Principles of Amalgam Restoration

1/95

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

96 Terms

dental amalgam metal composition

alloy + mercury

alloy = silver + tin + copper + zinc

% composition of dental amalgam alloy component

Ag = 70%

Sn = 16%

Cu = 13%

Zn = 1%

function of silver (Ag) in dental amalgam

strength

function of tin (Sn) in dental amalgam

expansion

function of copper (Cu) in dental amalgam

strength

function of zinc (Zn) in dental amalgam

deoxidizer

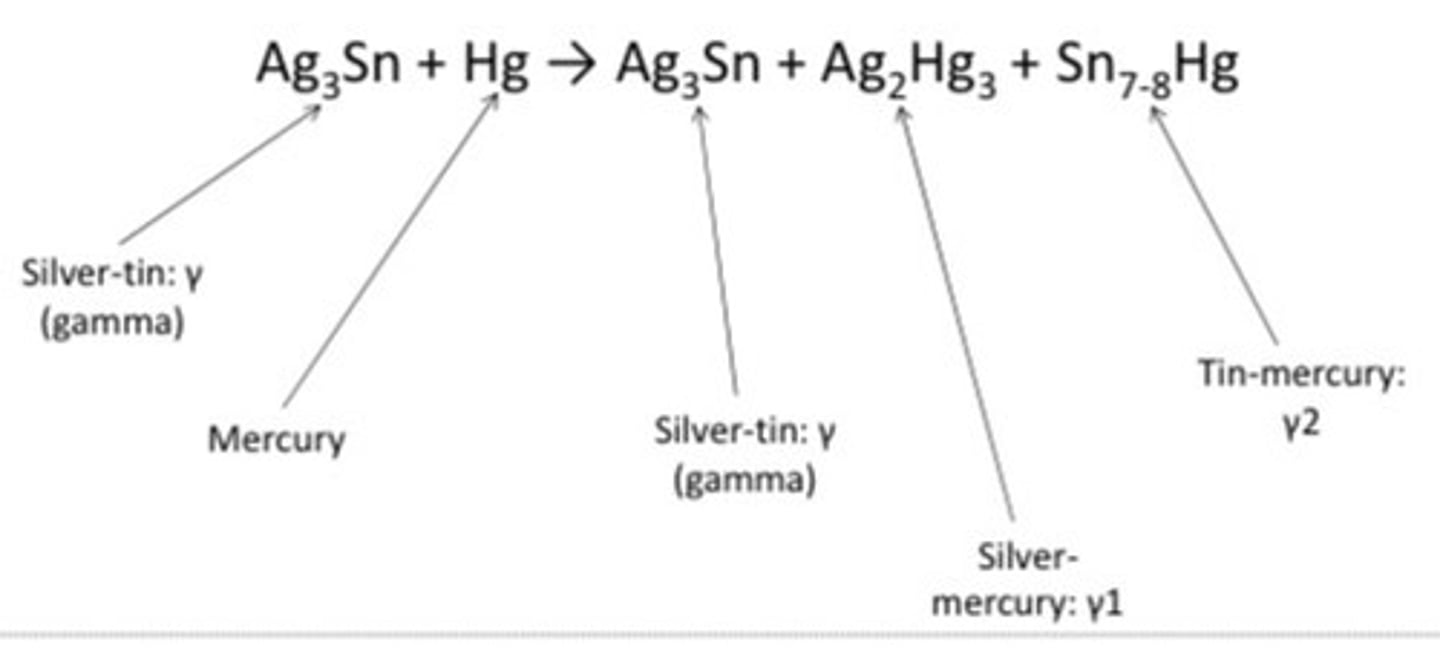

conventional amalgam equation in words

gamma + mercury --> gamma + gamma-1 + gamma-2

*gamma = AgSn

*gamma-1 = AgHg

*gamma-2 = SnHg

gamma

AgSn (silver + tin)

gamma-1

AgHg (silver + mercury)

gamma-2

SnHg (tin + mercury)

amalgam equation in chemistry molecules

AgSn + Hg --> AgSn + AgHg + SnHg

(equation = important)*

Ag

Sn

Hg

silver

tin

mercury

gamma phase involves ___ and is ___

silver-tin

very strong and corrosion resistant

gamma-1 phase involves ___ and is ___

silver-mercury

less strong + more corrosion susceptible compared to gamma phase

gamma-2 phase involves ___ and is ___

tin-mercury

the weakest and most corrosion susceptible of the three phases

strongest to weakest gamma phases

1. gamma (strongest)

