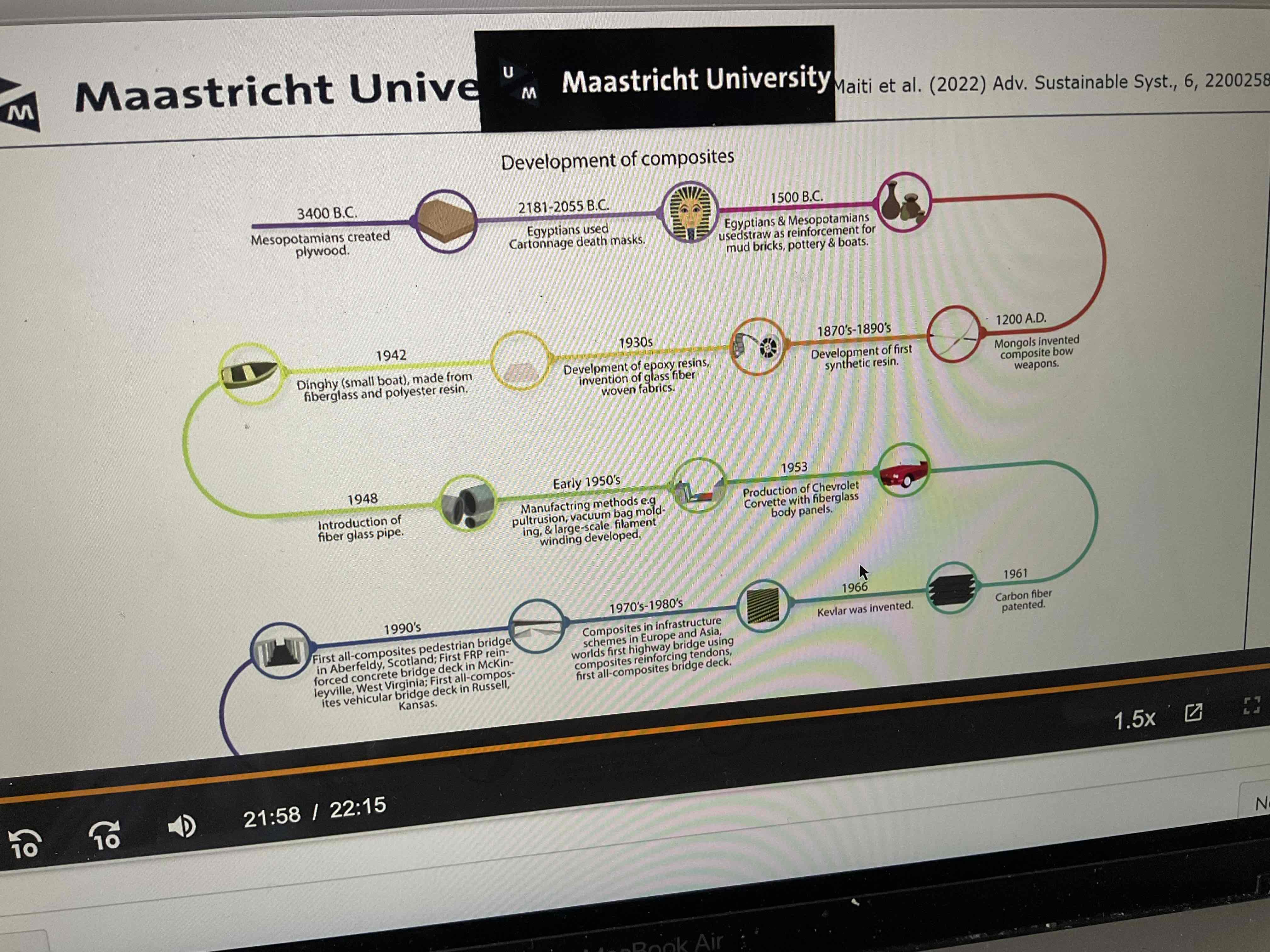

Materials engineering lecture 5 composites

1/55

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

56 Terms

What are composites

A combination of two or more materials with mostly different properties when out together give a unique set of properties. The materials to not blend or dissolve and can still be clearly distinguished from one another.

What are three types of composites and give examples

Natural: wood, bone, oyster

Synthetic: aerospace, automobile parts, appliances and parts, skis, nylon, fiberglass, reinforced concrete

Industrial: concrete, reinforced concrete, glass inforced aluminium, fiberglass

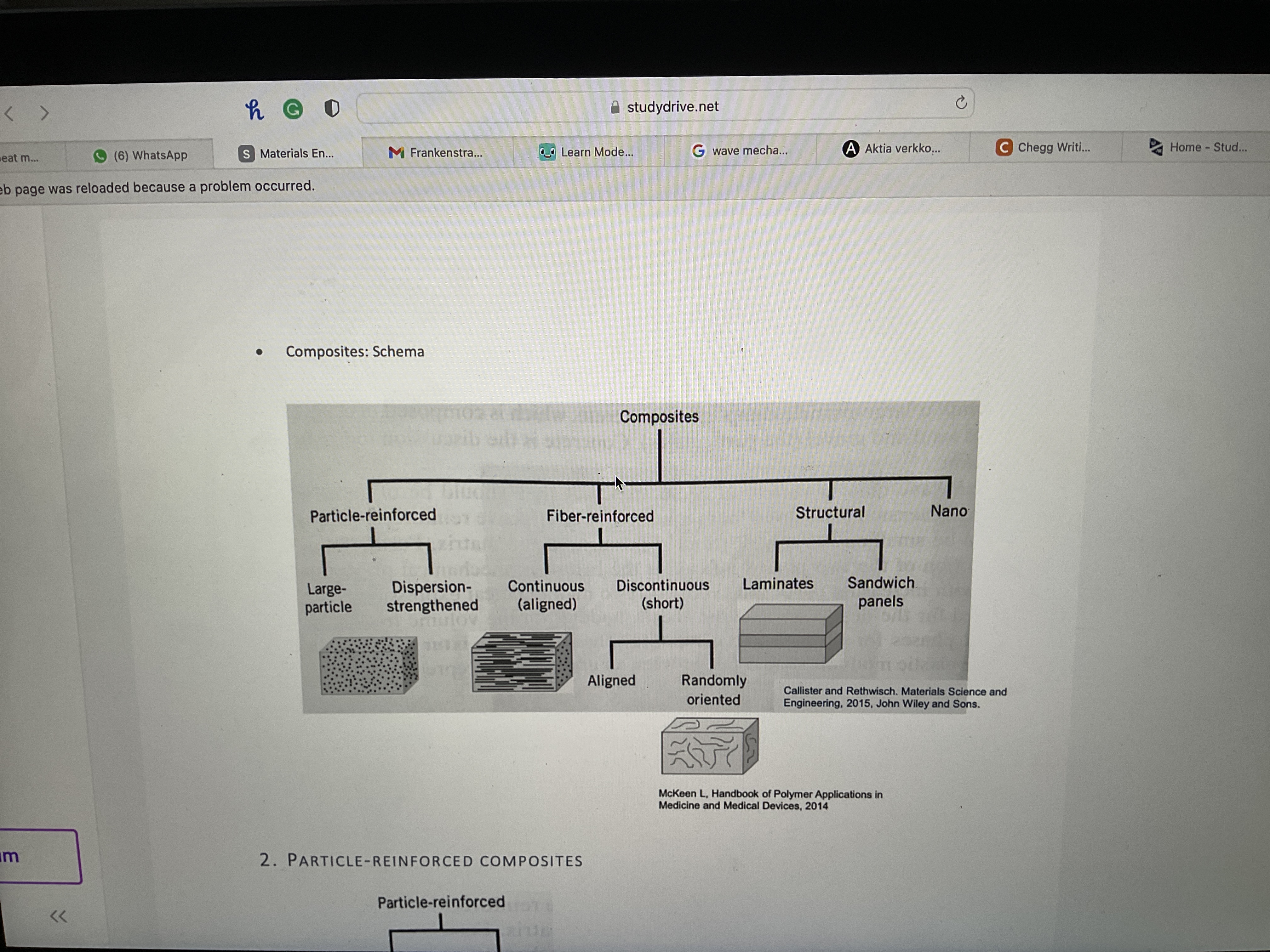

Draw the composite schema

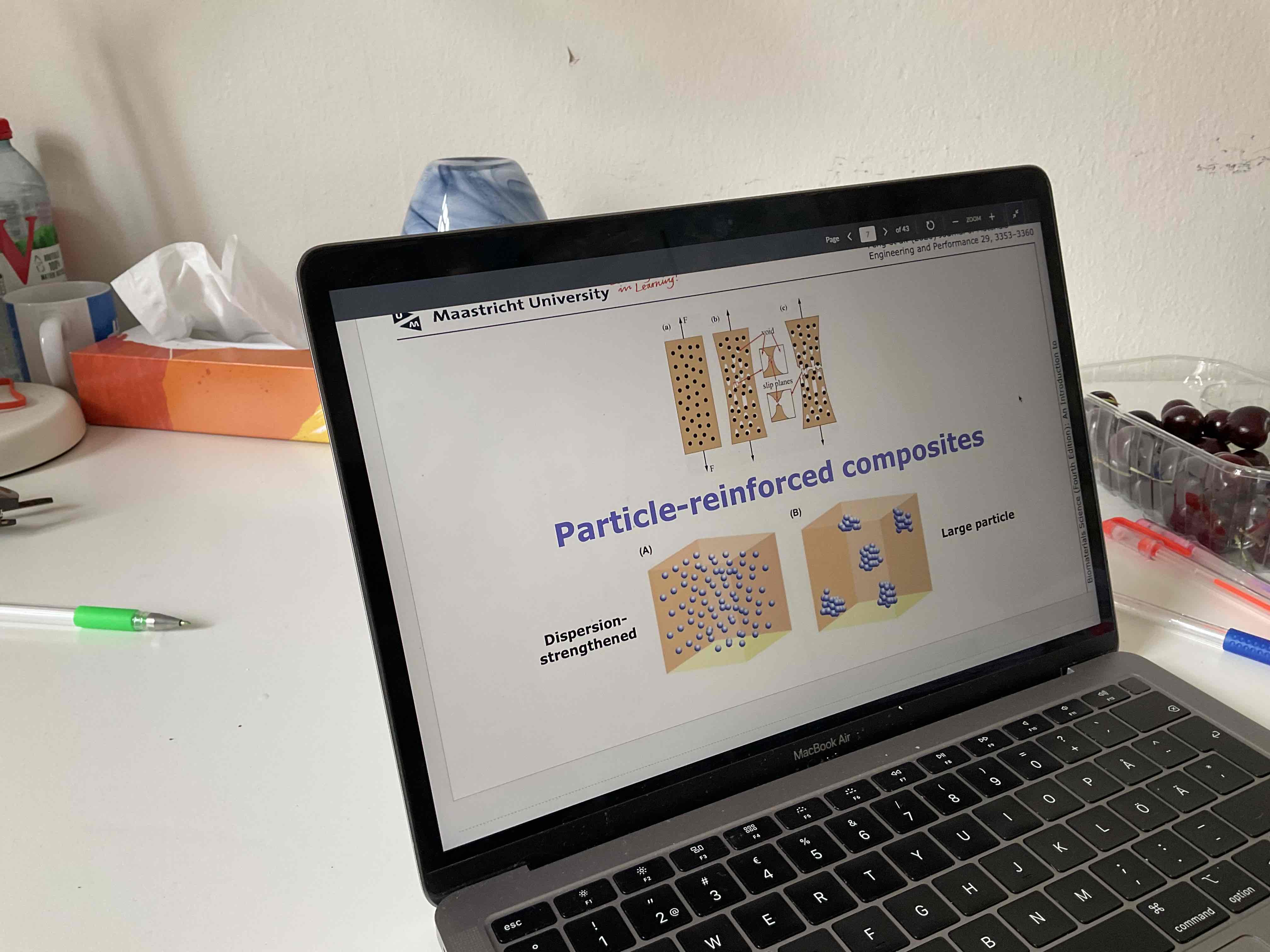

What main groups are particle reinforced composites in?

