Introduction to Materials Science and Engineering

1/87

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

88 Terms

Stone Age (2.6 million years ago – 3300 B.C.)

Bronze Age (3300 B.C. – 1200 B.C.)

Iron Age (1200 B.C – 600 B.C.)

Advanced Materials (early 20th Century)

Four historical periods for materials science and engineering

Stone Age

2.6 million years ago – 3300 B.C. Began about 2 million years ago.

Stone

Wood

Clay

Skins

Bronze Age

3300 B.C. – 1200 B.C.

Began about 5000 years ago

An alloy which is made up of more than one element, copper + <25% of tin + other elements.

Can be hammered or cast into a variety of shapes, can be made harder by alloying, corrode only slowly after a surface oxide film forms.

Iron Age

1200 B.C – 600 B.C.

Began about 3000 years ago (until today)

Use of iron & steel, a stronger and cheaper material changed drastically daily life of a common person)

Advanced Materials (early 20th Century)

Throughout the Iron age many new types of materials have been introduced (ceramics, semiconductors, polymers, composites...)

Understanding of the relationship among structure, properties, processing and performance of materials.

Intelligent design of new materials

Materials Science

Investigates relationships that exist between the structures, processing and properties of materials.

Develop or synthesize new materials

Material Chemistry

Materials Physics

Materials and Process Engineering

Scope of Material Science

Graphite

A material that is dull, opaque, soft, and common.

Diamond

A material that is brilliant, transparent, hard, and rare.

Materials Engineering

Design the structure of a material to produce a predetermined set of properties.

Materials Engineering

Create new products or systems using existing materials

Develop techniques for processing materials.

Materials Engineering

Focuses on how to translate or transform materials into useful devices or structures.

Material Science

Basic knowledge of materials

Material Science and Engineering

Resultant knowledge of the structure, properties, processing and performance of engineering materials.

Materials Engineering

Applied knowledge of materials

Subatomic level

Electronic structure of individual atoms that defines interaction among atoms (interatomic bonding).

Atomic Level

Arrangement of atoms in materials (for the same atoms can have different properties, e.g. two forms of carbon: graphite and diamond)

Microscopic Structure

Arrangement of small grains of material that can be identified by microscope.

Macroscopic Structure

Structural elements that may be viewed with the naked eye.

Physical Properties

Properties that can be observed or measured WITHOUT changing the composition of the material.

Density

Thermal

Electrical

Dimensional

Optical • Refractive index • Absorption • Transmission • Reflection • Scattering • Color

Magnetism

Permeability

Porosity

Mechanical Properties

Properties that involve a reaction to an applied load.

Response to mechanical forces, strength, etc

Hardness

Toughness

Elasticity

Plasticity

Ductility

Malleability

Brittleness

Tensile strength

Compressive strength

Shear strength

Fatigue strength

Impact resistance

Creep

Stiffness

Resilience

Chemical Properties

Properties that are discovered by observing chemical reactions.

Reactivity with acids

Reactivity with bases

Oxidation state

Corrosion resistance

Flammability

Toxicity

pH level

Heat of combustion

Electronegativity

Chemical stability

Radioactivity

Ability to tarnish

Enthalpy of formation

Solubility

Decomposition

Resistivity

A measure of the resistance of a material to electrical conduction.

Thermal Properties

Properties of a material that is related to its ability to conduct heat.

Thermal conductivity

Specific heat capacity

Thermal expansion

Melting point

Boiling point

Thermal diffusivity

Heat of fusion

Heat of vaporization

Thermal emissivity

Glass transition temperature

Thermal shock resistance

Electrical Properties

Properties of a material that is related to its ability to conduct electricity.

