Impression Materials: Linking of Labs to Clinics- Biomedicine in Relation to Dentistry III BDS3

1/45

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

46 Terms

How do we fabricate an indirect restoration?

The first step is to record an accurate impression, followed by casting up, investment of the pattern to a mould (lost wax technique) and construction of appliance

When are indirect restorations indicated?

Indicated when there is significantly less natural tooth remaining

Indirect restorations- less intraoral shrinkage

Greater morphology control

Allows use of machined or pressed ceramics

Higher degrees of polymerisation

Cost benefit basis for the patient

What materials do we use for indirect restorations?

Rigid materials:

High modulus of elasticity that can resist high stress without permanent distortion. Many behave as a brittle material

Ceramics: rigid and brittle

Pure gold: ductile

What are impression materials used for?

To record & reproduce the form and relationship of teeth and oral tissues and to record accurate impressions for appliances constructed outside the mouth

What are the 2 types of impression trays?

Stock trays: metals (reusable); polystyrene, nylon (disposable)

Custom trays: disposable

What are the 2 main classifications of impression materials?

1. Elastic materials: synthetic elastomers (e.g. silicones, polyethers); hydrocolloids (e.g. agar, alginates)

2. Non-elastic materials: impression plaster, zinc oxide pastes, impression compound, impression waxes

What are the ideal requirements of impression materials?

Accuracy

Rheological properties

Dimensional stability (short & long term)