Large particle and dispersion streangthened

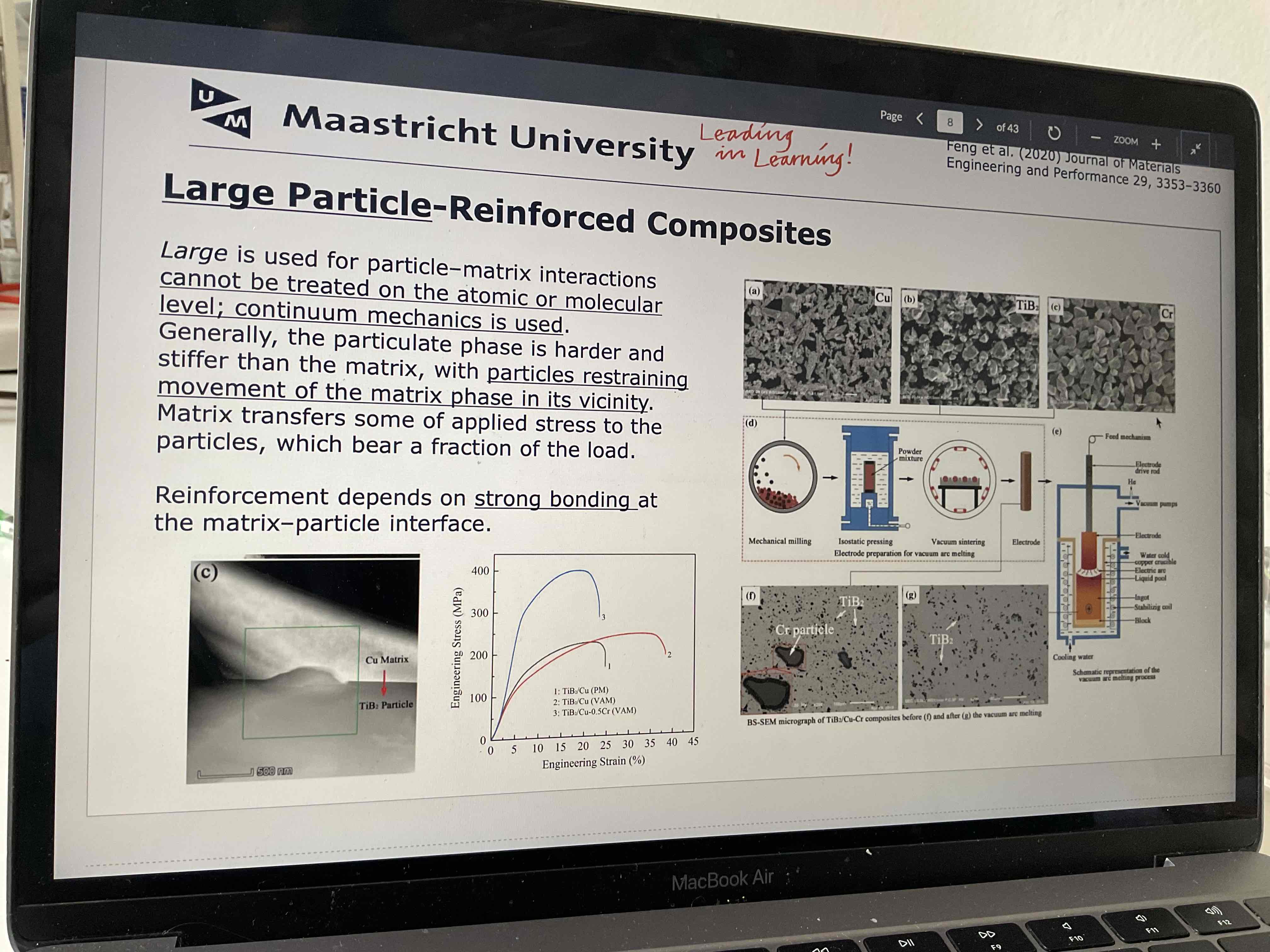

Tell about large particles: what? What do they do? Ex? Dimension?

Large particles, no atomic/molecular interaction between particles and the matrix

Large particles restrain movement of the matrix

Matrix transfer applied stress to particles that then bear a part of the load

Mechanical behaviour depends on bonding at the matrix particle interface

Example: concrete

Important: the particles have the same dimensions in all directions

Even distribution throughout the matrix—> good mechanical performance

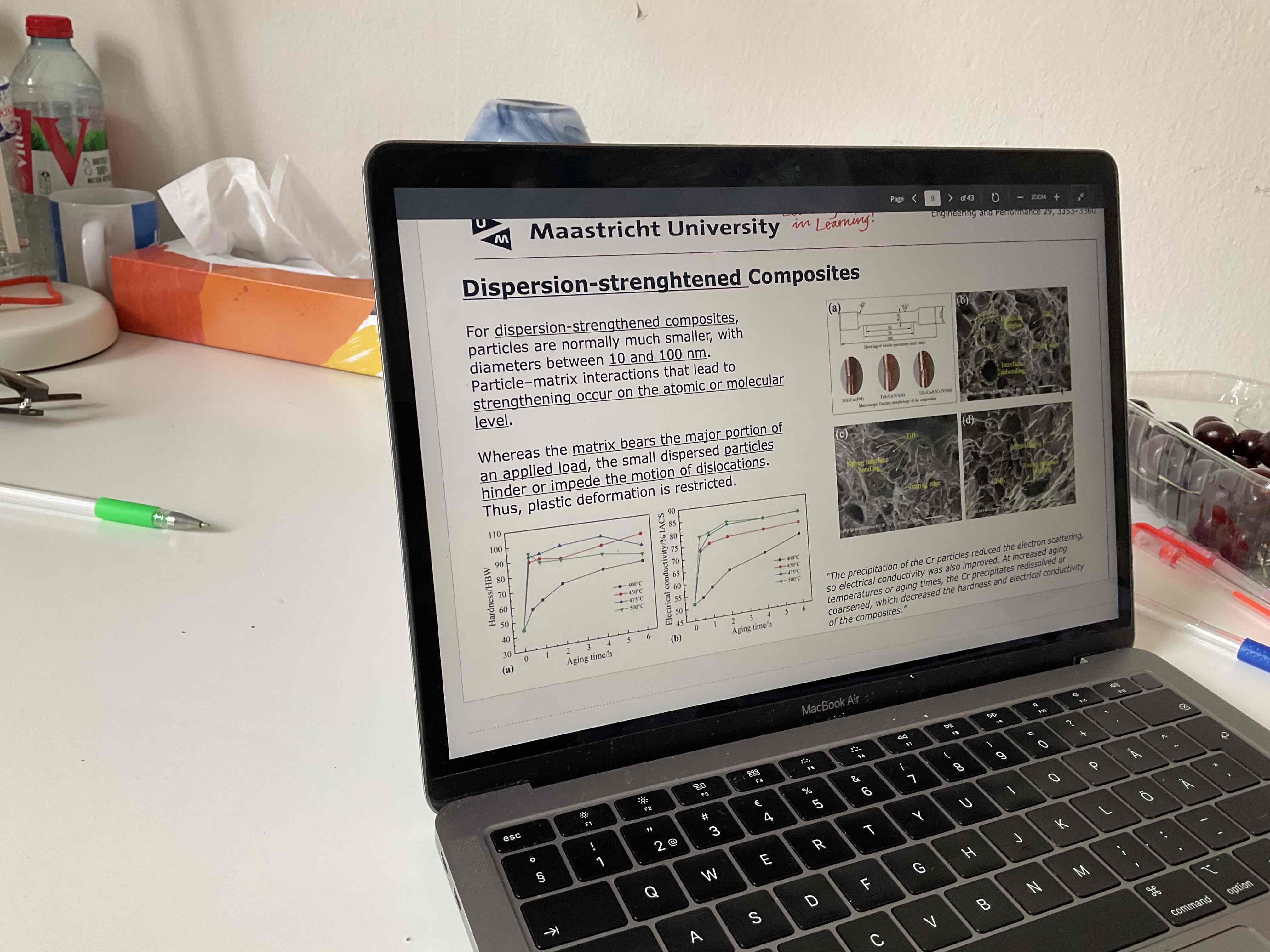

Tell about dispersion-strengthened. What? How strengthened? Ex + 3 prop? 3 props?

Smaller particles (10-100nm), interaction at the atomic/molecular level

fine, very hard particles uniformly dispersed

Dispersed particles unreactive with the matrix—> streanghtening retained at elevated temperature and for extended periods of time

Ex: sintered aluminium powder; high strength, high creep resistance, high insensitivity to high-temp exposure

High thermal conductivity

High melting point

Excellent thermal stability

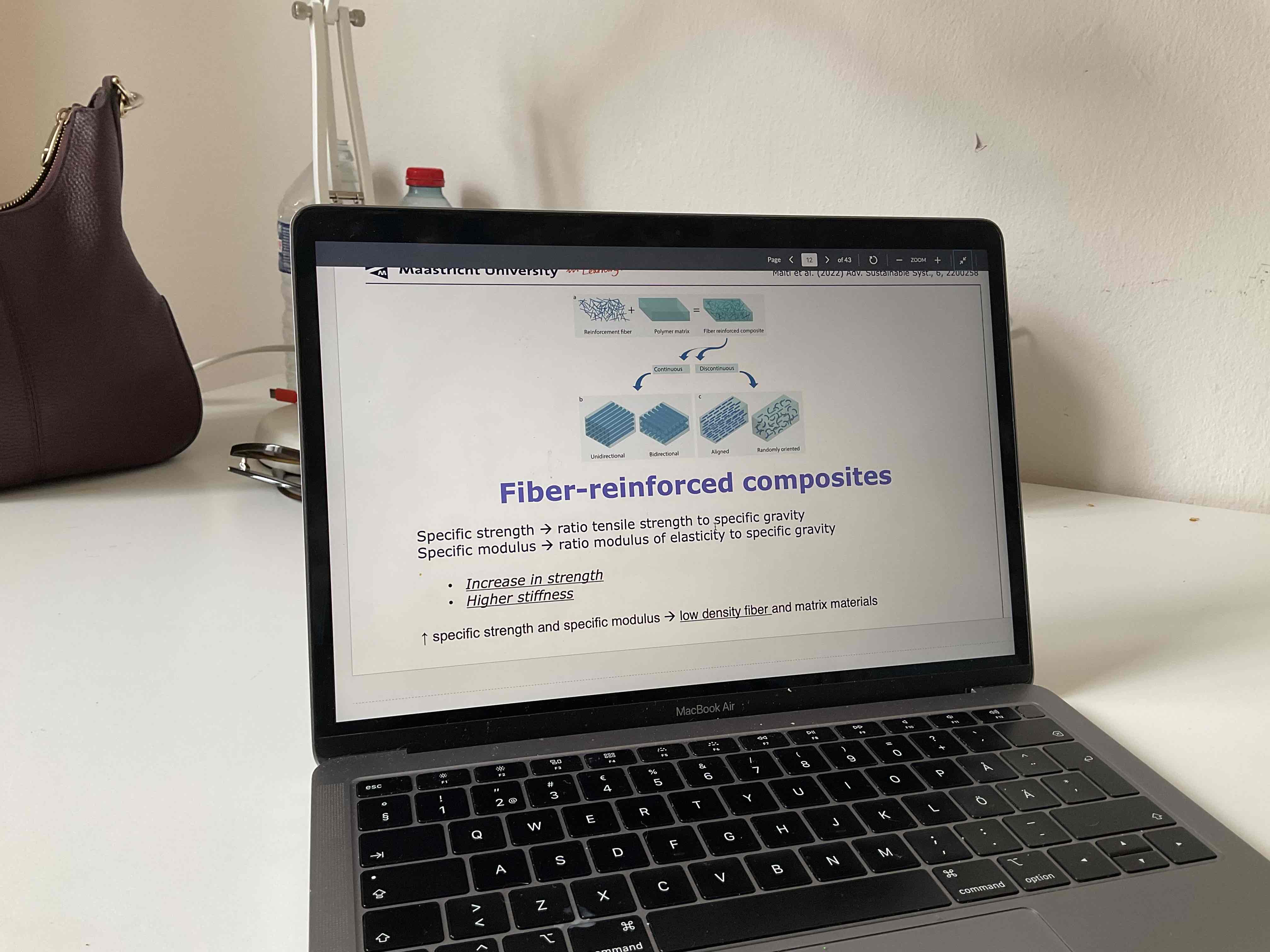

What are properties of fiber reinforced composites?3

High strength, stiffness, sensitive to gravity in terms of elasticity and specific strenght