Electrical conductivity

Electrical resistivity

Dielectric constant

Dielectric strength

Permittivity

Electrical permeability

Power factor

Insulation resistance

Hall effect

Superconductivity

Extrinsic and Intrinsic Factors

Two Size Effect Factors

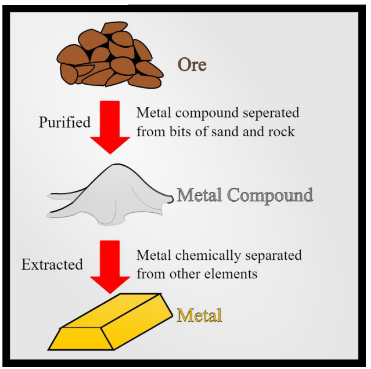

Processing

Purified Ore - Metal compound separated from bits of sand and rock

Extracted - Metal chemically separated from other elements

Extrinsic Factors

Geometry size

Surface morphology

Local feature size

Aspect ratio of parts

Intrinsic Factors

Grain size

Size/distance of precipitates

Material density

Dislocation mean free path

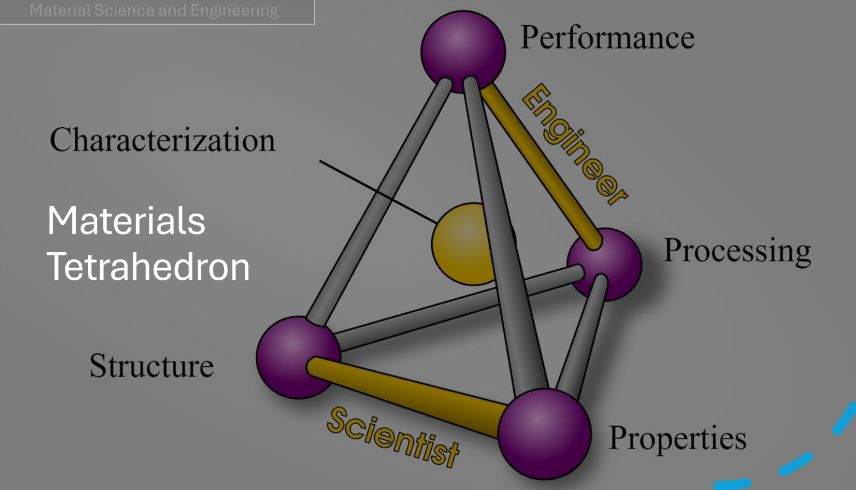

Interdependency between structure, properties, processing and performance of materials

Relationships in the material tetrahedron

Structure

Arrangement of constituents or its internal components

Depends on how it is processed

Properties

Strength, ductility, toughness, stiffness, corrosion resistance, creep resistance, etc.

A materials trait in terms of response to a specific environment and external forces

Processing

Fabrication, accuracy, surface finish, cost, and required quality, etc

Way the materials are made; synthesized, produced and integrated

What are the parameters involved (source of energy, duration, stresses experienced etc)

Will indicate the properties

Performance

Intended service environment, reliability, expected service life, frequency of failure, remaining life assessment,etc

