Robotics All

1/75

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

76 Terms

Spherical Workspace

Used for dexterous activities, i.e., welding or spray painting

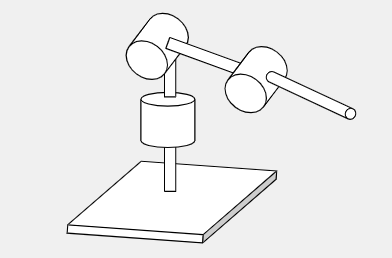

Anthropomorphic Robot Arm (RRR)

Spherical Workspace

Used for simple tasks that don’t require complex motion

Trades heavy loads for higher accuracy

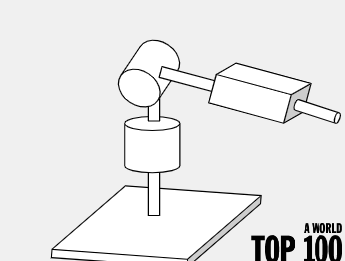

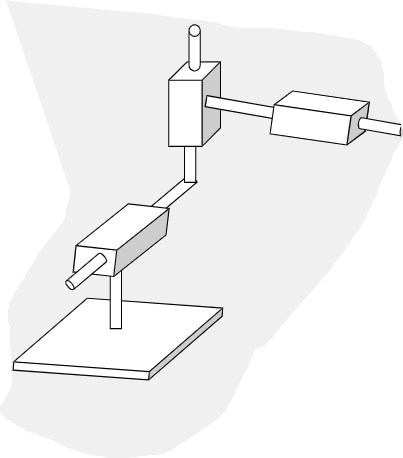

Spherical Robot Arm (RRT)

Cylindrical Workspace

Used for factory assembly in single planes

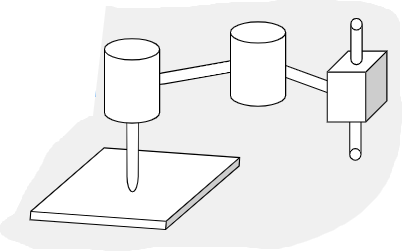

SCARA (Selective Compliant Articulated Robot for Assembly) (RRT)

Cylindrical Workspace

Used for basic jobs

Cylindrical Robot Arm (RTT)

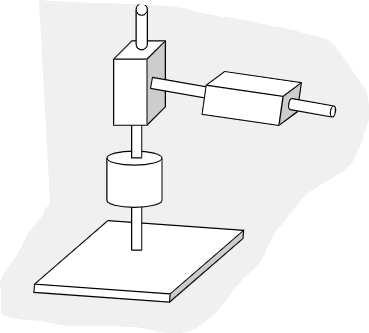

Prism Workspace

Known for high accuracy with less capacity for high loads

Cartesian Robot Arm (TTT)

Kinematics Definition

The study of motion without considering the forces and moments which are responsible for the motion.

The motion is described by trajectories, velocities and accelerations - in robotics the main interest is in trajectories and velocities.

Forward/Direct Kinematics

Given joint variables calculated the pose of end-effector

Forward/Direct Kinematics Additional Information

The solution is unique

Represents the simpler problemI

Inverse Kinematics

Given the pose of the end-effector calculate joint variables

Inverse Kinematics Additional Information

The equations are generally nonlinear

No closed form solution

No / Multiple / Infinite solutions may exist

Differential/Instantaneous Kinematics

Given joint velocities determine the end-effector linear and angular velocities

Inverse Differential Kinematics

Given end-effector velocities determine the joint velocities

Reachable Workspace

Set of points that can be reached by end-effector

Dexterous Workspace

Set of points that can be reached by end-effector with arbitrary orientation

Mechanical Structure of Robot Manipulator

Consists of a sequence of rigid bodies (links) interconnected by means of articulations (joints)

Characterisation of Robot Manipulator

An arm that ensures mobility, a wrist that grants dexterity, and an end-effector (gripper) that performs the task required

Task of Manipulator

Place an object grasped by the gripper to an arbitrary position and orientation in 3D

Path

Locusts of points required for travel of the manipulator

Trajectory

The path plus the timings involved for those point

Kinematic Redundancy

Number of DOF > number of variables needed to describe task

Can be obvious (7 DOF) or less obvious (task makes it redundant)

