Fusion Welding

1/27

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

28 Terms

What is welding?

A joining process where two or more parts are coalesced at their faying surfaces by heat and/or pressure, often using filler material.

What is a weldment?

An assembly of parts joined by welding.

What is a faying surface?

The surface in contact at a joint to be welded.

What are key advantages of welding?

Permanent joint

can be stronger than base materials

economical

can join similar or dissimilar metals

usable in the field

What are major limitations of welding?

Labour intensive

potential defects/difficult inspection

dangerous

non-disassemblable

What is a weld joint?

The junction of edges or surfaces joined by welding.

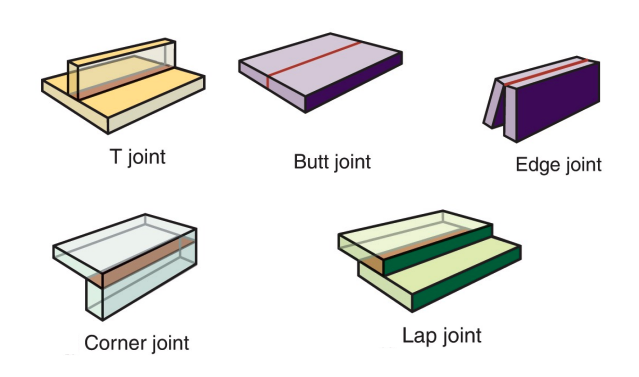

What are the main types of weld joints?

Butt

corner

lap

tee

edge

What are the main types of welds?

Fillet weld [weld is beside workpieces]

groove (butt) weld [weld is between workpieces]

plug weld

slot weld

spot weld

seam weld.

![<p>Fillet weld [weld is beside workpieces]</p><p>groove (butt) weld [weld is between workpieces]</p><p>plug weld</p><p>slot weld</p><p>spot weld</p><p>seam weld.</p>](https://knowt-user-attachments.s3.amazonaws.com/c305d42e-dfbe-4faf-ae25-2ec2ca890264.png)

What distinguishes a fillet weld from a groove weld?

Fillet weld is beside the workpieces; groove weld is between them.

What is fusion welding?

A process using heat to melt base and filler metals to create a joint.

What is power density in welding?

Power input per unit area, defined as PD = P / A (watts per mm²).

Why is power density important in welding?

It influences whether the metal melts or vaporises and affects welding speed and quality.

What happens if power density is too low?

Heat is conducted away without melting the metal.

What happens if power density is too high?

Metal vaporises in the affected region.

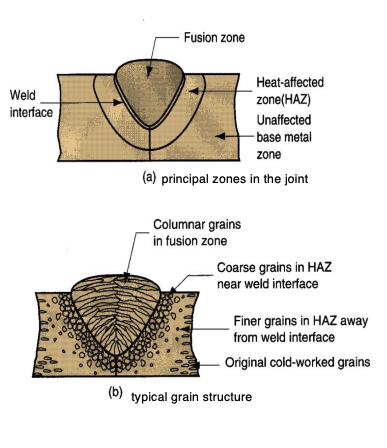

What are the zones in a fusion welded joint?

Fusion zone, weld interface (fusion line), heat affected zone (HAZ), and unaffected base metal zone (UBMZ).

What is the heat affected zone (HAZ)?

A region below melting that undergoes microstructural change, often reducing mechanical properties.

Where do welding failures often occur?

In the heat affected zone (HAZ).

What are residual stresses in welding?

Stresses remaining in a weldment after external loads are removed, caused by non-uniform heating and cooling.

What problems can residual stress cause?

Distortion, warping, cracking, and the need for costly treatments or fixtures.

How can distortion be minimised in welding?

Use welding fixtures

heat sinks

tack welding

control welding parameters

preheat

post-weld heat treatment.

How are fusion welding processes classified?

By energy source:

electrical (arc, resistance)

chemical

radiation (laser, electron beam).

What are the three fusion welding modes by filler use?

Autogenous (no filler)

homogeneous (same composition)

heterogeneous (different filler composition).

What is arc welding (AW)?

A process using an electric arc to melt the base metal and electrode, forming a joint.

What are consumable electrodes?

Electrodes that melt during welding and act as filler metal.

What are non-consumable electrodes?

Electrodes (like tungsten) that don’t melt but erode slightly during welding.

What is flux in welding?

A substance that protects the weld area from contamination, promotes wetting, and forms a slag.

Why is weld protection necessary?

To prevent oxidation and hydrogen/nitrogen contamination, which can weaken the weld.

What are three flux delivery techniques?

Granular flux onto welding operation

flux-coated stick electrodes that melt during welding

flux-filled tubular electrodes.