Final Exam Study Material for MMET 207 - Texas A&M University - Course Overview

1/476

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

477 Terms

Types of Hardness Testing (3)

Rockwell, Brinell, Vickers or Knoop

Can FCC or BCC hold more carbon?

FCC

Are Hardness Rockwell B (HRB) and Hardness Brinell (HB) the same or different tests?

Different

(more/less)

___ grains = ____ ductility = ____ slip

smaller grains = more ductility = more slip

vice versa

(higher/lower)

___ temp --> ___ grain size

higher temp --> larger grins size

(higher/lower)

___ MoE --> ___ deflection

higher MoE = less deflection (droop)

MoE of: (all x 10^6)

Carbon Steel

Titanium

Aluminum

Plastics

Carbon Steel: 30

Titanium: 20

Aluminum: 10

Plastics: .5

What is the microstructure of the Delta Iron Triangle?

BCC

Is grain size a determining factor in if a material is BCC/FCC or Austenite/Ferrite/Pearlite?

No, you can have any grain size of the same material

What motion is used for wear testing?

Rubbing

What heat treatments soften a material?

Tempering, annealing, stress relieving, and normalizing

Rockwell Hardness Testing (process)

Apply minor load, apply major load, remove loads, calculate the difference of the indentions

Rockwell Hardness Testing (Indentors)

1/16" Tungsten Carbide Ball for B&T

120 degree Diamond Cone or Brale for C, A, & N (EX: HRC)

Rockwell Regular loads

Minor: 10 kg

Major: 60kg, 100kg, 150kg

Rockwell Superficial loads

Minor: 3kg

Major: 15kg, 30 kg, 45kg

What does a major load mean?

Load that makes the second indention

Differences between regular and superficial loads

regular - prefer to use this

superficial - use if material is really thin or soft

Rockwell: difference between Beuler and Wilson?

They are just different brands, same type of rockwell hardness test

Brinell Hardness Test

Uses 10mm ball as indentor

Smash ball into metal surface and measure diameter of the indention

What are the mechanical properties of metals?

- strength

- formability

- stiffness

- toughness

- durability

Strength

The max load a material can take before fracture

Properties of Strength (6)

- tensile

- yield

- compression

- flexural

- shearc

- creep

Formability

The easiness to shape a metal; can I bend this w/o breaking it?

Properties of Formability (3)

- % elongation

- % reduction in area

- bend radius

Toughness

The energy required to fracture the volume of a material (measured in foot pounds)

Properties of Toughness (2)

- impact strength

- notch sensitivity

Durablilty

Wear resistance

Properties of Durability

- Hardness

- Wear resistance

- Fatigue strength

Stress

-A force distributed over an area or object

-Stress = F/Ao

-Units: (lb/in2) or (psi or ksi) or (N/m2)

Strain

-Percentage size change of a material in a particular direction when subjected to a force in that direction

-Strain (Es) = Lf - Lo / Lo

-Units: none or (in/in) or (m/m)