2. gamma-1

3. gamma-2 (weakest)

least susceptible to corrosion to most gamma phases

1. gamma (rarely corrodes)

2. gamma-1

3. gamma-2 (easily corrodes)

high copper amalgam equation words

gamma + copper + mercury --> gamma + gamma-1 + CuSn

high copper amalgam equation chemistry molecules

AgSn + AgCu + Hg --> AgSn + AgHg + CuSn

adding copper changes amalgam by

eliminating gamma-2 (CuSn forms instead)

what % Cu is needed to eliminate gamma-2 phase? what % Cu do new formulas contain?

12%

9-30%

high copper amalgam (CuSn instead of gamma-2) is much ___ compared to conventional amalgam

stronger and superior restoration

high copper amalgam has less _ than conventional amalgam

creep

creep

deformation of dental amalgam under a constant compressive stress

permanent deformation under dynamic loading during function

main con of conventional amalgam

creep

high copper amalgam has ___ edge strength which prevents ___

improved

marginal ditching over time

zinc is considered ___ which means it prevents ___

scavenger/ deoxidizer

oxidation of other metals

zinc containing amalgam must be placed in what type of environment? why?

dry field

to prevent delayed secondary expansion

if zinc is not in a dry field, it will absorb ___ from water and will produce ___ which is bad b/c ___

O2

H2 gas

H2 gas pressures restoration and causes expansion (delayed secondary expansion)

how long does zinc amalgam restoration expansion take?

- starts 3-5 days after placements

- continues for several months

mercury %

43-52%

is mercury safe to use? why?

yes

12 amalgam restorations is only 1/100 TLC value

what procedures remove a portion of mercury from amalgam?

1. condensation

2. precarve burnishing

3. carving

the remaining mercury left in amalgam after procedures will remain ___ but little to no ___ from amalgam restorations

