metal ceramic restorations

1/166

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

167 Terms

the metal-ceramic restoration consists of a ______ substructure supporting a ______ veneer that is _________ and _______ bonded to it

a metal substructure supporting a ceramic veneer that is mechanically and chemically bonded to it

how is does the chemical componentof the bond achieved

through firing

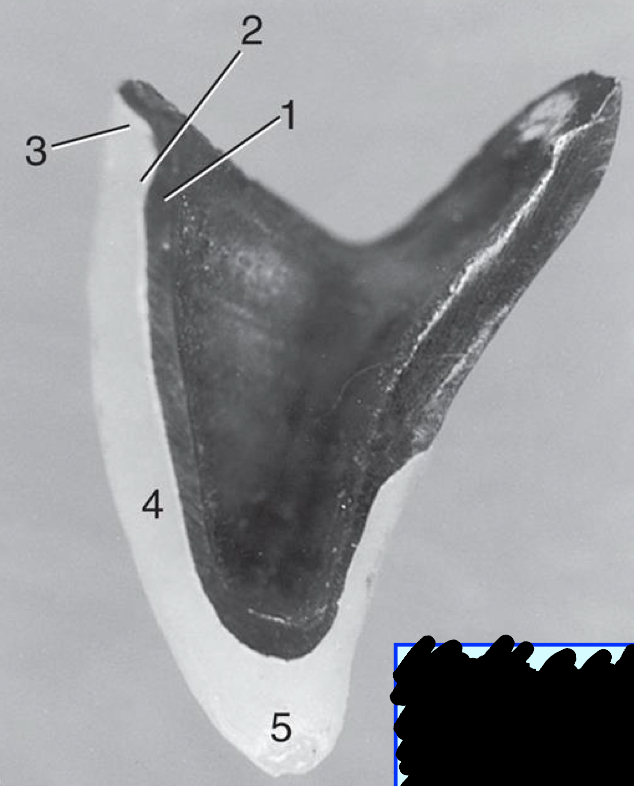

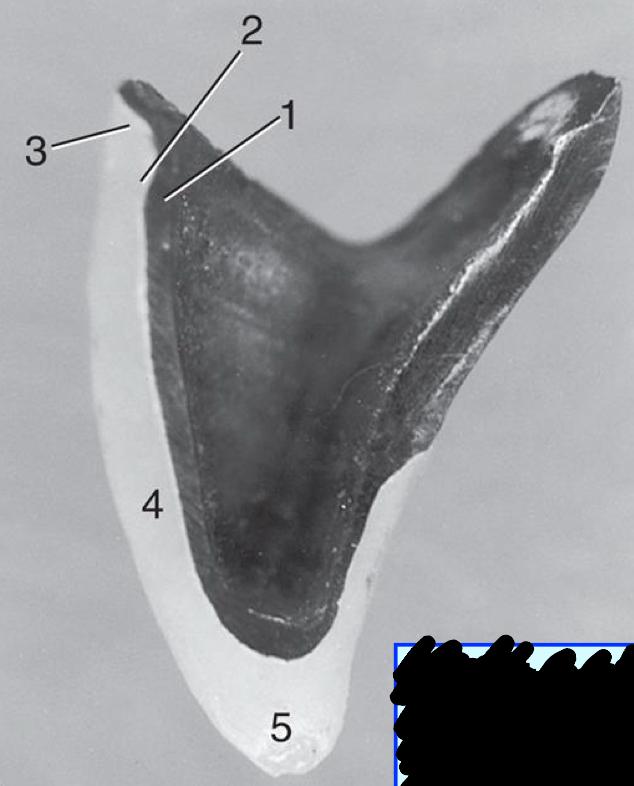

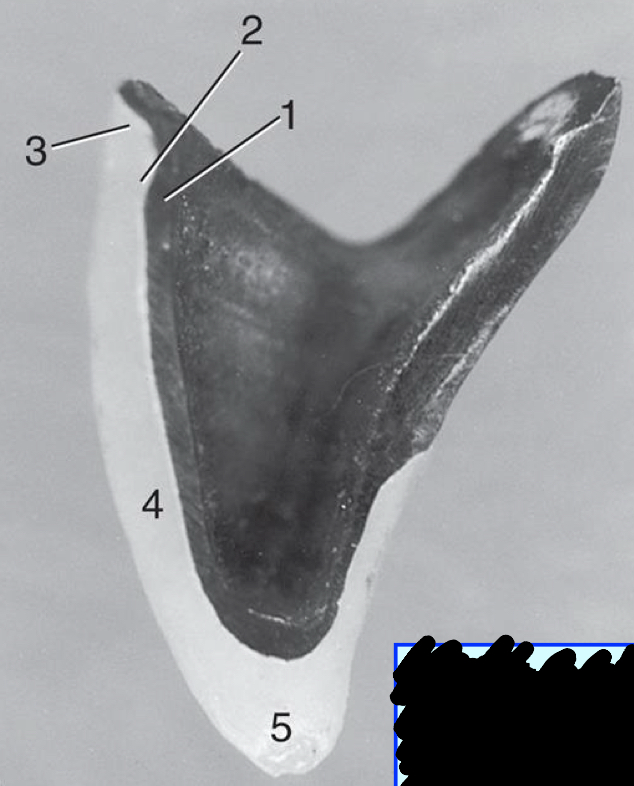

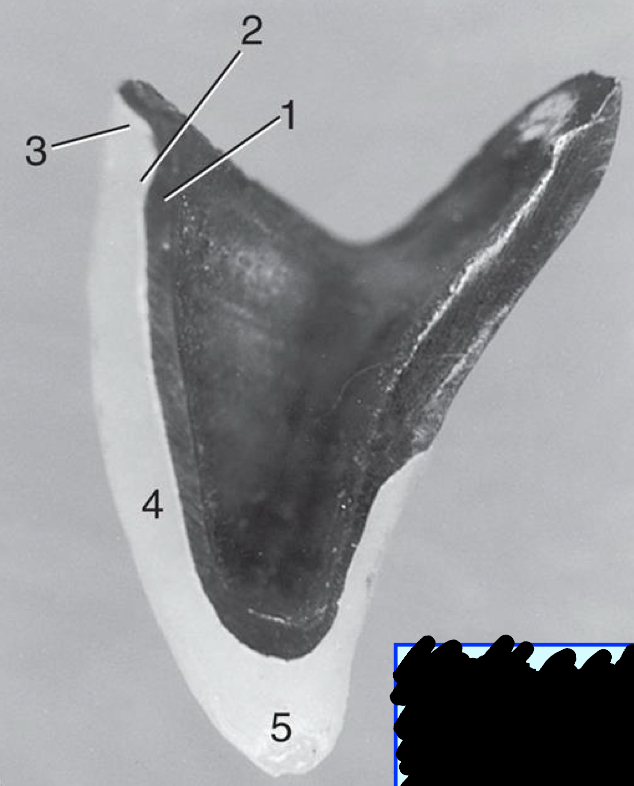

1

metal substructure

2

opaque porcelain

3

gingival porcelain

4

body porcelain

5

incisal porcelain

what are the types of metal ceramic restorations

metal ceramic crowns

porcelain fused to metal (PFM) crowns

ceramic-veneered crowns

indications for metal ceramic restorations (5)

similar for complete cast crowns:

extensive coronal destruction

maximum retention and resistance form

correction of axial wall

restore endodontically tx tooth

esthetic demands

are all-ceramic restorations or metal ceramic restorations more esthetic

all ceramic restorations

contraindications for metal ceramic restoration

pt has active caries or untx periodontal disease

young pts w large pulp chamber

when more conservative restoration is feasible

advantages of metal ceramic restorations (3)

strength of complete cast restoration w esthetics of all ceramic crown

is the better choice to serve as a retainer for fixed partial denture (FPD)

can be used for survey crowns

why are metal ceramic restorations better used to serve as a retainer for a FPD

its metal substrate can accommodate cast or soldered connectors

why can metal ceramic crowns be used for survey crowns

modified to incorporate occlusal and cingulum rests and milled proximal and reciprocal guide planes in their metal structure

disadvantages of metal ceramic restoration (6)

requires significant tooth reduction

in highly esthetic areas, margin needs to be placed subgingivally → inc potential for periodontal disease