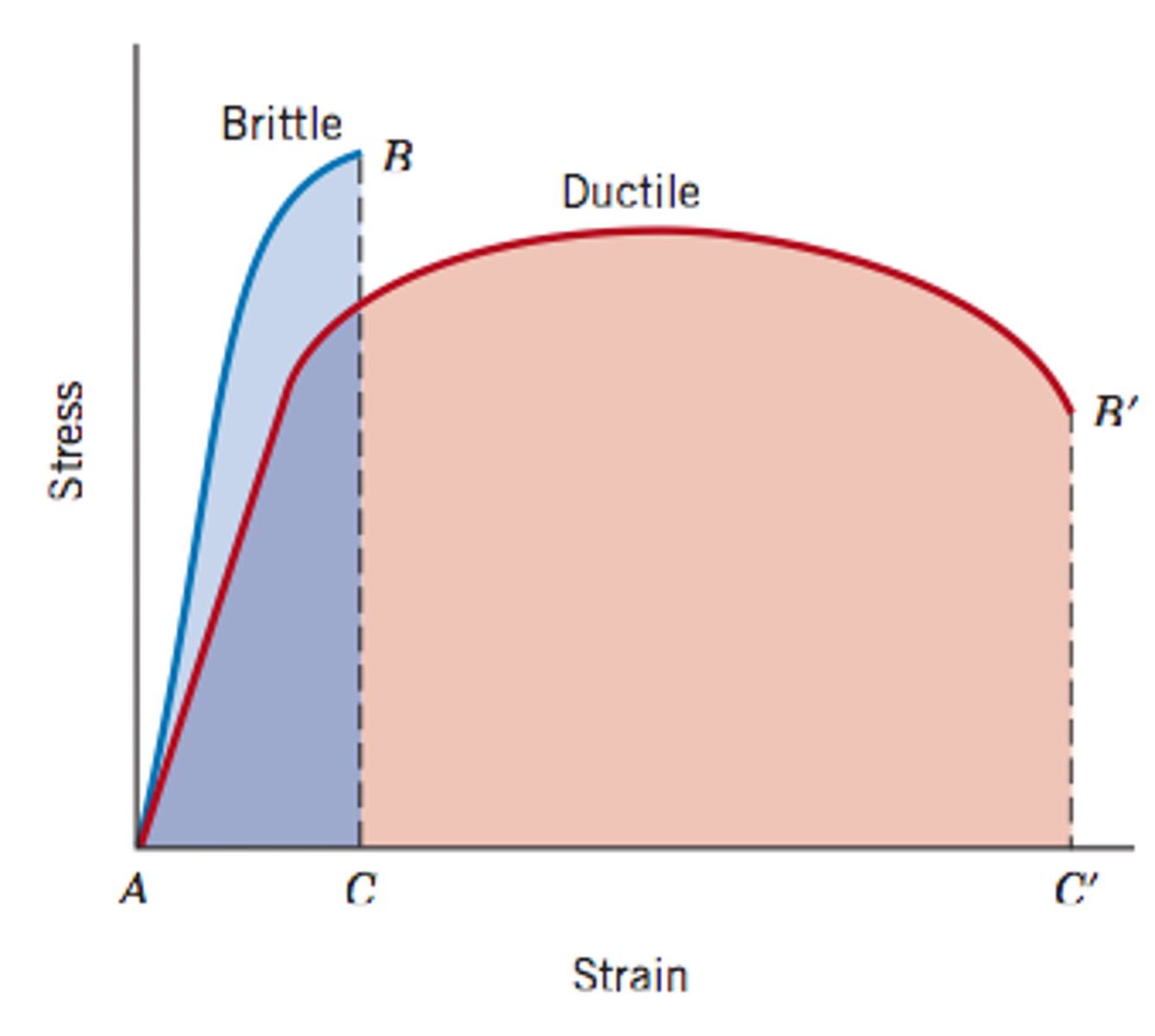

What does the size of the area under the stress-strain curve indicate about a metal?

How much energy is absorbed when the material breaks

Draw and label a stress-strain curve

What is the difference in stress/strain diagram for ductile and brittle materials?

Ultimate tensile strength

The maximum stress that can be applied to a material before it breaks

Elastic limit/Yield Point

point where a material goes from elastic to plastic; last point on linear part of graph

Break point

End of plastic behavior; where a material breaks

What is 0.2% offset yield (Engineering yield strength)

the stress at which a material exhibits a specified deviation from proportionality of stress/strain. Also, it hard to determine precisely so yield point is considered at an offset strain of 0.2%

How to find 0.2% offset yield

determining .002 strain and traveling parallel to modulus of elasticity

Modulus of Elasticity

(What is it?, formula, where on stress/strain curve, tell about the material?)

-A measure of rigidity ( or stiffness)

- Slope of linear line

- delta stress/ delta strain (Es)

- tells a material's stiffness

Modulus of Elasticity of Steel

E(steel) = 30x10^6 psi

Standard gauge for tensile specimens

2 inches

Elastic Behavior

returns to original shape

Plastic Behavior

Does not return to original shape... permanent deformation

Necking

Tensile deformation where relatively large amounts of strain localize disproportionately in a small region of the material (post UTS an about to break)

Impact testing (what for)

