Chapter 2: Deformation of Solids

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

the amount of stress a material can resist before fracture (permanently deformed)

what is strength

σ = force/instantaneous area

what is the equation for true stress

σ = force/original area

what is the equation for engineering stress

ε = change in length/original length

what is the equation for engineering strain

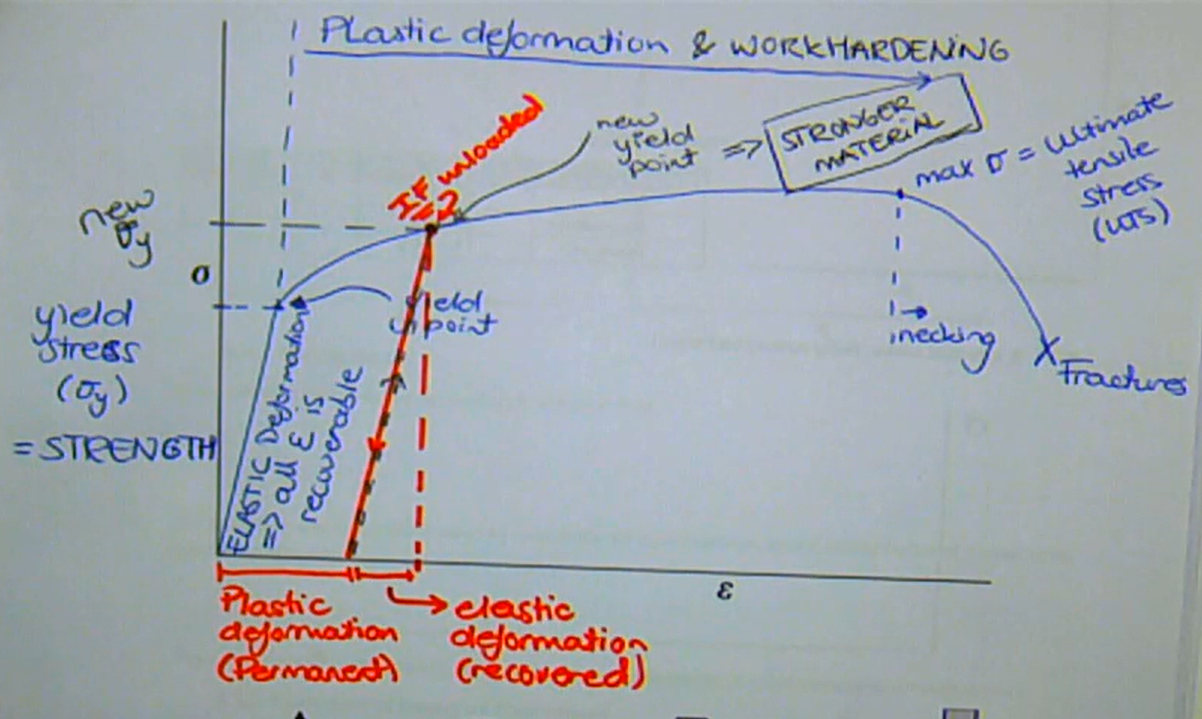

draw a stress-strain curve

recoverable

elastic deformation is what type of strain

straight line

what part of the stress-strain curve represents elastic deformation

permanent

what type of strain is plastic deformation

the maximum point

what point on the stress-strain curve represents the Ultimate Tensile Strength (UTS)

the local reduction in area of a material which occurs when stress is greater than the UTS

what is the process of necking

E = stress/strain

what is the equation for Young’s Modulus

ratio of how thin a material needs to be when stretched by a certain amount

what is Poisson’s ratio

v = - εx/εz

what is the equation for Poisson’s ratio

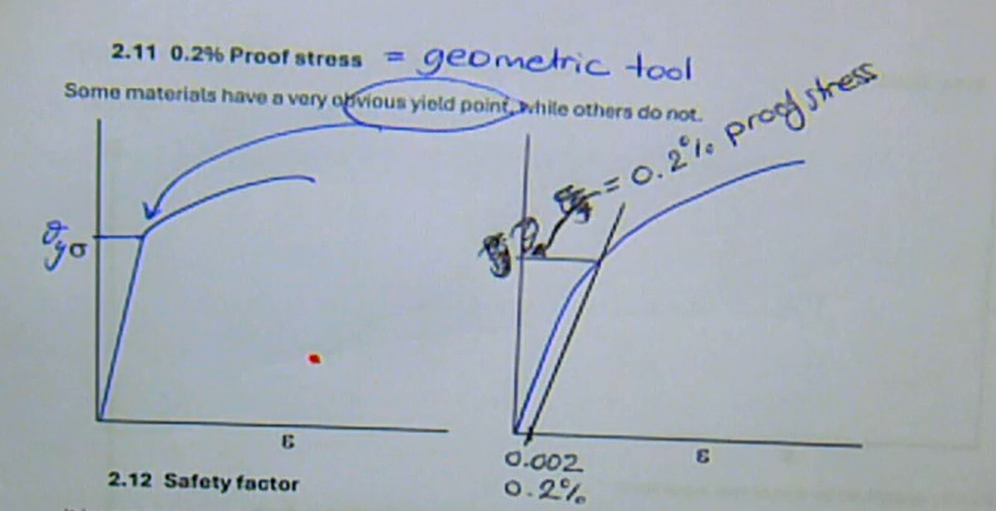

geometric tool used to find the yield point when its not very obvious

→ measure 0.2% of the total strain and draw a straight line going upwards

what is the 0.2% proof stress tool

pretend that:

material is weaker than it actually is

applied force is bigger than it actually is

what are the safety factors used by engineers when designing materials

elastic region where σ < σy

in what region of the stress-strain curve do engineers operate in

how much plastic deformation a material can withstand before fracture

what is ductility

% elongation: % EL = ∆L/∆L0 × 100%

% reduction in area: % RA = ∆A/∆A0 × 100%

what are the two equations that describe ductility

the energy required to fracture a material

what is toughness

area under the stress-strain curve

how is toughness calculated

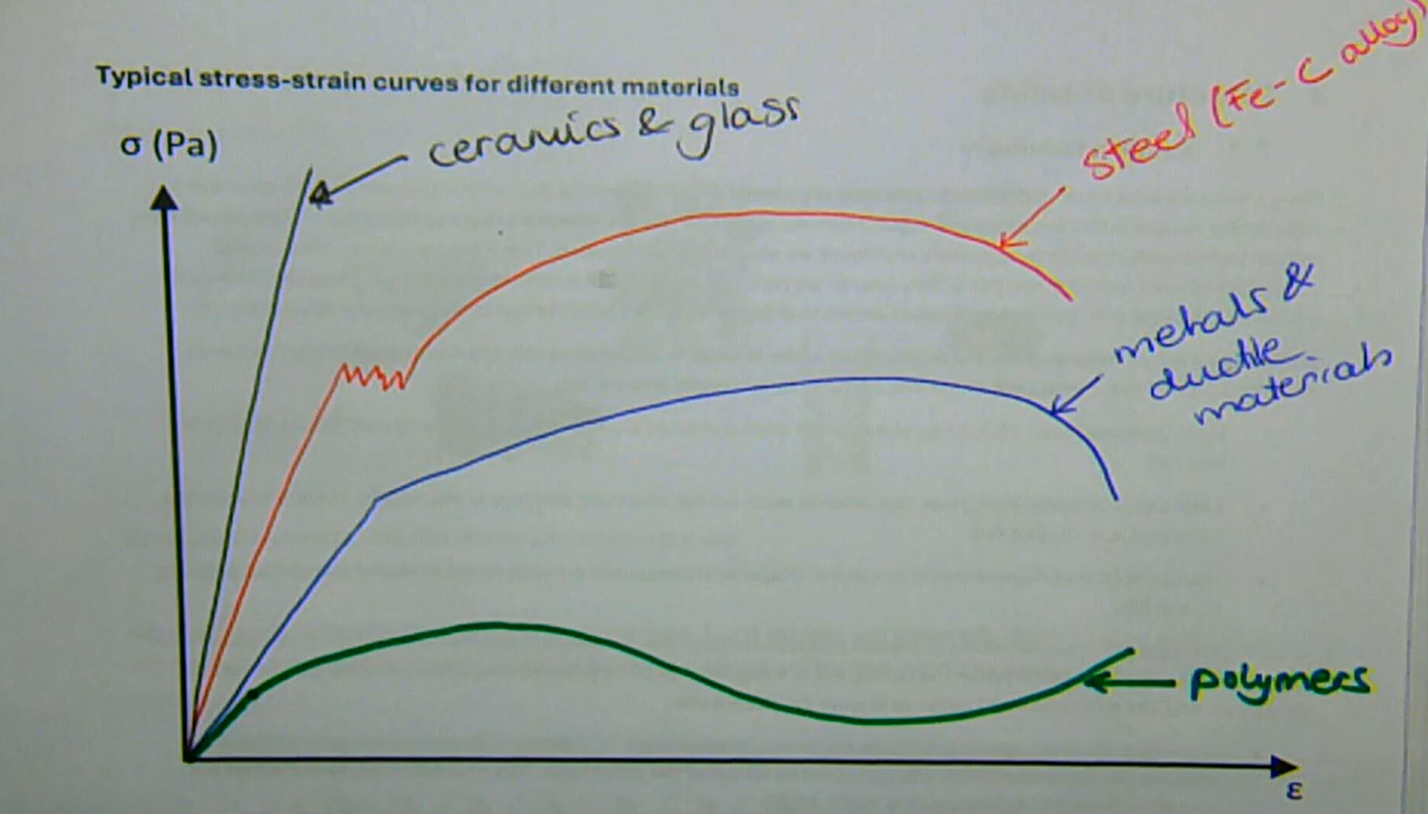

draw the stress strain-curve for ceramics and glass, steel (Fe-C alloys), metals and ductile materials, and polymers