Cellar and winery waste management exam study set

1/167

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

168 Terms

What is the philosphy of cleaner production?

Prevention better than cure

What is the conventional approach to waste minimisation in comparison to the cleaner approach?

CONVENTIONAL:

reactive

pay premium for disposal

CLEANER:

proactive

reduce/eliminate waste at the source

What are the benefits of cleaner production?

compliance at lower cost and less treatment/disposal

more efficient utilisation of resources and improved productivity

better quality of products/services

enhanced corporate image

improved OHS and employee relations

cost savings

What is involved in the cleaner production protocol?

Identify critical waste parameters

⬇

audit waste generation activities

⬇

devise practical methods for waste minimisation

⬇

assess benefits and costs

⬇

implement waste minimisation program

Why characterise WW?

to aid in design of treatment plan

to monitor and control operations

to meet legal requirements

to detect long-term trends

In the classification of WWW, what are some common test groups?

gross pollution measures → BOD, COD, grease, SS, NH3

tests for aesthetic appeal → colour, turbidity, taste, odour

microbiological tests → indicator organisms

tests for toxins → pesticides, heavy metals, radioactive

tests for health-risk materials → flouride, nitrate

tests to determine suitability for other incidental uses → corrosion effects Fe, Mn and hardness salts Ca and Mg

operational tests → monitor plant performance - e.g., blue-green algae

What are the population measures?

gross pollution measures

aesthetic appeal

microbiology

toxins

incidental use - suitability

determine process suitability

What is DO?

Dissolved O2

Essential to aquatic life, minimum ~ 5mg/L needed to sustain a balanced population of aquatic flora and fauna

saturation at 15 degrees - 10.2 mg/L (~10 ppm)

Pollutant addition - decreases available DO - may render life unsustainable

What measures are done for solids?

suspended solids - SS

dry weight retained on filter

classified as fixed and volatile (organic)

dissolved solids

remains after SS test

salinity indicator - can be measured by EC

settleable solids

volume of settable solids

imhoff cone

What are the gross pollution measures?

DO

temperature ~ 10-21 degrees

pH ~ 6-7

BOD

COD

What is total organic carbon?

Determines:

total concentration of C as organics

process → combustion in 2 furnaces

High temperature - organics + inorganics decompose → CO2

Low temperature - acid packing - only inorganics decompose

Difference = TOC (organic C content)

Problem:

plastic will register on TOC test

useful for industrial wastewaters - nutrient deficient or contains toxics

What is involved in nutrients N and P

NH3-N

most reduced form

composed of NH3 (ammonia) and NH-4 (ammonium) - unionized form most toxic

NO3-N

promotes excess growth

diseases can come from this

TKN - total kjedahl nitrogen

combination of ammonia and organic N

Toal P

phosphorous is not toxic but is often limiting nutrient for growth

excess - leads to algal blooms and eutrophication

As for aesthetic parameters what is included under taste and odour?

quantified by semi-subjective human repsonse

odour and taste panels

mainly volatile organics

disinfection by-products

algae (may produce toxins)

ammonia odours

anaerobic odours - sulphides, phenols

As for aesthetic parameters what is included under colour?

2 types: true and apparent

true: water colour in absence of turbidity (reflected, refracted and absorbed light)

apparent: observed colour

measured by comparison to unit colour standards

As for microbial measures what is included under microorganisms?

Indicator bacteria

fecal coliforms - indicator of fecal contamination - should be present if pathogens are present

viruses

algae

protozoa, ameoba and ocoocysts

As for toxin measures what is included under this?

heavy metals

organics - pesticides

other inorganics, cyanide, boron

What are the key chemical components in WWW and their relevance to land application?

