TPM MODUL 3

1/93

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

94 Terms

RELIABILITY GOOGLE DEFINITION

the quality of being able to be trusted or believed because of working or behaving well, or how well a machine, piece of equipment, or system works

RELIABILITY 1

Generally defined as the ability of a product to perform, as expected, over certain time.

RELIABILITY 2

Formally defined as the probability that an item, a product, piece of equipment, or system will perform its intended function for a stated period of time under specified operating conditions.

RELIABILITY 3

In the simplest sense, reliability means how long an item (such as a machine) will perform its intended function without a breakdown.

RELIABILITY 4

Reliability is performance over time, probability that something will work when you want it to.

MAINTENANCE AND RELIABILITY

to maintain the capability of the system while controlling costs

MAINTENANCE

all activities involved in keeping a system’s equipment in working order

RELIABILITY (IN MAINTENANCE CONTEXT)

the probability that a machine will function properly for a specified time

MAINTENANCE TACTICS 1

Implementing or improving preventive maintenance

MAINTENANCE TACTICS 2

Increasing repair capability or speed

TACTICS TO IMPROVE RELIABILITY 1

Improving individual components

TACTICS TO IMPROVE RELIABILITY 2

Providing redundancy

FOUR IMPORTANT ELEMENTS OF RELIABILITY

Probability

Performance

Time

operating conditions

PROBABILITY

value between 0 and 1, number of times that an event occurs (success) divided by total number trials)

e.g. probability of 0.91 means that 91 of 100 items will still be working at stated time

PERFORMANCE

Some criteria to define when and how product fails, which also describes what is considered to be satisfactory system operation

e.g. amount of beam collisions, etc

TIME

(system working until time (t), used to predict probability of an item surviving without failure for a designated period of time)

OPERATING CONDITIONS

conditions (environmental factors, humidity, vibration, shock, temperature cycle, operational profile, etc.) that correspond to the stated product life.

CONFLICTS WITH REAL WORLD

Probability

intended function

under stated conditions

prescribed procedures

CONFLICTS WITH REAL WORLD PROBABILITY

Customers expect a probability of 1, “It Works”

CONFLICTS WITH REAL WORLD intended function

The product may be used in unintended ways and still be expected to work

CONFLICTS WITH REAL WORLD under stated conditions

The product may be operated outside of the stated conditions and still be expected to work

CONFLICTS WITH REAL WORLD prescribed procedures

Customers may not have the required tools or skill level and may not follow procedures and still expect the product to work

IMPORTANCE OF REALIABILITY 1

Companies who control the Reliability of their products can only survive in the business in future as today's consumer is more “intelligent” and product aware

IMPORTANCE OF REALIABILITY 2

Liability for unreliable products can be very high.

IMPORTANCE OF REALIABILITY 3

Complexity of products is ever increasing and thus challenge to Reliability Engineering is also increasing.

IMPORTANCE OF REALIABILITY 4

Products are being advertised by their Reliability Ratings.

Reliability

can be considered as ”Quality over time”. Customers frequently use the terms ”quality” and ”reliability”. We need to understand what they expect.

Measurement of reliability

is related to failure rates, number of failures, warranty cost etc. Thus, reliability is experienced by the customers when they use the product.

Quality Level

is measured in terms of defect levels when the product is received as new

Quality and reliability

both can have significant impact on Safety.

Quality defects and failures

both can adversely affect safety of user, bystanders and equipment.

QUALITY, RELIABILITY AND SAFETY

Some quality defects can lead to unreliable and/or unsafe product.

examples of how unreliability can affect safety

Failure of automobile steering system, brake system, axles

Short circuit in electrical equipment

Failure of safety valve in a pressure cooker, leakage of regulator of an LPG cylinder

Poor reliability of a bridge

EFFECTS OF FAILURE

Operation

Reputation

Profitability

Dissatisfied customers

Idle employees

Profits becoming losses

Reduced value of investment in plant and equipment

Reliability Engineering

is concerned with analyzing failures and providing feedback to design and production to prevent future failures

Reliability and maintainability engineering

attempts to study, characterize, measure, and analyze the failure and repair of systems in order to improve upon their operational use by increasing their design life, eliminating or reducing the likelihood of failures and safety risks, and reducing downtime thereby increasing available operating time.