in finished restoration

mercury vapor leaks out

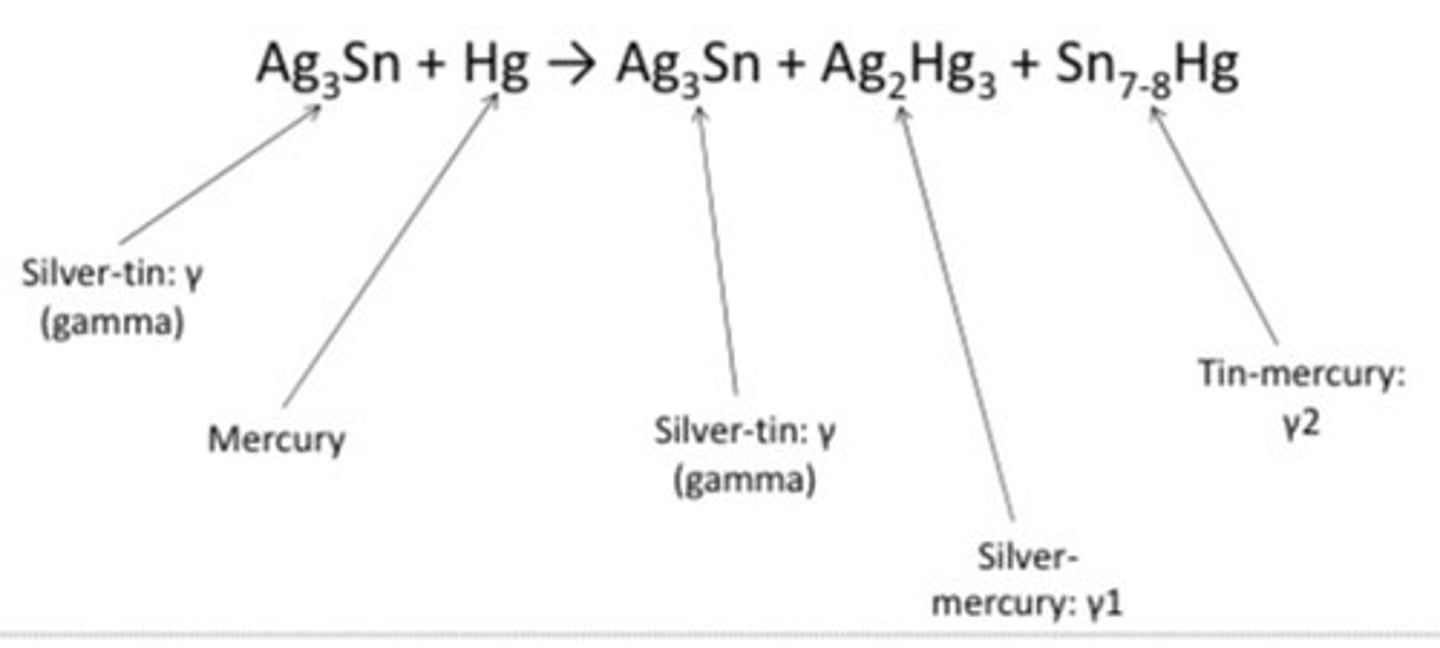

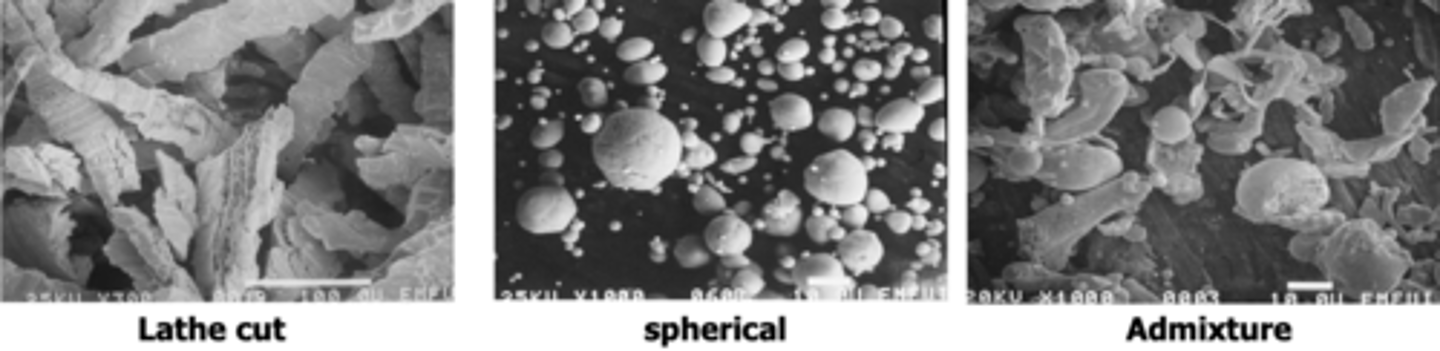

shape of alloy particle

1. lathe cut (irregular, not used)

2. spherical

3. admixed (spherical + lathe cut)

admixed alloy require

force during condensation --> ideal packing of material + proper adaptation to cavity walls

24 hr vs 1 hr admixed alloy strength

24-hour compressive strength is considerably greater than 1-hour strength

hand instruments and admixed alloys

wait at least 24 hr to use preparation and polishing hand instruments

spherical alloys require slightly less ___ due to ___ of spherical particles

mercury

small size

spherical alloys placement

easily placed and adapted to cavity walls w/ minimal pressure

spherical alloy strength at 1 hr compared to admixed alloys

much stronger

spherical alloys and hand instruments

hand instruments can be used 15 min after insertion

main con spherical alloys

hard to get proximal contact for class 2

admixed compressive strength at 1hr and 24hr

1hr = 12-18,000

24hr = 64-66,000

spherical compressive strength at 1hr and 24hr

1hr = 35-48,000

24hr = 65-70,000

amalgam coefficient of thermal expansion

2.5x that of tooth structure (more similar than composite)

is amalgam or composite coefficient of thermal expansion closer to actual teeth?