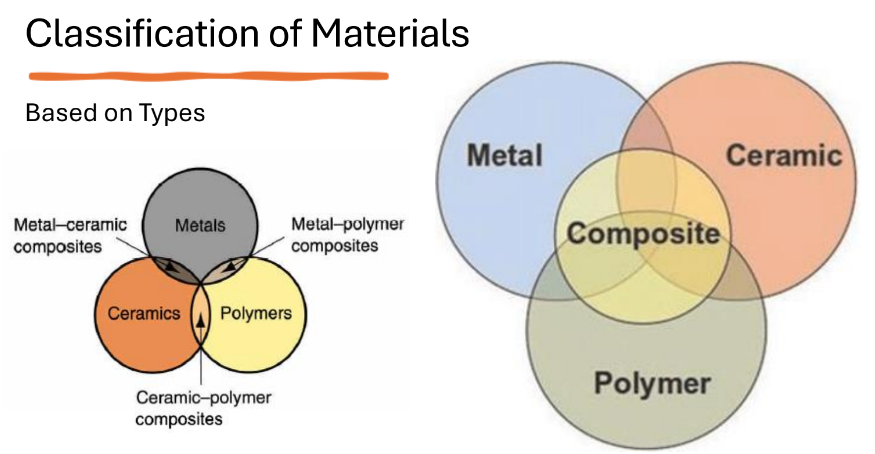

Metal and alloys

Ceramics

Composites

Polymers

Classification of materials based on TYPES

Metal and Alloys

Steel

Bronze

Brass Aluminum

Nichrome

Titanium

Berrylim-copper

Nickel

Niobium

Metals

Strong, ductile

High thermal & electrical conductivity

Opaque, reflective.

Examples: Beverage can: Aluminum alloy highly hardenable)

Deterioration

In the context of corrosion, is a loss in the properties of a material by chemical interaction with the environment

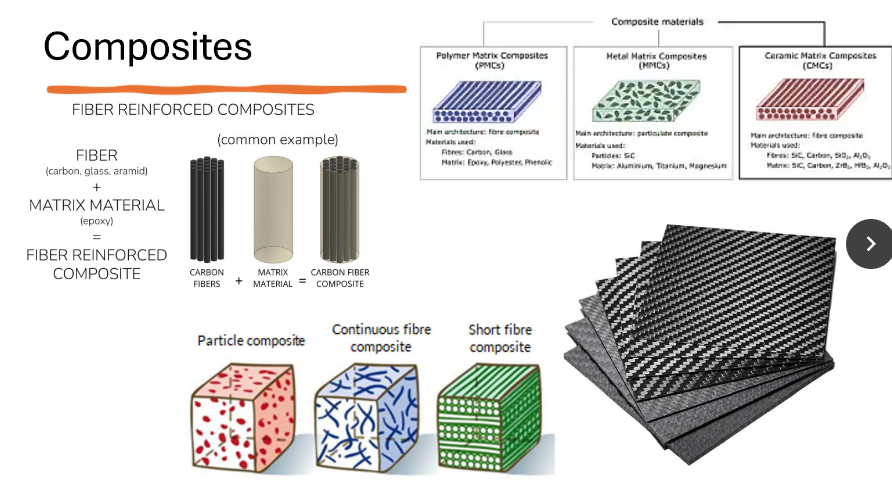

Composites

Metal Matrix

Ceramic Matrix

Polymer Matrix

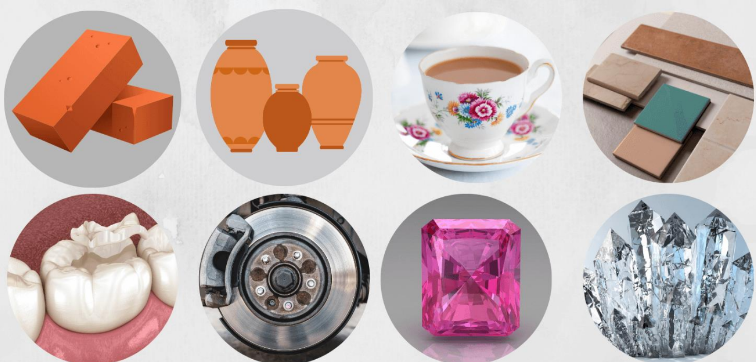

Ceramics

Brittle, glassy, elastic

Non-conducting (insulators)

Crystaline Ceramics

Ceramics

An inorganic non-metallic solid made up of either metal or non-metal compounds (oxides, carbides, nitrides, sulfides) that have been shaped and then hardened by heating to high temperatures.

In general, they are hard, corrosion-resistant and brittle.

Composites

A combination of two or more materials (metals, ceramics and polymers) to form a new one.

To achieve a combination of properties that is not displayed by any single material.

Composites

One type of material will become the base; called ‘matrix’ and the other material will act as ‘reinforcement’.

Natural and Synthetic Polymers

Two types of Polymer

Polymers/plastics

Soft, ductile, low strength, low density

Thermal & electrical insulators

Optically translucent or transparent.