BOD contributors: sugars, ethanol, tartaric & malic acids

COD contributors: phenolics & sulfite from wine

Cations (Na, K, Ca, Mg):

Sources include water hardness, bitartrate crystallization, and caustic cleaners

SAR (Sodium Adsorption Ratio):

Values >4 can lead to soil degradation during land application

Sulfates:

Arise from high-SO₂ must filtration and distillation residues

What are some common sources of WWW?

cleaning of tanks

hosing down of floors and equipment

rinsing of transfer lines

barrel washing

spent wine and product losses

bottling facilities

lab WW

stormwater diverted into or captured in the WW management system

What are the main requirements for WWW to be considered fit for use in vineyard irrigation?

acceptable pH, EC and cation balance

should not exceed thresholds for Na, K and toxic ions

biochemical oxygen demand levels must be managed to avoid odour and groundwater issues

must be tailored to soil type, crop requirements and irrigation cycles

How does WWW irrigation affect soil chemistry and structure?

increases Na and K in soil - can disrupt soil structure

leads to soil dispersion, reduced infiltration and clogging

can alter soil chemistry and increase leaching of salts and dissolved organic carbon

BOD is not harmful to soil if applied appropriately - may increase organic carbon

What is the impact of high Na and K in WWW on soil structure?

Na and K displace Ca - reducing soil stability

increases SAR and PAR

leads to soil dispersion and possibly erosion - especially in clay soils

poor soil structure can reduce plant growth and water movement

What is the sodium adsorption ration (SAR) and why is it important in WW irrigation?

SAR = Na / √(Ca+Mg)

indicates the risk of soil sodicity and dispersion

high SAR = higher risk of poor soil structure

SAR should be monitored to protect soil health

What benefits can WWW provide when used appropriately for irrigation?

increases organic carbon in low OC-soils

may improve soil microbial activity

supports recycling of nutrients and water

enables integrated waste management with crops and livestock

What are the risks of using WWW with high salt content on vineyards?

salt accumulation in soil - Na and K

reduced vine growth and possible yield loss

can cause osmotic stress and toxic ion effects on vines

may lead to wine quality issues - colour extraction problems in reds

What is the recommended approach to sustainably manage WWW irrigation?

match WW quality with soil and crop requirements

monitor SAR, PAR, EC, BOD and nutrients

use soil amendments (calcium nitrate) to manage ion balance

integrate with crop rotation and soil health practices

What is meant by “fit for purpose” in WWW treatment?

treatment tailored to intended use - e.g., land application, reuse, discharge

balances treatment intensity with environmental risk and economic feasibility

avoids over-treatment and focuses on key hazards - e.g., salt, BOD

What is the purpose of the slaking and dispersion test in soil management?

evaluates soil structural stability

Slaking = breakdown of macoaggregates = low organic matter

dispersion = breakdown of microaggregates = high Na or K present

helps decide if soil can withstand WW irrigation

What are some beneficial crops for WWW reuse?

lucerne, clover grass, maize, sorghum, soybeans

crops with moderate to high K uptake help reduce soil accumulation

grapevines: moderate K uptake - 150kg/ha for 15 t/ha yield

What are the key processes in winery liquid treatment?

preliminary treatment

primary treatment

secondary treatment

advanced (tertiary) treatment

post treatment

sludge disposal

Why do treatment processes widely vary in design?

due to:

WW composition and volume

treated WW quality requirements

new & improved technologies

variety of available processes

scale

chemical and resource availability

designers opinion and bias

What are the key drivers of liquid waste treatment?

end use (MOST IMPORTANT FACTOR)

all treatment options have strengths and limitations

in choosing treatment system - must minimise capital costs, operating costs and make system as automated and robust as possible

must be fit for purpose

What are the key quantitative indicators in liquid treatment?

operators

need rapid and reliable quantitative indicators

to determine if effluent meets allowable thresholds

diagnose, optimise & troubleshoot the plant processes

key indicators:

pH, EC, DO, COD, turbidity

BOD - biological oxygen demand - useful indicator, expensive too large a lag time to assist with day to day management

COD suggested as a surrogate

Sodium adsorption ratio (SAR) of irrigation water provides a good indicator of potential damage to soil structure through repeated application of the wastewater (reuse and irrigation)

What is a woodlot and how are they used in liquid treatment/disposal?

a designated area, where WWW ends up being irrigated on (instead of vineyard)

long term impacts of major concern to industry and regulators

sodium ions present can accumulate in soil

with time, sodicity causes dispersion of clay particles

leads to surface crusting, reductions in water infiltration, water logging, erosion and poor soil fertility

What is the typical impact of WWW irrigation on groundwater nitrate levels?

generally low risk

small peaks of nitrate-N (max ~ 3.6mg/L) detected in shallow ground water

levels well below 10 mg/L NO3--N (safe for potable use)

lower than nitrate levels after typical urea application ~20 mg/L

What is the most persistent issue in WWW management and how should it be addressed?

