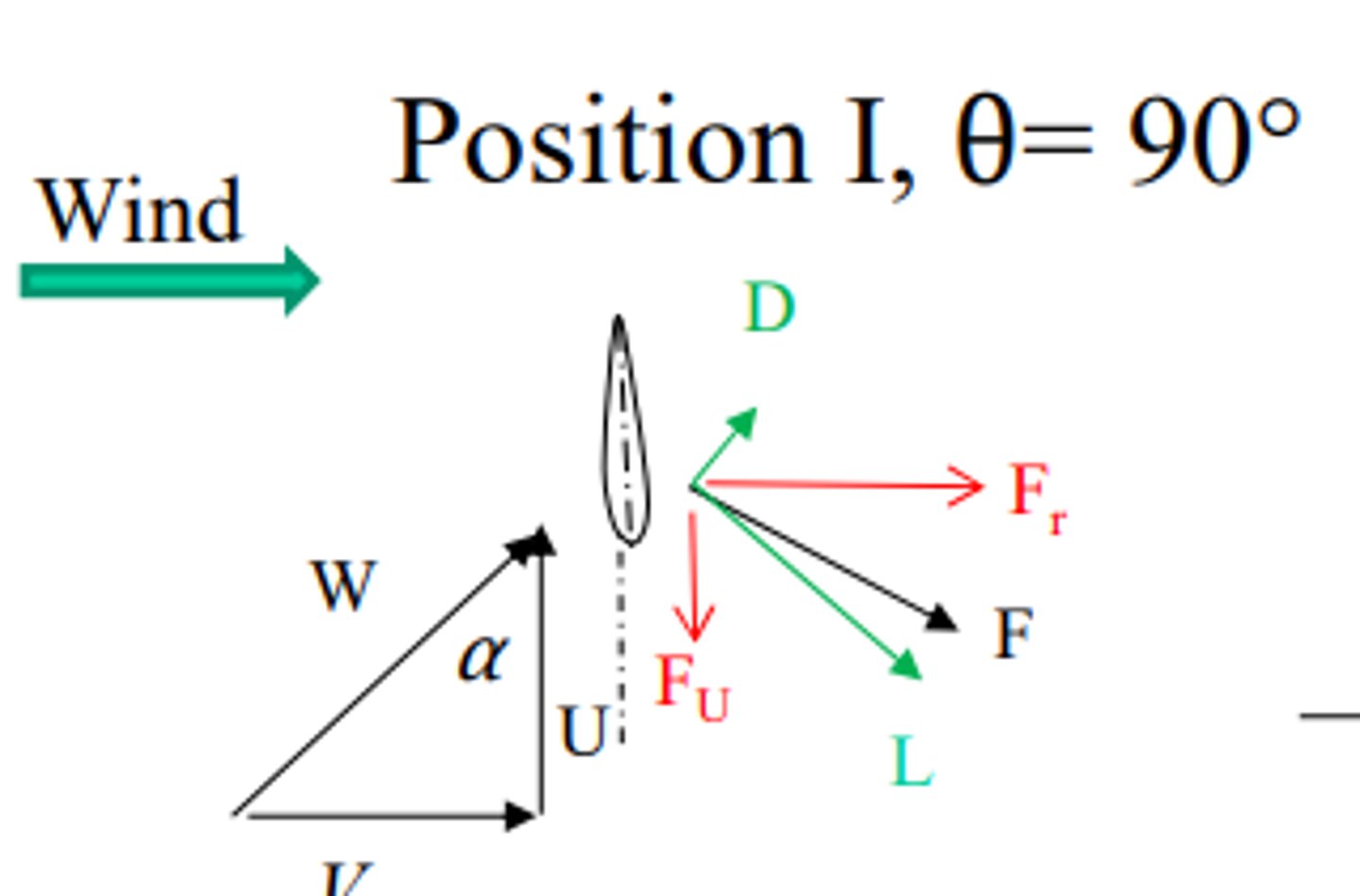

Using velocity and force components,show how a VAWT blade section generates torque at azimuth angle θ=90°

The velocity triangle and forces changes periodically depending on the azimuth angle θ during the rotation.

Upwind side (0°< θ <180°) FU pushes the blade in the rotational direction

show why the turbine blade is not helping for a chosen azimuth angle on the downwind side

180°< θ <360° downwind side. ( θ is azimuth angle)

at downwind FU drags the blade against the blade rotation

how to vary the pitch angle, β, along the blade (twist) from the root to the tip to maintain the same incidence for the cross sectional aerofoils for a given wind velocity.

-Along the blade from the root, the radius increases, so does the rotational speed 2πrω.

-From the velocity triangle diagram, it implies a decrease in Φ.

Since Φ= β+α to maintain incidence α, the pitch angle β needs to be decreased gradually from the root to the tip.

If the pitch angle can be controlled during the wind turbine operation, how would you change the pitch angle as the wind becomes weaker?

as the wind speed reduces, Φ decreases.

To operate at the design incidence, the pitch should be reduced.

angle of attack equation

angle of attack = sin^-1(wind speed / blade speed)

discuss why the VAWT can only operate at relatively high rotational speed

- if the rotational speed U is low compared with the wind speed VT the blade can experience very large incidences

-causes the flow to stall on the suction side of the blade.

-The lift-drag ratio drops significantly and the wind turbine will stop working.

Explain how stall regulation works at higher wind speed for HAWT.

-passive control (in HAWT or VAWT)

-blades set at fixed pitch

-blade is progressively stalled as wind speed is increased

-power control depends only on automatic changes of incidence angle

strategies for overspeed avoidance

1) rotate out of wind (yaw control)

2) for a fixed pitch angle, design the blade so that it stalls gradually (along blade) if the speed is too high

3) blade pitch control (pitch regulated machines)

4) shaft brake

5) turnable tips or spoilers on blades, activated by centrifugal force for fixed pitch WTs

Why are the actual aerodynamic forces acting on an HAWT rotor blade unsteady?

