Material science - 1

1/23

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

24 Terms

metals & alloys characteristics

strong, tough, heavy + expensive

What is a polymer

Typically organic materials made of non-metallic elements such as C, H, O, N, S, Cl.

➢ Consisting of very large molecules that are composed of many repeating units.

polymer characteristics

light, cheap, soft & biofriendly

Ceramics

inorganic, non-metal solids

Ceramics characteristics

hard and usually brittle,

They have very high melting points → heat-resistant.

They have excellent chemical stability → oxidation-resistant

usually composed of oxides, carbides & nitrides

Glass characteristics

Stiff, quite strong, brittle & low toughness

Composites

Made by combining materials from the other three classes, To mix the properties of different materials.

Semiconductors

A material with

electrical conductivity between

that of a conductor (like metals)

and an insulator (like plastics)

Nanomaterials + examples

Have at least one dimension in the nanometre scale.

Eg. Graphene- A flat layer of carbon atoms.

• Carbon nanotube- A rolled-up layer of carbon atoms

Natural materials

Found in nature, not significantly altered by human processes.

Isostatic pressure

occurs when a solid is subjected to equal compressive

stresses (or pressure) on all sides

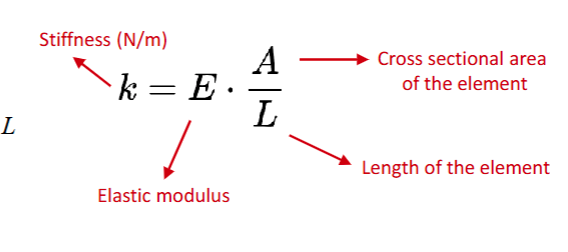

Stiffness

The stiffness of a material is its ability to return to its original shape after

an applied force is removed

Youngs modulus (E)

Slope of stress-strain graph during elastic region

E is an intrinsic property, independent of

the size or shape of the sample.

E is associated with stiffness of a material.

relationships between engineering stress/strain and true stress/strain

What is barrelling & how can it be minimised

Barrelling is the generation of a convex surface on the exterior of a

cylinder under compression. This happens due to friction between the

sample and the anvil that applies the load.

✓ This problem can be minimized by lubricating the anvils and the end

surfaces of the specimen.

what is hardness

Hardness is resistance to localized plastic deformation induced by either

mechanical indentation or abrasion

Hardness testing

Brinell test → steel sphere

o Rockwell test → steel sphere

→ diamond cone

o Vickers test → diamond pyramid

characteristics of tough materials

1) They fail only after absorbing

a lot of energy.

2) They strain a lot before failing

(i.e. they are ductile)

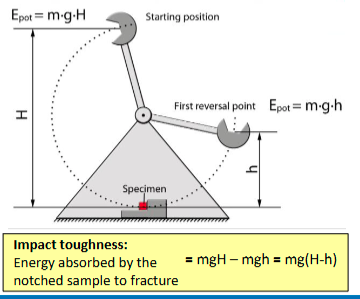

Notch toughness test

A material's ability to absorb energy and resist fracture when subjected to a

sudden impact or shock load.

The energy absorbed in fast fracture of a specimen that contains a notch

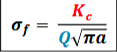

fracture toughness

Fracture toughness describes the ability of a

material containing a crack to resist fracture

under tensile stress.

(i.e. material's resistance to crack propagation)

fracture toughness vs crack length

fracture toughness is inversely proportional to square root of crack length.

Q is a constant, called the geometrical factor (usually ~ 1.0 )

Kc is called the critical stress intensity factor

What is necking

In a ductile material under tensile loading, after reaching the ultimate tensile strength (UTS), the specimen no

longer deforms uniformly.

Instead, a localized deformation point (a “neck”) forms, usually at some weak point along the gage length.

From that point, further deformation is concentrated in the necked region rather than distributed uniformly.