amalgam

amalgam compressive strength

equal to tooth structure

amalgam tensile strength

1/5-1/8 of tooth structure

amalgam is very ___ b/c it has low tensile strength, so to avoid issues, it must have ___ and ___

brittle

1.5-2mm thickness

90º margin

amalgam advantages (5)

- good wear resistance

- not technique sensitive

- can be placed w/ low isolation if needed (low zinc)

- corrosion products seal dentinal tubules

- low risk of secondary caries

how long does it take for corrosion products of amalgam to seal off dentinal tubules?

2-6 weeks

amalgam disadvantages (3)

1. good thermal conductor (bad!)

2. creep (only issue w/ conventional not contemporary amalgam)

3. invasive preps needed

to account for amalgam being a good thermal conductor, make sure you leave ___mm of dentin to ___. If this is not possible use a ___

2

spare the pulp

liner/ base

using bonding with dental amalgam (4)

- controversial

- less aggressive preps needed

- decent initial bond but deteriorates over time

- limits ability of amalgam to seal dentinal tubules

indications for amalgam restoration

all restorations (posterior and anterior) except class IV

when is it ok to use amalgam for anterior teeth?

- isolation problems

- high caries risk

- esthetics are not important (ex. low lip line)

contraindications for amalgam

1. allergy to alloys

2. esthetic areas (including molars/ premolars in some patients)

3. composite = more conservative (small lesions)

steps for amalgam restoration

1. matrix band

2. trituration

3. condensation

4. burnishing 1

5. carving

6. burnishing 2

7. polishing

matrix band purpose (3)

- provide proper contact and contour

- confine restoration material

- reduce excess material

matrix band indications

proximal surface restorations always + class 1or 5 amalgam restorations if needed