• mechanical unbalance (e.g. blade bending)

• gravity on large HAWT blades

• aerodynamic force variations

a) HAWT: wind faster at top and blades closer to tower at bottom

b) VAWT: cyclic change and force/torque cyclic variation

c) Gusts: HAWT 'coning' (blade deflection under heavy thrust loading due to Fx)

• gyroscopic forces (HAWT) - rotation about 2 axes - external moments caused by yawing about tower (vertical) axis - vibratory input to the hub and tower

• forces on tower and cables (e.g. von Karman vortex street)

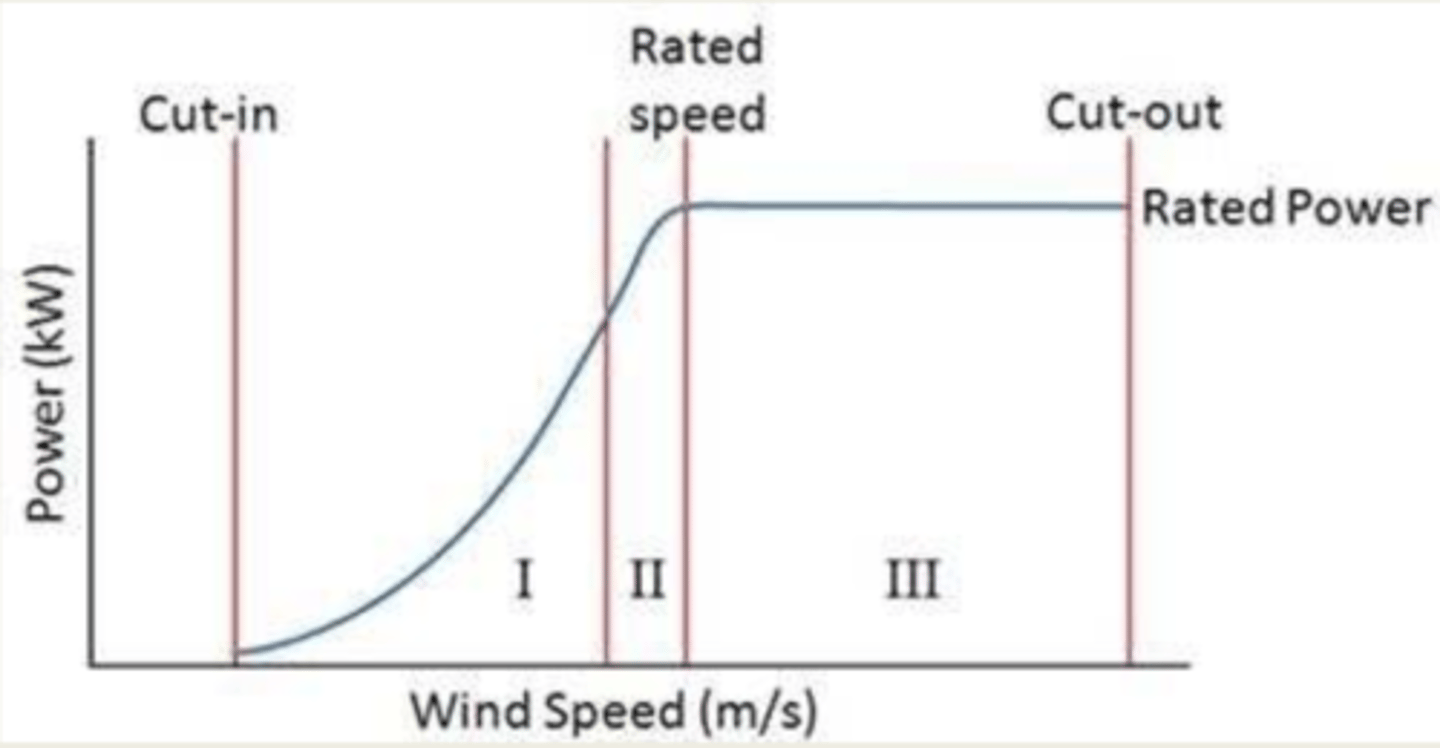

power curve for wind turbine

What is the "cut-in" speed of a wind turbine?

The lowest wind speed at which a wind turbine will operate is known

What is the "cut-out" speed of a wind turbine?

The maximum wind speed, above which the turbine is designed to shut down

AKA shut-down speed

what is rated wind speed?

The wind speed at which it reaches the rated power

rated power

The maximum power produced by a wind turbine

For maximum power generation, would you use a pitch controlled wind turbine or a stall controlled one with fixed pitch angle.

pitch control

Effect of fixed frequency on rotor design

+Cheaper, less complicated rotor design

+Smoother power output in stall controlled regime

+Lower maintenance requirement

+Longer life expectation

-reduced annual energy output because poor Cp at low V

What are the potential problems for small wind turbine projects?

- low average wind speeds, insufficient power (~100s W range)

- price per kilowatt very high for small scale WTs)