SALT most persistent problem

best addressed by controlling winery practices

reduced BOD/COD to simplify WW management and minimise wine loss

rapid irrigation after minimal treatment is cost-effective

requires monitoring to confirm consistency

What are the key challenges preventing effective waste minimisation in the wine indsutry?

practices often ad hoc and inefficient

lack of systematic methodology to target specific waste streams

external motivations are often the main drivers

failure to realise full potential due to lack of strategic planning

industry needs to follow reduce, reuse and recycle principles

What is recommended for improving waste minimisation in wineries?

adopt best practice principles - reduce, reuse, recycle

implement systematic, targeted waste management approaches

move beyond external motivations to internal sustainability strategies

What are key features of low-cost treatment systems for small wineries?

designed for wineries crushing a few hundred to few thousand tonnes

aim to minimise capital and operating costs

system should be as automated and robust as possible

prototype uses sedimentation/anaerobic digestion, low-level aeration, and a soil based WW bioremediation cell

shows promising results for rural small WWW treatment

What treatment strategies are suitable for larger wineries?

Can afford more complex and costly systems

options include:

conventional aerobic and anaerobic systems

sequencing batch reactors

combined anaerobic/aerobic systems

artificial wetlands

each technology has its own +/-

During preliminary treatment of WW what is involved?

screens

gross solids removal (coarse)

suspended solids (SS) removal (fine)

grit chambers

remove sand, rocks, heavy material

pH correction

acid - HCl, CO2; base - caustic, lime

During primary treatment of WW what is involved?

Sedimentation

rectangular/circular flow settling tanks with plates or tubes

may employ coagulation and flocculation to enhance particulate removal

Removal of SS > ~ 1μm

Dissolved air flotation

rectangular flotation tanks with skimmers

may employ coagulation and flocculation to enhance particulate removal

removal of SS with poor settling characteristics

During secondary treatment of WW what is involved?

Biological treatment

microorganisms convert organic (& inorganic) wastes to harmless end products

2 types: aerobic (O2 present) and anaerobic (O2 absent)

Main processes:

activated sludge

oxidation ditches

anaerobic digestion

tricking filters

wetlands

lagoons/ponds

What are the key features of sequencing batch reactors (SBR)?

can be operated as aerobic or anaerobic systems

provide similar COD removal in both modes

can tolerate shock loads (e.g., variable WW strength 0:25:1 to 5:1 COD:BOD)

generate high volatile suspended solids concentrations in sludge

what are the main advantages of SBRs for WWW treatment?

single reactor handles equalisation, clarification and biological treatment

high operating flexibility and control

small footprint (space efficient)

capital cost savings due to integrated design

What are the main disadvantages of SBRs?

require high operator skill - timers and control systems

high maintenance needs

risk of floating or settled solids being dishcharged during draw/decant phases

risk of aerator plugging

may need additional flow equalisation after SBR

what are the key operational features of membrane bioreactors?

adjustable solids residence time

can be used in both aerobic and anaerobic modes

allow for thigh control over biological treatment conditions

submerged mode is generally preferred due to lower fouling rates

what are the main challenges or problems associated with MBRs?

membrane fouling biggest issue

caused by slime polymers in supernatant

capsule polymers around bacteria promote flocculation and fouling

granulation of cells is poorly understood

SRT (solids retention time - average amount of time that solid particles (like microorganisms) spend in the treatment system), particle size, SS, low food-to-microorganism ratios

How can filterability be assessed in MBR systems?

filterability is a key performance factor

measured by analysing EPS - extractable polymer substances

EPS is primarily composed of proteins and polysaccharides

What is involved in anaerobic digestion?

Complex process

results in breakdown of organics : harmless end products CH4 and CO2

production line of microorganisms

sumarrised as:

carbohydrates, fats proteins → volatile fatty acids → CH4, CO2, H2S

needs steady conditions - sensitive to pH, temperature and shock loads

low energy use

What are the operating modes of anaerobic digestion?

conventional

continuous or intermittent feed

no solids separation

retention time ~ 30 days

anaerobic contact

separation and re-circulation of seed organism

retention time reduced to 6-12 hrs

CH4 production = 0.4 m3 gas/kg COD removed

During advanced/tertiary treatment of WW what is involved?