They decompose at moderate temperatures (100 – 400 C).

Polymers

A substance or material consisting of very large molecules, or macromolecules, composed of many repeating subunits. Intramolecularly bonded by covalent bonding.

Wires & cables

Ski boot

Modern telecommunications equipment

Natural Polymers

Polymers made by living organism.

Synthetic Polymers

Polymers made by chemical reaction in a laboratory.

Aerospace

Biomedical

Electronics

Magnetic

Optical

Structural

Smart Materials

Classification of materials based of FUNCTIONS

Functional materials

Generally characterized as those materials which possess particular native properties and functions of their own.

Aerospace

Engine, turbo fan (metals and alloys), wheels (synthetic polymers, aircraft (composites)

Biomedical

- implant, medicines

Electronics

- electronic board (ceramic matrix composites)

Magnetic

power magnetics (used in transformer), electromechanical component (hard drive)

Optical

optical lenses

Structural

bricks, cement, sand, concrete

Smart Materials

ferrofluid, metal foam, aerogel, nanotube

Stone

Bronze

Iron

Advanced Materials

Historical Perspective

Structure

Properties

Processing

Performance

Materials Science and Engineering

Earliest humans

Access to only limited number of materials those that naturally occur (stone, wood, clay, skins etc.)

Pottery and Metals

Earliest humans discovered techniques for producing materials that had properties superior to those of the natural ones. What is this?

Pottery

Made by forming a CLAY body into objects and heating them to high temperatures

Density

Implies the weight of a material, with higher __________ rates implying heavier materials.

Atomic Structure

Bohr Theory Model (orbital electron)

Wave-Mechanical Model (electron configuration)

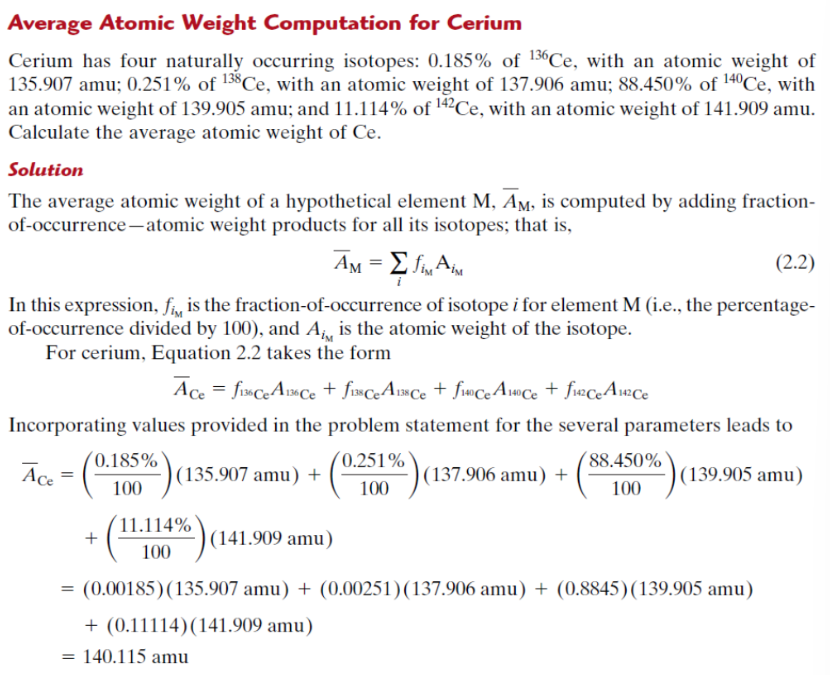

Isotopes

Atoms of some elements have two or more different atomic masses

ATOMIC NUMBER (Z)

Number of protons is equal to

MASS NUMBER (A)

No. of protons + no. of neutrons (A = Z +N)

Atomic Mass Unit (AMU)

Unit of mass relative to a single constituent of a Carbon atom

Principal (n)

Size of the shell in which a particular electron orbits arounf the nucleus and its energy.

