Finals-Engineering Graphics

1/115

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

116 Terms

Technical Drawings serve one of three purposes:

1) visualization

2) Communication

3) Documentation

Stages of Design Process

1) Problem identification

2) ideation

3) Refinement/Analysis

4) implementation/ Documentation

Concurrent Engineering

systematic approach that integrates the design and manufacture of products with the goal of optimizing all elements involved in the life cycle of the product (Efficient and saves money)

Sequential Engineering

Step by step approach to product development where each phase must be completed before the next begins. (Time is wasted and inefficient)

Life Cycle design

includes all aspects of a product except disposal and recycling.

Types of projections

Broken down into 2 main types: Perspective and parallel

Phantom line

Thin line of alternating long and short dashes. used to show alternate positions for moving parts and the positions of related or adjacent parts, and to eliminate repeated details

Cutting plane line

thick, dashed line used in technical drawings to indicate where an imaginary cut has been made through an object to reveal its interior features

Short-Break line

thick lines to indicate a break in an object, essentially showing that a part of the object has been shortened to save space on the drawing, while assuming the removed section is identical to the visible parts on either side

Centerline

Dark thin line which is just 3 dashes (long short long with the short dash in the middle)

Shows the axis of symmetry for a feature or part

indicates path of motion

shows the location for bolt circles and other circular patterns

Symmetry Lines

Dark, thick lines. indicates the axis of symmetry on an object

Dimension line

Thin line with arrowheads at each end that indicates size

Hidden line

Dark and thin dashes. lines in technical drawings that indicate edges, surfaces, or corners that are not visible from a given viewpoint

Visible line

a solid, thick line that outlines the visible edges and surfaces of an object

Section line

thin, parallel lines that indicate the cut surfaces of an object in a section view (Usually at an 45 degree angle)

Extension line

thin, vertical line, used to demonstrate the extent of a dimension or to indicate the boundaries of an object, often extending from the object to the dimension line.

Long-break line

thin solid lines that have zigzags to indicate a break

Drawing scale

the reduction or enlargement of the drawn object relative to the real object

Sens serif

means letters without this curves or spurs

Lettering standards

3 mm (1/8 in) tall

Sans serif

Spacing of letters and words

Letters:

- DO NOT SPACE YOUR LETTERING CAUSE IT WILL APPEAR UNEQUAL

Words

- Be sure to leave space between rows of lettering, usually equal to the letter height

Standard US sheet size measurements

A) 8.5×11 inch

B) 11×17 inch

C) 17×22 inch

D) 22×34 inch

Surfaces can be one of the following four types

1) planar

2) single curved

3) Double curved

4) Warped

Contours

Contrast between the positive and negative space

Edges

solid formed where 2 surfaces intersect

Vertices

A vertex of a solid is formed where 3 or more surfaces intersect

Point

Used to represent a location in space, has no width height or depth

Line

Used to represent the edge of a solid object

Important skills for sketches and drawings:

1) Accuracy

2) Speed

3) Legibility

4) Neatness

4 principle types of projection

1) Multiview

2) Axonometric

3) Oblique

4) perspective

Six standard views

top, bottom, left, right, front, and back

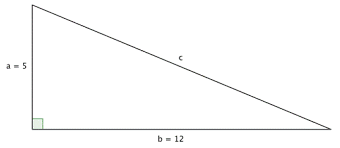

3 principle dimensions

1) height: Shown in the rear, side, and front views

2) Width: shown in the rear and top views

3) Depth: Shown in the side and bottom views

Third angle projection

Views are produced as if the observer is outside looking in. Mostly used in the US

First angle projection

Object is placed above the horizontal plane and in front of the vertical plane. Object is in the 1st angle

Precedence of lines

1) Visible

2) Hidden

3) Cutting

d) Centerlines

e) phantom

Views of surfaces

normal, inclined, oblique

3 aspects of good dimensioning

1) Technique of dimensioning

2) placement of dimensions

3) Choice of dimensions

Tolerance

The total amount that the feature on the actual part is allowed. Vary from what is specified by the drawing or model dimension

What are the lines used in dimensioning?

Dimension line, extension line, and centerlines

Dimensioning rules

1) There should be a visible gap between object and origin of extension line

2) Do not cross dimension line

3) Preferred dimension placement is off the view (NEVER INSIDE)

4) Each feature of an object is dimensioned once and only once

5) dimension lines should be aligned and grouped where possible to promote clarity and uniform appearance

6) when extension lines cross DONT BREAK. Break line when extension and dimension line meet

Leader

Thin, solid line directing attention to a note or dimension and starting with an arrowhead or dot

Leader rules

do not make leaders parallel to nearby lines of a drawing

do not make leaders through a corner of the view

do not make leaders horizontal or vertical (45 degree angle)

Reference

( )

Countersink

Depth

Spot face

Counterbore

Arc length

Slope

dimension origin

conical taper

Places, times, or by

X

Superfluous Dimensions

Unnecessary dimensions

Dimensioning Angles

Angles are dimension by specifying the angle in degrees and a linear dimension

Dimensioning Arcs, fillets, and rounds d

Circular arc is dimensioned in the view where its true shape is seen by giving the value for its radius and preceded by the abbreviation R.

