Preliminary Impression for CDs & Achieving a good working model

1/32

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

Primary Impressions for Complete Dentures: purpose, requirement

Purpose

For Diagnosis and Construction of Custom Impression Trays

Requirements:

Must capture all intraoral landmarks, retromolar pads, retromylohyoid

space, hamular notches, etc

Will be slightly overextended but must essentially capture the 3-D contours

of the vestibular borders of the limiting structures

An accurate primary cast that records all anatomic landmarks that should be

covered by a denture permits fabrication of properly extended custom trays

that will expediate boarder molding and facilitate a quality final impression

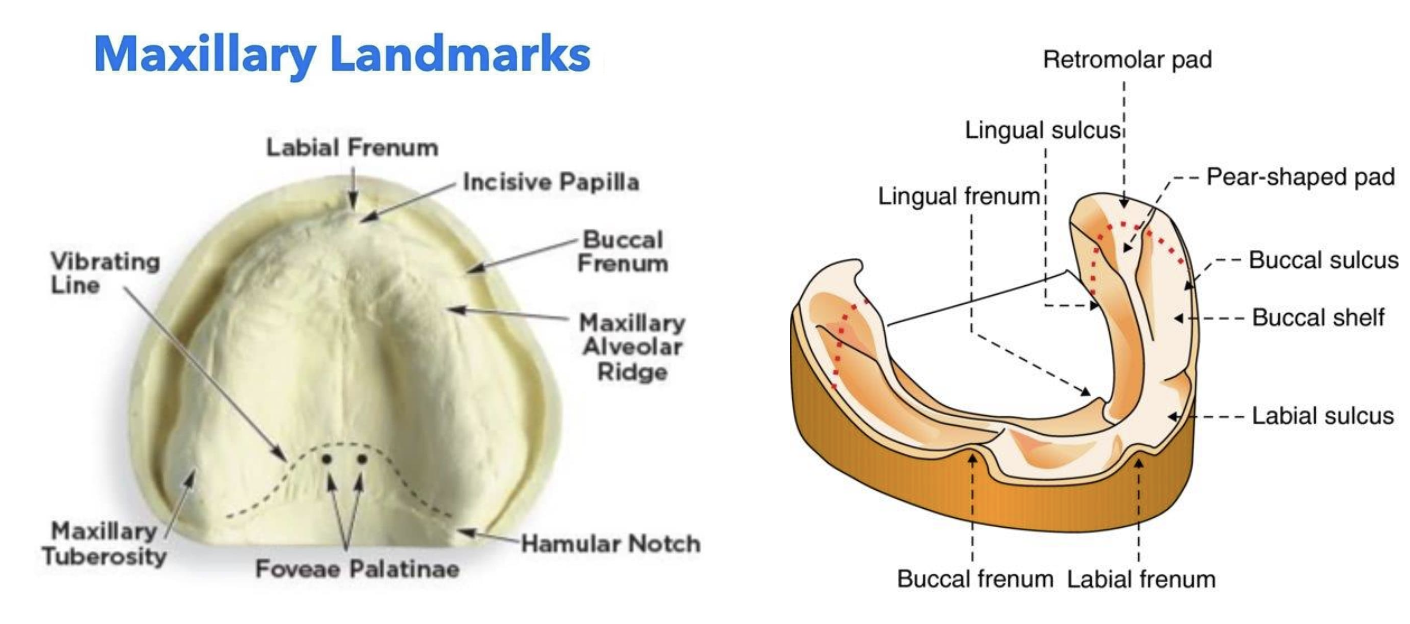

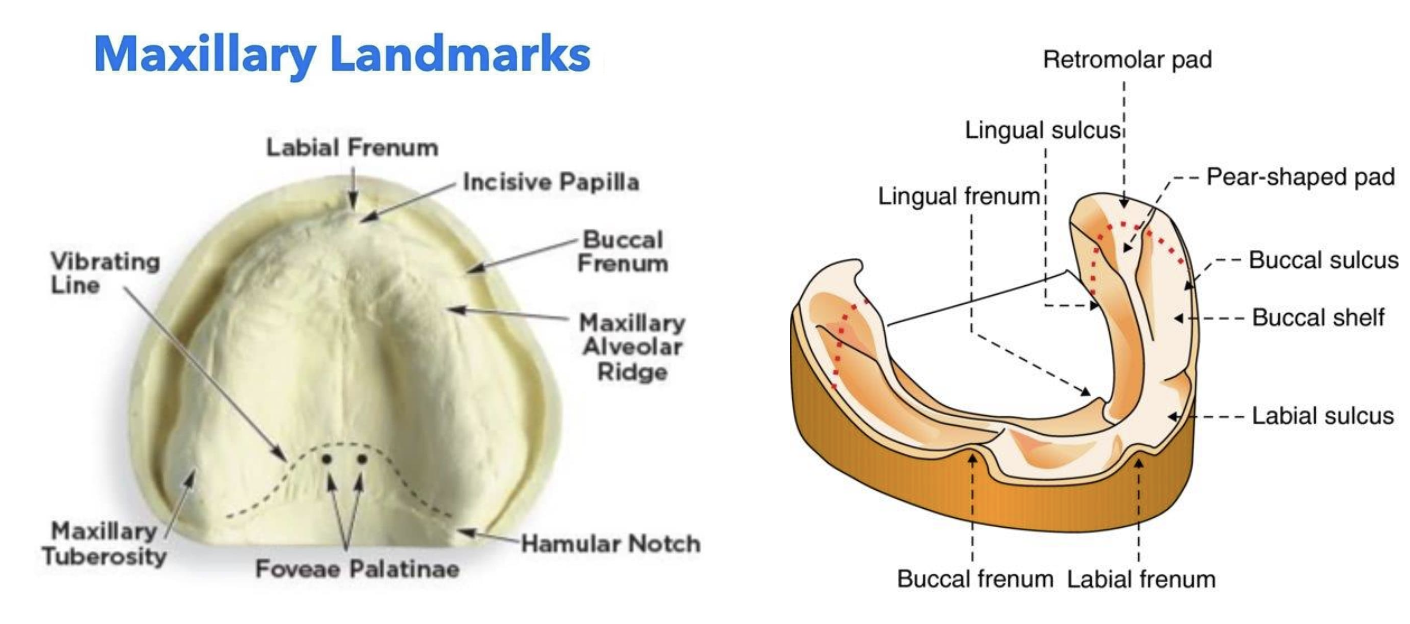

Maxillary and mandibular landmarks that should be seen in the cast from the primary impressions for CD

Primary impressions - Armamentarium

1. Alginate (reversible

hydrocolloid)

2. Tray adhesive

3. Edentulous metal stock

trays

4. Plaster mixing bowl

5. Round edge spatula

6. Periphery wax

7. Water bath

8. Mouth mirror 2X2 gauge

7 Steps - Primary Impressions for Complete Dentures

1. Select a stock tray

2. 3. Extend tray only where necessary with soft periphery wax

Warm the periphery wax in a warm water bath, insert in patient's mouth and mold the periphery wax to the intraoral contours