have slightly inferior esthetic compared to ceramic restoration

fx of ceramic layer when it is not designed or processed properly

difficult shade selection

more expensive laboratory costs

what are the 4 classifications of metal alloys for metal ceramic restorations

high noble alloys

titanium alloys

noble alloys

predominantly base alloys

examples of noble metal content

gold, platinum group metal

requirement for high noble alloys

noble metal content >/= 60% and gold >/= 40%

requirement for titanium and titanium alloys

titanium >/= 85%

requirement for noble alloys

noble metal content >/= 25%

requirement for predominatly base alloys

noble metal content < 25%

is silver a noble metal alloy

NO

high noble/noble-metal alloys have good ________ resistance

corrosion resistance

what high noble/noble-metal alloys have desirable yellow color

Au-Pt-Pd

what high noble/noble-metal alloys are added to for oxide layers to produce a desirable ceramic-metal bond

indium (In), Tin (Sn), and Iron (Fe)

what base-metal alloys provides tarnish and corrosion resistance

chromium

what base-metal alloys are added to dec the thermal coefficient of expansion

molybdenum

what base-metal alloy becomes important for metal ceramic restorations in the future/oxide layer

Ti alloys

what is the importance of the oxide layer

for when you want a bond between cermic and metal

do base-metal alloys or noble/high-noble alloys have a superior mechanical property (elastic moduli and hardness are high)

base metal alloys

base metal alloys can also be _____ for resin bonding

etched

negative characteristics of base metal alloys (6)

markedly higher corrosion in acidic environments

difficult finishing and polishing

dark, thick oxides

risk of pt allergy

difficult soldering

harder to cast and ensure appropriate marginal fit of restoration

why are base metal alloys harder to cast and ensure appropriate marginal fit of restoration

their liquidus temperatures are the highest among all prosthodontics alloys

what are the 3 types of dental ceramic (porcelain)

quartz (Silica-SiO2)