Dimensioning cylinders

Cylinders are usually dimensioned by giving the diameter and length where the cylinder appears as a rectangle

Dimensioning holes

The leader of a note should point to the circular view of the hole (if possible)

Finish mark

Used to indicate that a surface is to be machined, or finished, as on a rough casting or forging.

3 basic application of threads

1) To hold parts together

2) To provide for adjustment between parts

3) To transmit power

Axis

Imaginary line that runs through the center of a thread screw

Pitch

distance parallel to the axis between corresponding points on adjacent threads

Root

Bottom of the groove between two sides of a thread

Crest

highest point on a thread

Side

Also called the flank

Minor diameter

smallest diameter of the thread

Major diameter

largest diameter of the thread

Pitch diameter

diameter of an imaginary cylinder that passes through the thread profile

Depth

Distance between the base and the crest of the thread, measured perpendicular to the axis

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does ¾ represent?

Major diameter of the thread

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does ⌀ represent?

Diameter

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does 10 represent?

Threads per inch

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does N represent? (NC)

National (form)

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does C represnt? (NC)

Course thread series

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does 2B represent?

Class of fit

⌀.6562-↧1.38 ¾ -10 NC-2B LH-↧1.00

What does LH represent?

Left-hand modifier

MJ 10 × 1.5

What does M represent?

Metric thd

MJ 10 × 1.5

What does J represent?

Metric thd form

MJ 10 × 1.5

What does 10 represent?

Major Dia pitch of thd

MJ 10 × 1.5

What does 1.5 represent?

Pitch

1.125-5 ACME - 2G (21)

What does 2 represent? (2G )

Class of fit

1.125-5 ACME - 2G (21)

What does G represent?

Thread type

1.125-5 ACME - 2G (21)

What does (21) represent?

Thread gaging system

3 types of helical springs

1) Compression - offer resistance to compressive force

2) Extension -offer resistance to compressive force

3) Torsion- mechanical spring that works by exerting torque or twisting force when it is twisted along its axis.

Runouts

Used to represent filets that connect with plane surface tangent to cylinders

Partial View

A view may not need to be complete but needs to show what is necessary to clearly describe the object

Removed view

complete or partial view removed to another place on the sheet so that it is no longer in direct projection with any other view

Section views are used for 3 main purposes

1) To document the design and manufacture of single parts that are manufactured as one piece

2) to document how multiple parts are to be assembled or built

3) to aid in visualizing the internal workings of a design

Cutting plane view

Appears edgewise as thick dashes line called cutting line plane. The arrows at the ends of the cutting-plane line indicate the direction of sight for the sectional view.

Visible edges

Newly visibly edges cut cutting plane are crosshatched with section lining

Placement of section views

section views can replace standard orthographic views

Rules for lines in section views

Show edges and contours that now visible behind the cutting plane

omit hidden lines in section views

A sectioned area is always completely bounded by a visible outline-never by a hidden line

A visible line can never cross a sectioned area in a view of a single part

Section-lining technique

uniformly spaced by an interval of 2.5 mm

not too close together

Uniformly thin

distinctly thinner than visible lines

Lines should NEVER be parallel/ perpendicular to outline

Half section

exposes the interior of half of the object and the exterior of the other half. (symmetrical)

Broken out section

It often happens that only a partial section of a view is needed to expose interior shapes.

Revolved section

The shape of the cross section of a bar, arm, spoke or other elongated object can be shown

offset section

in sectioning complex object, it is often desirable to show features that do not lie in a straight line by “Offsetting” or bending the cutting plane.

(Remember the moving thing Prof did to look at inside parts of a shape that was not in a straight line)

Ribs in section

To avoid giving a false impression of thickness and solidity, ribs, webs, gear teeth, and other similar flat features are not hatched with section lining even though the cutting plane slices them

Aligned section

When parts with angled elements are sectioned, the cutting plane may be bent to pass through those features. The plane and features are then imagined to be revolved into the original plane.

Conventional Breaks and sections

Used to shorten the view of an object that is too long to show clearly at one scale on the drawing sheet

Auxiliary plane

To show the inclined surface true size, the direction of sight must be perpendicular to the inclined plane.