21.7 Machining Operations for Special Geometries

1/14

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

15 Terms

Screw threads

can be defined as grooves that form a spiral around the outside of a cylinder (external threads) or the inside of a round hole (internal threads)

Thread rolling

most common method for producing external threads, but the process is not economical for low production quantities and the work metal must be ductile

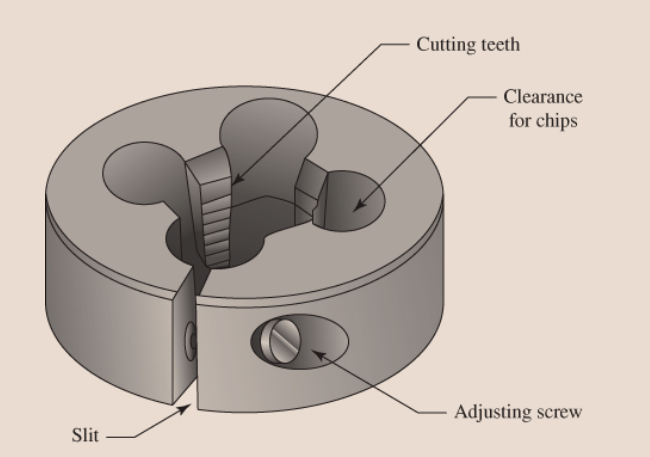

What is depicted?

Threading die

self-opening threading dies

designed with an automatic device that opens the cutting teeth at the end of the cut. This eliminates the need to unwind the die from the work and avoids possible damage to the threads

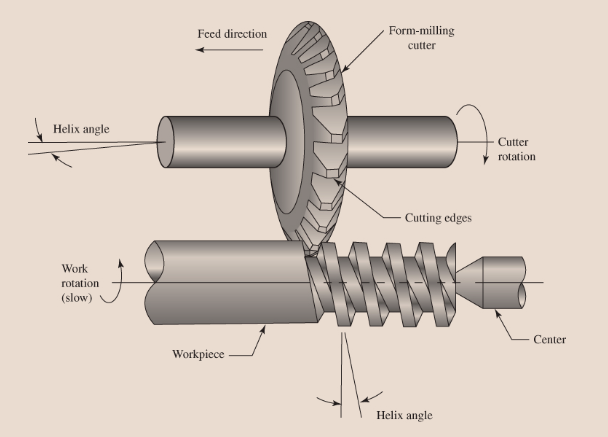

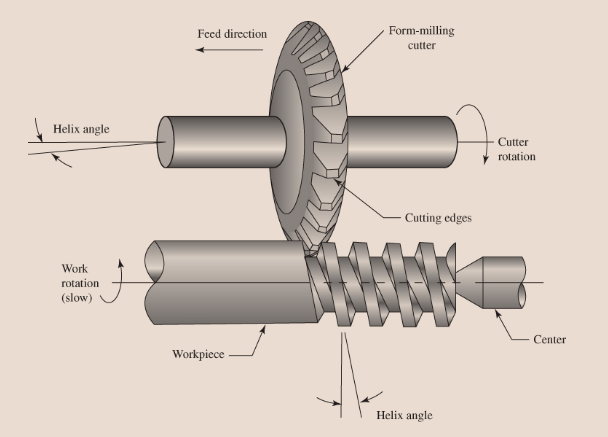

Thread milling

involves the use of a form-milling cutter to shape the threads of a screw. Both internal and external threads can be produced

Possible reasons for preferring thread milling over thread chasing

(1) the size of the thread is too large to be readily cut with a die, (2) the gear is made of a difficult-to-machine material, and (3) thread milling is generally noted to produce more accurate and smoother threads.

Thread grinding

similar to thread milling except the cutter is a grinding wheel with the shape of the thread groove, and the rotational speed of the grinding wheel is much greater than in milling

tapping

a cylindrical tool with cutting teeth arranged in a spiral, whose pitch is equal to that of the desired screw threads, is simultaneously rotated and fed into a preexisting hole

Collapsible taps

cutting teeth that automatically retract into the tool when the thread has been cut, allowing it to be quickly removed from the tapped hole without reversing spindle direction

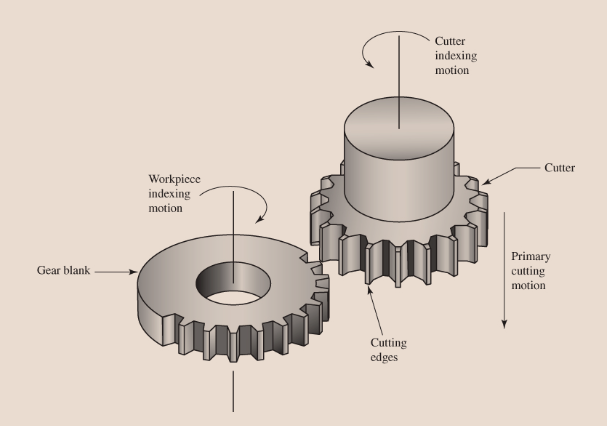

The principal machining operations used to cut gear teeth are

form milling, gear hobbing, gear shaping, and gear broaching

Form milling pros & cons

disadvantage: production rates are slow because each tooth space is created one at a time and the gear blank must be indexed between each pass to establish the correct size of the gear tooth, which also takes time.

advantage: milling over gear hobbing (discussed next) is that the milling cutter is much less expensive. The slow production rates and relatively low-cost tooling make form milling appropriate for low production quantities.

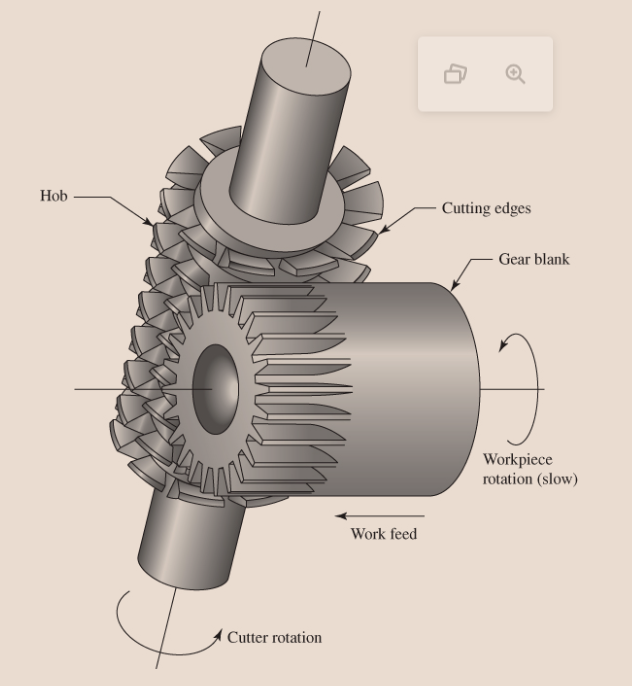

Gear Hobbing

For smaller batch sizes, they are not economical because of the cost of special tooling

Gear shaping

noted for short production cycle times and high tooling cost

Gear shaving

involves the use of a gear-shaped cutter that is meshed and rotated with the gear, and the cutting action results from reciprocation of the cutter during rotation

Gear burnishing

plastic deformation process in which one or more hardened gear-shaped dies are rolled in contact with the gear, and pressure is applied by the dies to effect cold working of the gear teeth