Corrosion & Degredation of Materials

1/15

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

16 Terms

Corrosion Process

Electrochemical such that there is a transfer of electrons from one chemical species to another

Reaction is from anode (oxidation) to Cathode (reduction)

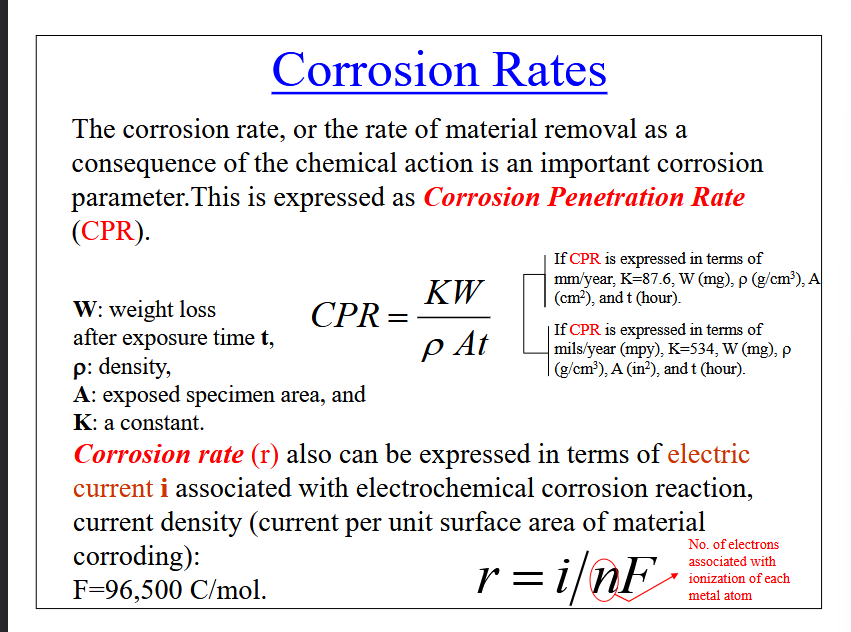

Corrosion Penetration Rate (CPR)

