OMIS 4300 Exam 1 - Woosley,

1/155

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

156 Terms

Product and Service Design

Aligns offerings with organizational strategy and goals.

Customer Needs

Requirements that drive product and service development.

Quality Goals

Standards set for product performance and reliability.

Cost Targets

Financial benchmarks for product development expenses.

Prototypes

Initial models used for testing product concepts.

Process Specifications

Guidelines for manufacturing based on product specs.

Inter-functional Collaboration

Teamwork across departments for effective design.

Market Opportunities

Potential areas for growth identified through analysis.

Economic Factors

Financial conditions influencing product design decisions.

Social and Demographic Factors

Trends affecting consumer preferences and behaviors.

Manufacturability

Ability to produce a product profitably.

Serviceability

Capability to maintain service at acceptable costs.

Quality Expectations

Standards set by customers and competitors.

Liability Issues

Legal responsibilities related to product safety.

Reverse Engineering

Analyzing competitor products for improvement insights.

Research and Development (R&D)

Efforts to innovate and enhance product knowledge.

Basic Research

Knowledge advancement without immediate commercial goals.

Applied Research

Research aimed at practical commercial applications.

Product Liability

Manufacturer's responsibility for product-related damages.

Uniform Commercial Code (UCC)

Legal framework ensuring product quality standards.

Sustainability

Resource use that protects ecological systems.

Life-Cycle Assessment (LCA)

Evaluates environmental impact throughout a product's life.

End-of-Life Programs

Strategies for managing products at their lifecycle's end.

Value Analysis

Cost-performance evaluation of product components.

3-Rs

Reduction, Reuse, and Recycling principles in design.

Global Warming

Increase in Earth's average temperature due to emissions.

Solid Waste Generation

Production of waste materials from products.

ISO 14000

Standards for environmental management and assessment.

Alternative Sources

Other materials or services that can replace current ones.

Remanufacturing

Refurbishing used products by replacing defective components.

Cost of Remanufactured Products

Sold for about 50% of new product cost.

Design for Disassembly (DFD)

Designing products for easy disassembly after use.

Recycling

Recovering materials for future use from products.

Cost Savings from Recycling

Reduces costs and addresses environmental concerns.

Design for Recycling (DFR)

Designing products to facilitate recovery of recyclable parts.

Standardization

Absence of variety in products or services produced.

Advantages of Standardization

Fewer parts, reduced costs, and improved quality control.

Disadvantages of Standardization

Less variety may decrease consumer appeal.

Mass Customization

Standardized goods with some degree of customization.

Delayed Differentiation

Postponing product completion until customer preferences are known.

Modular Design

Grouping components into easily replaceable modules.

Advantages of Modular Design

Easier repairs and lower training costs.

Disadvantages of Modular Design

Limited configurations and potential module scrapping.

Reliability

Ability to perform intended function under specified conditions.

Failure

When a product does not perform as intended.

Normal Operating Conditions

Conditions under which reliability is specified.

Robust Design

Products functioning over a broad range of conditions.

Ferrari Enzo

Example of a less robust automobile design.

Toyota Avalon

Example of a more robust automobile design.

Environmental Regulations

Laws requiring recyclability in products sold in the EU.

Supplier Suggestions

Recommendations from suppliers for product improvements.

Packaging Improvements

Enhancements to reduce costs or improve efficiency.

Combining Parts

Using multiple components together for efficiency.

Less Stringent Specifications

Relaxing requirements to save time or costs.

Product Life Stage Strategies

Approaches for managing different stages of product life.