Adequate thermal properties

Adherence to tray

Disinfection

Compatibility with model & dye materials

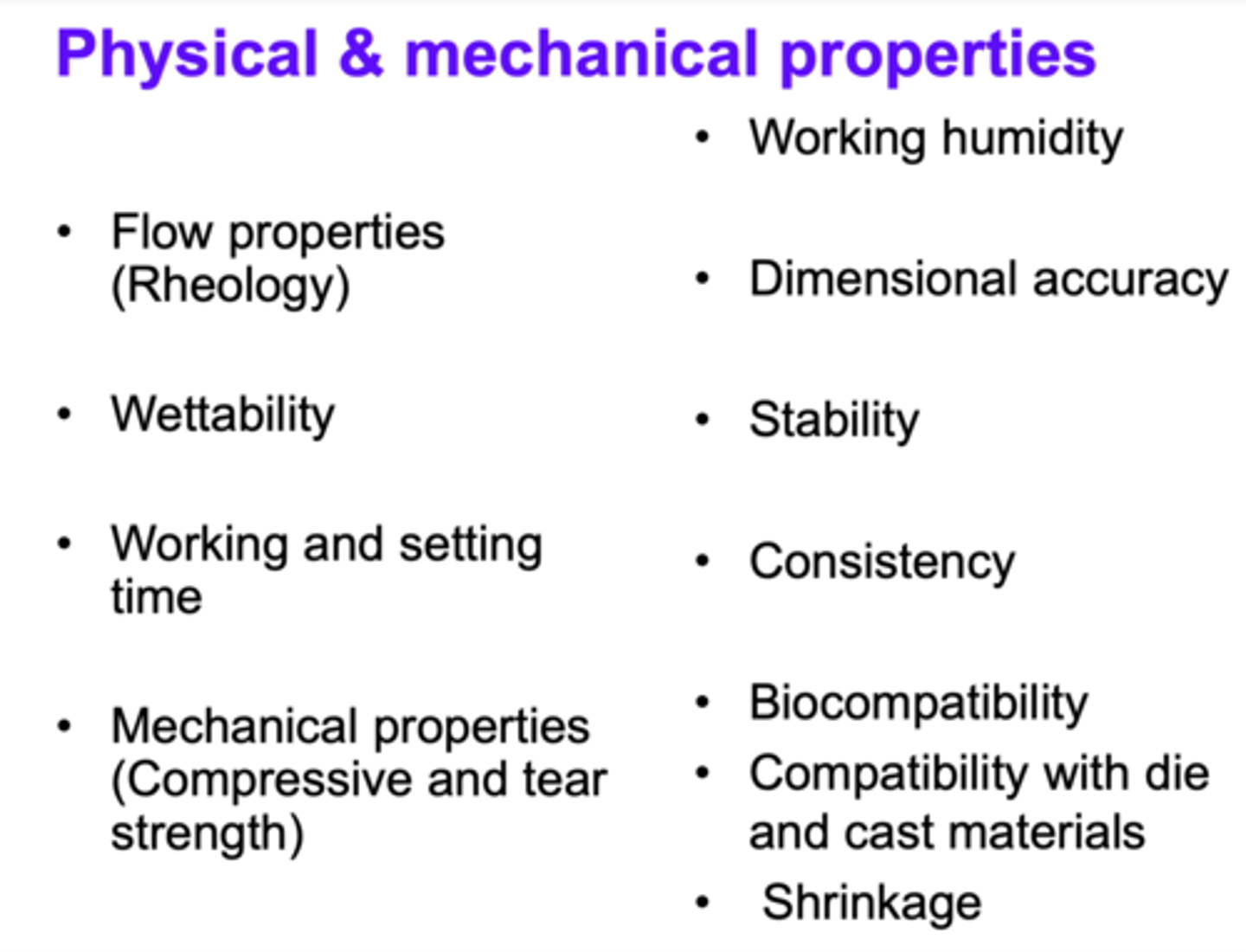

What should the physical & mechanical properties of impression materials be?

What is rheology?

The study of flow or the deformation of materials

It involves the measurement of viscosity and its variation with factors such as shear rate and time

What is the formula for viscosity?

η = shear stress/ shear rate

What does viscosity indicate in simple terms?

The consistency of a fluid

In scientific terms, it is a measure of a fluid's resistance to flow

How do we work out shear stress?

Shear stress = K(shear rate)^n

What is shear thinning?

Applying shear stress to the material (making it thinner), which increases flow and decreases viscosity (pseudoplastic)

What is shear thickening?

When viscosity increases as shear rate increases (dilatant materials)

Describe high/medium/low viscosity.

High viscosity: may not flow over undercuts, but provides a body for the impression

Medium viscosity: flow improves but may not be adequate for very accurate impressions

Low viscosity: Good flow, but still should be moderate otherwise may drip!

Why is wettability an important property to consider for impression materials?

Because you have to consider how it interacts with saliva

If it's hydrophobic: repelled by moisture- you get blow holes

If it's hydrophilic: good flow but may swell on storage

Which type of material is better suited to the oral environment: hydrophilic or hydrophobic?

Hydrophilic materials are more suited to the moist oral environment

However, hydrophilic materials tend to absorb moisture and undergo dimensional changes on storage

What do we mean by accuracy of impression materials?

Their ability to replicate the intraoral surface details

By what two means do impression materials set?