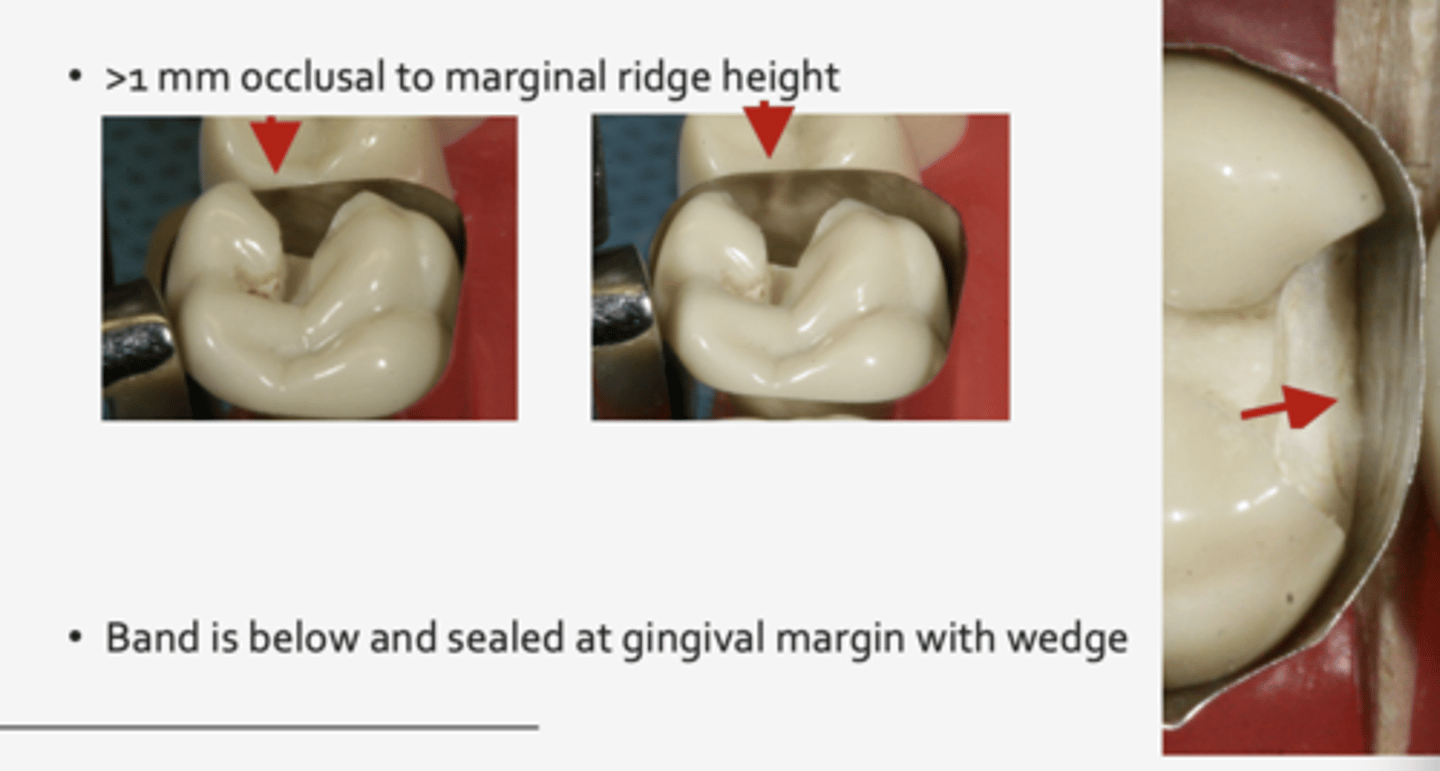

matrix band requirements (4)

1. easy to apply/ remove

2. extend below gingival margin

3. extend above adjacent marginal ridge height

4. resist deformation during insertion

why should matrix band be below gingival margin?

so it can be engaged by a wedge

why should matrix band be above adjacent marginal ridge height?

