Materials, Hardware, and Processes 1

1/97

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

98 Terms

Hardness

The ability of a material to resist cutting, penetration, abrasion or permanent distortion

Hardness is measured with…

either a Rockwell or Brinell hardness tester

Stress

The internal force within a body that opposes an external force

Tension

Two forces in-line away from each other.

Tends to pull an object apart

Compression

Two forces in-line towards each other

Tends to crush a material

Shear

Two forces opposite but not in line with each other

Tends to tear objects

Torsion

A combination of compression and tension acting perpendicular

Tends to twist objects

Bending

Two forces in-line towards each other

Tends to crush (compression) or pull apart (tension) a material

Strength

a materials ability to withstand stresses without deforming or failing

Types of Strength

Tensile Strength- An object’s ability to withstand tension

Yield Strength- A metal’s ability to resist deformation

Shear Strength- A metal’s ability to resist opposing forces

Bearing Strength- The ability of a joint to withstand excessive compressive distortion

Strength-to-Weight Ratio

The relationship of the strength of a material to its weight per cubic inch

Density

The mass per unit volume of a material (can be used to identify material)

Malleability

The ability of a metal to be hammered, rolled, or pressed into shape without cracking, breaking, or leaving some other detrimental effect

Ductility

The ability of a metal that allows it to be drawn into wire, extrusions, or rods

Elasticity

The ability of a material to return to its original shape once the deforming force has been removed

Toughness

A materials ability to resist tearing or breaking when it is bent or stretched

Brittleness

materials tendency to break or shatter when exposed to stress

Fusibility

The ability of a metal to be joined by heating and melting

Conductivity

The ability of a material to transfer heat or electricity

Thermal Expansion

The change in a metal’s size due to it’s change in temperature

Coefficient of Expansion

the amount of expansion or contraction at specific temperatures

Understand the difference between hardness, strength, and toughness

Ferrous Aircraft Metals

Any material where iron is the chief constituent

Carbon

Most common alloying agent found in steel

Allows the steel to be heat treated for hardness and strength

SAE Classifications

Based on a four-digit number

First digit- generally indicates major alloying agent

Second digit- generally indicates percentage of agent

Last two digits- percentage of carbon (in hundredths of a percent)

Stainless Steel

Group of steels that exhibit excellent corrosion resistance properties

Answer and Match the quote with its source: Is it racist if you dislike all races equally?

No. -Daniel

300 Series Stainless Steel

High percentage of chromium and nickel

Most common corrosion-resistant steel used in Aviation

Also known as 18-8 steel (18% Chromium and 8% Nickel)