Biological nutrient removal

microorganisms used to remove N and P by combination of aerobic, anoxic and anaerobic treatment processes

N removed as gaseous N2

P removed as M/O biomass

N and P responsible for eutrophication and algal blooms in receiving waters

treatment steps may be separate or combined

BNR may also be combined with secondary treatment

What processes (during advanced/tertiary treatment) can be used in the removal of N from WW?

breakpoint chlorination → NH3 removal (ammonia)

chemical coagulation → organic N removal

ion exchange → NH3/nitrate removal

filtration → organic N /nitrate removal

air stripping → NH3 removal (ammonia)

electrodialysis → NH3/organic N/nitrate removal

reverse osmosis → NH3/organic N/nitrate removal

What processes (during advanced/tertiary treatment) can be used in the removal of P from WW?

Lime or alum precipitation with sedimentation and filtration

when is chemical/physical treatment used in WWW management, and what does it achieve?

used when re-use or restrictive discharge standards must be met

involves a combination of chemical and physical methods

provides water suitable for:

re-use applications

discharges with strict quality requirements

goes beyond what secondary and nutrient removal can achieve

During post treatment of WW what is involved?

Disinfection

chlorine

chloramines

hydrogen peroxide

chlorine dioxide

ozone

ultraviolet light

During sludge disposal of treated WWW what is involved?

concentration

stabilisation

conditioning

dewatering

final disposal

During concentration in sludge disposal of treated WWW what is involved?

clarifiers - sedimentation thickening

flotation thickening

centrifugal thickening

gravity belt thickening

During stabilisation in sludge disposal of treated WWW what is involved?

reduce pathogens, eliminate odours and minimise putrefaction (decay/rotting) potential

anaerobic digestion

lime stabilisation

composting

heat treatment

During conditioning in sludge disposal of treated WWW what is involved?

for dewatering

chemicals - lime, chlorine

heat treatment

During disinfection in sludge disposal of treated WWW what is involved?

chemical - lime chlorine

incineration

high energy ionisation

pasteurisation

During dewatering in sludge disposal of treated WWW what is involved?

vacuum filtration

centrifugation

filter press

sludge drying bed

heat drying - fluidised bed

During the final disposal in sludge disposal of treated WWW what is involved?

incineration - land disposal

fertiliser

land disposal

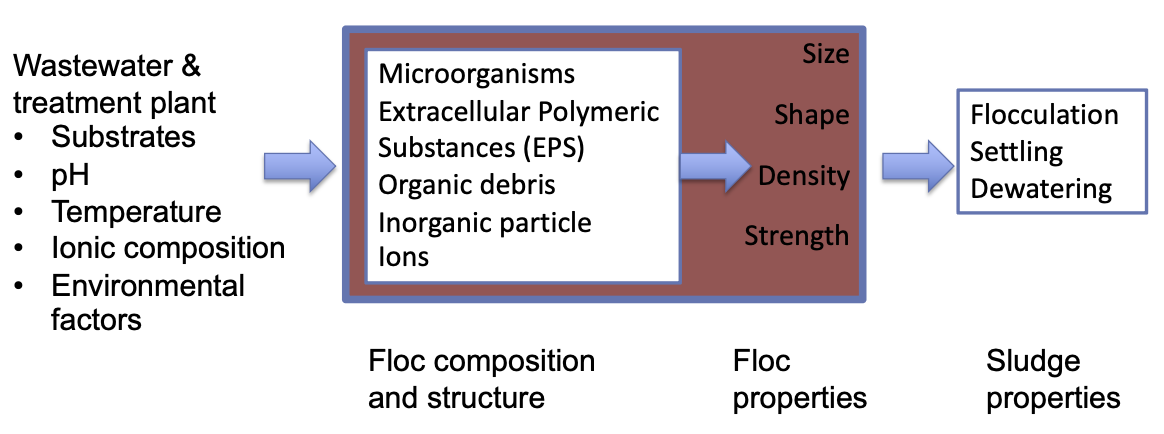

What occurs in the organisation of biomass?

complex heterogeneous structures

floc structure and shape determines how successfully the solids phase separate from the liquid phase in secondary clarifier

ultimately determines success of the process

What are flocs made up of?

filamentous matrix

microcolonies of bacteria

inorganic particules

all embedded in gel-like exocellular polymeric substances

What are the factors affecting floc formation?

