MECH2305 - Ceramics, Composites and polymers

1/23

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

24 Terms

Why are dislocations difficult in ceramics

Slip is extremely difficult due to ionic/covalent bonds, which cause shattering upon enough force.

How to shape ceramics

Powder metallurgy (general ceramics)

Slip casting (Clay)

Glass methods

Slip casting process

Clay slurry poured into mould

Mould absorbs moisture from slip, forming solid clay.

After thickness is developed, excess is poured out.

Dried and sintered.

Allows for complex shapes.

Characteristics of glass

Microcracks over surface, causing breakage at low tensile stress

Removing cracks with acid greatly increases strength

Liquid at high temperatures

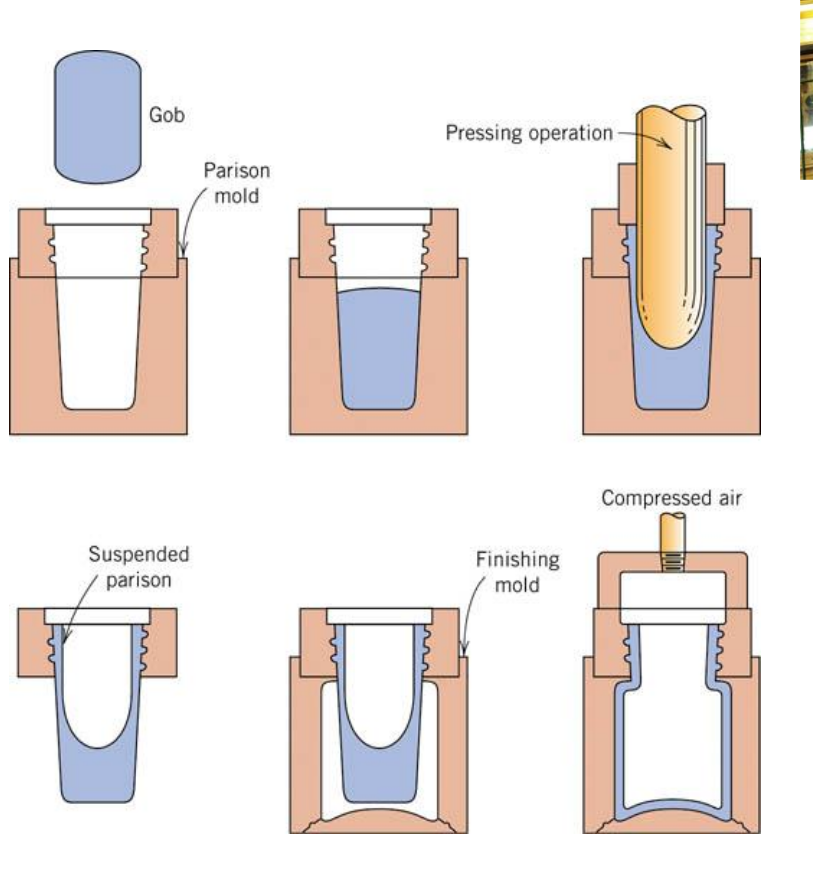

How to form glass bottles

Press glass glob into mould

Blown into final shape.

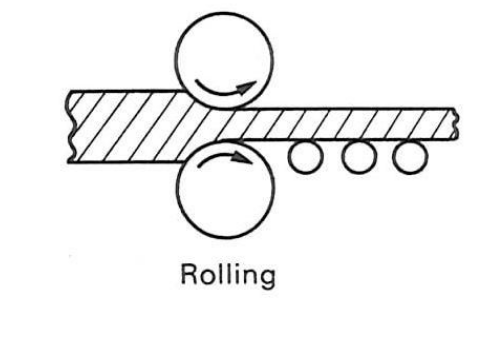

Rolled glass

Roll molten glass between two rollers so sheet is perfectly flat

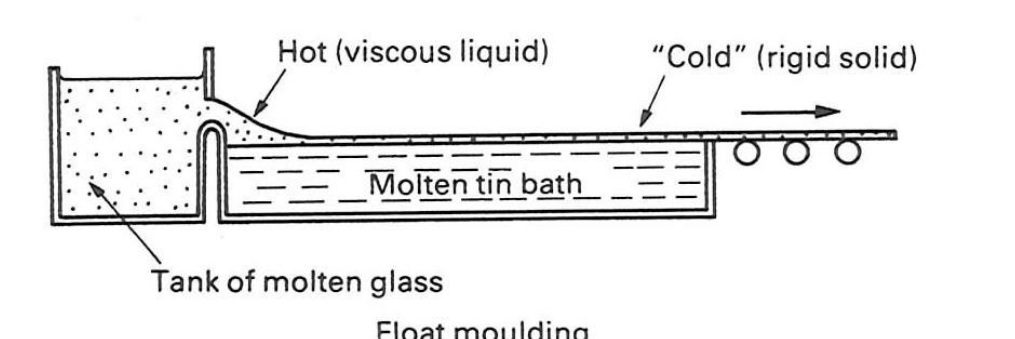

Float glass

Molten glass is floated off on bath of molten tin, creating very flat panes.

Laminated glass

Two or more layers are bonded by thin polymer layer

Tempered glass properties and process

Extremely strong, created through heating glass, cooling surface, forcing inside to go into compression

Polymers

Long molecules of repeating structures called monomers, extremely ductile, because long strands can simply decoil.