to allow for proper condensation

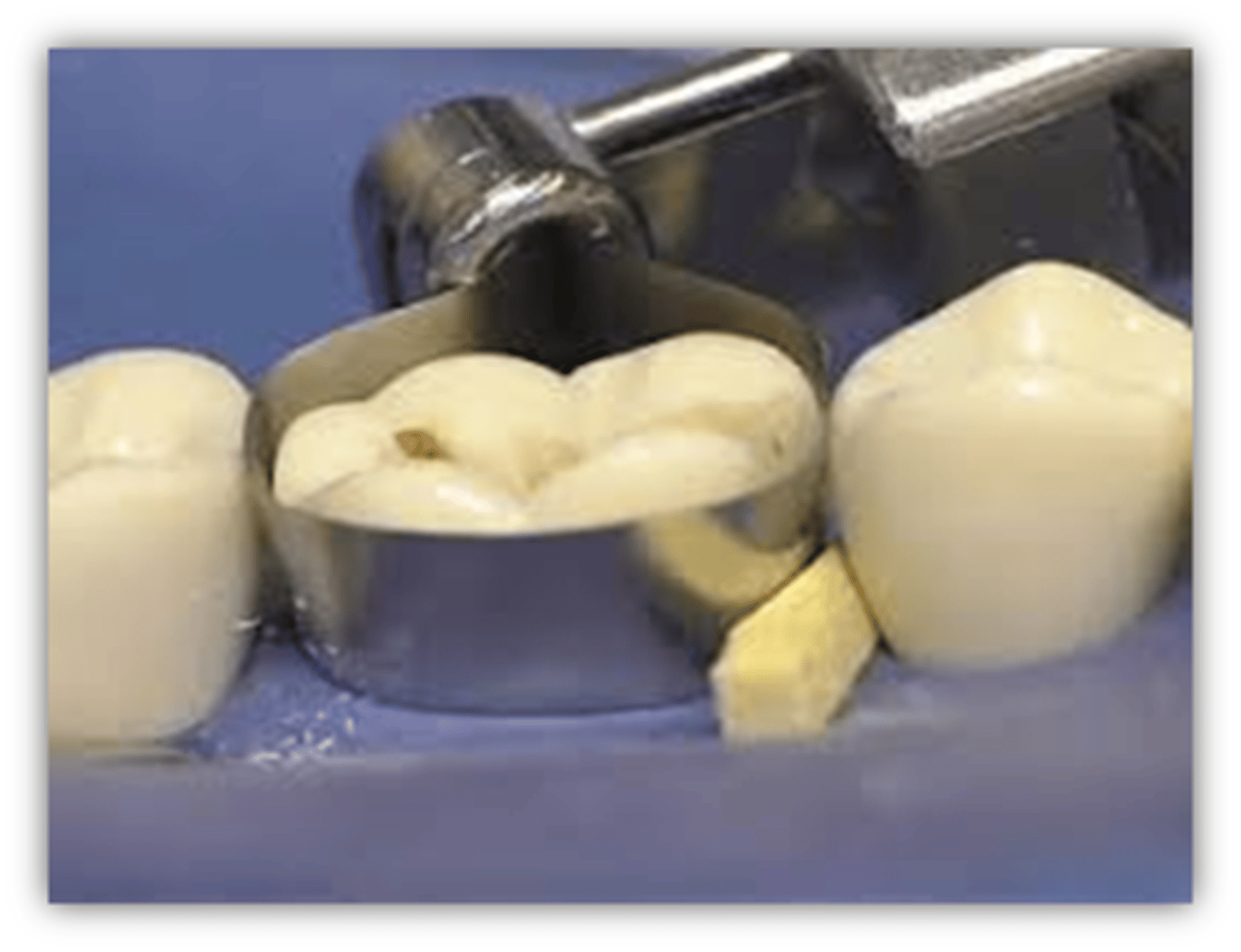

tofflemire matrix system components

1. band (may be trimmed for shallow gingival margin)

2. wedge

3. retainer

smaller circle of band goes over ___ part of tooth to be restored

cervical (wider part @ occlusal surface)

slots of head of tofflemire retainer head should be directed

gingivally

wedge must be properly placed to ___ and to allow proper ___

secure the matrix band

interproximal contour/ contact

wedge pros

1. avoid overhangs

2. proper interproximal contact (no gap between band and adjacent tooth)

3. proper interproximal contour

other types of matrix band

- automatrix

- ridged sectional (Garrison)