What problems can come from the microbes in WWW?

odours

bulking and foaming

caused by proliferation of filamentous bacteria

bulking: distinguished by filamentous bacteria extending out from floc surface and participating in interfloc bridging

foaming: development of a stable foam on the surface of aeration tanks

When does a winery need an EPA licence in SA?

When >50 tonnes of grapes are processed per year within the Mount Lofty Ranges Water Protection Area (MLRWPA)

When >500 tonnes of grapes are processed per year else where in SA

When must a winery consult or engage with the EPA? Even if no license is required?

during planning and development

referral body for planning applications where >50 tonnes will be processed annually (anywhere in SA)

wineries can seek informal advice to guide development decisions

if not licensed, wineries still have legal duties under:

Section 25 of the Environment protection act 1993 - must take all reasonable and practicable measures to prevent or minimise environmental harm

Clause 15 of the environment protection (water quality) policy 2015 -

must have a wastewater management system

system must be effective

waste must not enter water bodies or land where it may enter waters - via runoff or seepage e.g.

If an environmental incident occurs

under Section 83(1) of the act a winery must notify the EPA if there is an incident that causes or threatens environmental harm, including contamination of underground water

If complaints are received

the EPA may investigate odour, noise, or wastewater discharge complaints even for unlicensed wineries

When must a winery consult or engage with the EPA? Even if no license is required?

during planning and development

referral body for planning applications where >50 tonnes will be processed annually (anywhere in SA)

wineries can seek informal advice to guide development decisions

if not licensed, wineries still have legal duties under:

Section 25 of the Environment protection act 1993 - must take all reasonable and practicable measures to prevent or minimise environmental harm

Clause 15 of the environment protection (water quality) policy 2015 -

must have a wastewater management system

system must be effective

waste must not enter water bodies or land where it may enter waters - via runoff or seepage e.g.

If an environmental incident occurs

under Section 83(1) of the act a winery must notify the EPA if there is an incident that causes or threatens environmental harm, including contamination of underground water

If complaints are received

the EPA may investigate odour, noise, or wastewater discharge complaints even for unlicensed wineries

When does a winery need an EPA licence in SA?

When >50 tonnes of grapes are processed per year within the Mount Lofty Ranges Water Protection Area (MLRWPA)

When >500 tonnes of grapes are processed per year else where in SA

What are the licensing required for solid waste disposal?

required for all prescribed activities

with speical conditions attached e.g., environment improvement programs, codes of practices/guidleines

works approval - required for any activity that might require a licence, enforcment includes fines and imprisonment

What is included in the solids management hierachy?

TOP Avoid - reduce - recycle - treatment - disposal BOTTOM

with reuse and recovery connected to reduce and treatment

What are the general goals of solid waste management?

environmental compliance

health & safety

community perception (image)

economics (saving more money)

triple bottle line (economics, social, environment)

What are the common solid wastes from winemaking?

Marc

filter earth

waste treatment sludge

barrels/oak chips

chemicals or reagents

What are the common solid wastes from packaging and then consumption?

paper/cardboard

plastics

glass

metals

chemicals and reagents

consumption:

paper/cardboard

plastics

glass

What options are there for the disposal of marc?

Includes stalks, seeds, and skins generated during wine production

waste mmgt:

landfill

distillation

stock feed

compositing

vineyard application

extracts

energy recovery

In the distillation process of marc disposal what is involved?

In SA by Tarac in Nuriootpa and Berri

they accept marc for free - you have to pay for transport

and recived a return of up to $2/L alcohol

5-10$/tonne locally

20-30$/tone remote regions

In the vineyard application of marc disposal what is involved?

raw grape marc

stock piled 12 mths, or composted first - non composted marc too acidic CANNOT BE USED

mulched before application

higher K & N require mixing with other products like prunings, green wastes, bark manure etc

application rates of mulched grape marc high as 150m/ha

potential environmental impacts include:

odour, litter & dust

soil & surface water contamination with acidic leachates

potential fire hazards

breeding of vermin, vinegar flies, maggots etc

In the composting of marc disposal what is involved?

natural biological degradation - rotting

caused bacteria and other microbes

aerobic or anaerobic conditions can be used

aerobic preferred - minimise/avoid potential odour

involves 3 separate stages

mesophilic stage - several days: T heated to 40 degrees

thermophilic stage - up to a month: T above 40

maximum degradation & stabilisation

pathogens killed

cooling phase - month to several months

reduction in microbial activity, temp decreases

evaporative water release

pH stabilisation

What are the critical parameters fir aerobic composting?