- difficult to compete with conventional power supply

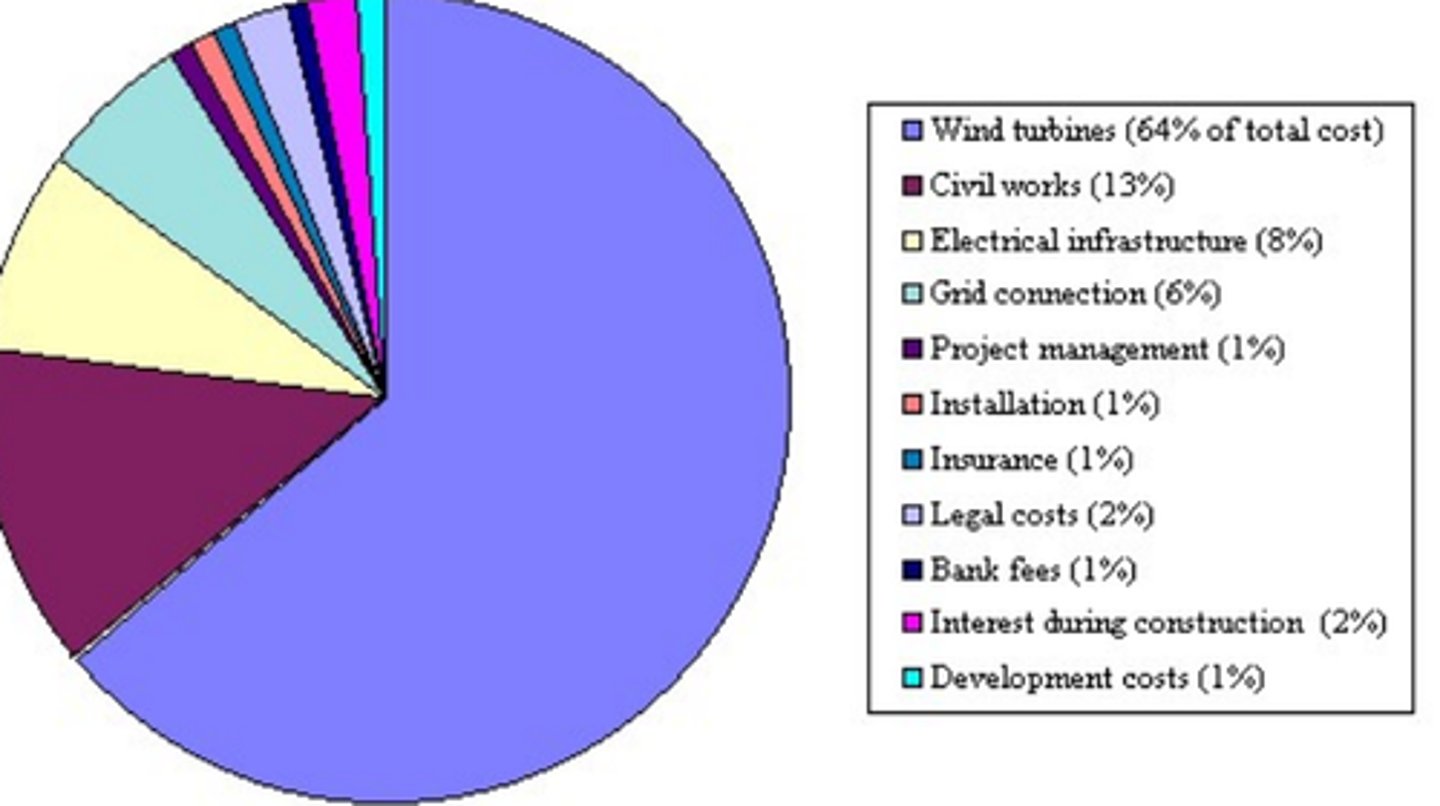

What is the most costly for a large wind turbine project?

Medium size wind turbines (above rooftop mounted or free-standing)

- issues with: planning permission, safety, insurance

- used by: farmers at remote site

-The payback period can be very long

Using the Dickinsons Diary Case study, write down the three steps in estimating the payback period for a wind turbine project.

1. Global estimate of wind energy at site:

2. Machine application

3. Economics

For the design of a wind farm layout, what needs to be considered from the aerodynamic view point?

-downstream from WT there is a WAKE from the wind turbine, where wind speed is reduced.

-downstream there is a spreading of the wake and the wake recovers towards free stream conditions

-wake effect is the aggregated influence on the energy production of the wind farm, which results from the changes in wind speed caused by the impact of the turbines on each other.

-need to consider wake effects from neighbouring wind farms and the possible impact of wind farms which will be built in the future.