feldspar

kaolin/other oxides

what is feldspar ceramic

potassium aluminum silicate orthoclase and sodium aluminum silicate

rank silica, kaolin, and feldspar from msot to least common dental ceramics

feldspar > silica > kaolin

classifications of dental ceramic

high fusing porcelain

medium fusing

low fusing

ultralow fusing

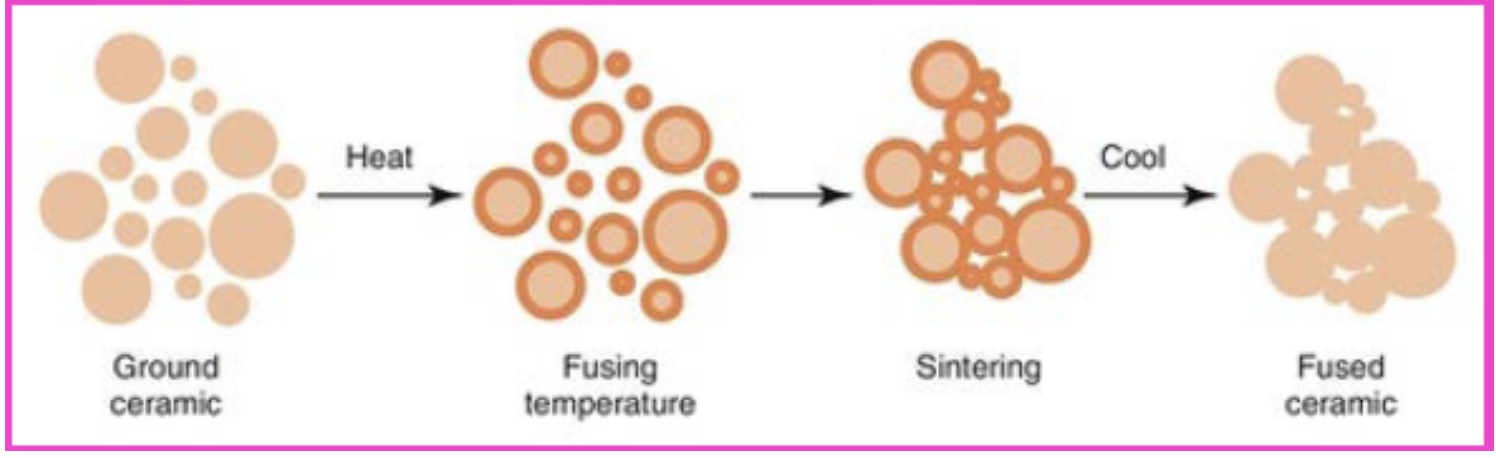

what is the fusion temperature

temp at which the powder particles of dental ceramic fuse together

applications for high fusing porcelain

denture teeth and fully sintered alumina and zirconia core ceramics

sintering temperature range for high fusing porcelain

> 1300 C

applications for medium fusing porcelain

denture teeth, presintered zirconia

sintering temperature range for medium fusing porcelain

1101-1300 C

applications for low fusing porcelain

crown and bridge veneer ceramic

sintering temperature range for low fusing porcelain

850-1100 C

applications for ultralow fusing porcelain

crown and birdge veneer ceramic

sintering temperature range for ultralow fusing porcelain

< 850 C

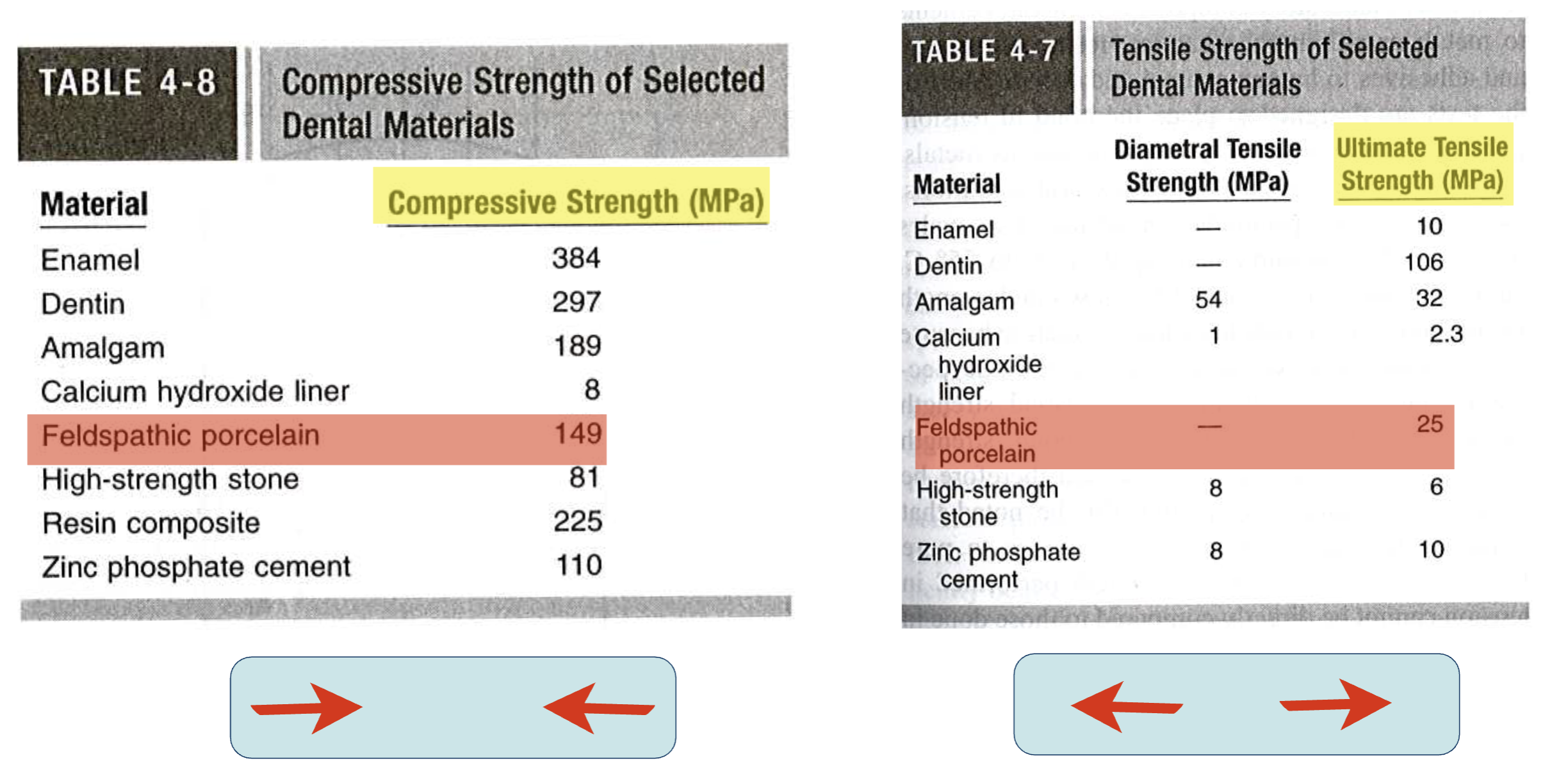

porcelain is _____ (strong/weak) under compression but ______ (strong/weak) when placed under tension