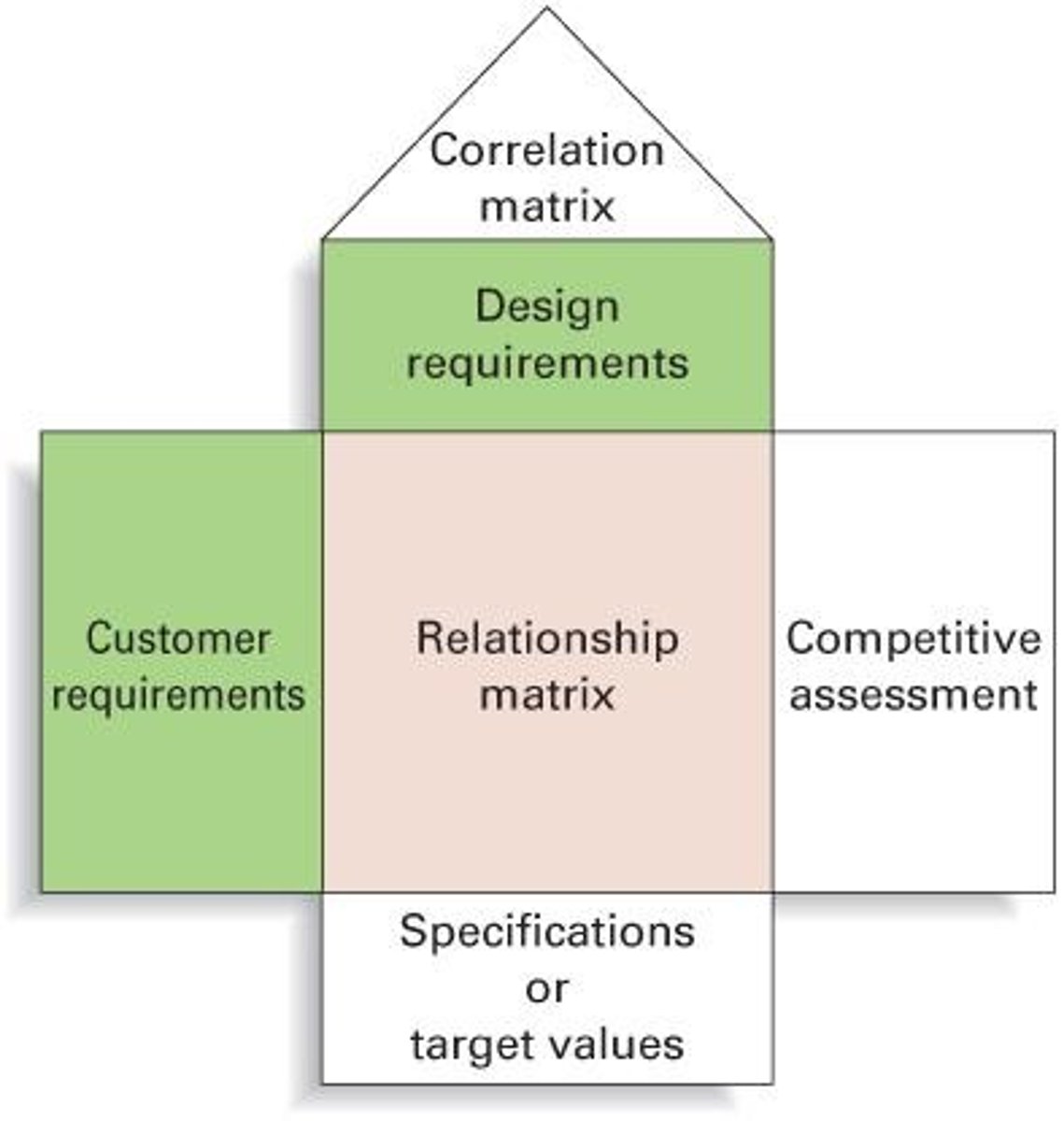

Quality Function Deployment (QFD)

Integrates customer voice into product/service development.

Voice of the Customer

Customer requirements influencing product/service design.

Customer Requirements

Factors ensuring customer satisfaction in development.

Listening to Customers

Central feature of Quality Function Deployment.

Kano Model

Framework categorizing customer satisfaction factors.

Basic Quality

Limited effect on satisfaction; dissatisfaction if absent.

Performance Quality

Satisfaction proportional to functionality and appeal.

Excitement Quality

Unexpected features causing customer excitement.

Phases in Design & Development

Steps from feasibility analysis to follow-up evaluation.

Feasibility Analysis

Assessment of project viability before development.

Prototype Development

Creating initial models for testing concepts.

Design Review

Evaluation of design before production begins.

Market Test

Trial phase to gauge product acceptance.

Product Introduction

Launching product into the market.

Follow-up Evaluation

Assessing product performance post-launch.

Concurrent Engineering

Integrating design and manufacturing early in process.

Cross-Functional Teams

Collaboration among various departmental personnel.

Production Requirements

Consideration of capabilities in design process.

Design for Manufacturing (DFM)

Designing products compatible with manufacturing capabilities.

Design for Assembly (DFA)

Focus on reducing parts and improving assembly.

Manufacturability

Ease of fabrication and assembly in production.

Component Commonality

Using similar parts across multiple products.

Service Delivery System

Facilities and processes for providing a service.

Product Bundle

Combination of goods and services for customers.

Service Package

Resources and features included in service delivery.

Service Design

Strategy determining service nature and target market.

Service Design Issues

Variation, customer contact, and involvement considerations.

Differences in Service and Product Design

Tangible products vs. intangible services.

Service Visibility

Services are highly visible to consumers.

Operations Strategy

Design strategies to achieve competitive advantage.

Operations

The part of a business organization that is responsible for producing goods or services.

Operations management

the management of systems or processes that create goods and/or provide services.

Goods

physical items that include raw materials, parts, subassemblies, and final products.

Services

activities that provide some combination of time, location, form or psychological value.

inputs; outputs

Value-added is the difference between the cost of __________ and the value or price of __________.

goods and services.

Product packages are a combination of ________.

more competitive.

Product packages can make a company _____________.

Supply Chain

a sequence of activities and organizations involved in producing and delivering a good or service.

Suppliers' suppliers > direct suppliers > producer > distributor > final customers

Supply Chain order

basic function of the business organization

Challenges of managing services

1.Jobs in services are often less structured than in manufacturing

2.Customer contact is generally much higher in services compared to manufacturing

3.In many services, worker skill levels are low compared to those of manufacturing employees

4.Services are adding many new workers in low-skill, entry-level positions

5.Employee turnover is high in services, especially in low-skill jobs

6.Input variability tends to be higher in many service environments than in manufacturing

7.Service performance can be adversely affected by many factors outside of the manager's control (e.g., employee and customer attitudes)

wasteful costly

Supply > Demand

Opportunity loos customer dissatisfaction

Supply < Demand

Ideal supply and demand

Supply = Demand

Process

one or more actions that transform inputs into outputs