Chapter 1: Introduction

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

Producer Goods

goods manufactured for other companies to use to manufacture either producer or consumer goods

Consumer Goods

goods purchased directly by the consumer or the general public

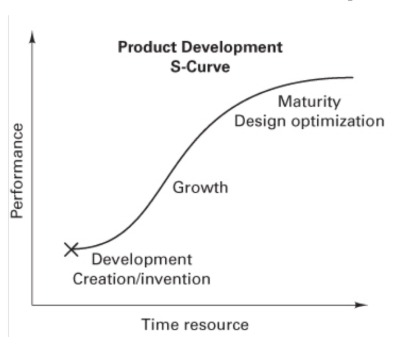

Product life-cycle curve

Sustaining Technology

Innovations in materials, processes, and design that bring more value to the consumer of existing products and services

Manufacturing System

A collection of operations and processes to produce a desired product(s) or component(s)

___________ __________ are arranged in the factory to form a manufacturing system

Manufacturing Processes

Production System

the total company and includes manufacturing systems

Goods

Material Things

Services

Nonmaterial things (i.e. transportation, banking, health care, education, etc.)

Manufacturing Processes

converts unfinished materials to finished products, often using machines or machine tools

Process

a sequence of steps, processes, or operations for production of goods and services

Machine Tool

an assembly of related mechanisms on a frame or bed that together produces a desired result

Job

the total of the work or duties a worker performs

Station

a location or area where a production worker performs tasks or a job

Operation

a distinct action performed to produce a desired result or effect

Treatments

operations that change or modify the product-in-process without tool contact

Tools

used to hold, shape or form the unfinished product

Lowest mechanism in the production term rank

Fabricating

the manufacture of a product from pieces such as parts, components, or assemblies

Processing

the manufacture of a product by continuous series of operations

Primary objective of manufacturing

to produce a component having a desired geometry, size, and finish

5 manufacturing system designs

Job shop

Flow shop

Linked-Cell shop

Project shop

Continuous process

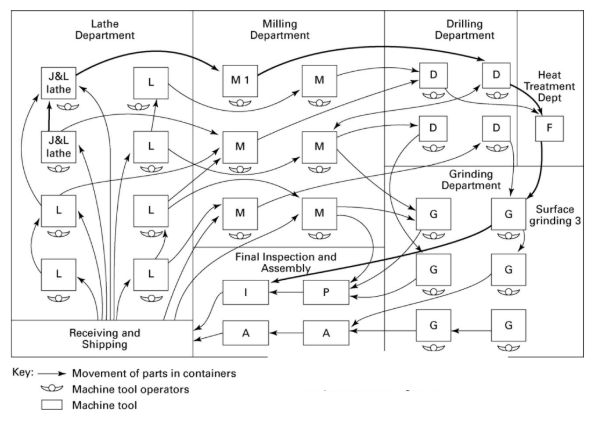

Job Shop Characteristics

Low Volume of production

General-purpose machines

Large variety

Flexible

Functional Layout

Functional Layout

Machines are collected by function (all lathes together, all

mills together, all grinding machine together)

Parts are routed around the shop in small lots to the various

machines

Material is moved from machine to machine in carts or

container

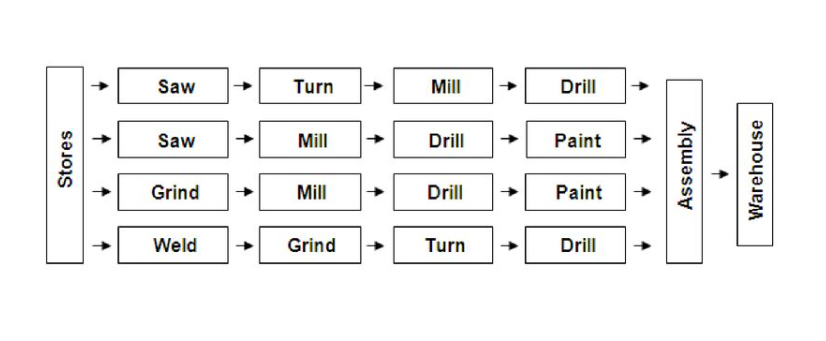

Flow shop

has a product-oriented layout composed of mainly flow lines

Flow Shop Characteristics

Larger Volume of the same part

Special-purpose machines + equipment

Less variety

Less Flexible

More mechanization

Flow line layout / Assembly Line

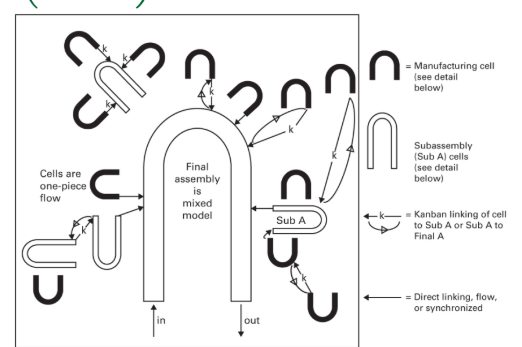

Linked-cell Manufacturing System (L-CMS)

Manufacturing and subassembly cells connected to final assembly by kanban links

U-Shaped Cells

One-piece-flow basis

Kanban

unique form of inventory and information control

Project Shop

Fixed position layout

immobility of the item being manufacturing

Workers, machines, and materials are brought to the site and removed after job is completed

Continuous Processes

Manufacturing of liquids, oils, gases and powder

Most efficient, but least flexible

Involve complex chemical reactions

Heat Treatment

heating and cooling of a metal for specific purpose of altering its metallurgical and mechanical properties

Packaging

to protect the product from the

environment

to protect the product during shipping

to hold fixed numbers of products for sale.

Product Life Cycle

Startup

Rapid Growth

Maturation

Commodity

Decline

Startup Stage Chracteristics

new product/company

low volume

small company

Rapid Growth Stage

products become standardized and volume increases rapidly. The company’s ability to meet demand stresses its capacity

Maturation Stage

Standard design emerges. Process development is very important

Commodity Stage

Long-life, standard-of-the-industry type of product

Decline Stage

Product is slowly replaced by improved products

Life Cycle Cost of a product

cost of materials

cost to manufacture

cost to use

cost to repair

cost to dispose