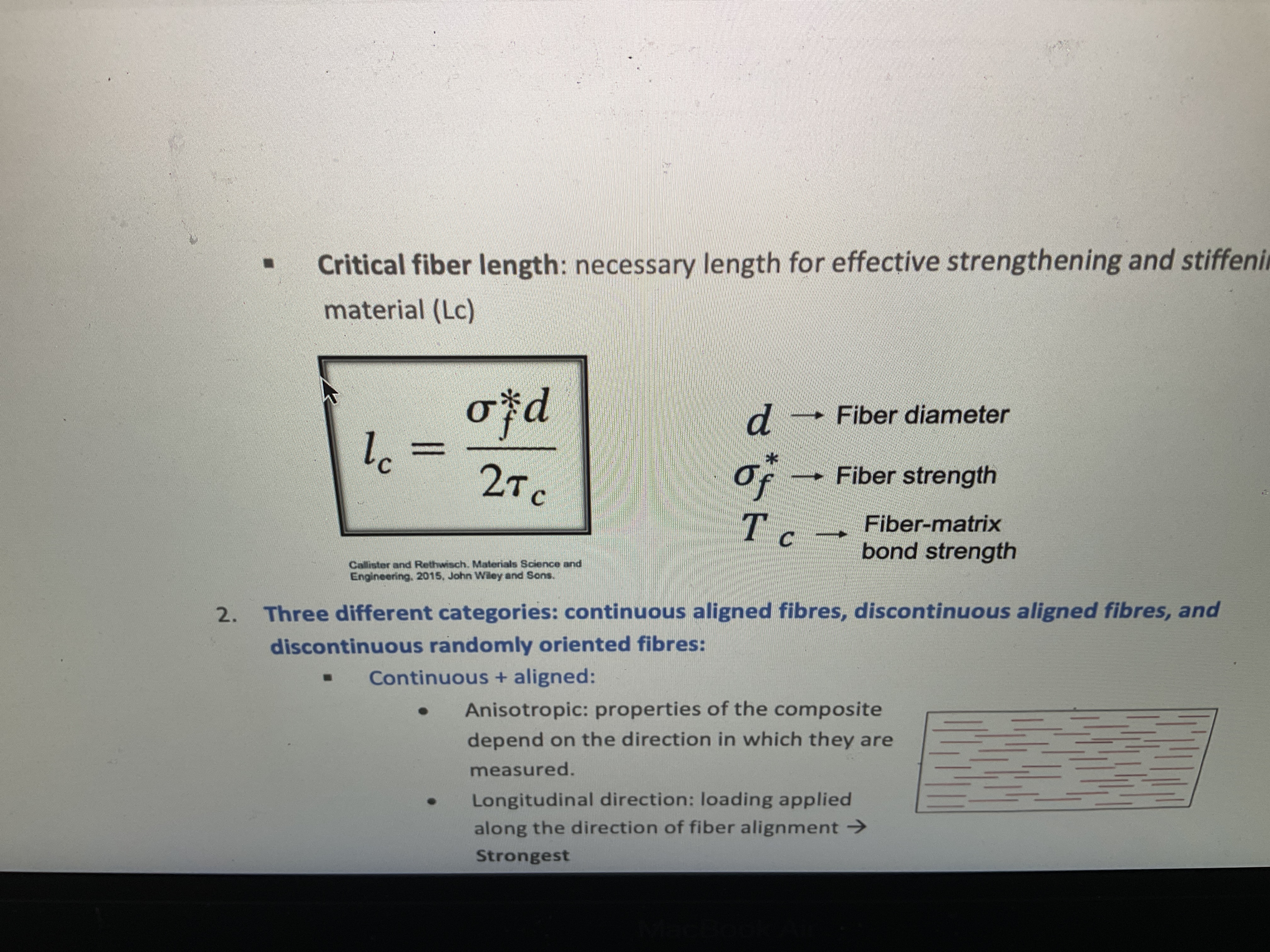

What does critical fiber length mean? And what is the formula?

Necessary length for effective strengthening and stiffening of the material (Lc)

What are the three types of fibers?

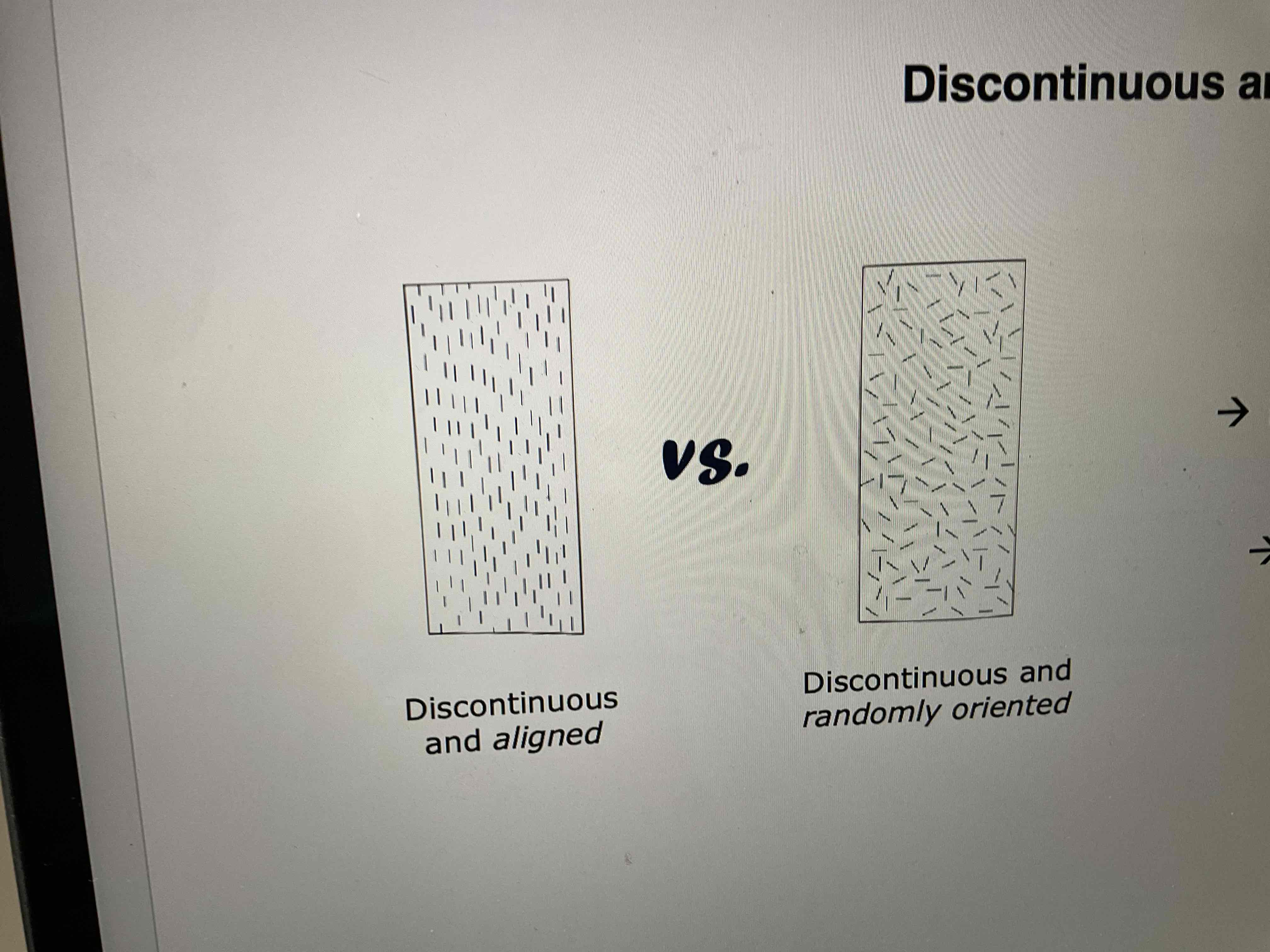

Continuous+aligned, discontinuous+aligned, discontinuous+randomly oriented

What are the anisotropic, longitudal direction and transversal properties of continuous+ aligned fibers? + draw pic

Anistropic: properties of the composite depend on the direction in which they are measured

longitudinal direction: loading applied along the direction of the fiber alignment—> strongest

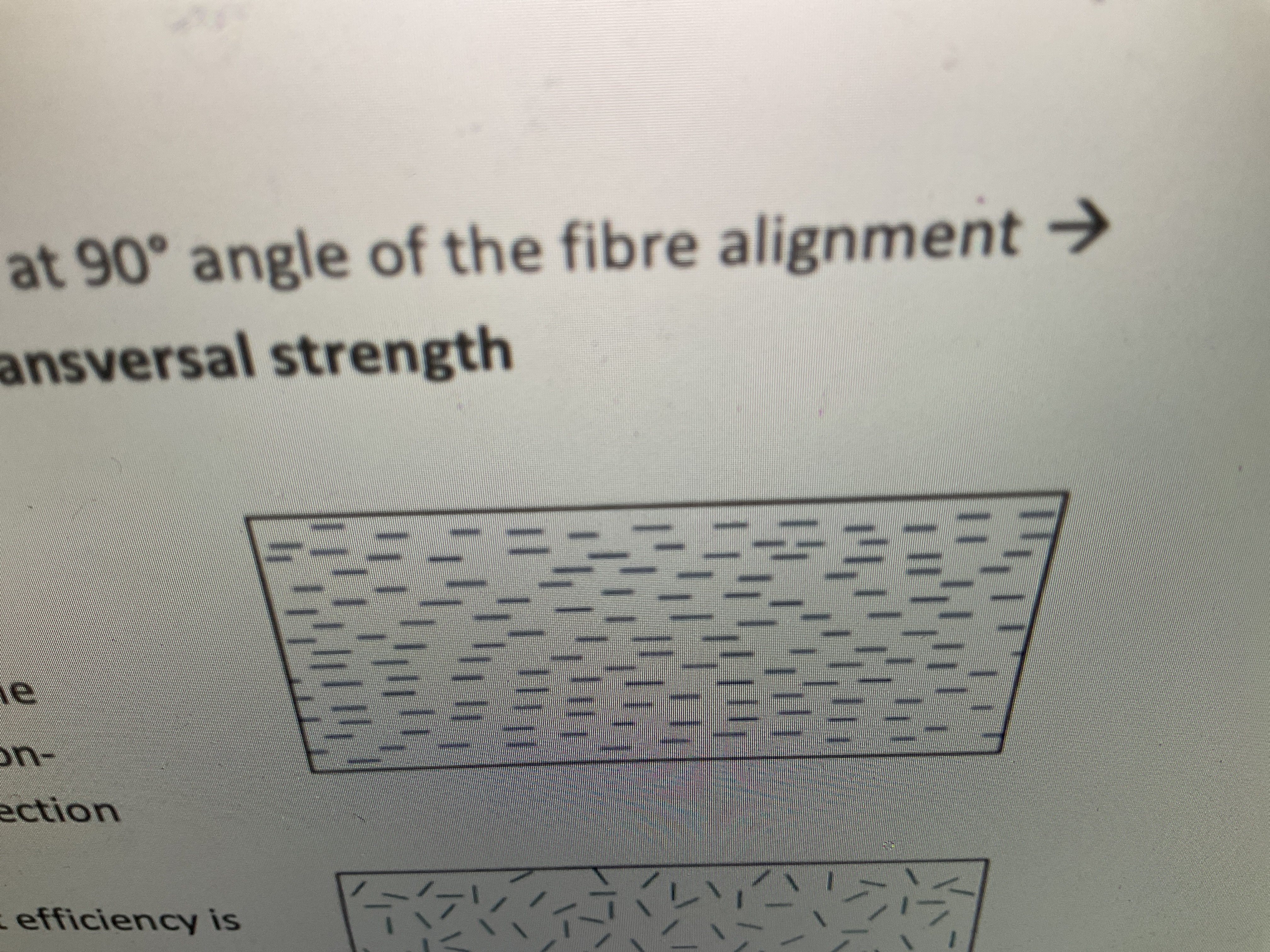

Transversal direction: loading applied at 90 degrees angle of fiber alignment—> premature failure: extremely low transversal strength (due to presence of voids)