Tests toughness; measures a materials ability to with stand a shock load

- Temperature also has a huge impact on it

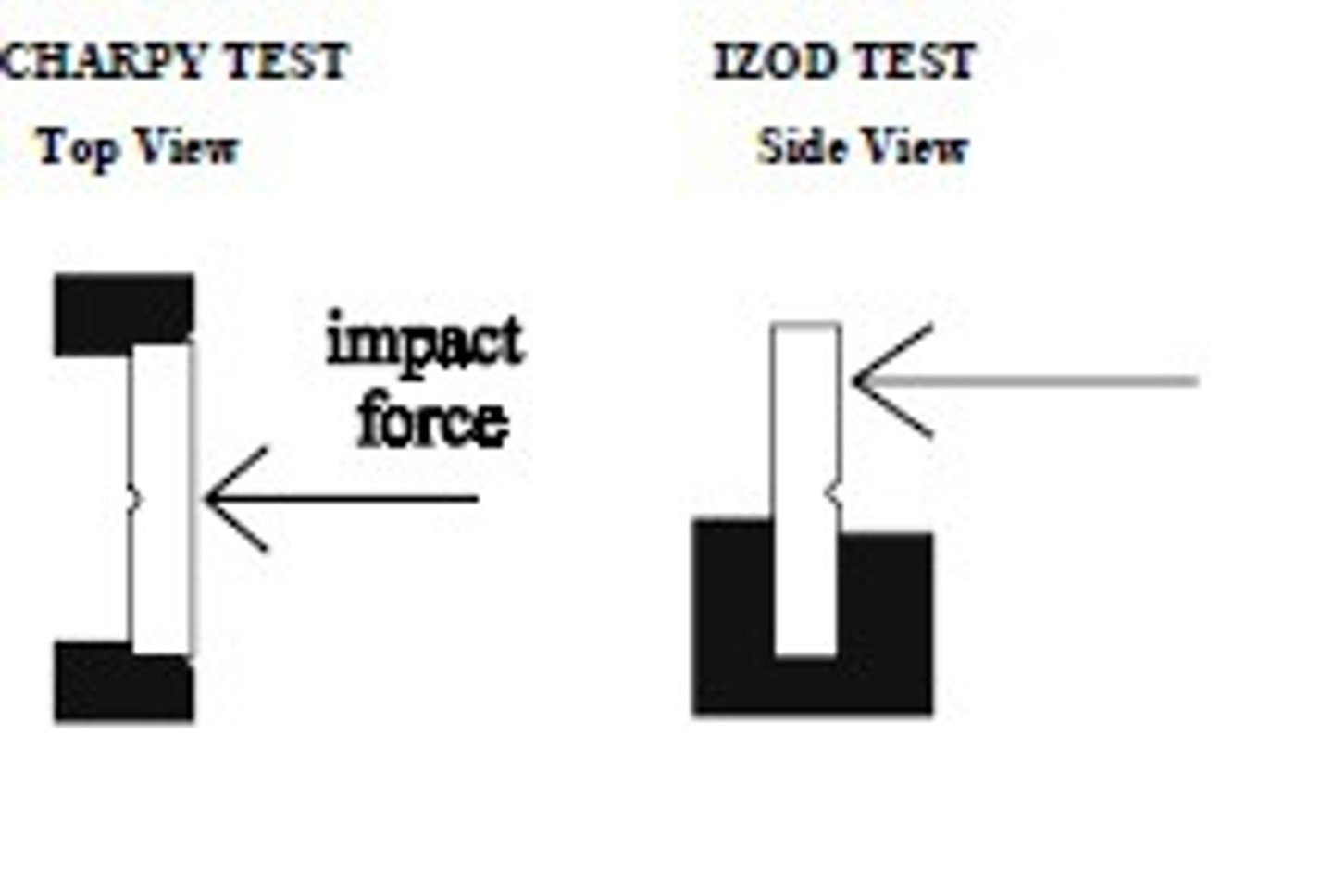

Impact Testing (how)

Take a material that is NOTCHED, whack it with pendulum or hammer; Charpy Vee or Izod

Charpy Impact Testing

- Has a notch in it and is facing away from impact

- Done more often, easier, faster

what does the difference between Charpy and Izod impact testing look like

Nil Ductility Temp

the temp at which the toughness of a material drops below the DBTT

DBTT

Ductile to Brittle Transition Temperature

Fatigue Strength

The highest stress that a material can withstand for a given number of cycles without breaking

Fatigue Strength/ Endurance Test

Continuously loading (bending back and forth) a material at given stress levels until it breaks

Endurance Limit/ fatigue strength

The point where you can bend a metal back and forth infinite times and it never breaks

Creep Strength

the resistance of a material to plastic deformation under a sustained load

Creep units

% deformation at a given stress

TRUE/FALSE: a Creep testing temperature must be shown

TRUE

Creep Testing

Used to rate the resistance of a material to plastic deformation under a sustained load and temp; a load is put on a material and when load is taken off, did it retain elasticity

- EX: Fan blade in container

Factors involved in material selection

Chemical, Mechanical, and Physical properties

Melting Point

The temperature at which a solid becomes a liquid

Specific Heat

The amount of energy required to raise the temperature of 1 gram of a substance by 1 degree celcius

Magnetic (Ferritic)

ferrous based material; retention and strength of magnetic field

Electrical Property

Conductivity and resistivity

Optical Property

Is it reflective

Acoustic Property

speed of sound traveling through a metal; used un ultrasonic inspection

Gravimetric Property

Density, weight

Color

Shiny, dull, light or dark; metals often used for decorative purposes

What is limestone used for

acts as flux (purifier) that removes impuritites

Coke

Used as a heat source to deoxidize; reduces gases that will detach from the oxygen