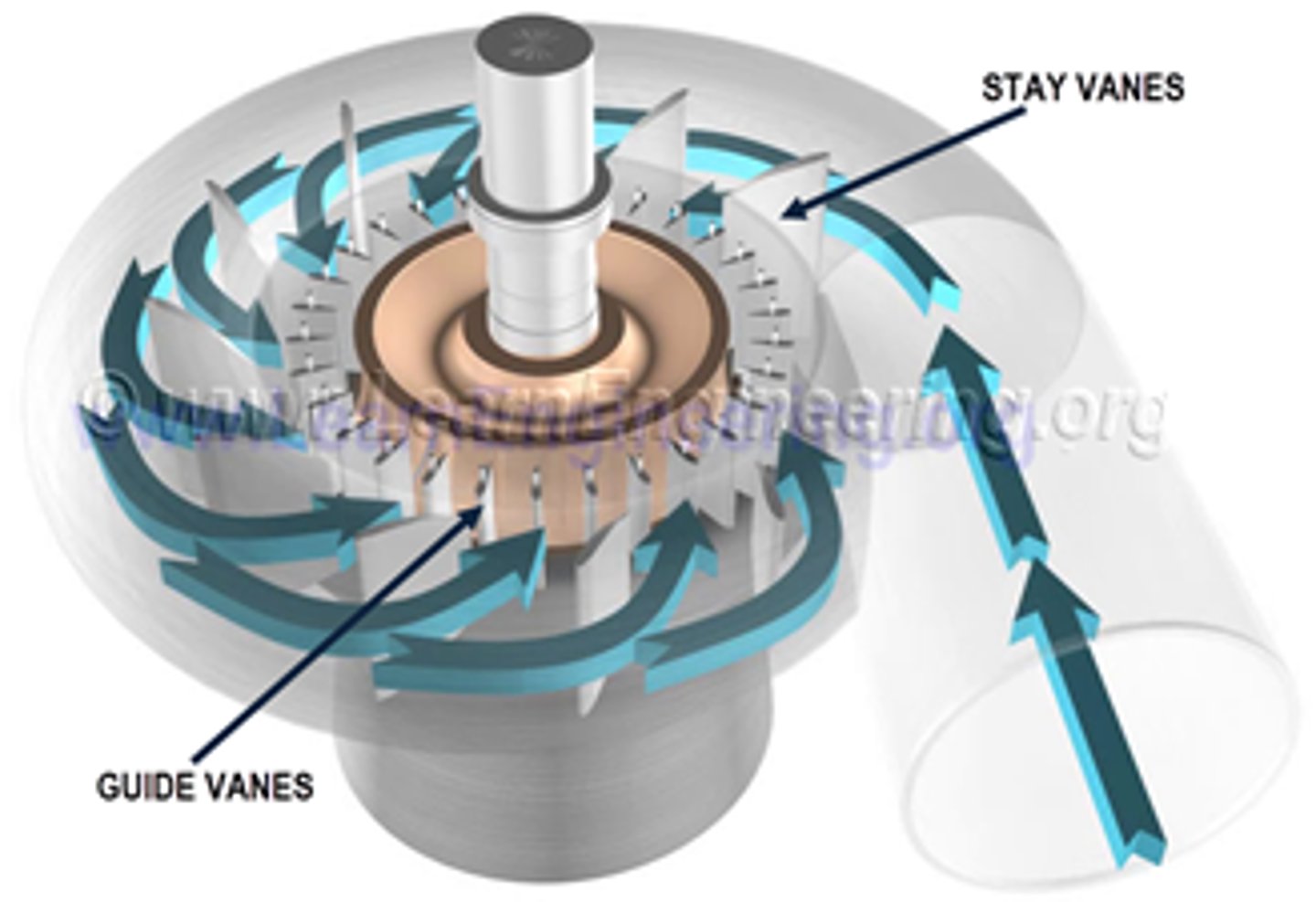

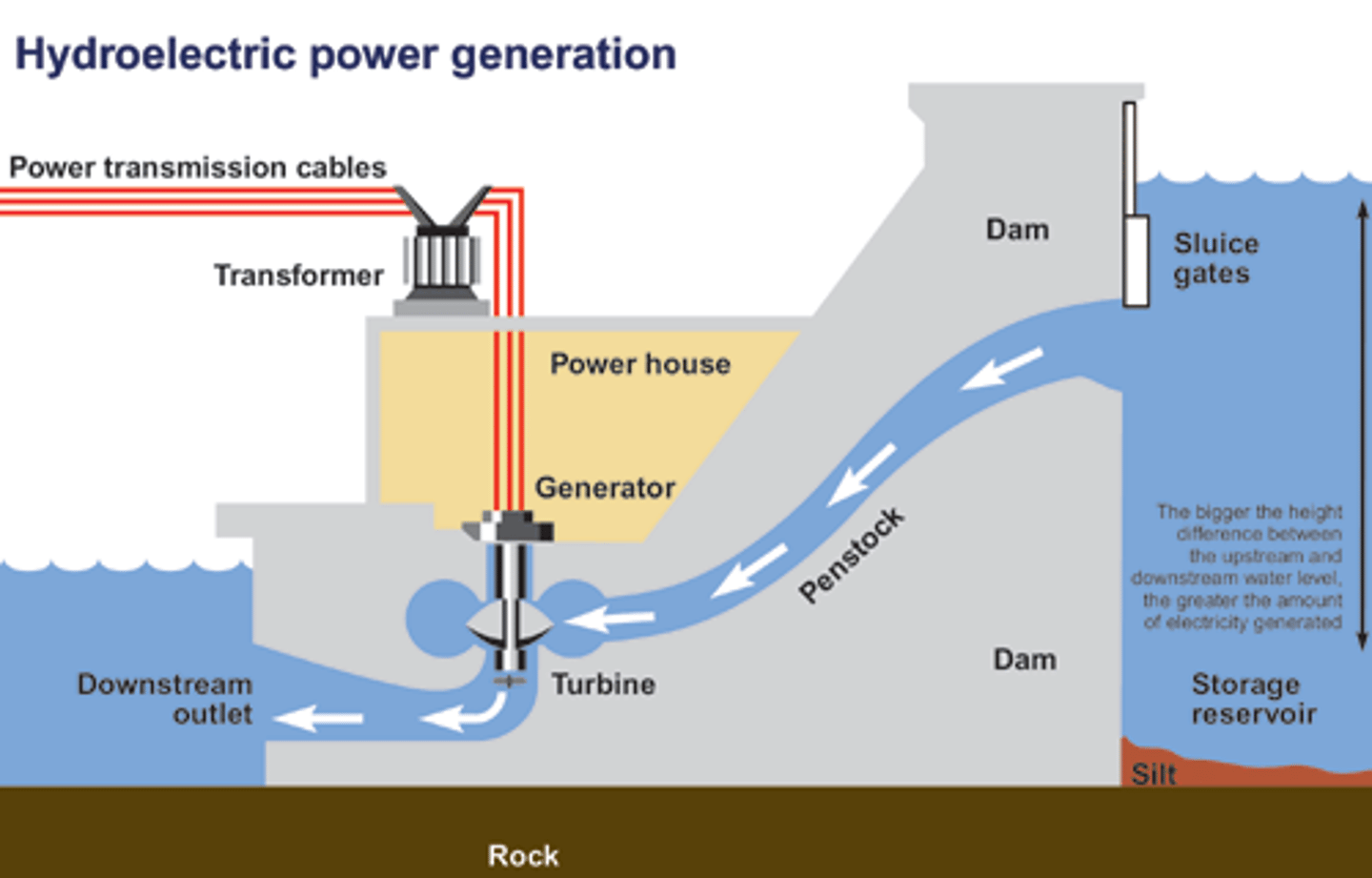

three kinds of turbines used in hydroelectric plants

1. Francis turbine

2. Propellers

3. Impulse turbines

Francis turbine

-most common hydro turbine

-up to 95% efficient

-not best choice at high heads with high speeds

Propellers in HEP

-axial flow turbine

-have largest bulk flow, normally used in low head situations

-high solidity and high pitch angle

impulse turbines (HEP)