Adds dexterity and versatility

Accuracy

Actual and computed kinematics not the same

Varies across the workspace

Error typically <1mm

Repeatability

Ability to return to same position

Depends on mechanical structure, sensors and controllers

Difference typically < 0.1mm

Singularities

Arise when Jacobian is rank deficient as the inverse is ill defined

Close to singular configurations small velocities in end-effector may cause large joint velocities

There may be infintie solutions to inverse kinematics, configurations where mobility is reduced

Sense-Plan-Act Architecture

Measurements translated into an internal world model

Generate set of actions to achieve goal

Generate motion commands

Shakey’s architecture

Sense-Plan-Act Disadvantages

Planning in real world takes a long time (Delays in reaction time)

Sensing not involved in planning (not good in dynamic environments)

Rely directly on sensed information

Sub Sumption Architecture

Behaviour based architecture, built from layers of interacting behaviours

Behaviours connect sensors to actuators

Multiple behaviours can be active

Higher level behaviours override lower level ones (subsume)

Higher level behaviours only active when needed

Sub Sumption Advantages

Led to faster, more reactive robots

Sense and react in dynamic worlds

Sub Sumption Disadvantages

Difficult to achieve long term goals

Difficult to optimise robot behaviours

Hybrid Layer Control Architecture

Reactive Layer (Controller) - Behaviour control

Stateless, sensor based, short time scale actions

Glue Layer (Sequencer) - Executive control

Has a memory of the past, selects primitive behaviours for controller

Planning Layer (Deliberator) - Planning

Plans for the future, time consuming operations

Behavioural Control

Directly connecting sensors and actuators

Concerned with here and now

Executive Control

Interface between (numerical) behavioural control and (symbolic) planning layers

Translation of high level plans to low level behaviours

Invoking low level behaviours at appropriate times

Monitoring execution

Concerned with what has just happened and what should happen next

Planning Control

Determining long range activities of the robot based on high level goals

Fully Autonomous

Autonomy level 10

Co operative mission supervision

Autonomy level 9

Mission supervision

Autonomy level 8

Goal supervision

Autonomy level 7

Real time multi robot co operation (work together)

Autonomy level 6

Real time multi robot coordination (swarm robots)

Autonomy level 5

Adapts to faults/events (Compensate for uncertainties)

Autonomy level 4

Robust response to real time faults/events

Autonomy level 3

Changeable mission

Autonomy level 2

Execute preplanned missions

Autonomy level 1

Remotely operated

Autonomy level 0

Sensor Definition

Device that measures some attribute of the world

Transducer Definition

Mechanism that transforms the energy associated with what is being measured into another form of energy

Passive Sensor

Environment provides medium/energy for observation

Active Sensor

Puts out energy into the environment to either change energy or enhance it (sonar)

Active Sensing

Using an end-effector to dynamically position a sensor for a “better look”

Proprioceptive Sensors

Internal Sensors

Position

Velocity

Acceleration

Motor Torque

Exteroceptive Sensors

External Sensors

Tactile

Force + Torque

Proximity

Range Finders

Vision

Inertial Measurement Units (IMUs)

Position/velocity/acceleration

Typically contain 3 orthogonal rate-gyroscopes and 3 orthogonal accelerometers

Measure angular velocity and linear ac eleration

Estimates position, orientation and usually velocities and accelerations using integration

Typically include 3 magnetometers to give heading and remove errors

Micro-electromechanical systems (MEMS Gyros)

Vibrating elements, no rotating parts

Measures angular velocity by measuring Coriolis force acting on the vibrating mass

Low power consumption

Small and low cost

Gyro Drift

The bias of a rate gyro is the average output from the gyroscope when it is not undergoing any rotation.