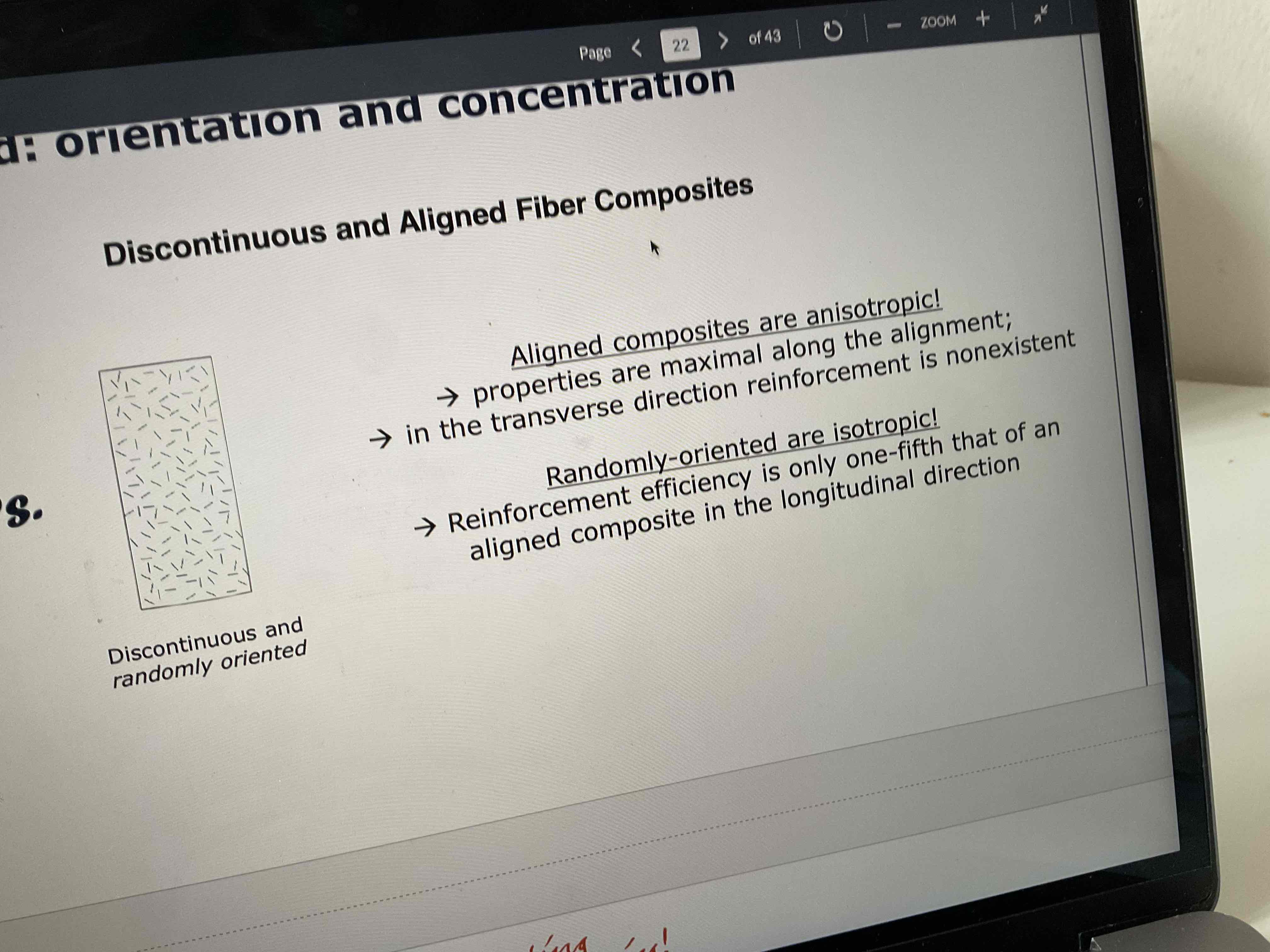

Is discontinuous+aligned anisotropic or isotopic? What properties does it have? Draw it

anisotropic!!!

Properties are maximal along the alignment, reinforcement is non-existent in the transverse direction

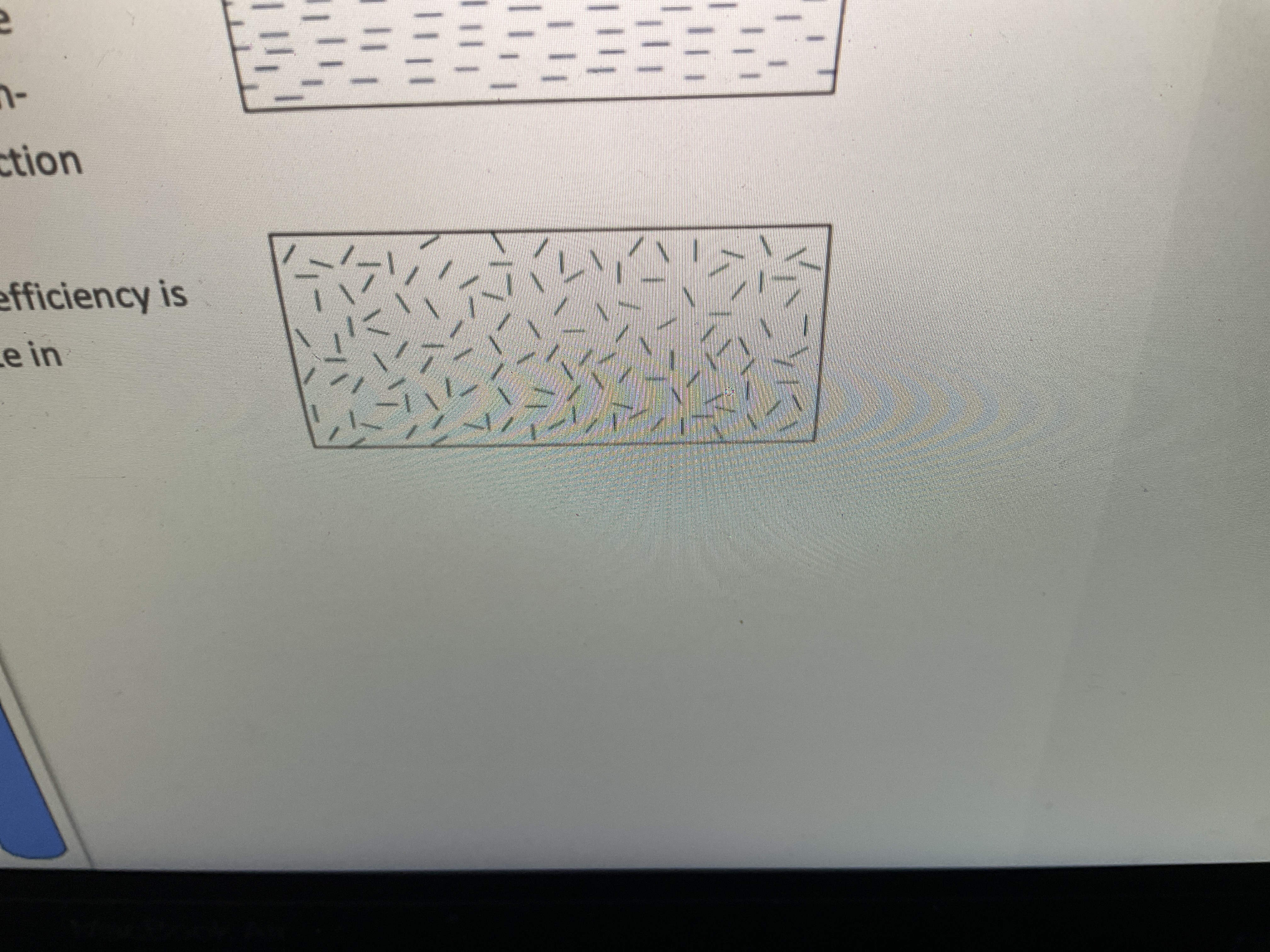

Is discontinuous+ randomly oriented anisotropic or isotropic? What is its reinforcement efficiency? Draw it

Isotropic!!! Reinforcement efficiency is 1/5 of an aligned composite in longitudinal direction

What are properties of whiskers (5)?

very thin crystal

Large length to diameter ratio

Flaw free (high crystalline perfection)

High strengths —> strongest known materials

Very expensive —> limited applications

what are properties of fibers? 2 and what materials usually 2

Polycristalline or amorphous

Small diameters

Either polymers or ceramics

What is the property of wires? What made of + 2 ex

metals (ex. Steel inforced concrete, molybdenum)

Large diameter

Read carefully (DONT CHEAT) polymer

easy fabrication low cost most common reinforcement (fibres) Glass → high-strength (composite), available, low cost, chemically inert Carbon → high specific modulus & strength, retained at elevated temp, not affected by moisture or solvents at room temp, specific engineering properties and cost effective Aramid → high strength, high modulus, relatively weak in compression, toughness, impact resistance, and resistance to creep and fatigue failure |

Read carefully (DONT CHEAT) ceramic

Resilient to oxidation at elevated temp

Improved fracture properties: advantageous when compared to only ceramic materials

Increase in fiber content improves strength and fracture toughness

What are 3 processing techniques of reinforced fibers

Pultrusion

Prepreg

Filament winding

What are properties of structural composites 6? What do they depend on?

multi layered

Low density

Structural integrity

high tensile

Compressive

Torsional strength

Properties also depend on geometrical design of the structural elements

What are the two main categories of structural composites?