Reliability engineers usually speaks of

Failures Causes

Failure Modes

Failure Mechanisms

HOW DO PRODUCTS REALLY FAIL

DESIGNED TO FAIL

MANUFACTURED TO FAIL

ASSEMBLED TO FAIL

SCREENED TO FAIL

STORED TO FAIL

TRANSPORTED TO FAIL

OPERATED TO FAIL

Two common types of failures 1

Sudden failure (no indicators)

Two common types of failures 1

Degradation (gradual wear out)

FAILURE

is an event when an item is not available to perform its function at specified conditions when scheduled or is not capable of performing functions to specification.

FAULT

The part of the item which must be repaired to prevent a failure

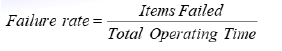

FAILURE RATE

The number of failures per unit of gross operating period in terms of time, events, cycles

TYPES OF FAILURE OF ITEMS

RANDOM

DEPENDENT

DEPENDENT FAILURES

CONSECUTIVE

FAILURES OF IDENTICAL ITEMS

DESIGN

ENVIRONMENTAL

FUNCTIONAL

FAULT CLASSIFICATION

PHENOMINOLOGICAL CAUSE

NATURE

PHASE OF CREATION OR OR OCCURENCE

SYSTEM BOUNDARIES

PERSISTENCE

PHENOMENOLOGICAL CAUSE

PHYSICAL

HUMAN MADE

NATURE

ACCIDENTAL

NONMALICIOUS INTENTIONAL

MALICIOUS

PHASE OF CREATION OR OCCURENCE

DEVELOPMENTAL

OPERATIONAL

SYSTEM BOUNDARIES

INTERNAL

EXTERNAL

PERSISTENCE

PERMANENT

TEMPORARY

Reliability, Availability, Maintainability, Safety and Quality

are what the Customer says they are, not what the Engineers or the Designers say they are.

Safety

is the probability that a system will either perform its functions correctly or will discontinue its functions in a manner that does not disrupt the operation of other systems or compromise the safety of any people associated directly or indirectly with the system.

Maintainability

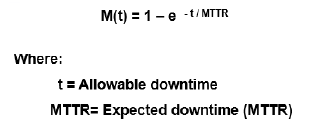

is defined to be the probability that a failed component or system will be restored or repaired to a specified condition within a period of time when maintenance is performed in accordance with prescribed procedures -M(t).

AVAILABILITY

is defined as the probability that a component or system is performing its required function at a given point in time when used under stated operating conditions -A(t).

RELIABILITY

defined to be the probability that a component or system will perform a required function for a given period of time when used under stated operating conditions -R(t).

AVAILABILITY

Machines with more frequent but less severe breakdowns are better in terms of process stability and inventory cost than machines with less frequent but more severe breakdowns.

Accurate assessment of availability and variability calls for high data integrity.

Must show all downtime for internal setups and failures

MAINTAINABILITY

is the measure of the ability of a system or item to be retained or restored to a specified condition when maintenance is performed by qualified personnel using specified procedure and resources

SPECIFIC PRINCIPLES OF MAINTAINABILITY

Reduce life cycle maintenance costS

Reduce the amount, frequently and complexity of required maintenance tasks.

Reduce mean time to repair (MTTR)

Determine the extent of preventive maintenance to be performed

Provide for maximum interchange ability

Reduce the amount of supply supports required

Reduce or eliminate the need for maintenance

Consider benefits of modular replacement versus part repair or throwaway design

SPECIFIC PRINCIPLES OF RELIABILITY

Maximize the use of standard parts

Use fewer components for performing multiple functions

Design for simplicity

Provide adequate safety factors between strength and peek stress values

Provide fail-safe design

Provide redundancy when required

Minimize stress on components and parts

Use parts and components with proven reliability

BATHTUB CURVE

The failure rate is expected to vary over the life of a product

A-B Early Failure / Infant mortality / Debugging / Break-in

Teething’ problems. Caused by design/material flaws

Eg: Joints, Welds, Contamination, Misuse, Misassembly

B-C Constant Failure / Useful life

Lower than initial failure rate and more or less constant until end of life

C-D End of life failure / Wear out phase.