e.g Pelton Wheel

-used for very high head situations

-jets of water fired at cup arrangements

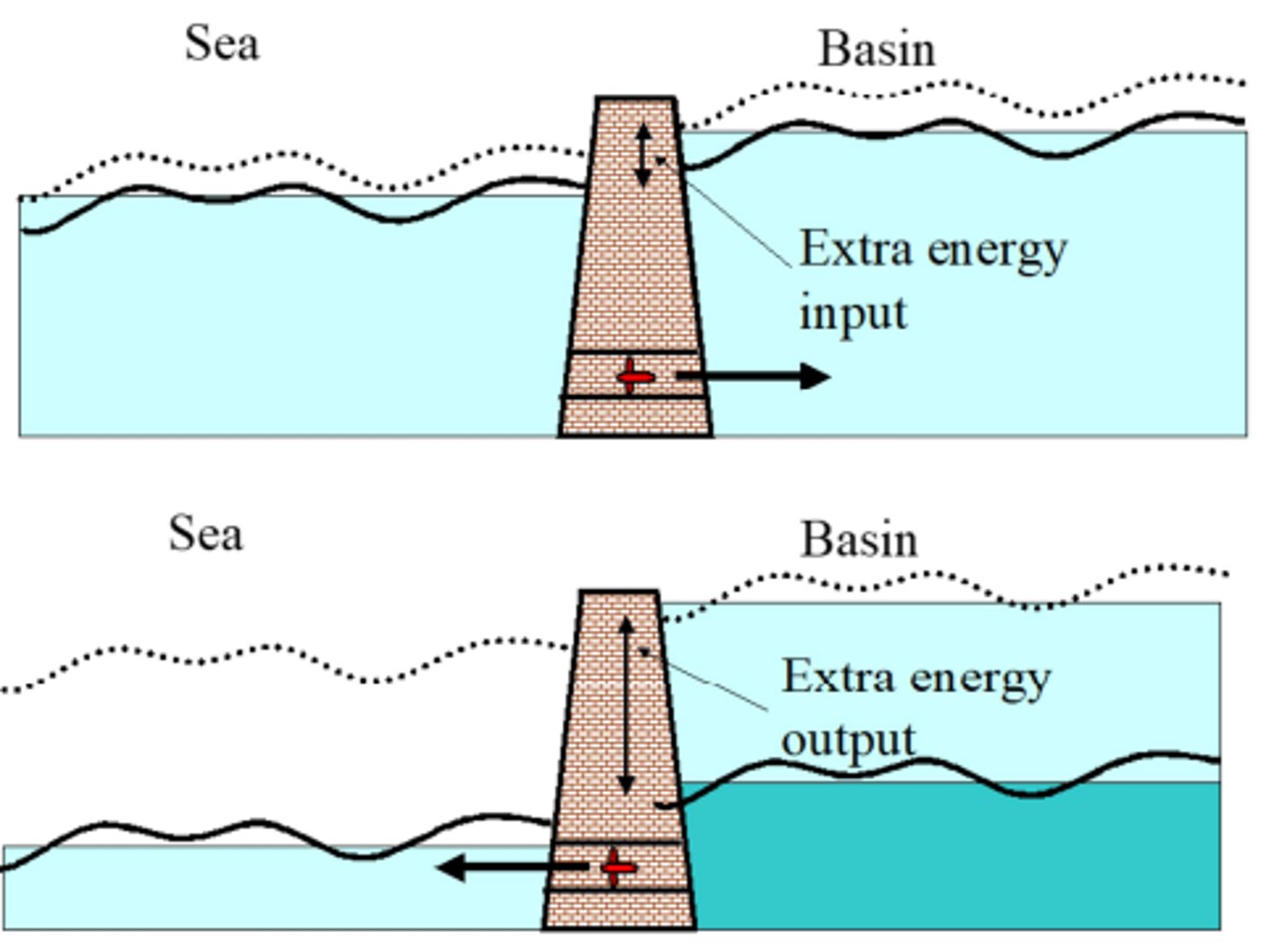

tidal energy

-rise and fall of sea caused by gravitational pull of moon

-use of twice-daily upstream flow and downstream ebb of the tides

-min useful tidal range is 5m

hydro-electric power

electricity made by water-powered engines

wave power

-sea waves move up and down caused by wind over surface

-wind shear on water surface causes waves to form

-wave energy depends on wave length, wave height and wave period

problems with wave power

-more complicated to harvest energy than in hydro or tidal

-no large scale commercially viable solution yet for wave power

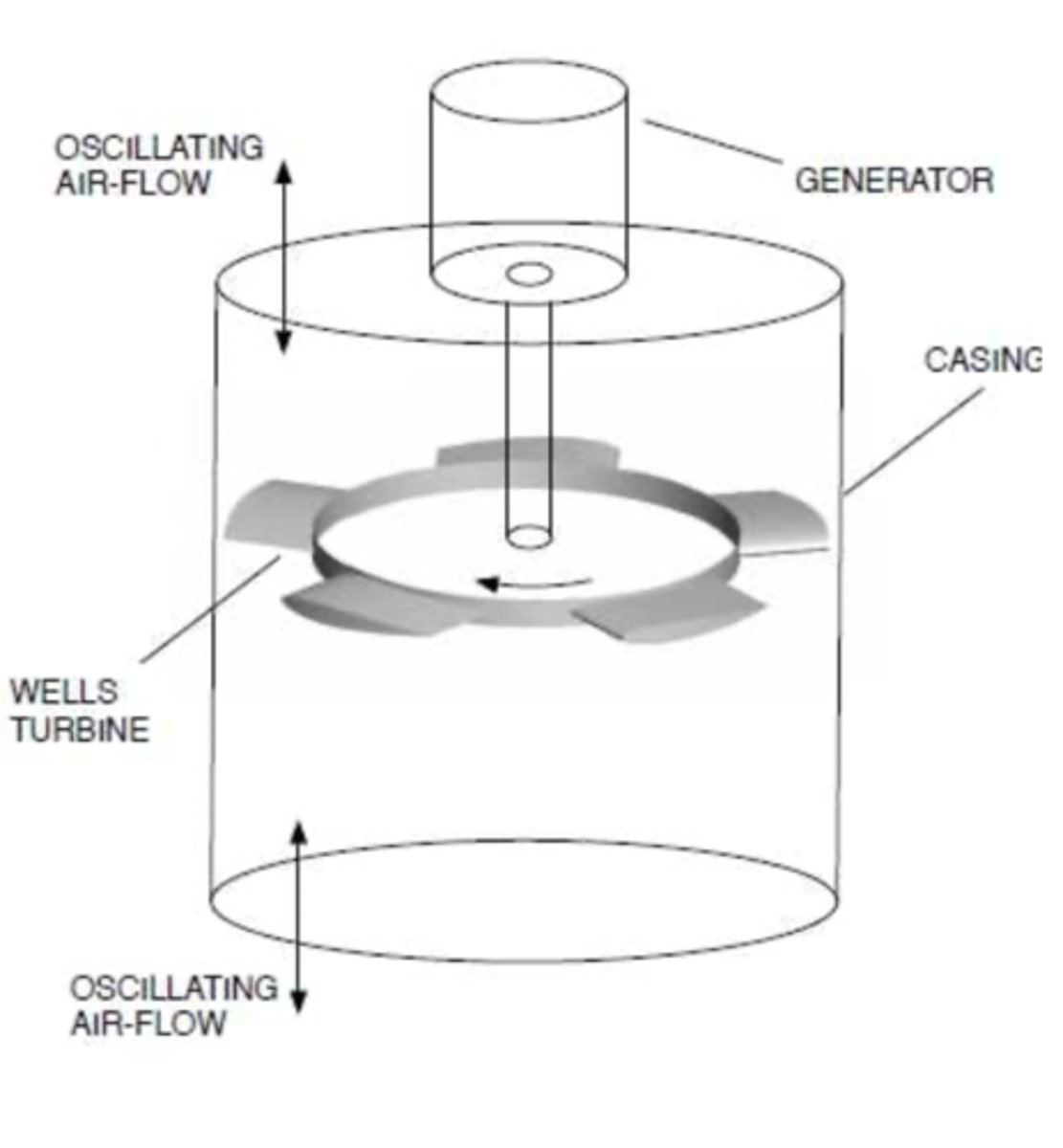

two types of wave generators

1. fixed devices

2. floating devices

examples of fixed wave generators

-TAPChan (tapered channel)

-OWC (Oscillating Water Column)

-OSPREY (Ocean Swell Powered Renewable Energy)

-The Wells Turbine

examples of floating wave generators

-CLAM (circular interconnected air chambers)

-DUCK, wave motion turns into hydraulic energy through the spine linked to the generator

-BBDB (Backward Bent Duct Buoy)

-WHALE, floating version of OWC

-pelamis wave generator, points towards waves, moves like a snake to push hydraulic fluid through generators

explain, for hydroelectric power, how the pressure head is related to velocity and then to power?