When integrated, this cause an angular error which grows linearly with time

To correct fuse IMU signals with additional sensors

Kalman and particle filters

Absolute positioning systems (GPS)

Magnetometers

Global Positioning System

Provides 3D position estimate, based on received radio signals from ensemble of satellites

Compare time delays to triangulate position

Signal may be unreliable

Require unobstructed line-of-sight to satellites

Depends on atmospheric conditions

Can pass through glass and plastic

Accuracy 20-25m horizontal, 43m vertical

Sonar / Ultrasonic

Measures time between acoustic pulse and echo

Low cost, light weight, low power consumption, low computational effort

Distance = speed of sound /(2 * time of interval)

Receiver disabled during pulse transmission and after first echo to avoid interference and false readings

Max detectable distance ~ 6.5m

Poor directional resolution

Low sensing rate

Oblique walls do not produce detectable echos

Artefacts from multiple reflections

Collaborative Robots

A robot that can be used in a collaborative operation

Defined by the operation that they are doing not by the type of robot itself

Collaborative Operation

A state in which a robot works in direct cooperation with a human within a defined collaborative workspace

Collaborative Workspace

A workspace within the safeguarded space where the robot and human can perform tasks simultaneously during production operation

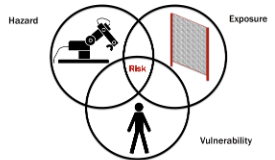

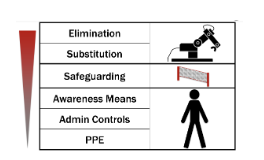

The Robot Risk Model

Robot Risk Reduction

ISO 10218 Part 1

Outlines the six steps to be considered as part of a risk assessment

The intended operations of the robot, including teaching, maintenance, setting and cleaning

Unexpected startup

Access by personal from all directions

Reasonably foreseeable misuse of the robot

The effect of failure in the control system

Where necessary, the hazards associated with the specific robot application

ISO 10218 Part 2

Requires a risk assessment for collaborative applications to evaluate task/hazard combinations and set appropriate limits

Means of anticipating tasks and hazards with the goal of applying suitable risk reduction measures

Uses iterative process to determine the desired effect is achieved

Avoids “one size fits all”

ISO TS 15066

Technical Specification about collaborative operations, which may include one or more of the following methods:

Safety rated monitored stop

Hand guiding

Speed and separation monitoring

Power and force limiting

Safety Rated Monitored Stop

What the collaborative robot does in the presence of an operator or obstruction

Stop motion condition ensured

Drive power remains on

Motion resumes after obstruction clears

Robot motion resumes without additional action

Protective stop delivered if stop condition is violated

Hand Guiding

Where an operator leads robot movement through direct interface

Robot stops when operateor arrives

Operator grasps enabling device, activating motion

Robot motion responds to operator commands

Non-collaborative operation resumes when operator leaves collaborative workspace

Speed and Separation Monitoring

Where the robot speed reduces when an obstruction is detected

Separation distances are monitored

Robot speed directly correlates to sparation distance

Stop given if direct contact proximity is attained

Power and Force Limiting

Where incidental contact initiated by robot are limited in energy to not cause the operator harm

Forces robot can exert are limited

Robot system design eliminates pinch points, sharp edges, to prevent the robot trapping operators

Robot complies and reacts when contact is made

Reduce robot velocity or inertia

Modify robot posture, to increase possible exposure surface area (reduce pressure)

Avoid sensitive body areas

ISO TS 15066 Onset of Pain Study

Guidance for power and force limits based on study examining these conditions and the onset of pain in 29 body regions.

Robot (ISO 8373)

Actuated mechanism programmable in two or more axes with a degree of autonomy, moving within its environment, to perform intended tasks

Autonomy (ISO 8373)

Ability to perform intended tasks based on current state and sensing, without human intervention

Industrial Robot (ISO 8373)

Automatically controlled, reprogrammable, multipurpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications

Service Robot (ISO 8373)

A robot that performs useful tasks for humans or equipment excluding industrial automation applications (Personal/Professional)

Artificial Intelligence (ISO 8373)

Software systems designed by humans that, given a complex goal, act in the physical or digital dimension to achieve the given goal

Europe Robotics Culture

Trustability, explainable AI

Strong competencies in hardware engineering

High ethical standards

Very concerned, critical, fearful society

America Robotics Culture

Data driven service robotics startups, strong venture capital support

Advantages in data collection and AI

Deregulated, liberal society

Asia Robotics Culture

Financial support, technology enthusiasts

Strong competencies in computer engineering and hardware engineering

Embracing new technology

Ethical, legal, social and economic issues not a concern