Laminates and sandwich panels

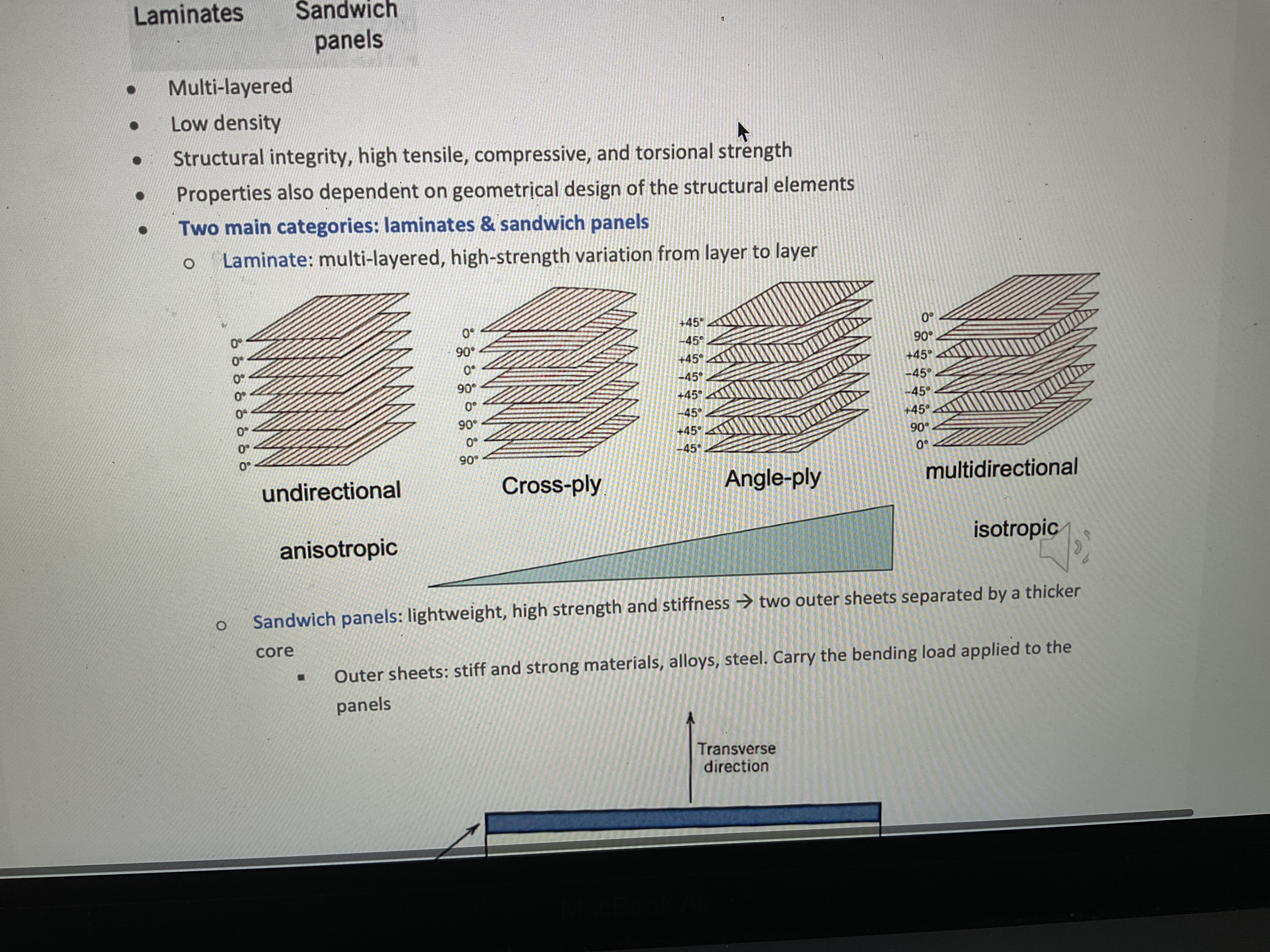

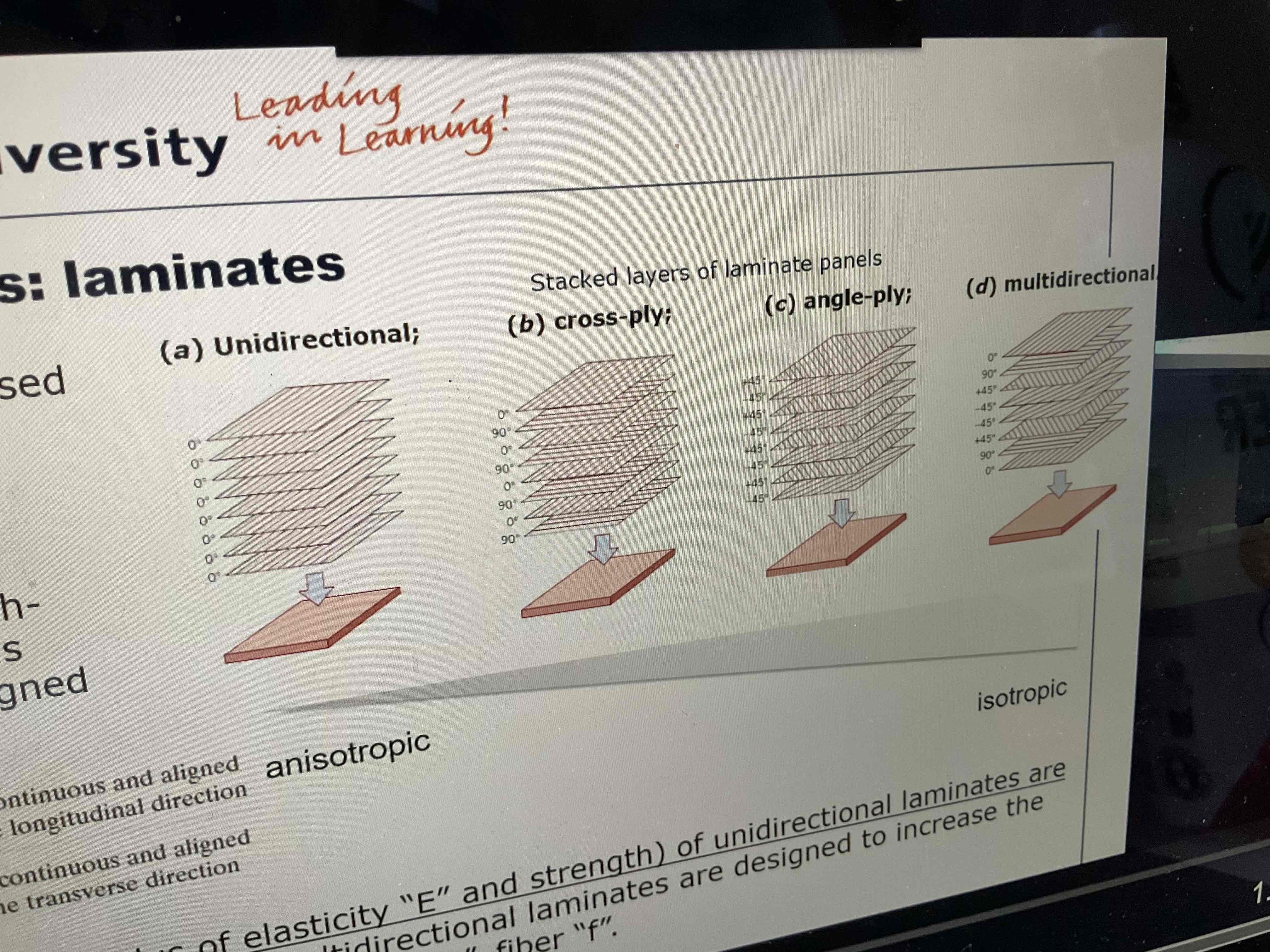

what are laminates? What do they look like? And what are the 4 options from anisotropic to isotropic?