Blast Furnace

Furnace charged with iron ore, limestone, and coke

Heat melts iron, limestone forms slag, slag and metal separate, liquid is poured into molds, makes pig iron

Pig Iron

Has 3-5% carbon, good for being made into steel

Reduction Reaction formulas

1. C (coke)+ O_2 (air) → 〖CO〗_2 (carbon dioxide)

2.〖CO〗_2+C (excess coke) → 2CO (carbon monoxide)

1. 2〖Fe〗_2 O_(3 ) (ore)+3C (coke) → 4Fe+3CO_2

2.〖Fe〗_2+3CO → 2Fe+3〖CO〗_2

What is reduction

The process of removing iron ore to produce iron; limestone and coke remove oxygen

Types of steel refiners

Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF)

How is steel refined

Converts pig iron, scrap, or ore into steel

Basic Oxygen Furnace (BOF) Process

Charged with molten pig iron → oxygen is blown into the furnace to bring molten slag pool to the top = steel and slag is separate (ITS LIKE BLOWING BUBBLES IN MILK)

Electric Arc Furnace (EAF) Process

Charged with solid pig iron → arc is struck and melts the metal → oxygen lance is brought in and arc pulls impurities to the top → slag and steel are separated

- Circular furnace shape

What do iron sulfides do to steel

- Create soft spots in steel

- Silican improves the fluidity of molten metal

- adding Manganese (MnS) keeps iron sulfides from being harmful to steel

Primary steel refining

Removing Carbon from Pig Iron

Secondary steel refining

is aimed at altering chemical composition and reducing non-metallic inclusions; produces higher quality steels and alloys

Continuous casting

Continuously pouring metal through a tundish into an open ended mold to make simple, various slab shapes

- End up with semi finished billet, bloom, or slab

- Only uses killed steels

Vacuum Degassing

ingot mold is melted in an evacuated chamber and then is poured through a vacuum to suck out dissolved gases; makes very flat steel

Vacuum Arc Furnace (VAR)

Ingots are melted in a vacuum by making an arc b/w each ingot and water-cooled copper mold; as the arc picks up the inclusions they're sucked out by the vacuum

- used for super alloys and extra clean steel

Electroslag Melting (ESM)

Similar to VAR but w/o vacuum; melting metal from ingot passes through flux that acts as an electrode slag to remove impurities

Vacuum Induction Melting (VIM)

Charge is melted in a crucible → causes convection current stirring → inclusions go to the top and are sucked out by a vacuum ; used to melt solid scrap or liquid charges

- used for specialty alloys

Electron Beam Refining

Molten metal is poured down a tundish → as it flows down an electron beam vaporizes (zaps) impurities out of the metal

- used for aerospace kind of materials

Ladle stirring injection

Bubbling argon through the melt from a port in bottom of ladle → desulfurization and deoxidation

Ladle Furnace Heating

Used to restore heat to the metal in the ladle; electric arc heats melt at the top

Oxides

Non metallic inclusions, doesnt have strength of metals

Cleanliness

How many inclusions, porosity....

Tapping the Furnace

Take liquid steel out of furnace

Rimmed Steel

Ingots that solidify with a skin that is purer than the center; lots of chemical segregation

- Only slightly deoxodized

- low carbon surface layer very DUCTILE

- HAS A VERY NICE SURFACE LAYER

Capped Steel

Have a thin low-carbon rim; semi killed steel with similar characteristics to rimmed steel

- greater use of capped steels overs rimmed steels lately

- more expensive but stronger than rimmed

Semi-Killed Steel

- Intermediate in deoxidation b/w killed and rimmed; has less killing agents

- composition more uniform than rimmed

- used when cold-forming, surface char, or uniformity is NOT essential

Killed Steel

strongly deoxidized; chemical segregation is minimized b/c dissolving elements are added to remove oxygen

- high degree of uniformity in composition and properties

- Cost more, but have better properties

- continuous cast steels

Galvanized

Zinc-coated steel products. The zinc is applied by hot dipping.

Galvannealed

Zinc-coated and heat-treated steel. The heat treatment given to galvanneaied steels creates an oxide layer that allows better paint adhesion.

What/How are ingots made

They are a cast shape that will undergo further finishing

Molten metal is poured into large molds of basic shapes

Non-metallic inclusions

Oxides, sulfides, or alumina that form during conventional melting and refining

Forms of semi finished steels

Billet, bloom, slabs

Billet

Bars, Rod, Tube rounds, Cold-drawn bars, wire, seamless pipe