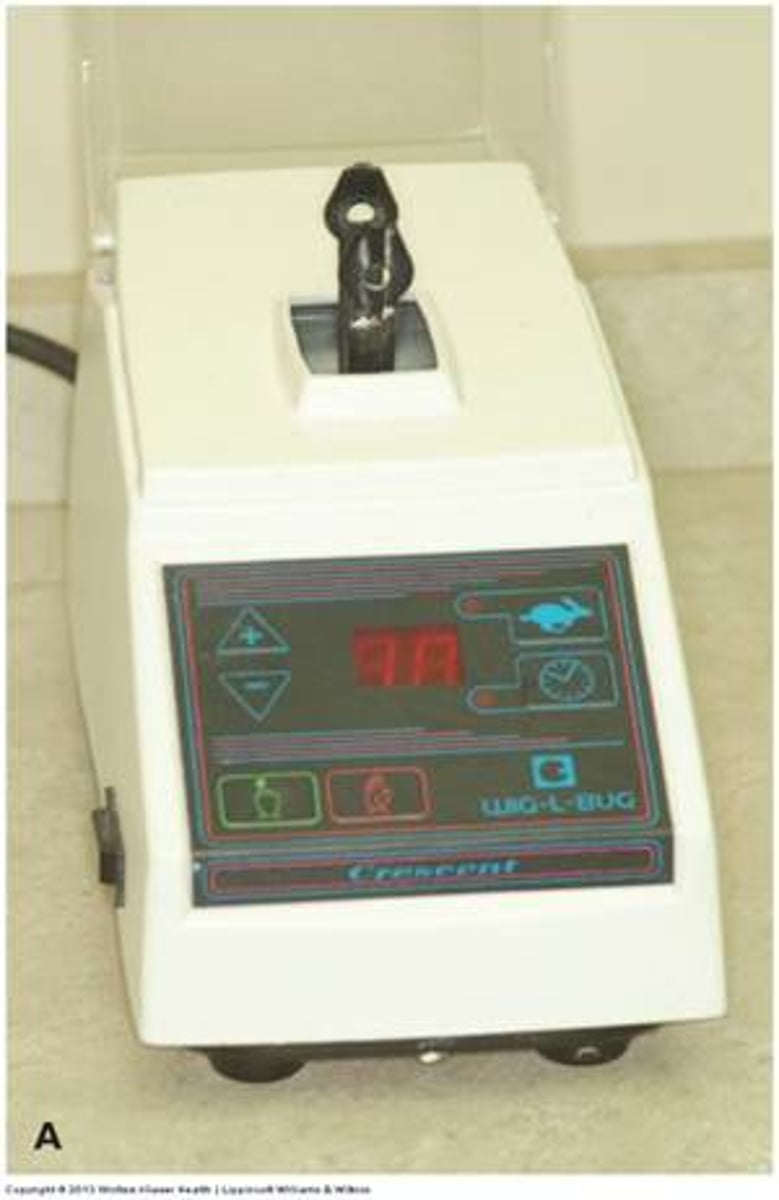

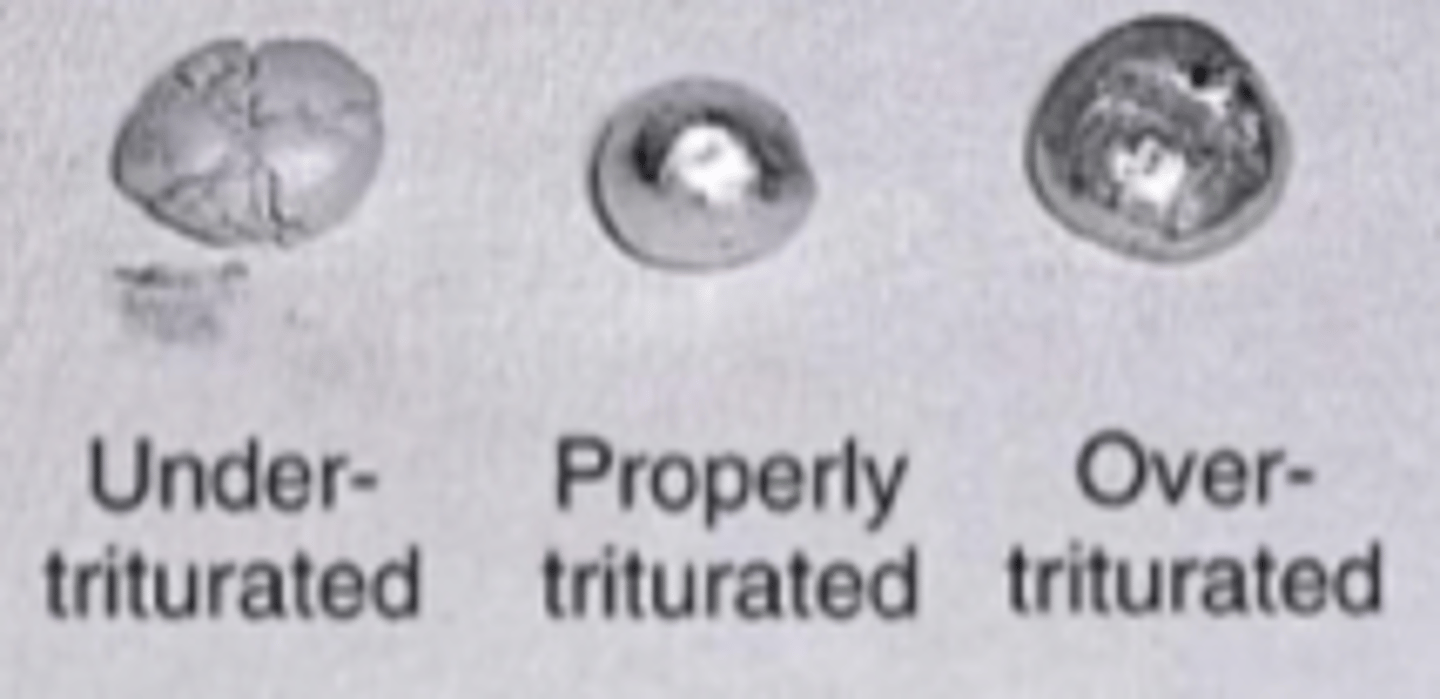

trituration (mixing) speed & time determines

mechanical properties + setting rxn

after trituration, amalgam should not be ___ and instead have a sufficient ___

dry/ crumbly

wetness

condensation insertion uses an ___ to pick up/ dispense amalgam

only press handle when ___

amalgam carrier

dispensing amalgam (not collecting)

condensation objectives (4)

1. adapt amalgam to prep walls + matrix

2. prevent voids

3. ↓ marginal leakage

4. ↓ mercury content in final restoration

with condensation, different forces are needed for

different types (spherical vs. admixed) of alloy particles

each portion must be condensed before

placement of the next increment

condensing stroke and the previous condensing stroke

condensing stroke should overlap the previous condensing stroke

what type of amalgam condenser is used first? why?

smaller amalgam condenser

so amalgam is condensed into internal line angles + secondary retention features

why should amalgam preps be overfilled?

to ensure condensation on occlusal surface

condensation and time

need to work fast (time specified by manufacturer)... discard mix if it becomes too dry

lateral condensation

facially, lingually, and proximally directed condensation

lateral condensation is important in ___ portions of prep

proximal box

benefits of lateral condensation (3)

1. amalgam in margins

2. eliminates voids

3. ideal proximal contact

precarve burnishing (burnishing #1 step)

overpacked amalgam is burnished immediately with a large burnisher, using heavy strokes mesiodistally and faciolingually