The rate at which material is removed as a consequence of the chemical reaction

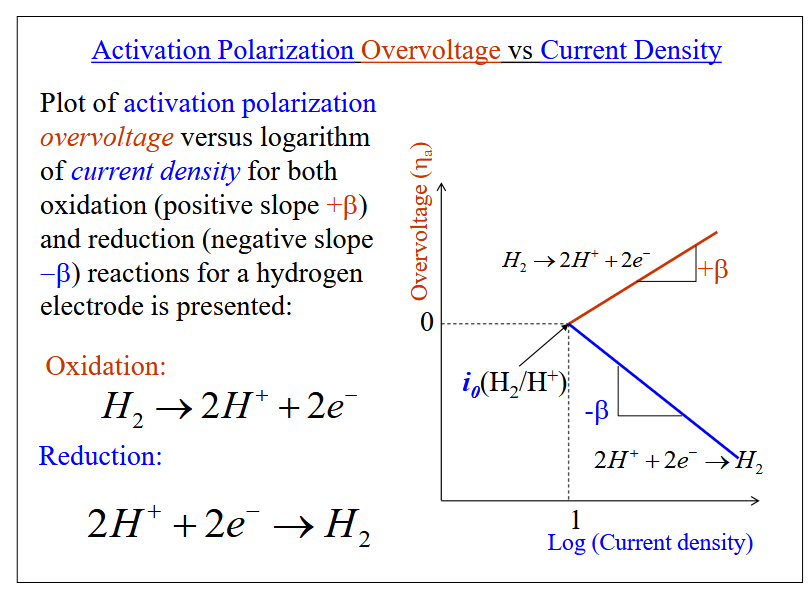

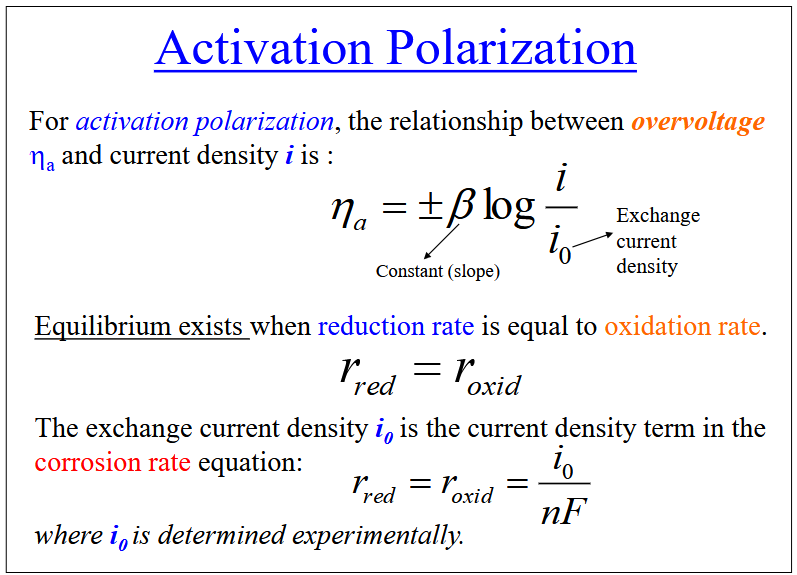

Polarization

The displacement of each electrode potential from its equilibrium value. The magnitude of this displacement is the overvoltage

Activation polarization: The rate determining step is the step with the lowest rate

Influence of Concentration and Temperature on Cell-Potential

The EMF series only applies to pure metals in 1 Molar solution at 25 degrees celcius

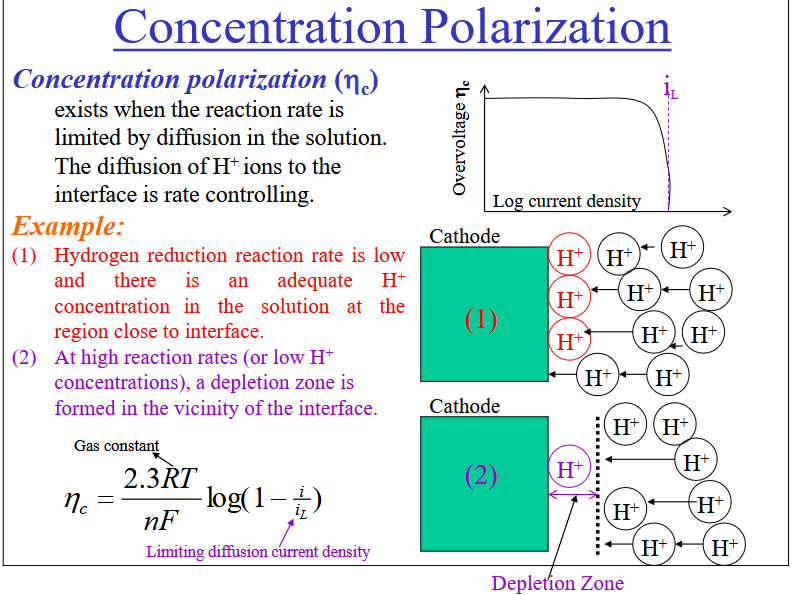

Concentration Polarization

The reaction rate is limited by diffusion in the solution

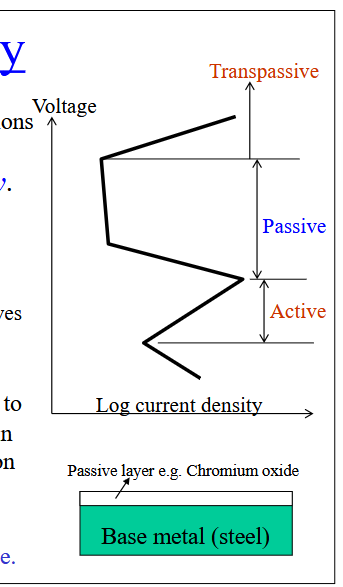

Passivity

Some metals and alloys lose their chemical reactivity and become extremely inert. Results from the formation of a thin oxide film on the metal surface.

Parameters Damaging Passivity

High temperature

salt

High voltage

Uniform Corrosion

Electrochemical corrosion that occurs with equivalent intensity over the entire exposed surface, often leaving behind a scale of deposit.

Galvanic Corrosion

Occurs when two metals or alloys with different compositions are electrically couples while exposed to an electrolyte. The more reactive metal (anode) will experience corrosion, the less reactive metal (cathode) will not.