4. Spray with adhesive

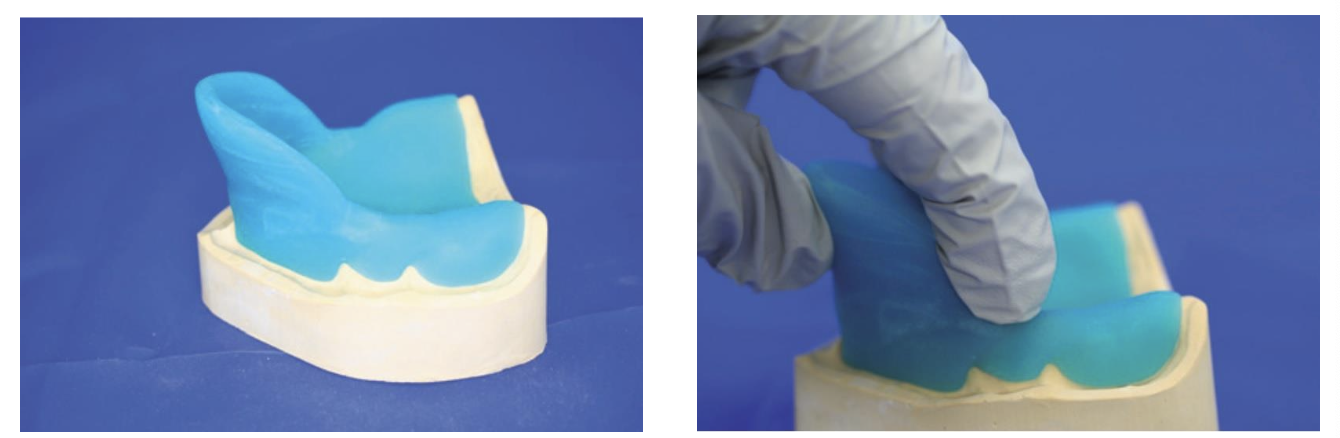

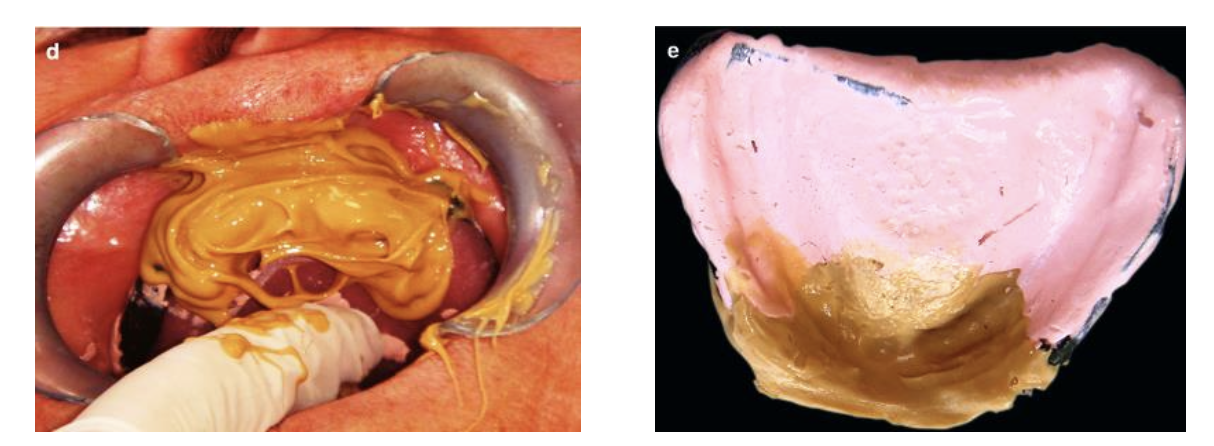

5. Irreversible hydrocolloid impression

6. The primary impression should have no major pressure

spots or voids and it should capture all peripheral

extensions

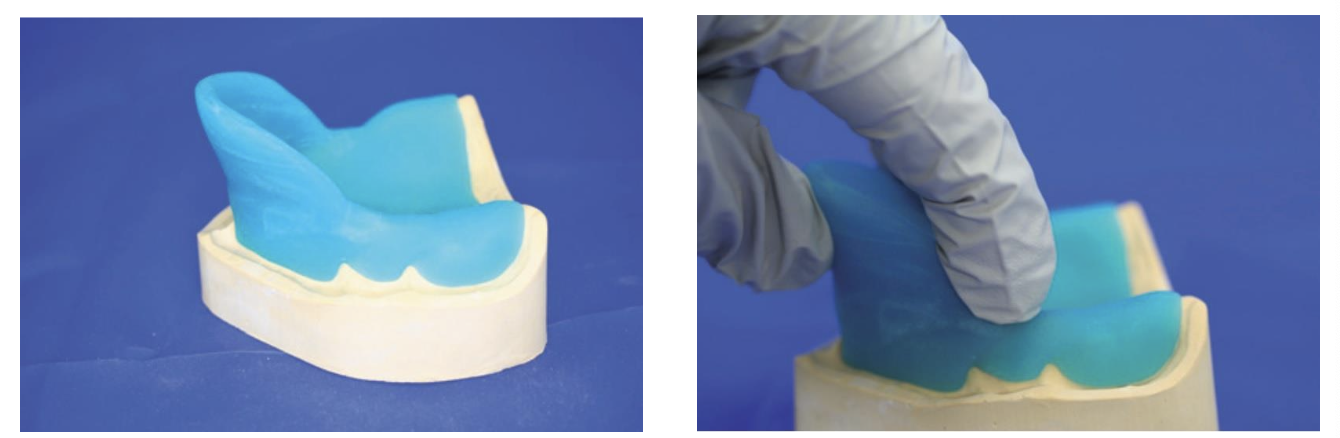

7. Pour impressions in plaster with adequate bases including

the central “tongue” area of the mandibular impression

How should an ideal mandibular alginate impression be?