Identification of Ferrous Metals

Spark Testing

Color

Electrochemical Test

Aluminum

Non-ferrous Aircraft Metals

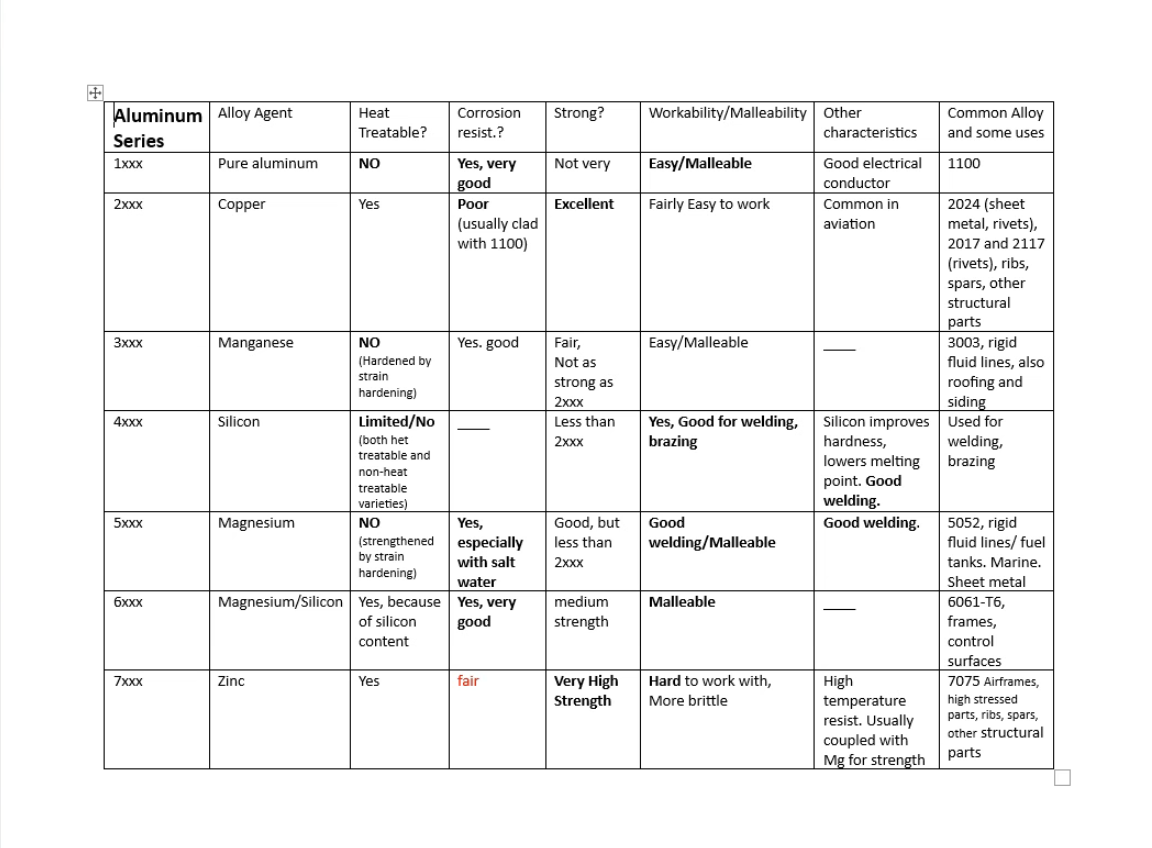

Wrought Aluminum Classification

Based on four-digit number

First Digit- Major alloying agent

Second Digit- Variations of initial alloy “modification”

Last Two Digits- Other alloying agents (except 1xxx series)

1xxx – Pure Aluminum

2xxx – Copper

3xxx – Manganese

4xxx – Silicon

5xxx – Magnesium

6xxx – Magnesium and silicon

7xxx - Zinc

8xxx – Other Elements

Alloy Structure Adjustments

F – As fabricated

W – Solution heat treating no aging

O – Annealed

T3 – Solution heat treated then cold worked

T4 –Solution heat treated

T6 – Solution heat treated then artificially aged

T8 – Solution heat treated, cold worked then artificially aged

H – Strain hardened

H1 – Strain hardened only

H2 – Strain hardened and partially annealed

H3 – Strain hardened then stabilized

There will typically be another digit following the H1, H2, H3. This indicates to what degree the material was hardened. 2 = ¼ hard, 4 = ½ hard, 6 = ¾ hard, 8= full hard

Monel

68% nickel, 29% copper

Inconel

80% nickel, 14% chromium

Four requirements when selecting replacement parts

Maintain original strength (and flexibility) of the structure (most important)

Maintain contour or aerodynamic smoothness

Maintain original weight if possible, or at least minimum weight

Maintain original corrosion resistant properties

Hot-Working

Process of forming a metal at an elevated temperature

Pressing

Used to form large and heavy parts

Drop Forging

Hammering process where hot metal is placed between formed dies and a weight of several tons is dropped on the upper die, forcing the metal to take the shape of the die

Hammering (Smith Forging)

Metal worker physically hammers a piece of metal into its finished shape

Cold working

working with a metal below it's critical temperature

Cold rolling

A form of cold working where a metal is rolled at a room temperature until it is the appropriate size

Cold drawing

Used to make seamless tubing, wire, and other stock

Extruding

The process of forcing a metal through a die which imparts the required cross-section to the metal

Hardening

process of heating metal above it's critical temperature and then quench with water, oil or brine

Tempering

The process of heating metal below It’s critical temperature,

soaking, and then allowing to cool at room temperature

Annealing

the process of heating metal above it's critical temperature, soaking, and then allowing to cool very slowly in the furnace

Normalizing

the process of heating metal above it's critical temperature, soaking, and then allowing it to cool in still air

Case Harding

A process which gives the surface of a metal a hard, durable bearing surface, but allows the core material to remain strong but not brittle

Carbonizing

Nitriding

Alclad aluminum

consists with an aluminum-alloy core coated with a layer of pure aluminum

Solution heat treatment

heated above critical temperature, allowed to soak, then quenched.

designated with a "t"

Precipitation heat treating

designed to increase the strength of the alloy beyond the level provided by solution heat treatmen

Strain Harding

a process by which non-heat treatable alloying can have their strength increased

Brazing

a non-ferrous metal usually brass Or bronze, is used as the adhesive material.