porcelain is strong under compression but weak when placed under tension

what is the coefficient thermal expansion

the change in length per unit length of a material for a 1 degree C change in temperature

the coefficient thermal expansion of the metal alloy needs to be slightly ______ (higher/lower) than the dental cermic

metal needs to be slighly higher than ceramic

what factors can affect the bond between the ceramic and metal

the oxide layer between the metal and cermic

airborne-particle abrasion w aluminum oxide (alumina) on alloy castings to provide mechanical interlocking

the linear coefficients of thermal expansion for th emetal and ceramic must closely match to achieve a strong bond interfacial bond

what technique is commonly used in the fabrication of porcelain

lost wax technique

what are the layers of procelain during fabrication

opaque layer

body porcelain

enamel porcelain

surface glaze

what is waxing to anatomic contour

full anatomic contour and then cutting back for a consistant amount of porcelain

having even porcelain thickness will provide superior ______ properties in the completed restoration and standardizing ______ reproduction

superior mechanical properties; standardizing shade reproduction

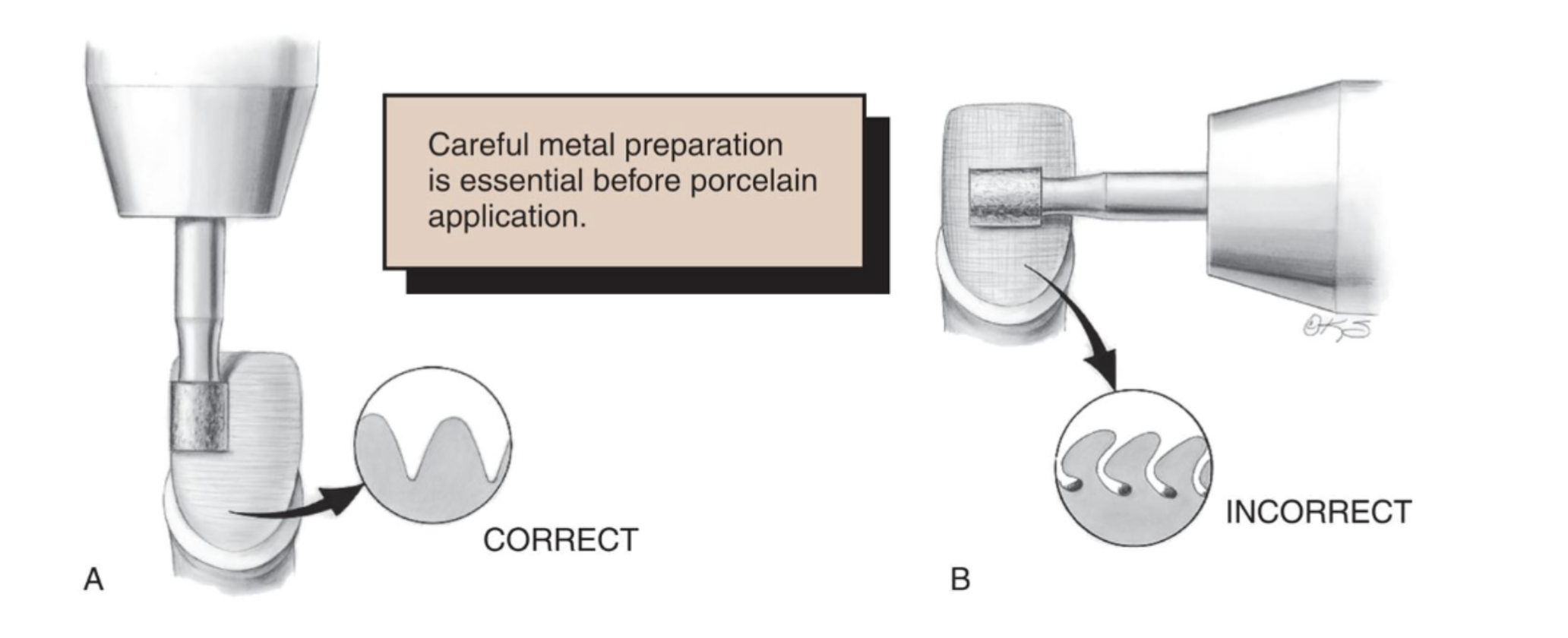

shape of metal preparation

avoid sharp angles on the veneering surface

convex surfaces and rounded contours

smooth surface

why should you avoid sharp angles on the veneering surface of the metal preparation