Ideal Impression should:

Show no pressure spots

Record the ridge, peripheries, retromolar pads and retromylohyoid fossa

Why can’t we work with primary models?

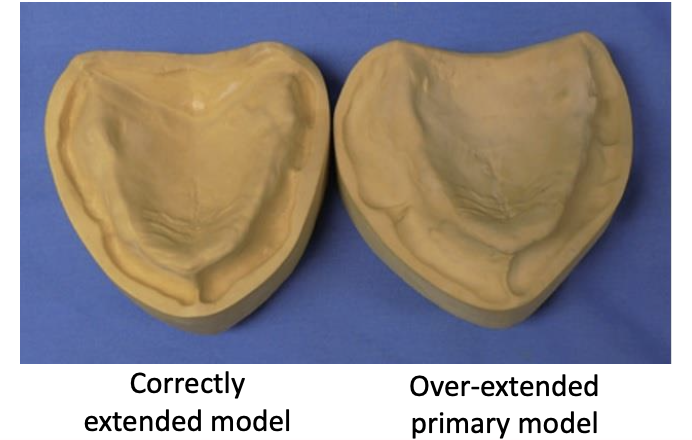

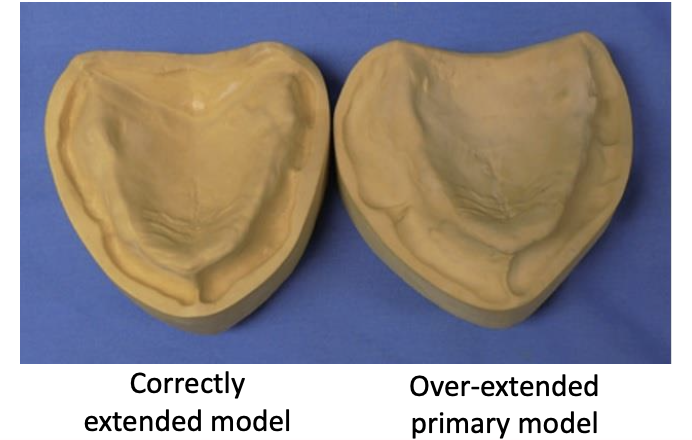

1. Primary impressions taken in stock trays always cause overextension of the denture bearing area because the impression is displaced into the sulci

An accurate recording of the functional sulcus is essential to define the denture extension and resulting retention and stability

Retention depends on the denture extending to fill the sulcus and thus creating a seal; if the denture is overextended, stability is compromised and the muscles may be displaced.

Excessive thickness of the material used in primary impressions results in poor accuracy both because of the amount of contraction on setting and over time and because of distortion resulting form the differing thickness of the material over the impression

To achieve a good-quality working impression, it is essential to use a well-designed customized tray in conjunction with the appropriate impression material

WHat is essential to achieve a good working model?

To achieve a good-quality working impression, it is essential to use a well- designed customized tray in conjunction with the appropriate impression material

What should allow a customized impression tray?

A customised impression tray should:

allow easy control of the impression material

guide the impression material to the mucosa; support the impression material to provide even contact with the oral tissues

enable pressure on selected areas of the denture-bearing area

provide an even layer of impression material

support the set impression material

be rigid and retain its shape throughout the impression procedure and during the pouring of the model

What should ensure the design of the tray?

the tray is rigid

the entire denture-bearing area is included

the periphéry of the tray finishes such that impression material can flow into the buccal and labial sulci without causing displacement of the soft tissues

the tray is spaced appropriately for the amount of undercut present

the handle is designed to avoid displacing the lips

the tray allows free movement of nay muscle attachments

Primary considerations when selecting an impression tray and material

amount of undercut present

whether any areas of the mucosa are mobile or unsupported

When can we chose a close-fitting tray?

where the majority of the denture-bearing area is free from large undercuts, close fitting trays should be used

action of close fitting trays

closefitting trays allow pressure to be exerted on the denture-bearing area during the impression-taking procedure

compressing the mucosa and ‘adapting’ the relaxed mucosal tissues closely to the underlying alveolar bone helps in that the resultant fitting surface of the denture mirror that of the mucosa under load during function

this allows the masticatory forces acting on the denture to be transmitted directly and comfortably to the alveolar bone