Pressure head: ΔP=ρgh

velocity:

v = sqrt(2ΔP/ρ) = sqrt(2gh)

power:

Power=pressure head x volumetric flow rate

describe how flood pumping helps for extracting tidal energy

-energy input much smaller compared with extra power from additional head during ebb cycle

-because pressure head in the sea water higher tide is used

what are the three wave parameters that determine wave energy?

wave length, wave height and wave period

how does a Wells turbine work?

-always spins in same direction as the air flow approaches from either side

-symmetric blade produces rotation no matter which direction air comes from

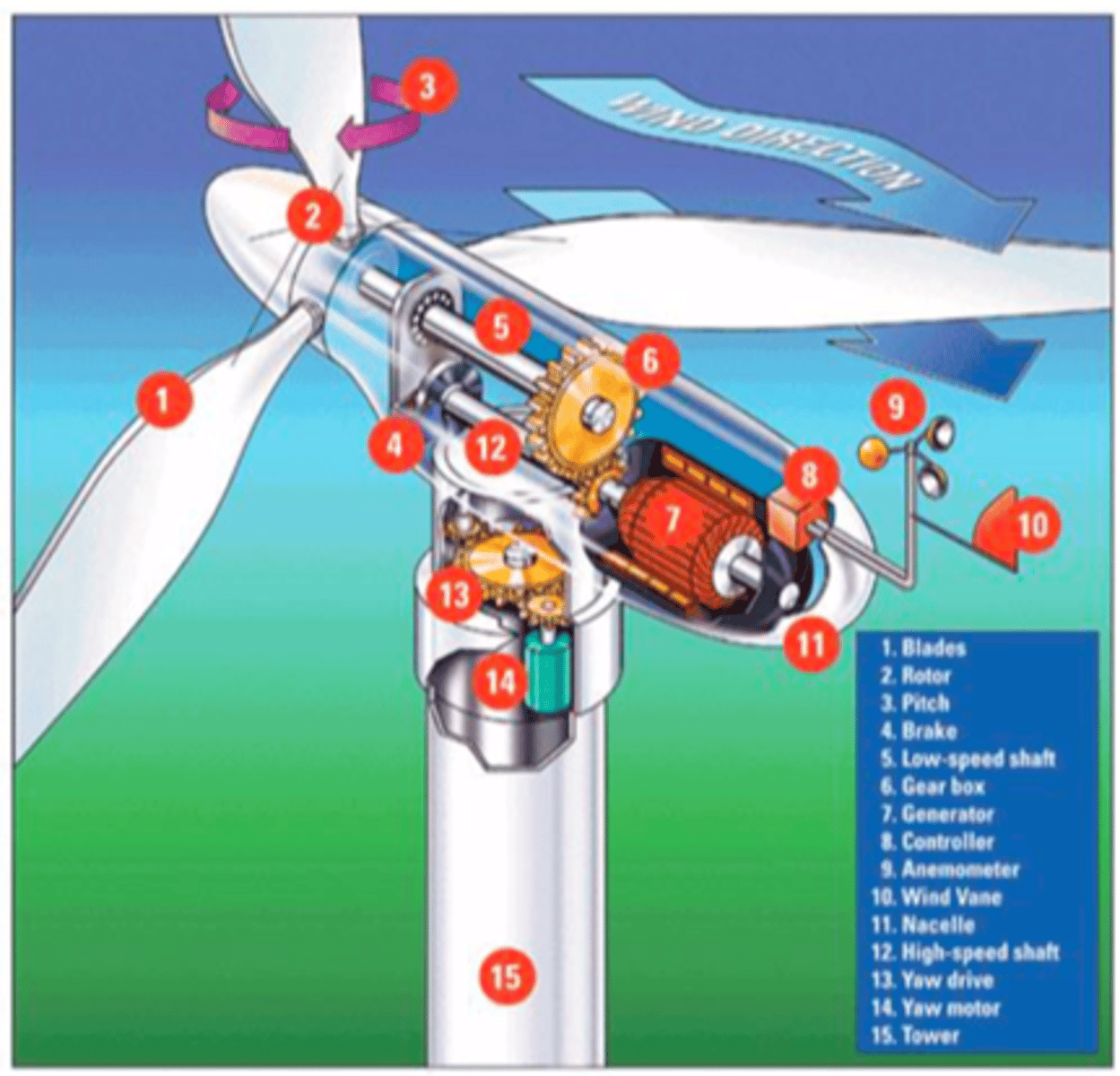

components of a wind turbine

What are the two most used substructure types for current offshore wind turbines?

Monopile and Four‐legged jacket are most used substructure types for current offshore wind turbines.

What are the key considerations in designing a commercial WT?

Power rating; rotor blade control, rotor speed (fixed or variable); design tip speed ratio, and generator type and speed.

What are the key advantages of designing variable‐speed WTs?

Variable‐speed rotors can be operated at the optimum tip speed ratio to maximize power conversion in low wind and at lower tip speed ratios in high winds to reduce loads on the drivetrain.

For a variable‐speed wind turbine, when operating below the rated rotor speed, what is the control strategy? After the wind speed reaches the rated level, how the turbine is controlled to maintain turbine power at the rated level?

-At low winds, the generator control is designed to extract power by automatically operating on maximum power tracking.

- Above the rated wind speed, the blades pitch to maintain turbine power at the rated value.

What are the reference wind speeds for wind turbine classes I, II, III defined in the IEC61400‐1 international standard?

For wind turbine class I, II, and III, the reference wind speed is 50, 42.5 and 37.5 m/s respectively.

What is the drivetrain of a wind turbine? What is the indirect or direct drivetrain design of a wind turbine?

The drivetrain consists of all the rotating components of the wind turbine (excluding the rotor hub), including the main shaft, gearbox, couplings, brakes, and generator.