Multi layered, high strength variation from layer to layer

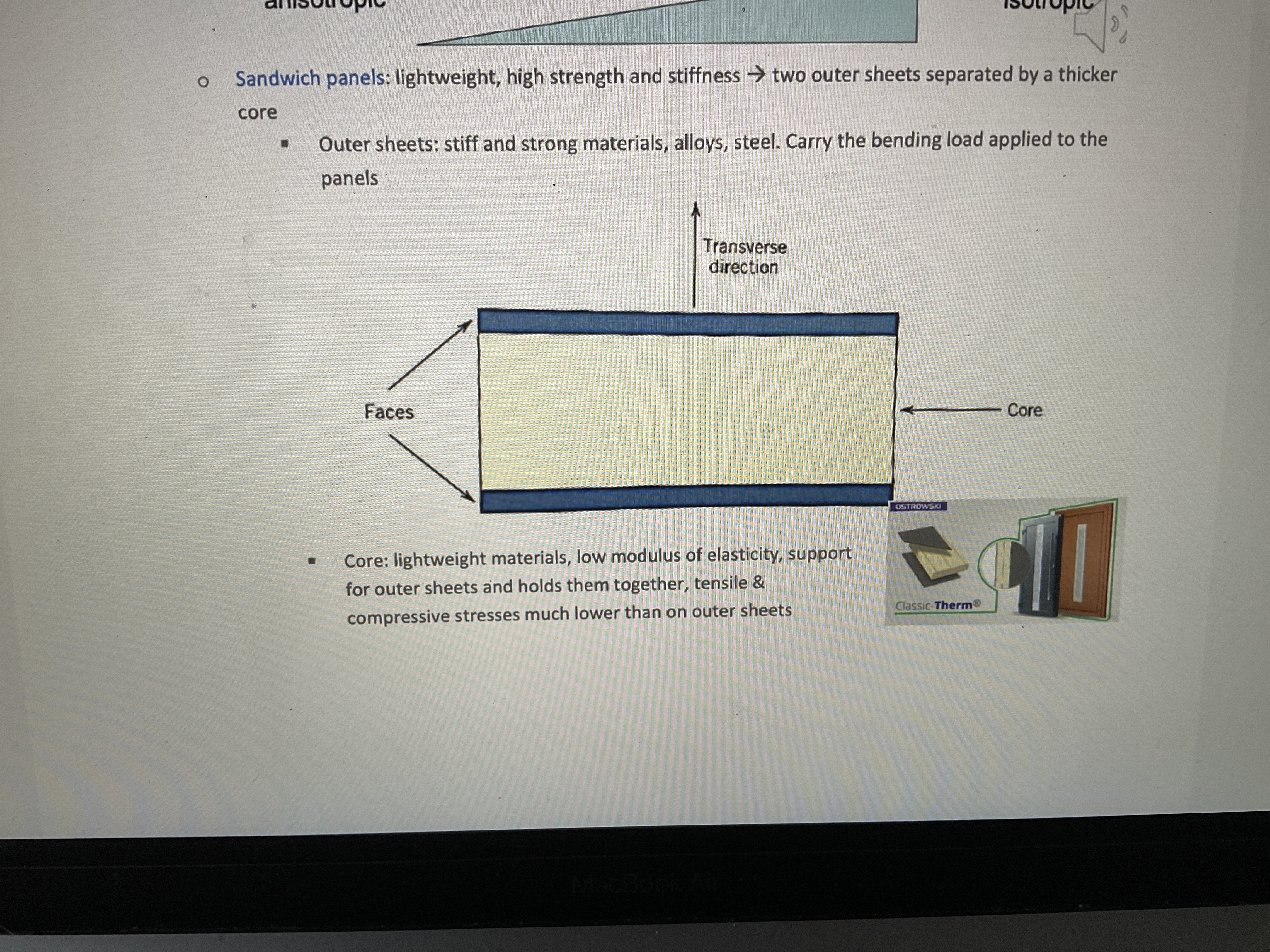

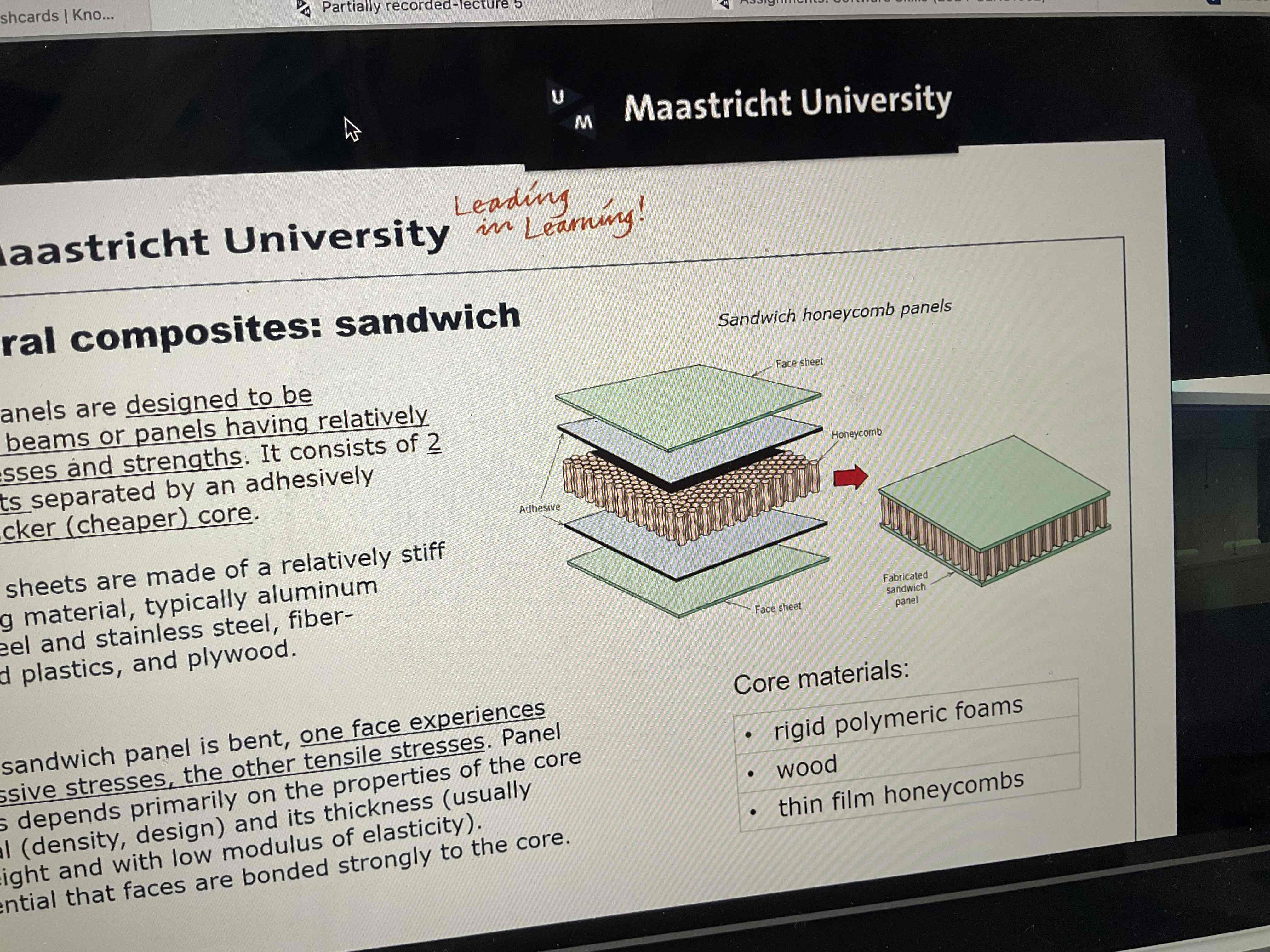

What are sandwich panels? Draw their build and explain about core

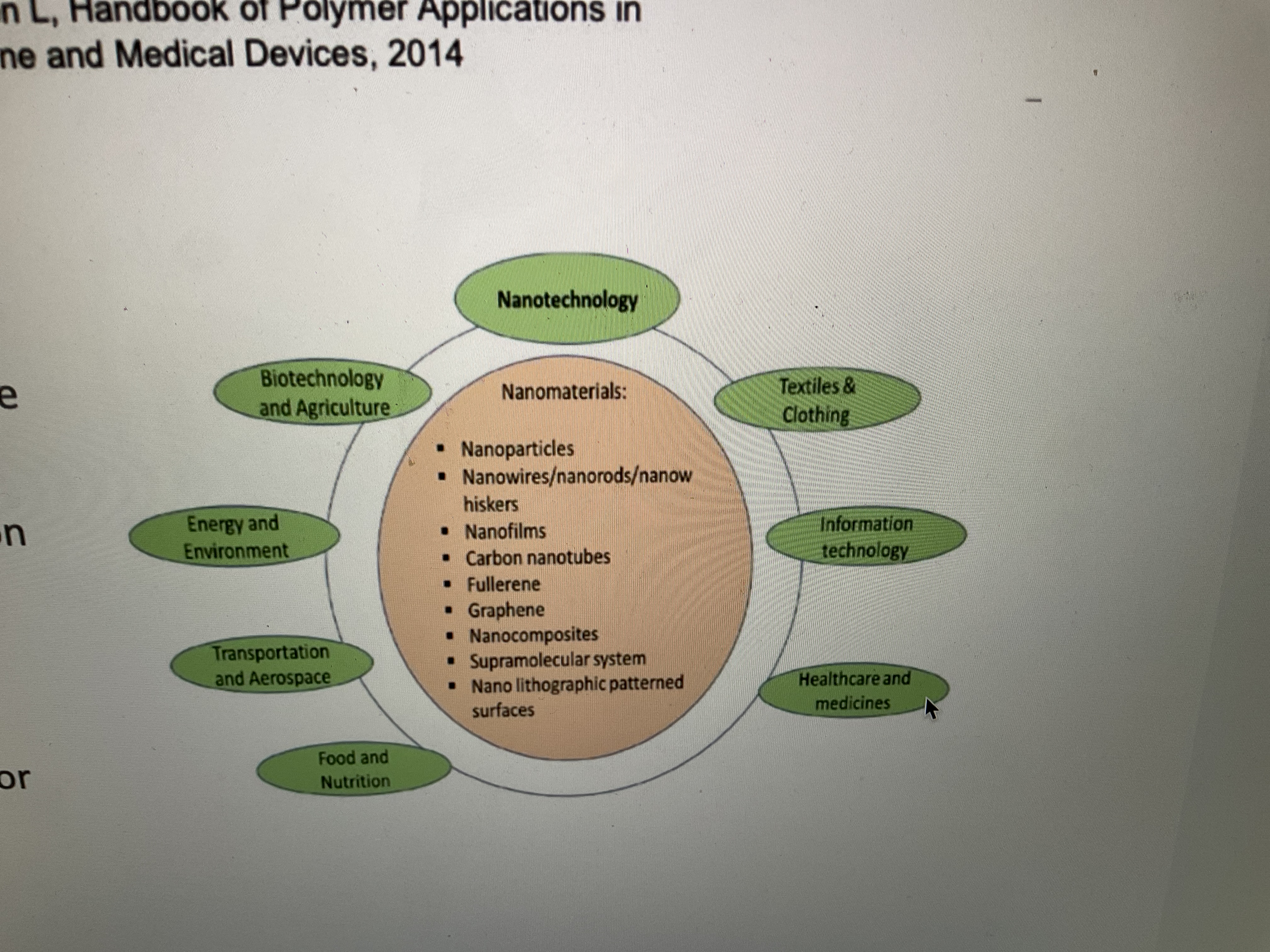

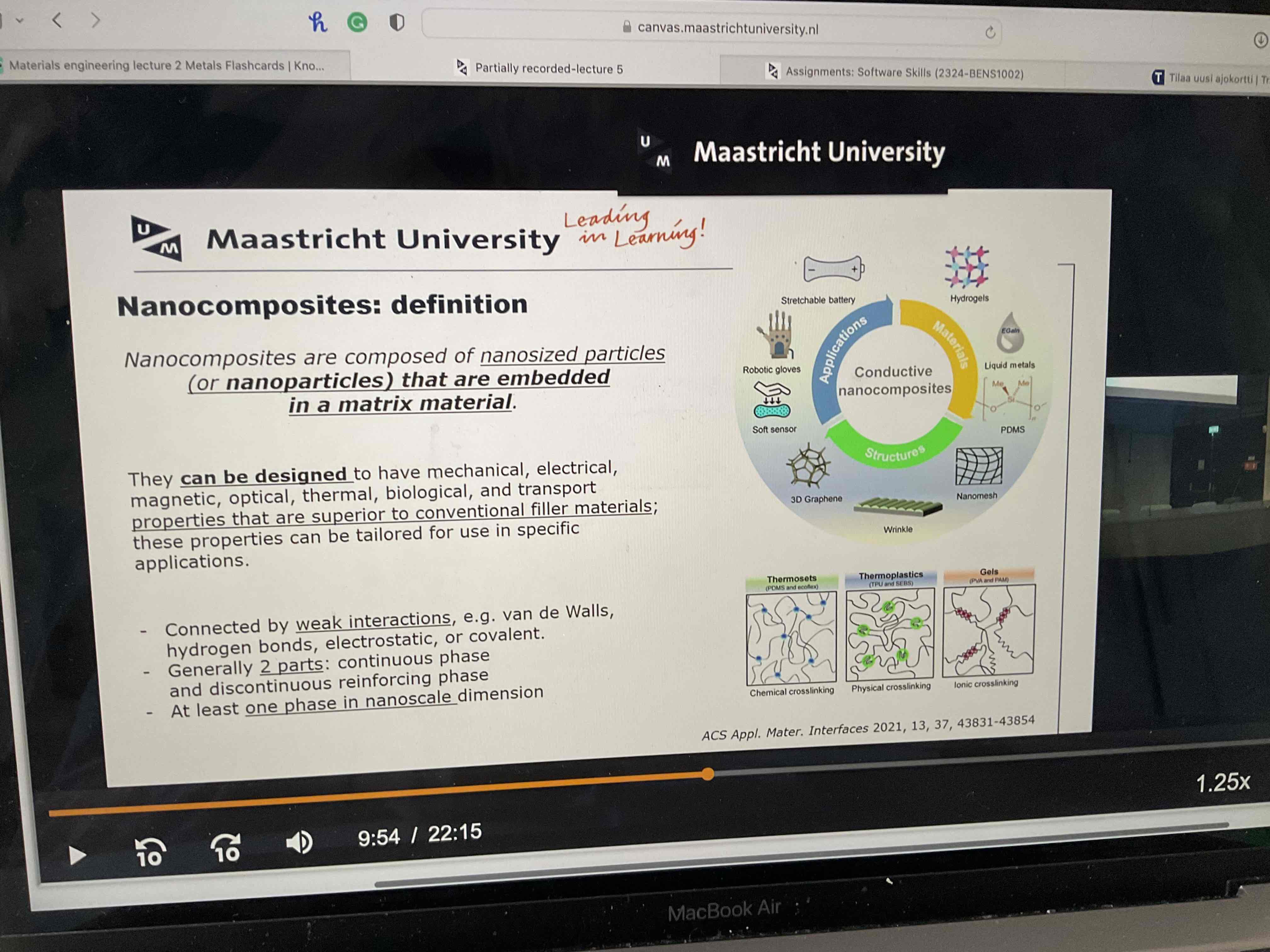

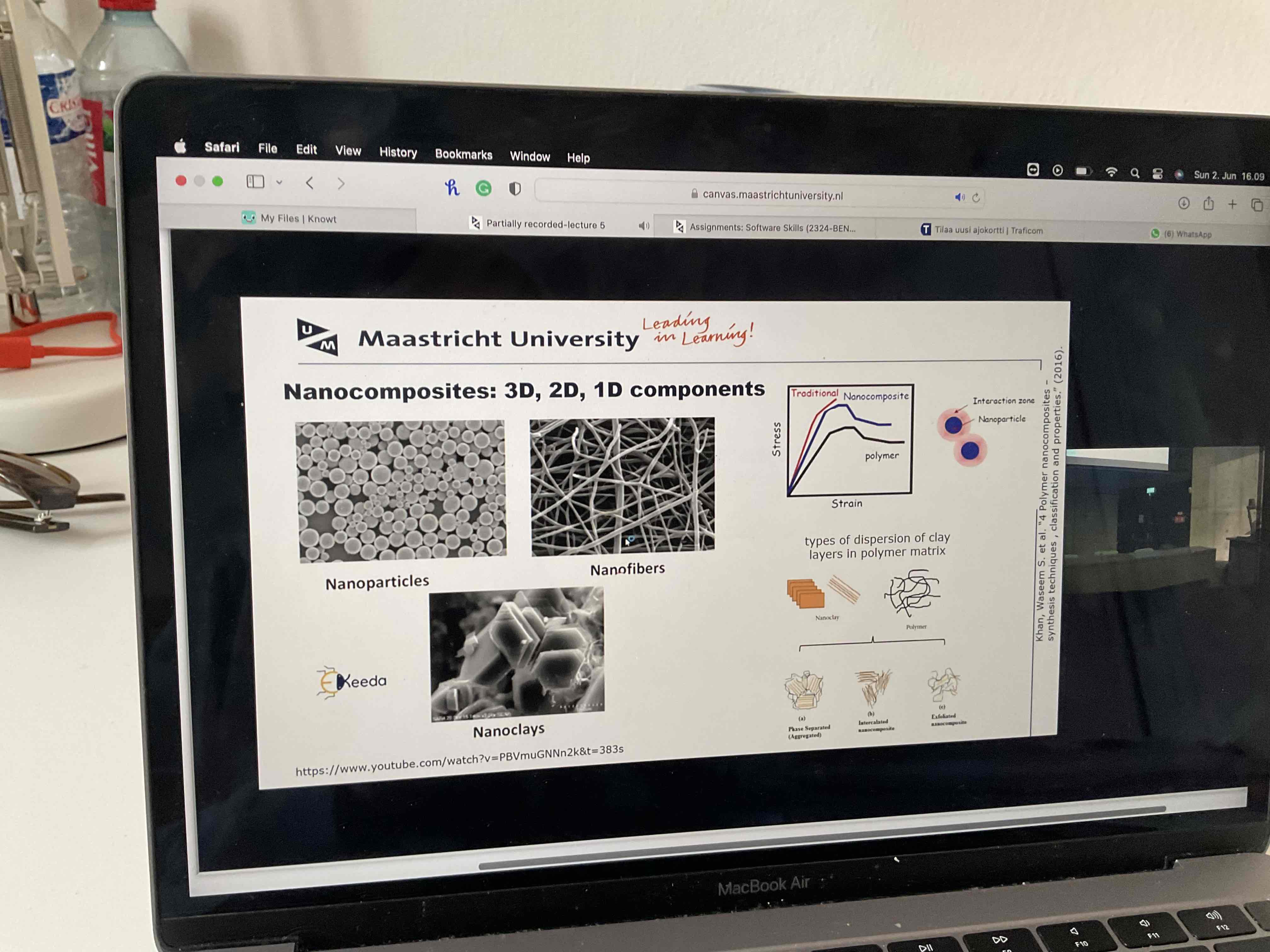

What are nanocomposites?