Type of impression done by close-fitting trays

mucocompressive impressions

benefits close fitting trays

allow a thin, uniform layer of impression material to be used

shrinkage on setting or over time is then minimal

impression material for close-fitting trays and why

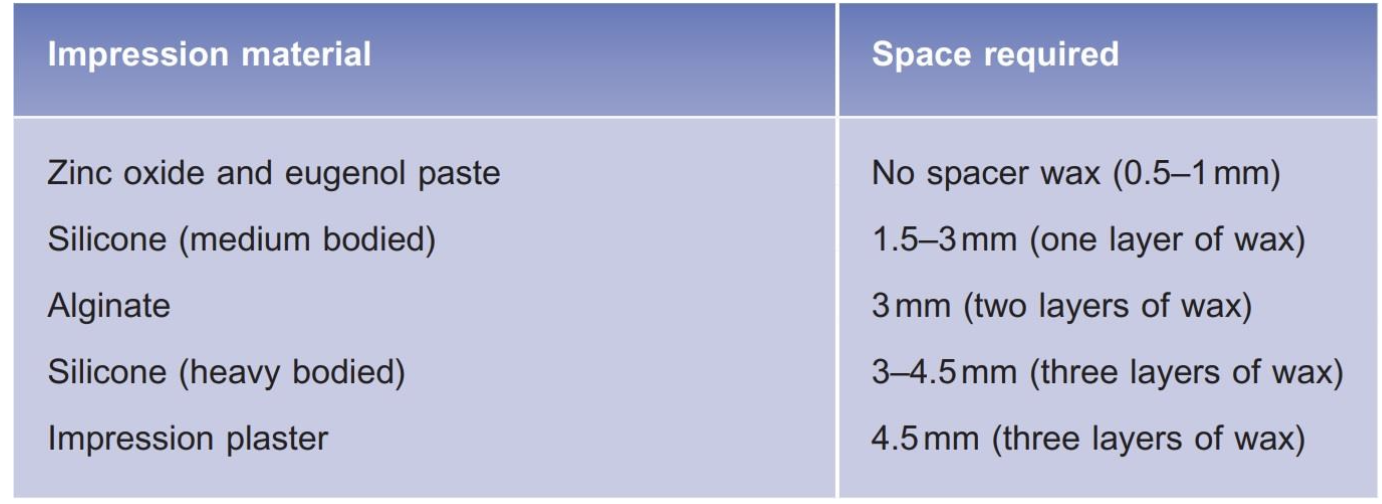

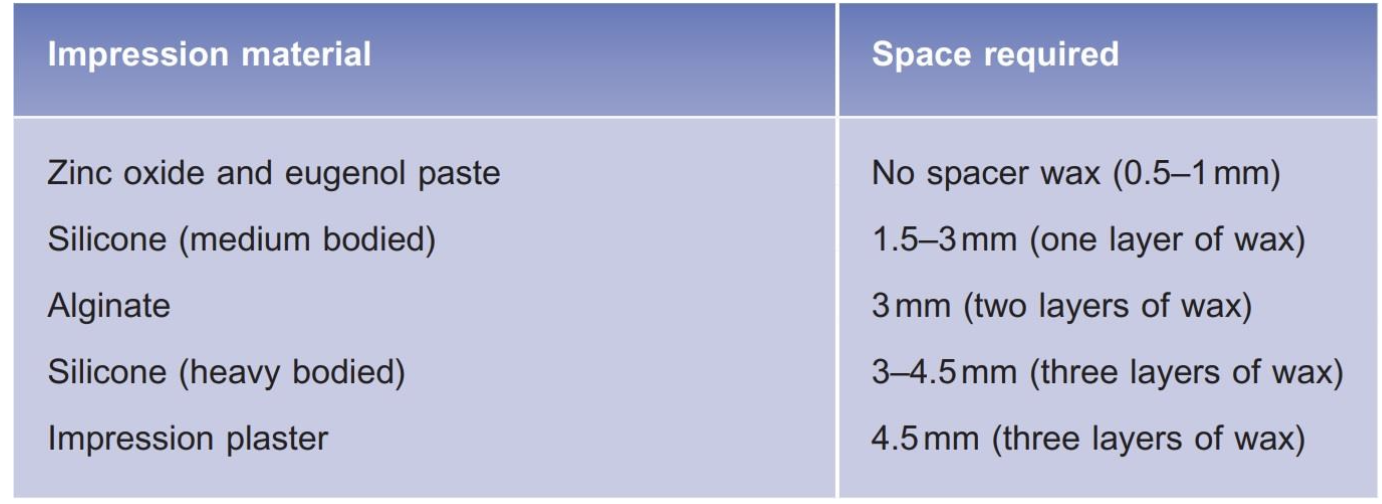

as there are only small amounts of undercut present: we may use impression material that are nonelastic or rigid once set like zinc oxide and eugenol paste

