Quality Control (L23, 24)

1/30

Earn XP

Description and Tags

See slides for additional

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

31 Terms

Quality

1) Product conformance to design

2) Freedom from deficiencies

What does Freedom from deficiencies mean?

The product has everything that you do want and nothing that you do not want.

Causes of Random variation

Human variability

Raw material variability

Machine vibration, etc.

Assignable Variation

An exception from normal operating conditions

Not account for by random variations

Can be attributed to a cause (systematic error)

Operator mistakes

Defective raw materials

Tool failures

Machine malfunctions, etc.

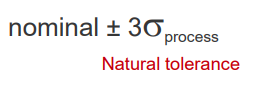

Natural Tolerance Limits

Use of natural tolerance limits will yield 99.73% of parts within specification

PCI = 1

2700 defective parts per million

What is a preferred PCI value

PCI > 1.33

PCI = 2 is the goal

Control charts

track key process variables over time

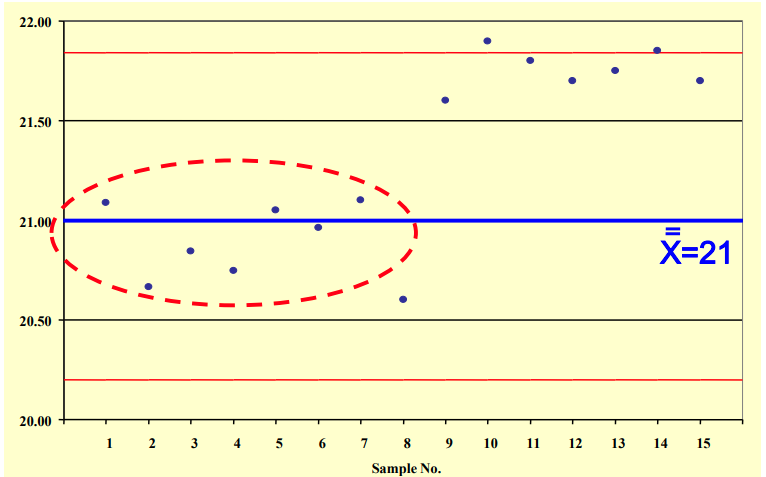

What is depicted?

Process Shift

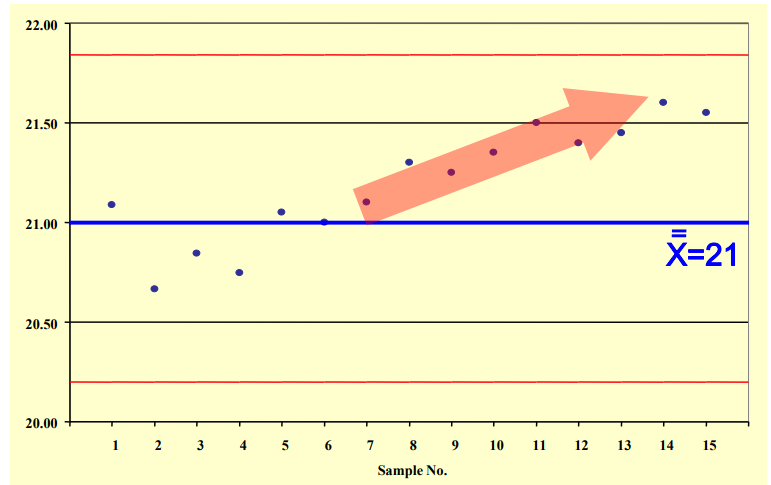

What is depicted?

Process Drift

Control charts for attributes

Do not assess a specific quantitative variable

Focus on monitoring defect rate over time

Use of p and c chart

p Chart

fraction of defects per sample

c Chart

number of defects per sample

Inspection

Use of measurement and gaging to determine conformance to design specifications

Measurement

Comparison of an unknown quantity relative to a known standard

Two types of inspection

1) inspection by variables

2) inspection by attributes

inspection by variables

actual values of key dimensions are measured

Inspection by attributes

Gaged to determine if they are within tolerance (Pass/Fail)

(Not as good for SPC)

Quicker and cheaper

Manual Inspection

Inspection procedures are often performed manually

The work is boring and monotonous, yet the need for precision and accuracy is high

Because of the time and cost of manual inspection, statistical sampling procedures are often used to reduce the need to inspect every part

Risk can be reduced by using a larger sample size

Note: Many defective parts cannot be visually inspected

Functional inspection required or hidden features prevent contact inspection

100% Inspection

Theoretically, the only way to achieve 100% good quality is by 100% inspection

▪ All defects are screened and only good quality parts are passed

Problems with manual 100% inspection

1. The expense - the unit inspection cost is applied to every part in the batch

2. Human errors - in 100% manual inspection, there are almost always human errors

▪ Operator fatigue

▪ “Cherry-picking”/inspector bias

▪ Therefore, 100% inspection using manual methods is no guarantee of 100% good quality product

Parts sortation

separating parts into acceptable and unacceptable bins

Automated 100% inspection can accomplish what corrective actions

1) Parts sortation - separating parts into acceptable and unacceptable bins

▪ Three bins: acceptable, reworkable, & scrap

2) Feedback of inspection data can be used in upstream operation so compensating adjustments can be made in the process to reduce variability and improve quality

Methods of automated inspection

Coordinate measuring machines

2. Lasers

3. Machine vision

Coordinate Measuring Machine (CMM)

Measuring machine consisting of a contact probe and mechanism to position the probe in three dimensions relative to surfaces and features of a work part

CMM Advantages

Higher productivity

Greater inherent accuracy and precision that conventional methods

Reduced human error

Reverse engineering

Scanning Laser Systems

laser beam deflected by a rotating mirror to sweep a beam of light past an object

Machine Vision

Acquisition, processing, and interpretation of image data by computer

Edge detection

determining locations of the boundaries of an object by identifying contrast in light intensity between adjacent pixels at borders

Feature extraction

determining feature values of an image

template matching

Compare one or more features of an image with corresponding features of a model

(template) stored in computer memory

Machine Vision Applications

Inspection

Part identification

Visual guidance and control

Safety monitoring