An impression material sets by either

-chemical change

-physical change of state

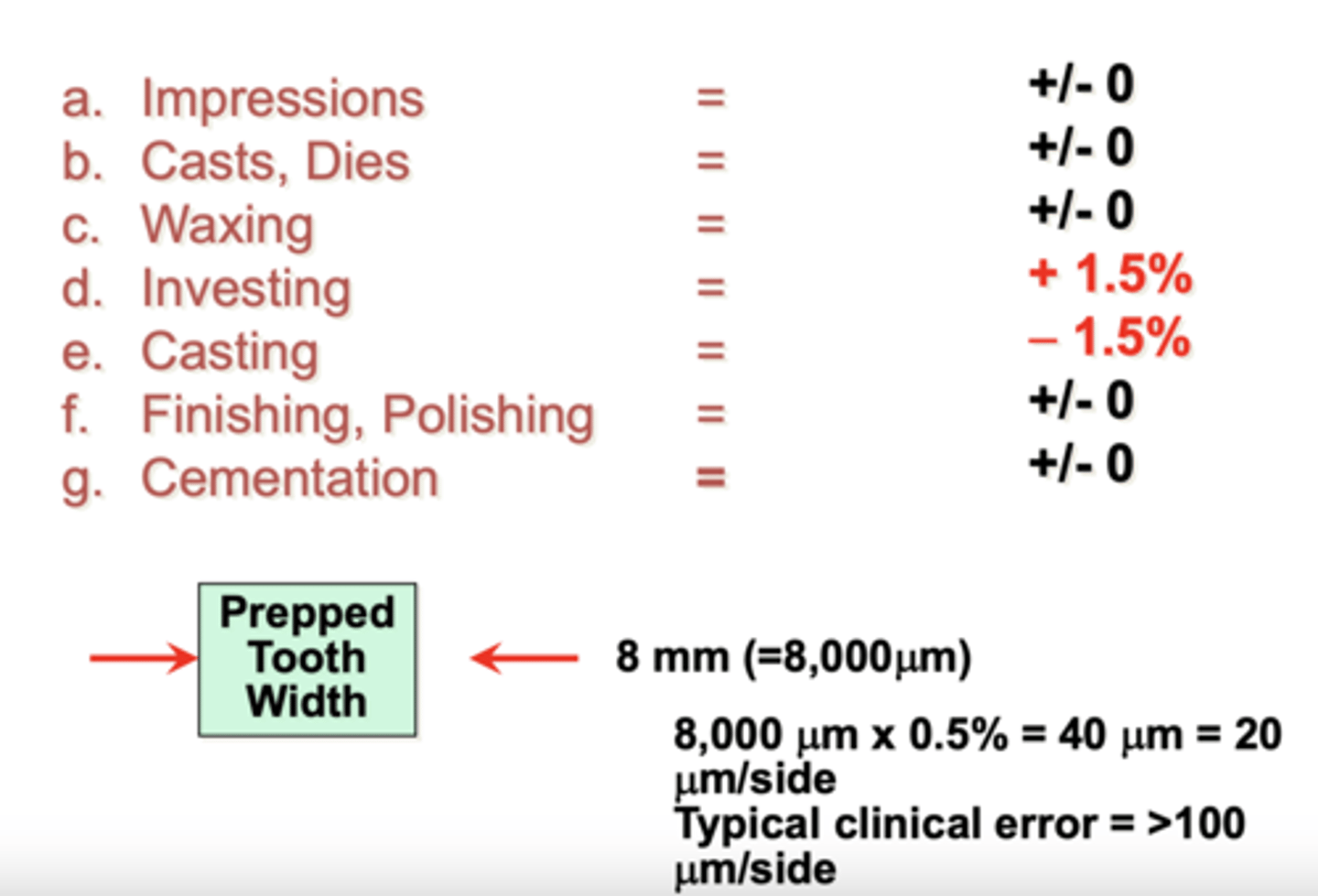

What does 0.1% shrinkage mean clinically and what are tolerable limits for 'error' in clinical procedures

How can we manage shrinkage?

If you take a heavy body material which has a high filler content, and therefore would contract less, and place it on the tray whilst you cover the tooth with a thin amount of light bodied impression material (so that the material is able to flow), then this will minimise shrinkage

