Textiles for interior designers

1/75

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

76 Terms

what is a shower-head like tool that viscose is forced through to form synthetic fibers?

A spinneret

Name 2 cellulose fibers

cotton and linen

name 2 protein fibers

wool and silk

cellulose fibers

A natural fiber made from plant cellulose, commonly used in textiles. Examples include cotton and linen.

protein fibers

Natural fibers made from protein, often sourced from animal hair or plant proteins. Examples include wool and silk.

textiles

Flexible materials made from fibers, used for making clothing, upholstery, and other fabric products.

Fibers

Raw materials that produce yarns & fabrics.

Yarns

Continuous strands made from fibers, used to create fabrics and textiles.

Fabrics

When fibers and yarns go through a weaving or knitting process to create a material.

cotton

A natural fiber derived from the seed fibers of the cotton plant, commonly used in textiles due to its softness and breathability.

linen

A natural fiber made from the flax plant, known for its durability, breathability, and ability to wick moisture.

wool

A natural fiber obtained from the fleece of sheep and other animals, valued for its warmth, elasticity, and moisture-wicking properties.

silk

A natural fiber produced by silkworms, prized for its luxurious texture, sheen, and ability to regulate temperature.

Mineral an metallic

Created from naturally occurring minerals including the metals gold, sliver, and copper.

manufactured fibers

Derived from synthetic chemicals, natural solutions are chemically treated.

viscose

Organic liquid regenerated into fibers for the making of textiles.

microfiber

manufactured fibers that are finer than all natural fibers, including silk.

cellulose

plant and wood fibers

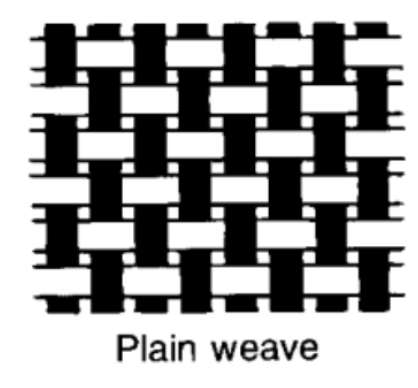

plain weave

made by the simple interlocking of warp threads and weft threads. (simple over under).

warp threads

vertical or lengthwise

weft

horizontal or crosswise

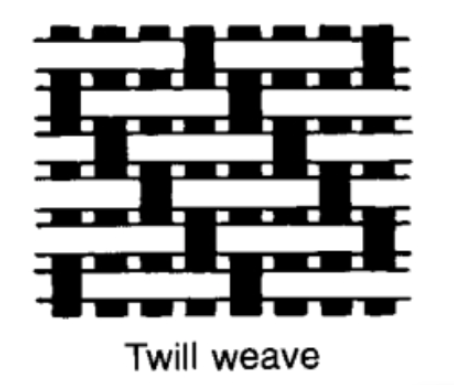

Twill weave

Two or more threads pass over or under another set of threads. skips at regular intervals to create a diagonal effect.

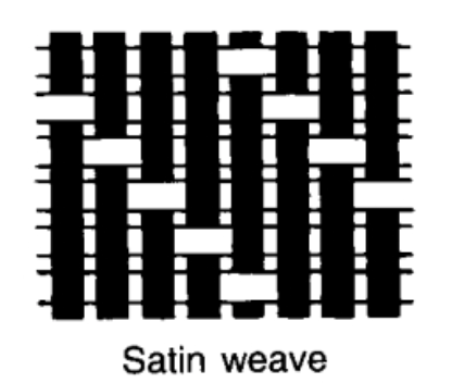

satin weave

floats one warp warn over four or more weft yarns. This makes the fabric really soft.

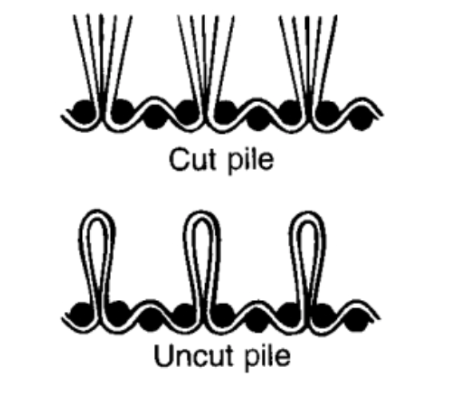

Pile Weave

produced by additional threads in weft or warp that form loops or tufts of yarn that stand out from service of the fabric. Loops can be cute or uncut.