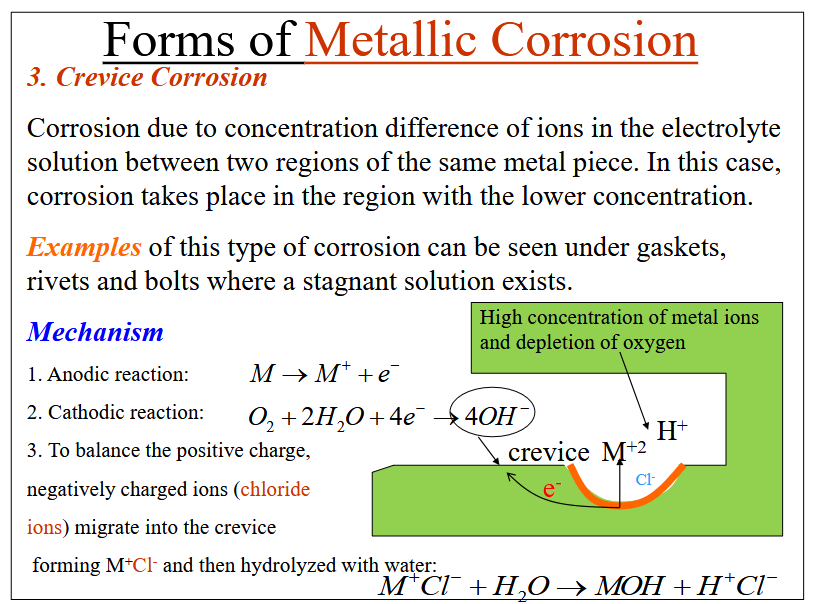

Crevice Corrosion

Corrosion due to the difference of ions in the electrolyte solution between two regions of the same metal piece. Corrosion occurs in the region with the lower concentration

Pitting Corrosion

A form of very local corrosion in which small pits or holes form

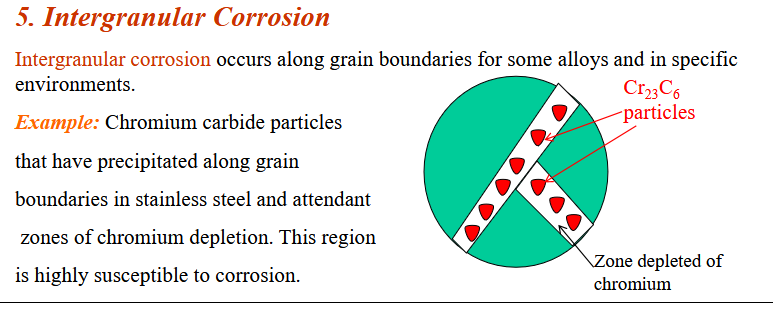

Inter-granular Corrosion

Corrosion along the grain boundaries

Selective Leaching Corrosion

Occurs when one element is purposely removed during corrosion.

Erosion - Corrosion

The combination of chemical attack and mechanical abrasion/wear as a consequence of fluid motion. Commonly found in pipe bends, elbows, and abrupt changes in pipe diameter position.

Occurs when fluid changes its direction of flow, suddenly becoming turbulent

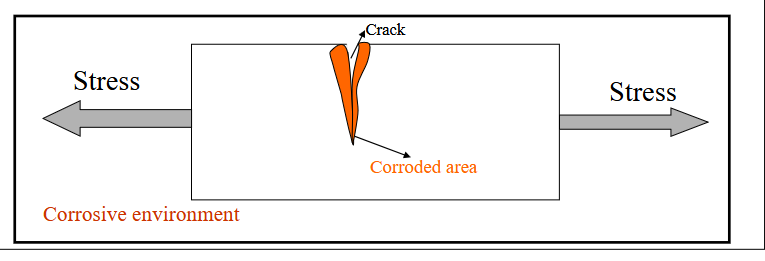

Stress Corrosion

Results from the combined action of an applied tensile stress and a corrosive environment. Small cracks form and then propagate in a direction perpendicular to the direction of stress.

Results in failure

Hydrogen Embrittlement (Hydrogen Stress Cracking)

When an atom of hydrogen penetrates into steel causing a significant reduction in ductility and tensile strength.

H-atoms diffuse interstitially through the crystal lattice, leading to cracking, usually transgranular