Flexible Containers

1/24

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

25 Terms

Value of Flexible Packaging

-less material

-less weight

-portability

-technology advancement closing the gap on rigids

Components/functions

- Bags/Pouches

- Seals/fitments

- Printing/Labels

Converting Process Definition

Transform raw materials in the form of polymer pellets or film substrates (including paper and foil) into a final packaging structure

Common Layers

- Barrier

- Sealant

Typical Substrates - Printing

- Paper

- OPP

- PET

- Monolayers are surface printed

Printing Challenges

- Surface quality: treatment

- Dimensional stability

- Gravure and Flexography are the 2 main processes (roll to roll printing)

Barrier Materials

- Metallized films

- Glass coated films

- PA (Nylon)

- Oriented films (OPP & PET)

- Coated films

- Foil

Common Sealant Layers

LLDPE, LDPE, CPP

LLDPE

whole range of modified sealants for sealing through contaminants to peelable seals

LDPE

when no serious demands such as heat and chemicals are involved

CPP

higher temp applications require polypropylene

Shrink Materials -- Labels and Sleeves

- PVC

- PET

- OPS

- PLA

Materials - Fitments

- Made of PP or PE: must be compatible w/ sealant layer

- Injection molding for precision

- Zippers are extrusion molded

- Can be pre-applied to pouch or as pouch is being formed and filled

Purpose of Fitments

dispensing, reclosing, aeration

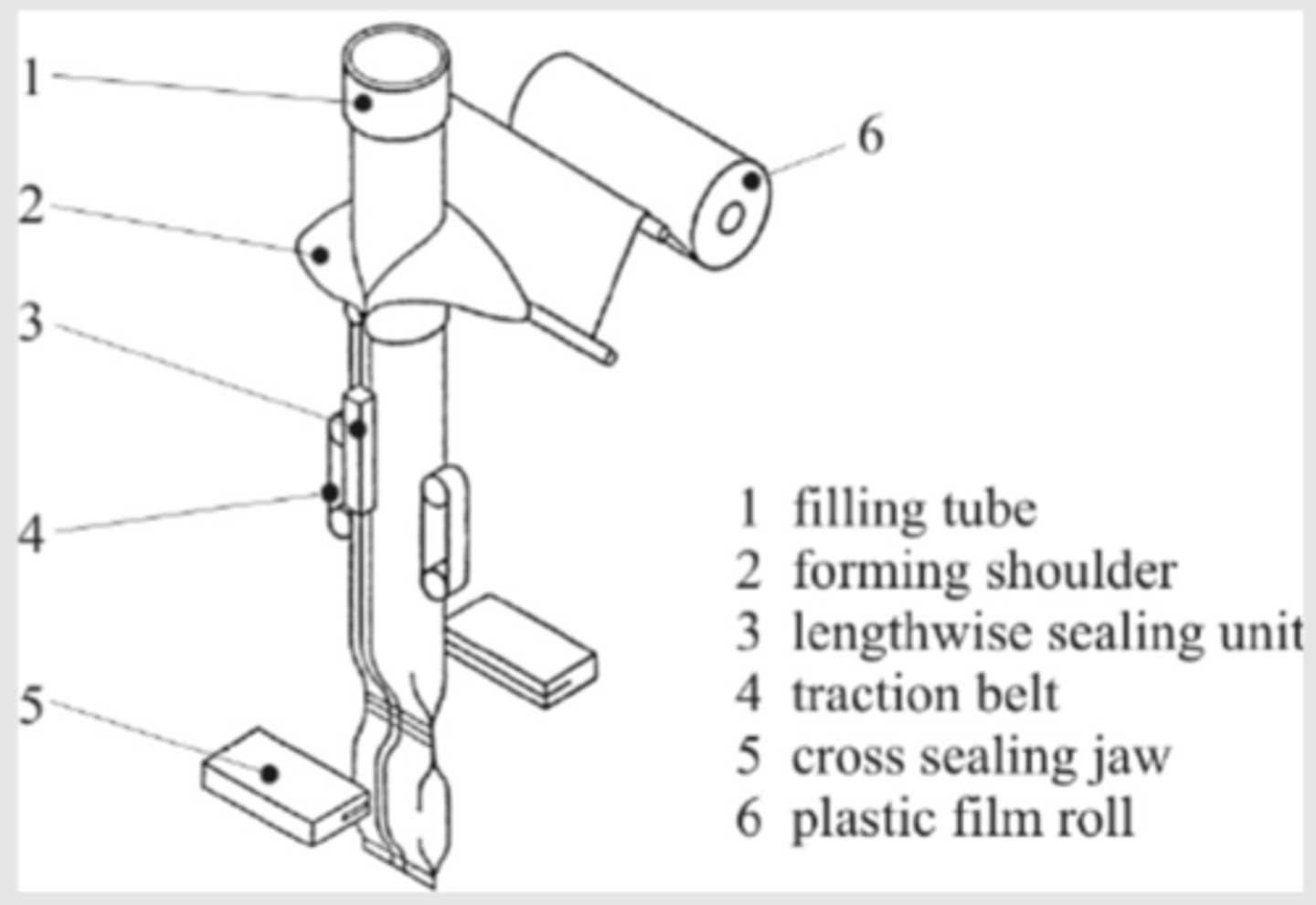

VFFS - Vertical Form Fill and Seal

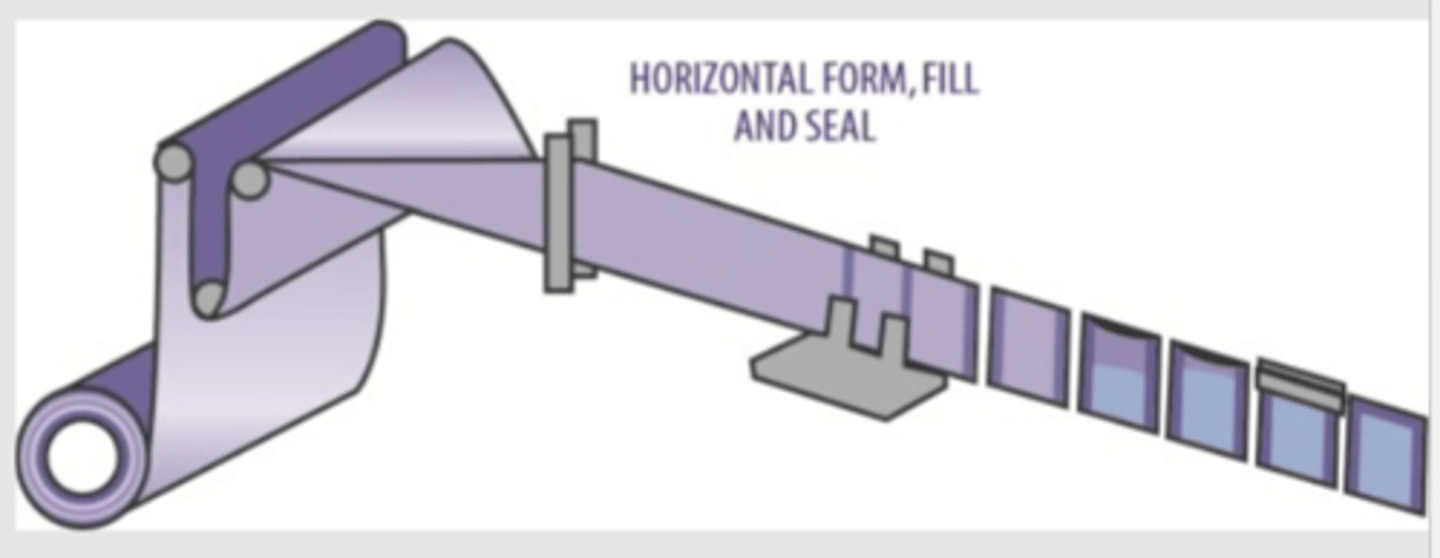

HFFS - Sachet

Pre made pouches

-stand up with a separate gusset

-stand up with a folded bottom

-box pouch

-4 side seal flat

Seal Jaw Design

serrations

Fin or lap seal

lap seal saves material but the outer and inner have to seal

What are the most vulnerable areas of seals

folded areas

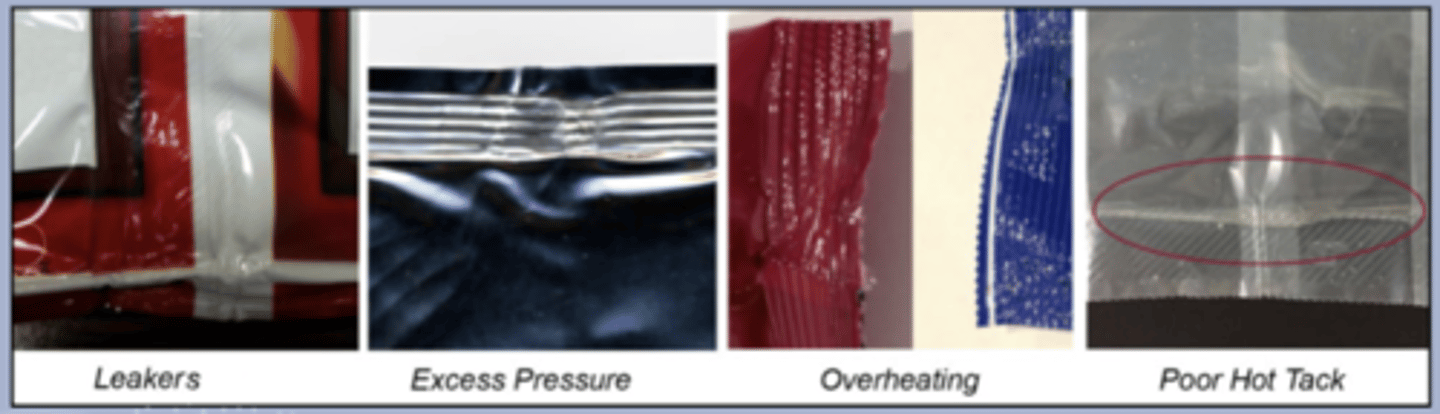

Seal Failures & Defects

Package Validation is directly related to

safety

Safety

extractables, toxicity, retained solvents, heavy metals

Barrier

porosity, microbial barrier, gas transfers, light transmission

Durability

flexural, bond strength, tensile, puncture, tear, thickness