Nanoparticles embedded in a matrix

what size induced properties do nanocomposites have? 2

Increase in ratio of particle surface area to volume

Particle size

What material is the matrix usually? 3

Matrix may be metals and ceramic, the most common are polymers

Explain about nanoparticle properties 3

properties depend on shape of nanoparticles (Nanocarbons, nanoclays, nanocystals)

Properties can be taylored to meet requirements of specific applications

Size induced properties

Study this pic. What is nanotechnology used for? Ex of materials

Give examples of three natural fibers and three synthetic fibers

Natural: palm, chicken fether and banana

Synthetic: carbon, Kevlar and glass

To effect a significant improvement in strength of the composite the fibers must be ___!

Continuous

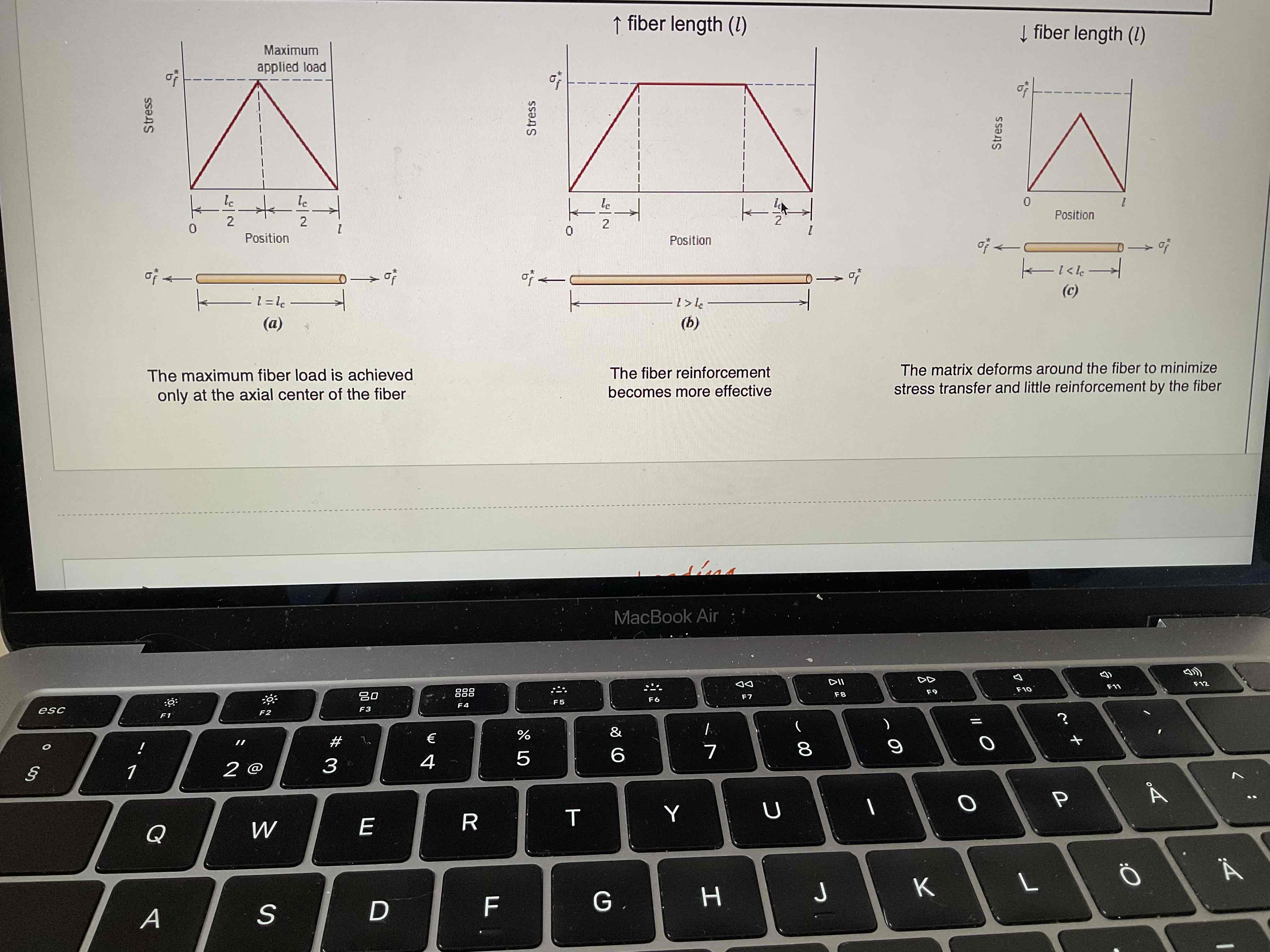

=<> of the scenarios

Critical fiber length= lc

Fiber length= l

A) l=lc

B) l>lc

C) l<lc

What do the mechanics of continuous and aligned fibers depend on?

stress strain behaviours

Phase volume fractions - fibers and matrix

Direction of the applied stress

Direction of the applied load

What does anisotropic mean?

Properties of the composite depends on the direction in which they are measured

What’s a fiber fracture?

Onset of composite failure. Once the fibers have fractured, the load borne by the fibers will be transferred to the matrix.

What is transverse strength influenced by?

properties of the fiber and matrix

Fiber matrix bond strength

Presence of voids

Is reinforcement efficiency lower or higher for discontinuous fibers?

Lower

Which is anisotropic and which is isotropic?

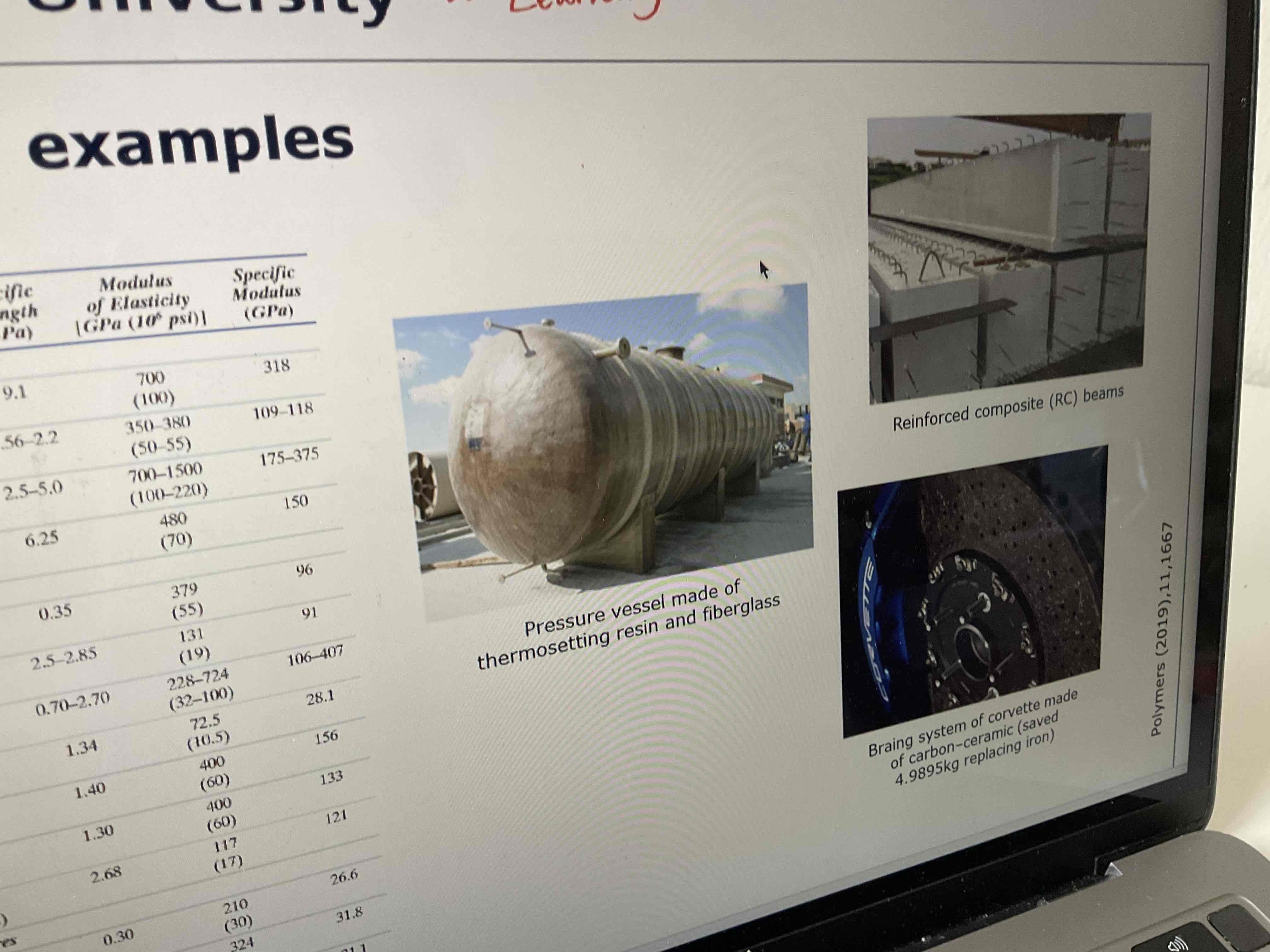

Tell about why would you want to process glass as fiber reinforced

high strength composite

Highly available

Low cost

Easy fabrication

Chemically inert

Tell about the reinforced matrix phase for metals

Ductile

Can be used at higher

temperatures → advantageous

Reinforcement improves stiffness, strength, abrasion resistance, creep resistance, thermal conductivity, stability

Noninflammable

Resistant to degradation

EXPENSIVE → limitation

Tell me why would you want to process carbon as fiber reinforced? 5

high specific modulus and strength, retained at elevated temp

High t oxidation

Moisture/solvents resistant at RT

Specific engineering (composite)

Cost effective

What are the 10 processing methods for reinforced fibers (ex glass and carbon)

Dry hand lay-up process

Resin transfer molding

Spray lay-up process

Vacuum-Assisted resin transfer molding process

Injection molding

Silicon rubber molding process

Compression molding

Filament winding process

Pultrusion (extrusion “pull”)

Autoclave molding process

Give three examples of when to use fiber reinforcements.

What is a structural composite?

Multilayered/hierarical and normally low density composite used in applications requiring structural integrity, ordinarily high tensile, compressive and torsional strengths and stiffnesses.

What do the properties od structural composites depend on?

properties of the consistent materials

Geometrical design of the structural elements

What are laminar composites composed of+

two dimensional sheets or panels (piles or laminae) bonded to one another

What are the different kinds of stacked piles of laminate panels (from most anisotropic to isotropic)

What are sandwich panels designed to be? And what are they made of (+structure)?

lightweight beams or panels having a relatively high stiffness and strength

Consists of 2 outer sheets separated by an adhesively bonded thicker (cheaper) core

The outer sheets are made of relatively stiff and strong material, typically aluminium alloys, steel and stainless steel, fiber reinforced plastic and plywood

What happens when a sandwich panel is bent? What does the panel stiffness depend on?

One face experiences compressive stresses, the other tensile.

Panel stiffness depends primarily on the properties of the core material (density, design) and it’s thickness (usually lightweight with low modulus of elasticity)

Give example of three core materials for sandwich panels

rigid polymeric foams

wood

Thin film honeycombs

What are examples of where sandwich panels are used?