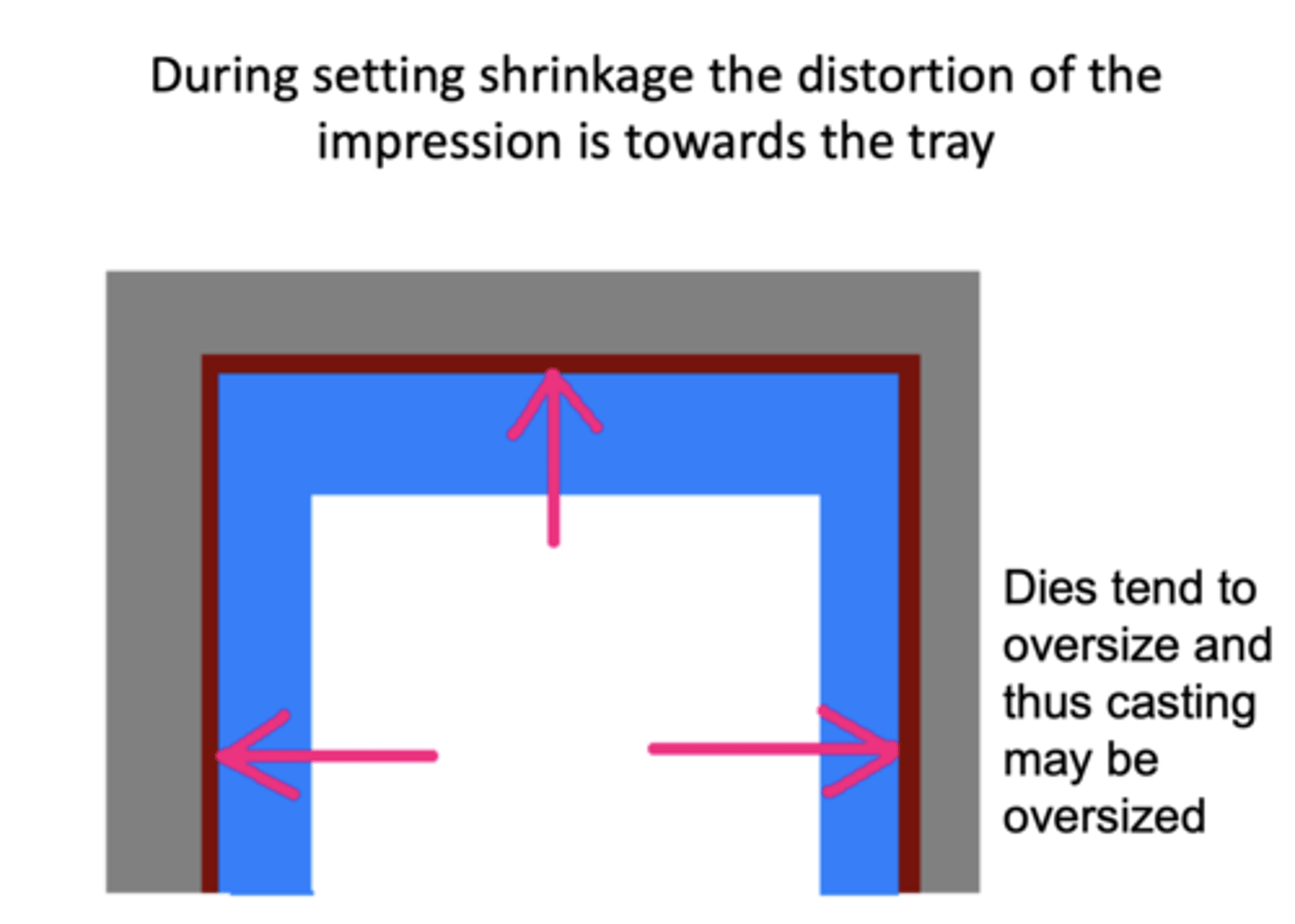

Illustrate the shrinkage that can occur on setting of an impression material.