or if unavailable, use medium-bodied silicone material

spaced trays: when?

large undercuts (bc in close-fitting trays, removal from the mouth with large undercut would be difficult without distortion and removal from the cast model would cause fracture of the cast)

How should be increased the spacing between the tray and the tissues?

according to the depth of undercut, tear strength and elastic limit of the impression material

in short, the greater the depth of the undercut, the more likely the material is to tear or exceed its elastic limit on removal

the solution is to provide greater spacing where large undercuts are present

the amount of spacer required depends on the tear strength of the impression material being used: the weaker the material the thicker the spacer required

impression material used with space trays

weak material such as alginate

Further considerations while choosing spaced trays

viscosity of the unset impression material

if it is very high, additional spacing is necessary to allow seating of the tray without using excessive force

the use of such high-viscosity material is rarely indicated in CD

What is low & high viscosity materials?

Viscosity is a measure of how resistant a fluid is to flow. Low viscosity materials, such as water, have a lower resistance and flow more rapidly whereas high viscosity materials, such as honey or tar, resist deformation and flow more slowly

Types of impression material and spaced required

when do we use windowed trays?

where fibrous ridges are present, impression techniques must be adapted to ensure that the mobile tissues is not displaced during the recording procedure

windowed trays: how is the impression done?

the impression is taken in two stages using a customized tray designed such that there is a ‘window’ over the fibrous ridge

first, a close-fitting impression is taken over the denture-bearing area in a modified tray using a zinc oxide/eugenol impression material

once set, a second mucostatic material can be used to record the mobile area

windowed trays: impression material used?

impression plaster is ideal as it can be applied without causing distortion and readily adheres to the impression tray

alternatively, low-viscosity silicone may be used

Method to identify the peripheral extension

the simplest method is to mark the extension with an indelible pencil on the alginate impression, with subsequently ‘tattoos’ onto the primary model

use a permanent marker pen on silicone materials

if convenient, the required peripheral outline may be drawn directly onto the model

Method to identify the peripheral extension

an approximation of the peripheral extension may be made using the primary model

the simplest method is to identify the deepest part of the sulcus, then draw the proposed periphery relative to this, taking into account the thickness of the impression material

this allows room for the material to wrap around the periphery of the tray

for a 1.5 mm spaced tray, draw the extent of the tray 1.5 mm toward the alveolar ridge from the deepest part of the sulcus as shown in the relative Fig.

Prescription information - fabricating customized trays

the type of impression material that will be used for the working impression

the type of tray required

the amount of spacer wax required

an indication of the peripheral extension of the tray, taking into account the thickness of the impression material to be used

any special features required (outline window tray positions and whether a variable thickness of spacer wax is required)

type of handle required (intramural, extra oral, finger stops, stepped or not and where the handle for a windowed tray should be placed)

consequences of under extending close fitting tray

can detached from the tray and would be likely to distort during model preparation

the mechanically weak impression materials will be unsupported and susceptible to distortion

consequences of overextended close-fitting tray

the tray will displace the muscle insertion and lead to an inaccurate impression

how should the close fitting tray be at the periphery? why?

thin to prevent the sulcus becoming overloaded with impression material and to allow room for the impression material to fully mould around this area of the tray without the tray ‘pushing the material away during impression taking

consequences of excess impression material or thick trays

can cause displacement of the soft tissues, resulting in a false record of the sulcus. The alveolar suffers little resorption in these areas

best design handle of close fitting tray

intraoral

avoid distortion of the labial sulcus

the height of the handle should be such that it is level with the top of the lip and it should extend distally around the ridge to the premolar region → this allows the clinician’s fingers to exert pressure on the baseplate evenly along the entire impression tray after seating the impression