C/N rations

should be 25-30:1

require amendment - e.g., straw, sawdust, recycled compost, fertilisers

moisture content

ideally 50-60%

temperature

optimum 45-55 degrees

pH

to minimise odour potential

What is involved in the Aerated static pile system of aerobic composting?

grid of aeration piping underlays

screened waste material & bulking agent and amendments

aerated using blowers

composted for 21-28days, cured for 30+

typical pile heights of 2-2.5 m

What is involved in the windrow system of aerobic composting?

waste material & bulking agent

piles 20-100m long

typical pile heights of 1-4 m

regular turning and mixing achieves aeration

composting period 21-28 days

what is industry practice in terms of composting?

composting may be on site or contracted out

on site composting may involved strict regulations, especially buffer distance over 500m

licensed companies e.g., peats soil and garden supplie, jeffries garden soils

typical processing costs $10-15/m3 + freight

In the landfill disposal of marc disposal what is involved?

may be on/off site

onsite strictly regulated

time consuming + difficult approval processes

long-term management

usually contracted out

costs $10-25/t + freight

In the stock feed of marc disposal what is involved?

Marc can be used as animal feed supplement or replacement

as for feed sources it comes in different options

DM (~50%) - dry matter - higher better, lower freight costs

CP (~13%) - crude protein - total crude protein in feed - no account for proteins digestibility or degradability

ADF (~61%) acid detergent fibre - as % increases, digestibility of feed decreases, measures cellulose and lignin content, ruminants - low utilisation of cellulose and lignin indigestible, for alternative roughages ADF indicates proteins digestibility

ME (~6%) metabolisable energy - measure of energy in feed, >7 best

In extracts during marc disposal what is involved?

New & improving area

GrapEx - Tarac - making:

wine additive - enhance colour and palate structure

involves counter current extraction from marc concentration ands filtration

Vinlif

nutraceutical product - similar process to GrapEx

other example

grape seed oil production

In energy recovery during marc disposal what is involved?

biomass utilisation

transforms organic matter into energy

classified as renewable energy

technologies:

anaerobic digestion → methane + sludge

incineration → heat

gasification → syngas

pyrolysis → combustable gas + liquid hydrocarbons

energy

= $40 per megawatt-hour plus carbon credits

What is filter earth used for?

wine clarification processes

bentonite, diatomaceous earth or/and perlite

what are the common approaches of filter earth disposal?

tartrate recovery - performed at Tarac

disposal with marc

landfill

other

In the treatment of waste sludge, what are the methods used?

from liquid effluent treatment - contains organic and inorgainc matter e.g., filter earth

waste management methods?

concentration

stabilisation

conditioning

disinfection

dewatering

final disposal

What are the common disposal practices for contaminated timber?

stockpiling on vineyard sites

recycling for landscaping

land filling

steel and plastic posts as replacement

Why can treatment processes widely vary in design?

wastewater composition and volume

treated wastewater quality requirements

new and improved technologies

variety of available processes

scale

chemical and resource availability

designers opinion and bias

What are the key drivers of treatment options for wastewater?

the end use of winery wastewater - most important

all treatment options have strengths and limitations

in choosing treatment system - must minimise capital costs, operating costs and make system as automated and robust as possible

must be fit for purpose

r

r

r

r

Why might you characterise wastewater?

design treatment plan

monitor and control operations

meet legal requirements

detect long-term trends

What sort of things are being tested in gross pollution measures?

BOD, COD, grease, suspended solids, NH3

What sort of things are being tested for aesthetic appeal?

Colour, turbidity, taste, odour

What sort of tests can be done for the presents microbiological behaviour?

indicator organisms

What sort of things are being tested in tests for toxins?

pesticides, heavy metals, radioactivity

What sort of things are being tested in test for health-risk materials?

fluoride, nitrate