bc they can contribute to internal stress in the fired porcelain

purpose of smooth surface in the shape of metal preparation

facilitates wetting of the framework by the porcelain slurry

the intended metal-ceramic junx should be as ______ and as ______ as possible

should be as definite (90 degree angle) and as smooth as possible

metal framework thickness requirements for noble metal alloys vs base metal alloys

noble metal alloys: 0.3 mm

base metal alloys: 0.2 mm

the metal-ceramic interface must be far away from all centric occlusal contacts and must be distinct, it needs to be at least ___ mm away

1.5 mm

after investment removal, how should it be cleaned

ultrasonic

airborne particle abrasion

steam

during metal preparation, the oxide layer has been formed on the metal surface duing ____ must be partially removed w ____ or _____ abrasion

during casting; removed w acid or air abrasion

achieving a successful bond depends on a controlled thickness of the…

metal-oxide layer

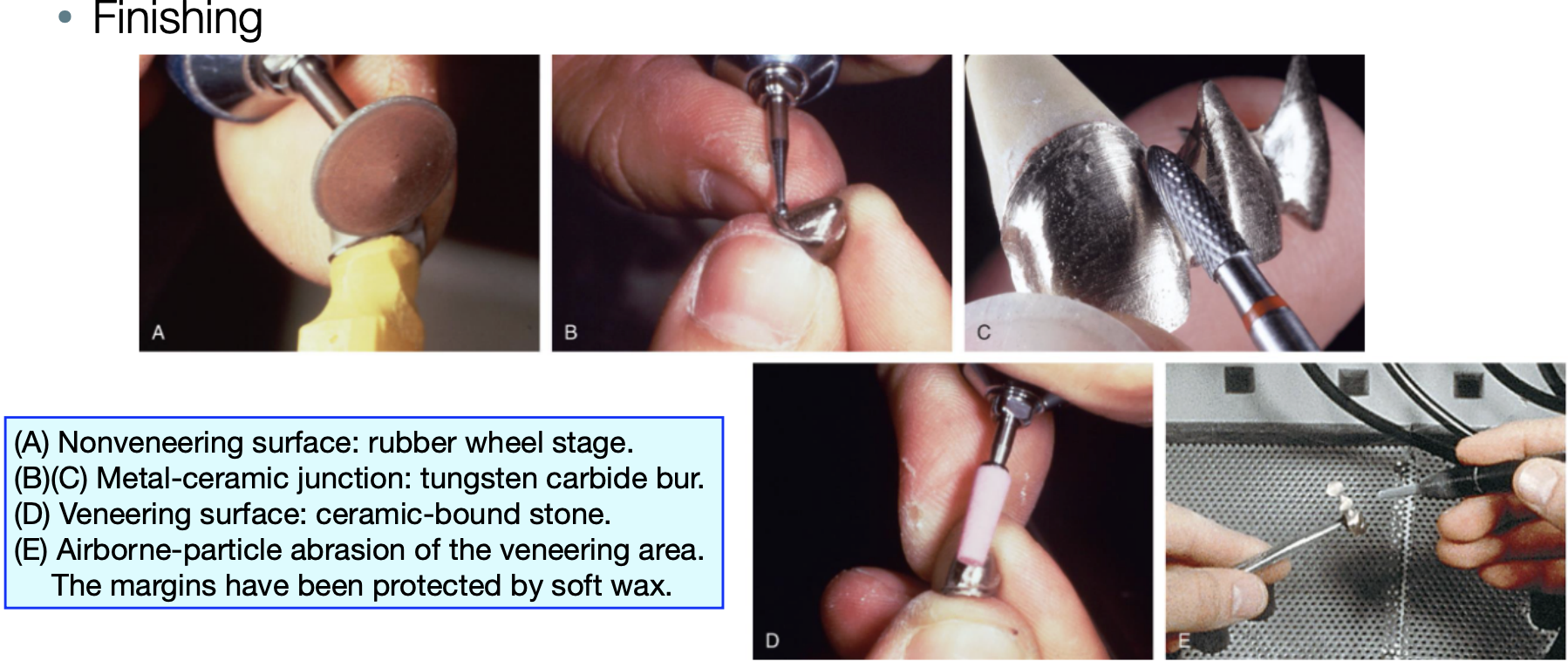

how should you do metal finishing

one direction without dragging the metal over itself- entrapping air and grinding debris