end of life Failure rate rises again due to components reaching

eg.: Corrosion, Cracking, Wear, Friction, Fatigue, Erosion, Lack of PM

Reliability management

concerned with performance and conformance over the expected life of the product

RELIABILITY

______ of a system is often specified by the failure rate λ.

λ

failures per time unit (in a collection of systems)

bath-tub curve

For most technical products (incl. embedded systems), λ(t)

RELIABILITY MEASUREMENT FORMULA

MTBF

Mean Time Between Failures - The average time between failure occurrences. The number of items and their operating time divided by the total number of failures. For Repairable Items

MTTF

Mean Time To Failure - The average time to failure occurrence. The number of items and their operating time divided by the total number of failures. For Repairable Items and Non-repairable Items

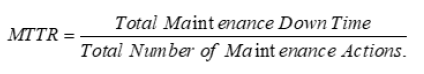

MTTR

Mean Time To Repair - The average time to restore the item to specified conditions.

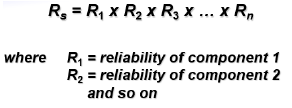

Improving individual components

Providing redundancy

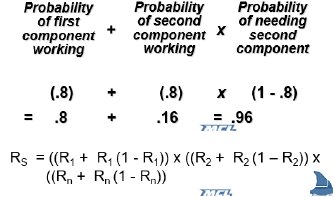

DESIGN

The most important aspect of reliability is the design.

It should be as simple as possible.

The fewer the number of components, the greater the reliability.

Another way of achieving reliability is to have a backup or redundant component (parallel component).

Reliability can be achieved by overdesign.

The use of large factors of safety can increase the reliability of a product.

When an unreliable product can lead to a fatality or substantial financial loss, a fail-safe type of device should be used.

The maintenance of the system is an important factor in reliability.

PRODUCTION

The second most important aspect of reliability is the production process.

Emphasis should be placed on those components which are least reliable.

Production personnel.

TRANSPORTATION

The third most important aspect of reliability

packaging

shipment

Performance of the product by the customer is the final evaluation.

Good packaging techniques and shipment evaluation are essential.

AVAILABILITY

It is a time-related factor that measures the ability of a product or service to perform its designated function.

The product or service is available when it is in the operational state, which includes active and standby use.

This measure of availability might be preferable because it gives incentive to reduce Both MTTR and internal setup time.

Setup time and MTTR are often interrelated to the extent that poorly maintained Equipment is harder to change over and adjust.

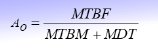

OPERATIONAL AVAILABILITY

MTBM-Mean time Between Maintenance

MTD- Mean Downtime

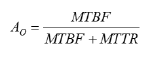

INHERENT AVAILABILITY

MTBF- Mean time Between Failures

MTTF- Mean Time to Repair

Availability differ from reliability.

Reliability involves an interval of time, while availability at an instant of time.

availability of a system depends

depends not only on how frequently it becomes inoperable but also how quickly it can be repaired.

system

can be highly available yet experience frequent periods of inoperability

AVAILABILITY AND MAINTAINABILITY

For long-lasting products and services such as refrigerators, electric power lines, and front-line services, the time-related factors of availability, reliability, and maintainability are interrelated

MAINTAINABILITY FORMULA

MTBMA

Mean Time Between Maintenance Actions including preventive and corrective maintenance tasks

OBJECTIVES OF MAINTAINABILITY 1

To influence design to achieve case of maintenance thus reducing maintenance time & cost.

OBJECTIVES OF MAINTAINABILITY 2

To estimate the downtime for maintenance which, when compared with allowable downtime, determines whether redundancy is required to provide acceptable continuity of a critical function

OBJECTIVES OF MAINTAINABILITY 3

To estimate system availability by combining maintainability data with reliability data.

OBJECTIVES OF MAINTAINABILITY 4

To estimate the man-hours and other resources required for performing maintenance, which are useful for determining the costs of maintenance and for maintenance planning

ADVANTAGES OF MAINTAINABILITY PREDICTION 1

It highlights areas of poor maintainability which require product improvement, modification or change of design.

ADVANTAGES OF MAINTAINABILITY PREDICTION 2

It highlights areas of poor maintainability which require product improvement, modification or change of design.

PROBABILITY OF REPAIR WITHIN THE ALLOWABLE DOWNTIME FORMULA