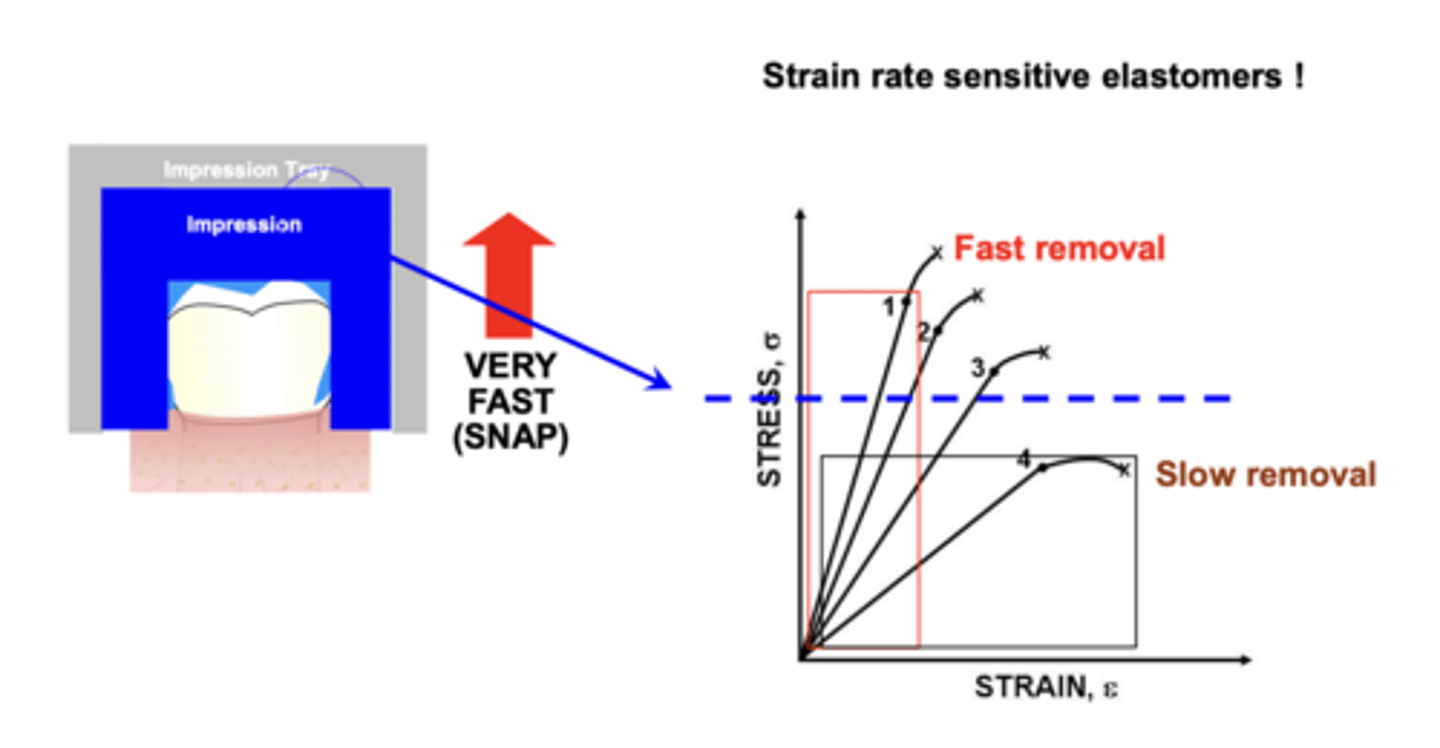

Why is it recommended to remove an elastomeric impression material from the mouth with a 'snap'?

Because they are strain rate sensitive elastomers

What is the working time?

The amount of time you have to allow proper mixing and dispensing of the impression material in a flowable state when the viscosity of this mix does not rise

What is another factor that affects impression dimension accuracy?

Uniform thickness of impression material- this provides equal dimensional change during setting

What happens if you don't have uniform thickness of impression materials?

Too thick = increased polymerisation shrinkage

Too thin = increased % strain during removal and more viscoelastic flow possible

What is dimensional stability?

On storage the impression should not expand or contract, absorb moisture or dehydrate

A minimum or no change in dimension should occur during storage of the impression

What factors affect dimensional stability?

Continued setting reaction

Slow elastic recovery may continue after withdrawal of the impression

Distortions due to recovery of internal stresses

Loss of volatile components

Uptake of moisture

Why does the coefficient of thermal expansion of the impression material also have an effect on the accuracy of impressions?

Mouth Temperature- 32 to 37 0C

Room temp- 21-25 0C

When the impression material is taken out of the mouth, thermal contraction may lead to inaccurate impressions

How can you minimise thermal contraction?

By having the coefficient of thermal expansion of the material similar to that of the stock tray

What mechanical properties are relevant in terms of impression material?

Resistance to tear

Thin sections should withstand stresses generated during removal of impressions

Tear strength: should be high since external force is applied to remove the impression

Compressive strength: adequate

Why is tear strength an important property for impression materials to have?

Because it's very important for sulcus reproduction and sulcus response so always inspect closely for residual material in the sulcus as impression material remaining in the sulcus can lead to severe periodontal reaction

What are the requirements in terms of biocompatibility for impression materials?

Acceptable taste and odour

Non toxic (no irritation to oral mucosa)

What are the minimum tests that need to be done for an impression material before it can be used in the mouth?

In vitro cytotoxicity

Ames test for mutagenicity

Mucous membrane irritation (Hamster's pouch test)

Sensitisation test (animal models)

Carcinogenicity

What 2 other factors are advantageous for an impression material to have?

Long shelf life

Cheap

What are the currently available delivery systems for impression materials?

Currently available options:

Pad-mix

Automix- less bubbles produced in impression

Syringes- keep diameter narrow to maximise the pseudoplasticity effect

Bulk mixers- for 500ml cartridges

The use of an auto-mix system has been shown to reduce the number of voids in impressions when compared to the traditional pad-mix method and so auto-mixed addition silicone materials are claimed to have excellent properties

What is the best way to mix dilatant, Newtonian, and pseudoplastic materials?

Dilatant & Newtonian fluids are best mixed on mixing pads (eg silicone) whilst pseudoplastics such as polyether and poly vinyl siloxane can be mixed in auto mixing tips

What are some examples of non-elastic impression materials?

Plaster of Paris/Impression plaster

Impression compound

Zinc oxide-eugenol

Impression waxes

What is the main constituent of impression plaster?

Main constituent is calcined ß calcium sulphate hemihydrate and mixing with water yields rigid calcium sulphate dihydrate

How can you reduce expansion on setting of impression plaster?

The addition of potassium sulphate

What does potassium sulphate do?

Potassium sulphate accelerates the reaction thus borax is added to retard the rate of reaction

What are some properties of impression plaster?

Can record fine details, initially has low viscosity, small dimensional changes may occur however the material is very brittle

Why is the treatment of impression plaster before casting a plaster model crucial?

Because otherwise it's impossible to separate the two

What are the properties of the two types of impression compound?