in metal preparation, what do you want to finish w

ceramic-bound stones or tungsten carbide burs

after the metal surface has been smoothed, what should you do

should be airborne-particle abraded w aluminum oxide according to the manufacturer instructions

what is necessary to verify that the metal substructure conforms to all specified minimum dimensions

dial or metric caliper

in metal preparation, less than ____ mm may lead to distortion during firing

0.3

steps of finishing in metal preparation

(A) nonveneering surface: rubber wheel stage

(B) (C) metal ceramic junction: tungsten carbide bur

(D) veneering surface: ceramic bound stone

(E) airborne-particle abrasion of the veneering area

how to protect the margins during finishing

soft wax

how to clean metal in metal preparation

immersion in a general-purpose cleaning solution in an ultrasonic unit for 5 minutes

steam clean

a controlled oxide layer must be created on the metal surface to establish…

chemical bond between metal and porcelain

how to create the oxide layer

insert substructure into a porcelain furnace above the porcelain firing temp w or w/o vacuum

to create an oxide layer, which requires a longer holding time

high noble alloy

noble

base metal

high noble alloy

to create an oxide layer, which requires a less holding time

high noble alloy

noble

base metal

noble

to create an oxide layer, which has no required oxidizing cycle

high noble alloy

noble

base metal

base metal

purpose of opaque porcelain

bonds to alloy

masks the color of the alloy

________ (body/enamel) of dental porcelain powders provides the most shade to match natural teeth and bonds to the opaque porcelain

body

________ (body/enamel) of dental porcelain powders is the most translucent

enamel

condensation techniques is by ______ action in the dental porcelain technique

capillary

how to do the condensation technique

gentle patting w a brush and light tapping on the cast produces adequate vibration during the preliminary stage of condensation; a tissue is held close for removal of excess surface moisture

what is sintering

when the mass is heated, individual porcelain particles conglomerate and bridge together

during sintering, a loss of interstitial space occurs, accompanied by as much as a ___% to ____% volumetric shrinkage after firing

27%-45%

outcome of bisque bake

not as shiny as tooth

to create a shiny surface similar to the natural teeth, a bisque baked ceramic needs to be _____

glazed

what happens to porcelain after being glazed

the surface porcelain is vitrified a glossy and smooth surface is created

what is autoglazing

oven temp is raised to the fusion temp and the bisque baked is maintained in that temp before cooling, occlusal contacts are altered during glazing

what is overglazing

a seperate mix of powder and liquid is applied to the surface and the restoration is fired

to create a natural looking tooth, ___________ may be incorporated

colored pigments

how to add internal characterization

pigments can be incorporated in the opaque, body, or incisal powder

when is external characterization done

is preformed during overglazing

what is external characterization

pigments are added to the surface of the bisque baked porcelain then they are fired in glazing temp

steps for metal-ceramic restoration as the same as

complete cast crown

what can cause fx during bisque bake (4)

improper condensation

improper moisture control

poor framework design

incompatible metal-porcelain combination

what can cause bubbles in metal-ceramic restorations (5)

too many firings

air entrapment during buildup of restoration

improper moisture control

poor metal preparation

poor casting technique

what can cause unsatisfactory appearance in metal-ceramic restorations (4)

poor communication w technician

inadequate tooth reduction

excessive thickness of opaque porcelain

excessive firing

what can cause clinical fx in metal-ceramic restorations (3)

poor framework design

centric stops too close to metal-ceramic interface

improper metal preparation

christensen’s survery estimated the longevity of crowns to be from…

21 to 22 years

survey by Maryniuk and Kaplan survey for longevity of metal-ceramic crowns were

12.7 years

in review of records in 40 Dutch dental offices, leempoel et al told of 10-year survival rates in _____% for full crown and ___% for metal ceramic crowns

98% full crowns; 95.3% for metal ceramic crowns