For indirect and direct drivetrain designs, state the most important advantage and the most important disadvantage.

-Indirect drivetrain: most large wind turbines include a gearbox to increase the speed of the rotor shaft to the required high speed of the generator thus reduce its size and weight.

-direct drive trains simplify the design and improve reliability without using gearbox; although there are considerable challenges in designing direct drivetrain that is lighter or more cost‐effective than the conventional geared drive trains.

What are the most commonly used generator types for variable‐speed operation of wind turbine?

Synchronous generator and induction generator are two most commonly used generator types for variable‐speed operation of wind turbines.

What PMSG, WRIG, and SQIG stand for?

PMSG: Permanent Magnet Synchronous Generator; WRIG: Wound Rotor Induction Generators; SQIG: Squirrel Cage Induction Generator.

What are the advantages of WRIGs when compared with other types of generators?

A Wound Rotor Induction Generator (WRIG) consists of stator and rotor both having windings of copper wire; rotor windings are accessible via brushes and slip rings. Power can either be extracted or injected into the rotor via the brushes and slip rings of a WRIG. WRIGs are compact and fairly rugged (except for the brushes and slip rings) and are less expensive than SGs, but more expensive than SQIGs.

What is the drivetrain design configuration using DFIG?

A drivetrain using DFIG (Doubly Fed Induction Generator) has the ability to transfer power into or out of the rotor, as well as out of the stator. This configuration allows a range of operating speed of the induction generator, from approximately 50% below synchronous speed to 50% above

What are the key mechanical components in the conventional drivetrain of a wind turbine?

The gearbox, main shaft, couplings and mechanical brakes.

What are the most important considerations in designing a wind turbine gearbox?

The speed up ratio between the rotor shaft and generation rotating shaft; number of gear stages required; gearbox loads, dynamic characteristics, weight and cost.

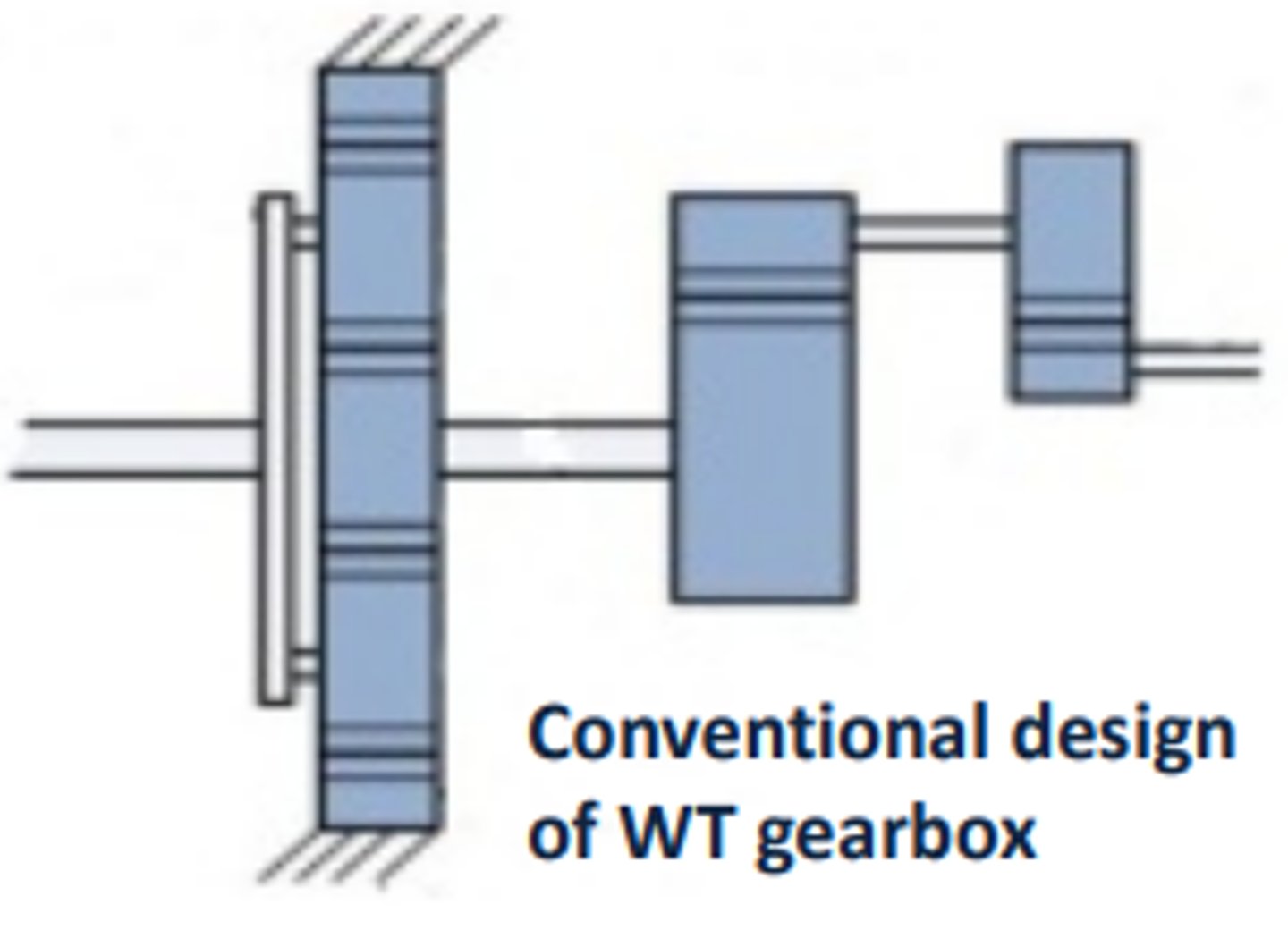

For a conventional design of WT gearbox, identify the ring gear, planet gears and sun gear in the planetary stage.

What are the typical design load cases to be considered in a wind turbine gearbox design, required by the IEC standard?

The IEC standard requires the following design load cases to be considered: Normal power production; Power production plus fault; Start up; Normal stop; Emergency stop; Parked; Idling; and Transport/assembly.

Give an example of the causes of stochastic loads in a wind turbine

Wind turbulence causes short‐term variations in wind speed thus rapidly varying aerodynamic forces applied on the blades.

Give three examples of the events causing transient loads in a WT.

Wind turbine starting up, stopping, wind gusts, blade pitching etc.