Thermoplastic in nature: Consist of resins such as colophony, shellac, talc as fillers and lubricants (stearic acid)

Type I: Lower fusing materials

-available as thick sheet, can be used for edentulous patients

Type II: Higher fusing materials

-used as tray materials

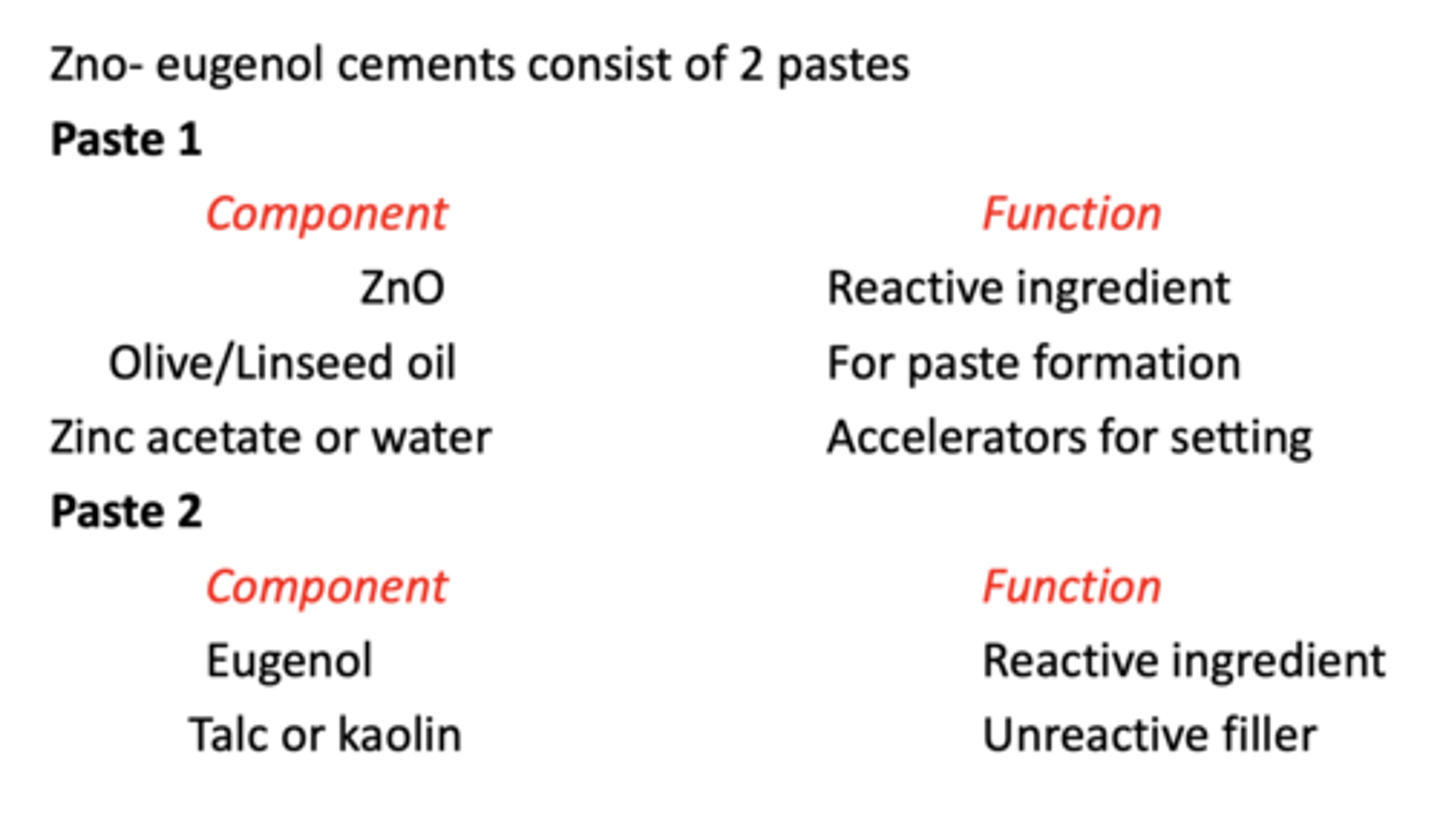

Describe the composition and function of the two pastes that constitute zinc oxide-eugenol cements.

How do zinc oxide-eugenol cements work and what are its limitations?

Two molecules of eugenol react with zinc oxide to yield zinc eugenolate

Pastes of 1 mm thickness are used to minimize dimensional changes

Major problem is a lack of elasticity

Set material has a tendency to distort or fracture when removed from undercuts