Secondary/ Azimuthal (l)

Specifies the angular momentum of orbiting electron and determine the shape of the orbit

Magnetic (mₗ)

Controls the number of allowed spatial orientations characterized by l in a given shell.

Pauli Exclusion Principle

No two electrons may have the same quantum number within any atom.

No more than two electrons with opposing electronic spin may be present in each orbital

Electropositive

Electronegative

Electronegativity

giving up electrons to become + ions

accept electrons to form - ions

increases in moving from left to right and from bottom to top

Ionic bond

Transfer of electron between metals and non-metals

Nondirectional, magnitude of the bond is equal in all directions around an ion

Electrically and thermally insulative

High Melting Point, Brittle, Hard

Covalent bond

Sharing an electron between two similar electronegative elements

Electrical insulators or semiconductor

High Melting Point, Hard, Nonconducting

Metallic bonding

Formed between the metallic elements in which electropositive atoms donate their valence electrons to form a “sea” of electrons

Good conductors of electricity and heat

Intermolecular Forces

Attraction forced between molecules

Dipole

Polarized molecule having partially positive and negative poles.

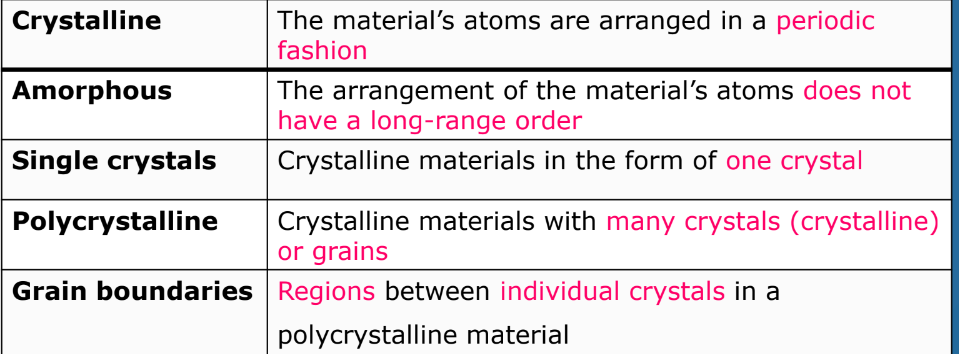

Amorphous

Does not have a long-range order

Single crystals

One crystal

Polycrystalline

Many crystals or grains

Grain boundaries

Regions between individual crystals

Magnetic materials

Those materials that can be easily magnetized and can be used to make magnets.

Examples are iron, nickel and steel.

Diamagnetic Materials

Paramagnetic Materials

Ferromagnetic Materials

3 Primary Categories Of Magnetic Materials

Diamagnetic Materials

Materials which are weakly repelled by a magnet;

Magnetized in opposite direction;

when freely suspended in a uniform magnetic field it slowly aligns itself in a direction perpendicular to the applied magnetic field;

lose their magnetism on removal of external magnetic field;

in a non-uniform magnetic field

they move from a stronger to a weaker field due to repulsion

examples: copper, gold, silver, water, air, argon, hydrogen.

Paramagnetic Materials

materials which are weakly attracted by a magnet;

weakly magnetized in the same direction of magnetic field;

when freely suspended in a uniform magnetic field it slowly aligns itself parallel to the applied magnetic field;

also lose their magnetism on removal of external magnetic field;

move from a weaker to a stronger field with a weaker attraction;

examples: aluminium, chromium, alkaly, metals, alkaline, earth metals, platinum, oxygen

Ferromagnetic Material

materials which are strongly attracted by a magnet;

strongly magnetized in the same direction;

when freely suspended in a uniform magnetic field it quickly aligns itself parallel to the applied magnetic field;

DO NOT lose their magnetism on removal of external magnetic field (THEY ARE A PERMANENT MAGNET);

move from a weaker to a stronger field due to strong attraction;

examples: iron, cobalt, nickel, steel