Define what is the capacity factor of a wind turbine.

It is defined as the percentage of the actual annual energy production over the rated annual energy production from a wind turbine or a wind farm.

What do MTBF, MTTF and MTTR stand for? How do they relate to the Failure rate and Repair rate?

MTBF = Mean Time Between Failures; MTTF = Mean Time To Failure; MTTR = Mean Time to Repair.

failure rate

λ=1/MBTF

repair rate

µ=1/MTTR

What is the availability of a wind turbine?

Availability is the probability of finding a system in the operating state at some time into the future.

Manufacturer's availability:

A = (MBTF-MTTR)/MBTF = 1 -(λ/µ)

Operator's or technical availability:

A = MTTF/MTBF < 1 -(λ/µ)

What are the means to improve the WT availability?

Increase Availability by reducing the failure rate and time to repair (down time).

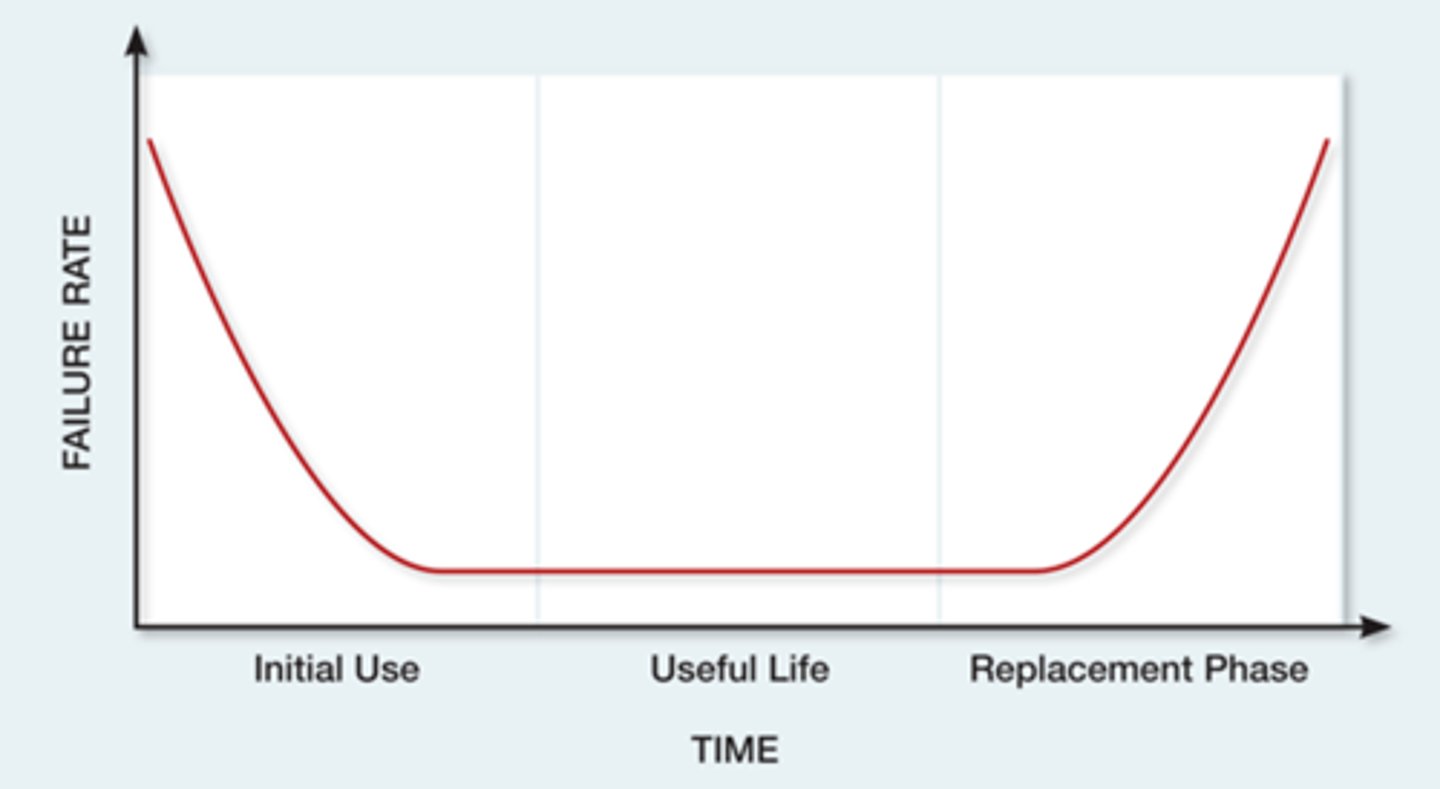

bathtub curve

What is the average solar power density incident on the Earth's surface?

1 kW/m^2

Match the following band gaps to the following semiconductors:

Ge, InAs, GaAs, CdTe, GaInP, Si,

1.1 eV, 0.66 eV, 0.35 eV, 1.5 eV, 1.9 eV, 1.4 eV

Ge - 0.66 eV

InAs - 0.35 eV

GaAs - 1.4 eV

CdTe - 1.5 eV

GaInP - 1.9 eV

Si - 1.1 eV

Name two considerations when deciding which materials to use in a multi-junction solar cell

current matching and lattice matching

what is current matching?

requires that each sub-cell absorbs a roughly similar number of photons (careful tuning of the band gaps) so that they all produce the same current; the current will be limited by the weakest sub-cell.

what is lattice matching?

-means having the same inter-atomic spacing for each material.

-materials need to be grown as a single crystal structure, so any difference in "lattice constant" will cause dislocations that hinder device performance.

efficiency of a silicon solar cell

anywhere in the range 15-21 %

What are the two main reasons why silicon solar cells cannot be 100% efficient?

-Silicon's bandgap prevents the semiconductor from efficiently converting higher-energy photons into electrical energy.

-some energy is lost due to internal resistance.

mass action law (need to remember!!!!!!!!!!!1)

(n_i)^2=np

where

n = free electron concentration

p = free hole concentration

n_i = intrinsic carrier concentration

Pauli Exclusion Principle

no 2 electrons can have the exact same energy

silicon

-4 atoms in outer shell

-diamond structure with covalent bonds

-each atom shares 4 electrons with 4 other atoms

semiconductor

-can conduct electricity when illuminated or moderate heat applied.

-electrons require certain amount of energy (called band gap) to 'break free' from host atom.

-band gap depends on material