Double cloth weave

woven in two attached in quilted appearance and gives off a quilted affect.

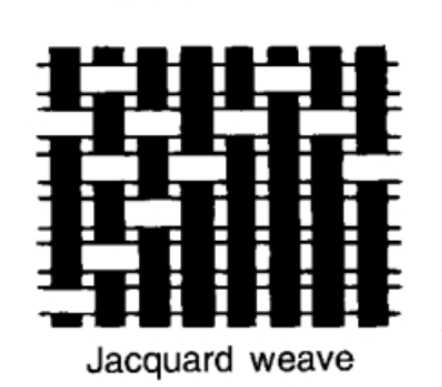

Jacquard weave

Requires an intricate series of hole-punched cards that tell the machine which threads to raise and which threads to drop.

Knitting

Knitting is a method of creating fabric by interlocking loops of yarn with blunt needles.

What is twisting?

Twisting is the process of interlocking and knotting yarn.

Felting

Process of subjecting a mass of fibers to moisture, heat, and pressure. Produces a compact sheet that doesn’t fray, absorbs sounds, provides insulation, and has high resistance to fire.

Bonding

results when two fabrics are adhered chemically or by heat.

Coloring

The process of adding color to materials, including textiles, through various means such as printing ad painting.

Dyeing

The method of applying color to fibers or fabrics using dyes allowing for uniform color throughout the material.

solution dyeing

coloring agent added to viscous l

Stock Dyeing

Dye applied to the fibers BEFORE processed into yarn.

Yarn dyeing

Skeins of yarn dyed BEFORE woven into fabric.

piece Dyeing

Dyeing the fabric AFTER its been woven.

Dye lot

Each time a new batch of color is mixed to dye fabric, it may slightly vary in color from the last one. This is why we have dye lots. It is IPERITIVE to make sure that all the fabric ordered for a job comes from the same dye lot, or else the colors might not match up exactly how me want them.

beetling

gives luster

bleach

whitens

calendering

Provides a smooth finish and tightens weave

chemical finishing

to improve flammability

Heat setting

Add stability, especially for permanent pleating.

Mercerizing

Soaking in caustic soda to cause fibers to swell, which results in improved luster and strength.

Peaching

produces a soft feel.

Pre-shrinking

Make it ready for finishing & prevent fiber contraction when exposed to moisture.

Raising

Produces a flannel like texture.

scouring

removes natural wax & non-fibrous impurities

Singeing

Removes surface fuzz or lint.

Antimicrobial finish

Help prevent mold and mildew.

Antistatic finish

Help guard against static.

Carefree finish

Help resist creasing or wrinkling.

Flame retardant finish

improve insulation qualities.

insulation finishes

improve insulation qualities.

moth proofing finishes

help prevent damage from insects.

soil repellent finish

help resist soiling.

water repellant finishes

helps resist against water and moisture.

hand printing

normally happens after woven and requires manual labor.

Batik printing

section of cloth are colored with wax, dipped into dye, then the wax is removed leaving a pattern.

Hand block printing

A hard wooden block is carved, lined with ink, and stamped onto fabric to create the design.

Tie dye

fabric is wrapped in string and knots, covered in dye, once strings are removed it creates a design.

silk screen

fabric screen resists the color except in desired areas.

machine printed

unlimited styles

roller printing

transfer of color from an engraved copper roller onto fabric.

embossing

engraved rollers produced a pressed high-low design into the fabric.

hand

the feel of the fabric.

wyzenbeek test

a test to count the number of times you can rub a fabric before it starts to wear.

commercial fabrics

25,000 rubs or more

residential fabrics

3,000 rubs per year

colorfastness

measure fabrics resistance to fading from the sun’s rays and from various cleaning methods.

crocking

the color rubbing off onto another fabric or skin.

flammability