Thermoplastics

Polymers that can be heated and melted

Thermosets

Cross linked polymers cannot melt, heating simply causes burn

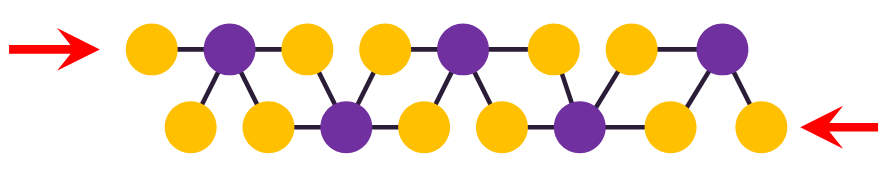

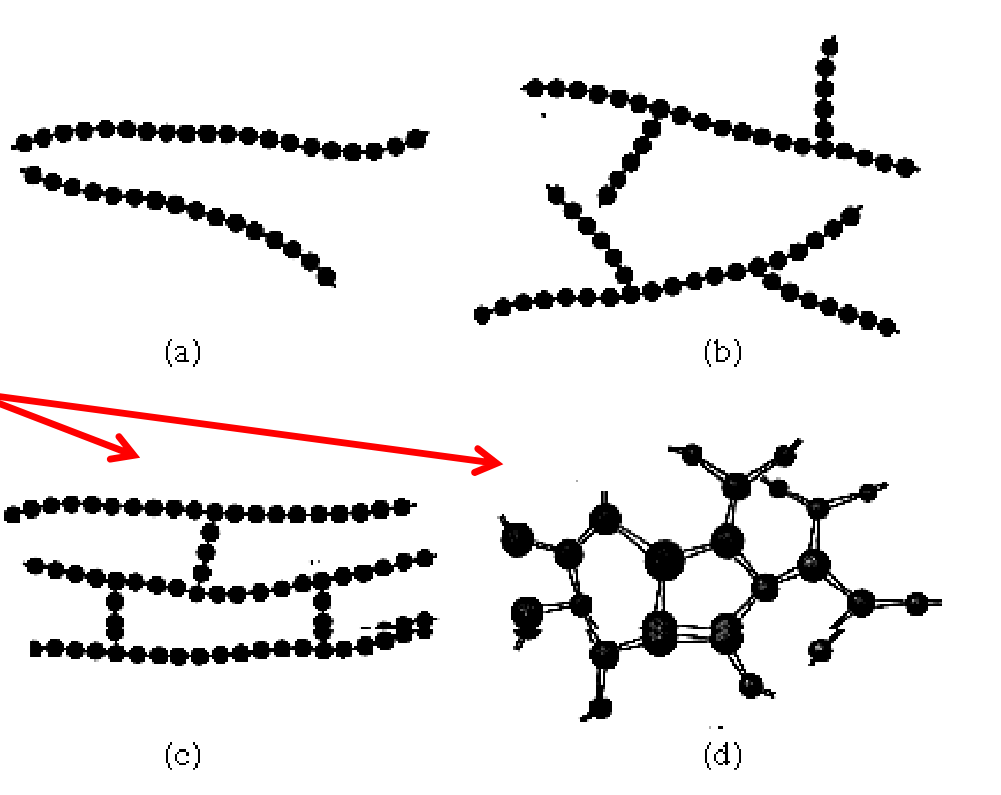

4 Polymer structures

a.) Linear polymer (straight line)

b.) Branched polymer (branches)

c.) Cross linked polymer

d.) Network polymer

Polymer crystallinity

Long random intertwined polymer chains, increasing density, strength and hardness

Glass transition temperature

Temperature where sharp decrease in mobility

4 Ways to process polymers

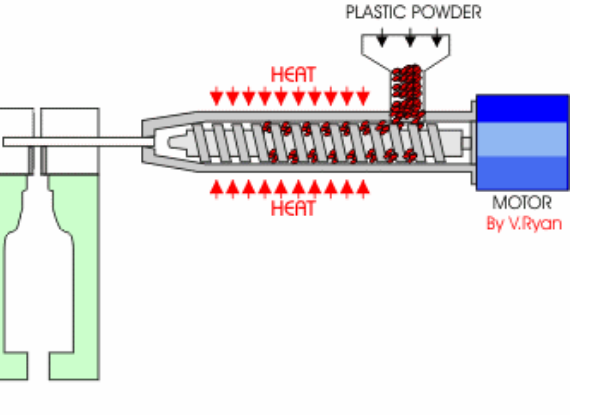

Extrusion

Injection moulding

Blow moulding

Blown film

Injection moulding process

Molten material injected into mould under high pressure

Advantages of injection moulding

Fast and efficient

Forms complex shapes

Low waste

Disadvantages of injection moulding

High initial costs

Thin walls are dificult to mould

Long lead time (takes months to create)

Blow moulding

Gas is used to expand hot viscous polymer against steel die

Blow moulding advantages & disadvantages

Very good to create hollow parts

Seamless construction

Very limited wall thickness control

limited shapes can be made

Composites

Mixtures of two different materials to create a new one with different properties

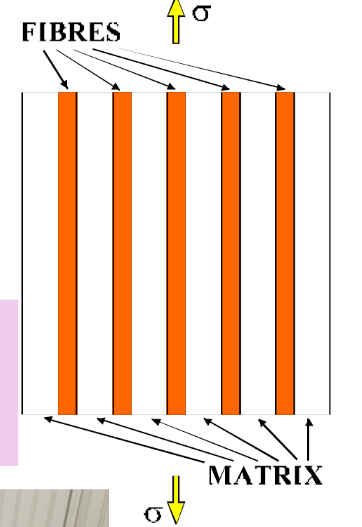

Fibre reinforced composites

Contain fibres in a matrix, causing a lightweight strong material

Fibre reinforced composite good and bad

Crack size is limited by change in material throughout matrix

Material is unfortunately highly anisotropic (i.e. directional)