precarve burnishing purpose (3)

- finalize condensation (especially for marginal amalgam)

- remove excess mercury-rich amalgam

- initiate carving process

carving purpose

1. contour to achieve proper form and function

2. remove excess @ margin

carving: use ___ instruments, keep blade on tooth to ___, and reproduce proper ___

sharp

avoid submargination

anatomy

postcarve burnishing (burnishing #2 step) is done with ___ and involves ___

small burnisher

lightly rubbing the carved surface w/ burnisher to improve smoothness + satin (not too shiny) appearance

pressure of postcarve burnishing

surface should NOT be rubbed hard to produce grooves in the amalgam

postcarve burnishing advantages

1. improves marginal integrity

2. improves smoothness

3. substitutes conventional polishing when paired w/ precarve polishing

occlusion and postcarve burnishing

some practitioners check/ adjust occlusion before postcarve burnishing to better visualize the articulation paper markings

polishing considerations for amalgam

1. use rotary instruments

2. not always required

3. wait 24 hr for admixed amalgam

advantages of finishing/ polishing amalgam

1. refine anatomy, contours, and marginal integrity

2. refine surface texture

3. ↓ SURFACE corrosion

4. esthetics... but not really

___º angle to margin should be used when finishing so ___ and prevent ___

45

unprepared tooth can guide bur

unnecessary removal of amalgam

differences between pre and post carve burnishing

pre = heavy force, large burnisher

post = light force, small burnisher

admixed + spherical alloy at 1 hr is what fraction of its final strength?

admixed = 1/5

spherical = 1/2-3/4