What are nanocmoposites?

What two factors account for size induced properties in nanoparticles?

Ratio of particle surface to area volume

Particle size

Give an example of as the size of the particle decreases, the relative ratio of surface atoms to bulk atoms increases; this means that surface phenomena begin to dominate

ex. The permanent magnetic behaviour of some materials (for example iron cobalt and iron oxide) disappears for particles having diameter smaller than about 15 nm

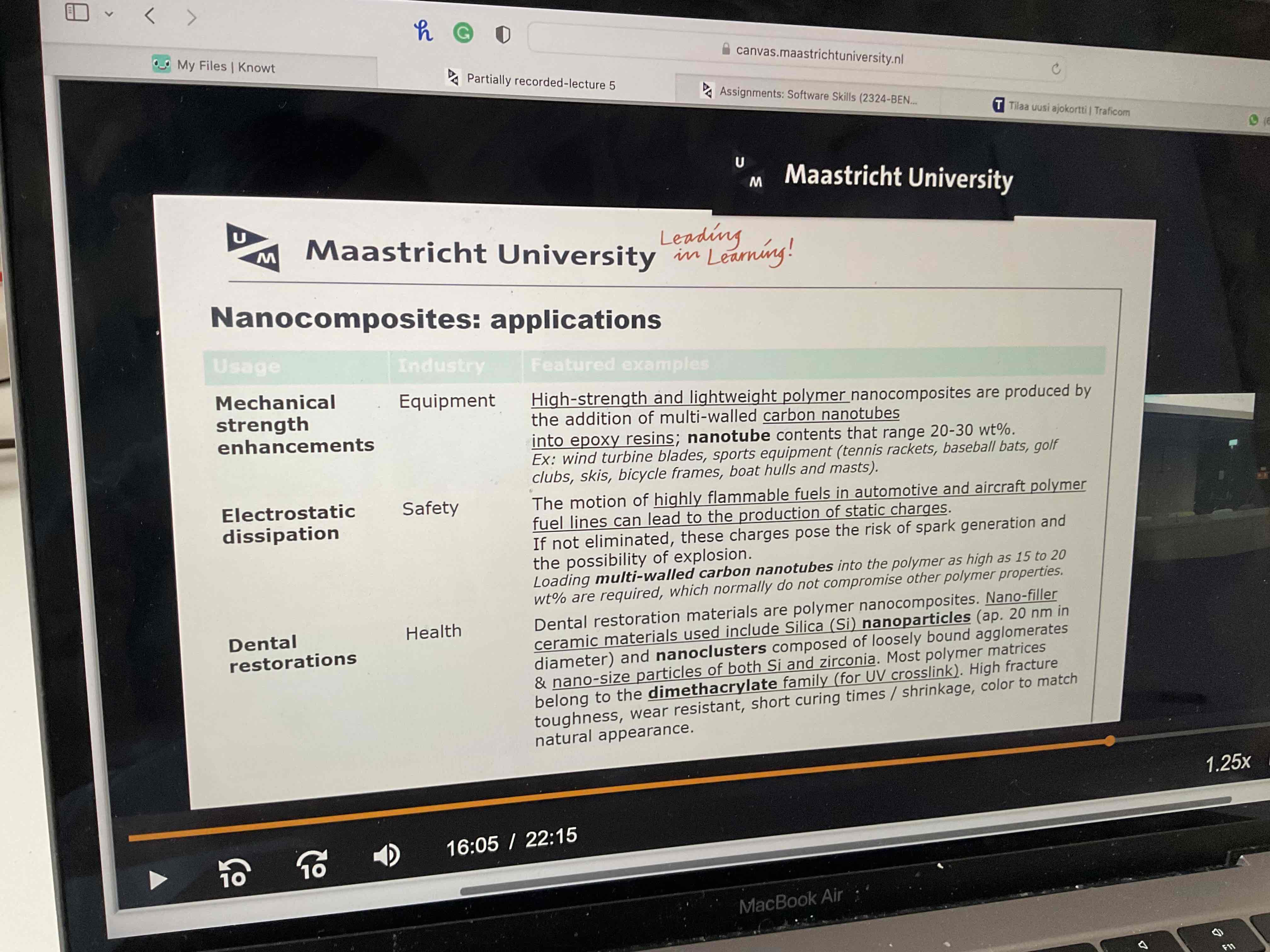

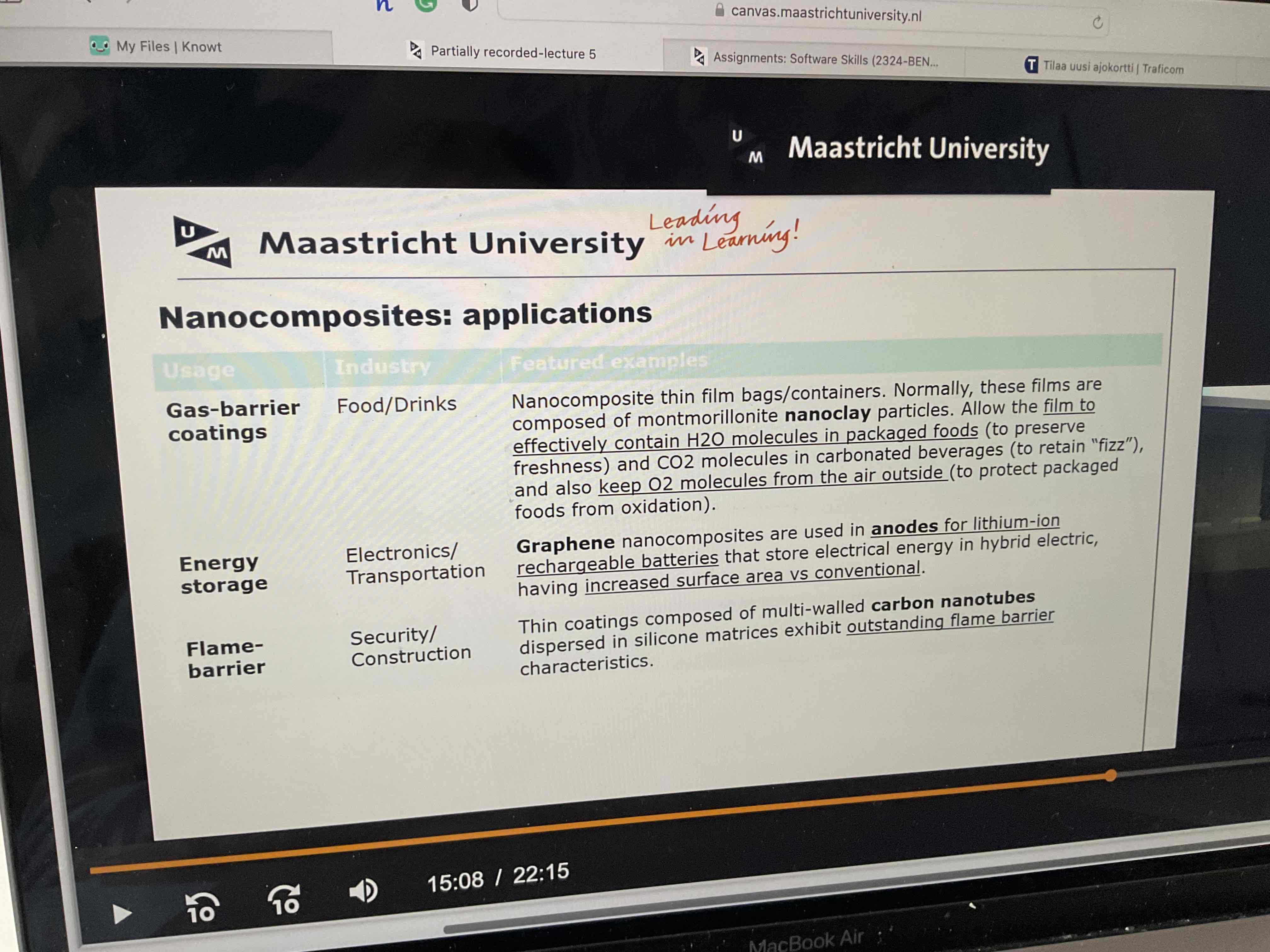

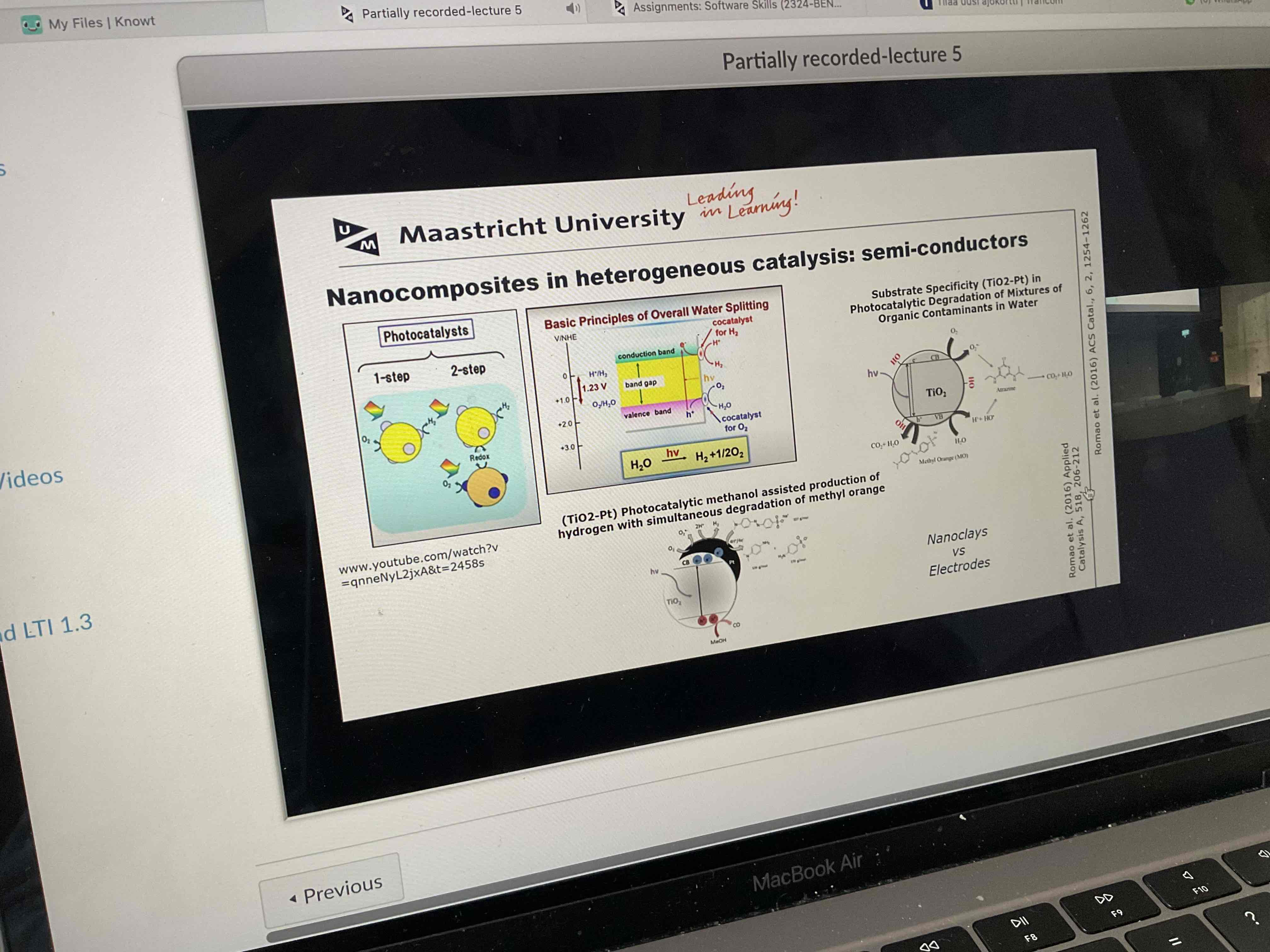

What can napcomposites be used for? 6 (dont look at pic before answering)

Look at pic

Read

Skim through