Soldering

follows the same concept as brazing

Hard/Silver soldering

variant term for brazing

Proper preparation is key to a quality soldered joint. T or F

True

Flux

cleans material & improves adhesion

Welding

a method of joining pieces of metal by fusion

Types of welding

gas, electric arc welding ( shielded metal arc welding, gas metal arc welding, tungsten arc welding)

Types of weld repairs

simple welded patch, welded split reinforcing sleeve, figerpatch, tube splice, cluster replacement, engine mount

Good welds should

weld should be of consistent width throughout, the two edges should form a parallel line, face of the weld should be slightly convex not more than 1/16", free of excessive spatter, scale, and pitting, etc…

Wood

(standard) - Sitka spruce; high strength to weight ratio, relatively free from defects, available in large sizes

Wood quality

must have straight grain, no spike knots, hard knots up to 3/8" D.I.A.,

Pitch pockets

Compression wood not acceptable

Checks, Shakes, splits not acceptable

Thermoplastics & thermo setting

Materials that are hard in their normal state, but become soft and pliable when heated

Harden upon heating and reheating has no softening effect. Typically used in composite layups

Composite

material made up a mixture of different materials

Cloth

Linen cloth impregnated with a thermosetting resin called phenol-formaldehyde (Phenolic Material), used to make control cable pulleys

Metal-Faced Honeycomb

Honeycomb core material is bonded to thin sheets of Aluminum Alloy

Types:

Paper and glass, metal, wood, and foam

Rubber

Natural

Synthetic

Synthetic types:

Butyl

Bunas

Neoprene

Magnesium is one of the world's lightest structural metals and has excellent fire protection capabilities. T or F

False

The main alloying ingredient for 6001 aluminum is [x]

Magnesium and Silicon

On an aircraft, (a), (b), and (c), structural and (d), (e), (f), (g), and (h) are manufactured from stainless steel.

a. Exhaust Collectors

b. Stacks

c. Manifolds

d. Machined Parts

e. Springs

f. Castings

g. Tie Rods

h. Control Cables

[x] is the primary alloying agent in bronze.

Tin

18-8 stainless steel is made up of x Chromium and y Nickel.

x = 18 %

y = 8 %

Composite structures can be made with or without an inner core of material. T or F

True

Aluminum that is in its annealed condition is designated with a [x].

O

Titanium is not subject to [a] corrosion, [b] corrosion, [c] corrosion, or [d] corrosion.

Galvanic

Intergranular

Fatigue

Stress

When adding nickel to steel, hardness, tensile strength, and elastic limit increase while appreciably decreasing the ductility. T or F

False

An alloy is created when other metals are added to a base metal. T or F

True

Molybdenum is added to a steel alloy because it (a) the strength of steel without affecting Ductility or (b)

a. Raises

b. Workability

What two reasons allow aluminum to be the most widely used metal in aviation construction?

Ease of fabrication

High strength-to-weight ratio

The main alloying ingredient for 5052 aluminum is [x].

Magnesium

A metal that has been hardened using solution heat treating and then artificially aged has the designation of [x].

T6

Monel is not good to use for gears and chains. T or F

False

The main alloying ingredient for 2024 aluminum is [x].

Copper

What is Hardness (Match Terms Selection 1)

What is Malleability (Match Terms Selection 2)

(1) The ability of a material to resist cutting, penetration, or abrasion.

(2) The ability of a metal to be bent, formed, or shaped without cracking.

Copper is normally used in an aircraft's electrical system for:

Bus Bars

Bonding

Lock Wire

The two classes of plastics used in aircraft construction are:

Thermosetting

Thermoplastic

When classifying aluminum, which digit indicates the major alloying agent?

First

The process of softening a material is known as [x].

Annealing

What two reasons allow aluminum to be the most widely used metal in aviation construction?

Ease of fabrication

High strength-to weight ratio

Magnesium is very corrosive and brittle. T or F

True

Drop forging is the process where a worker physically hammers a piece of metal into its finished state. T or F

False

What is the agent that is added to a resin to increase its viscosity to prevent it from running off a surface?

Thixotropic Agents

The mass unit volume of a metal is known as

density

Monel and Inconel two common alloys of magnesium. T or F

False

[x] is the standard wood used in aircraft construction.

Sitka Spruce

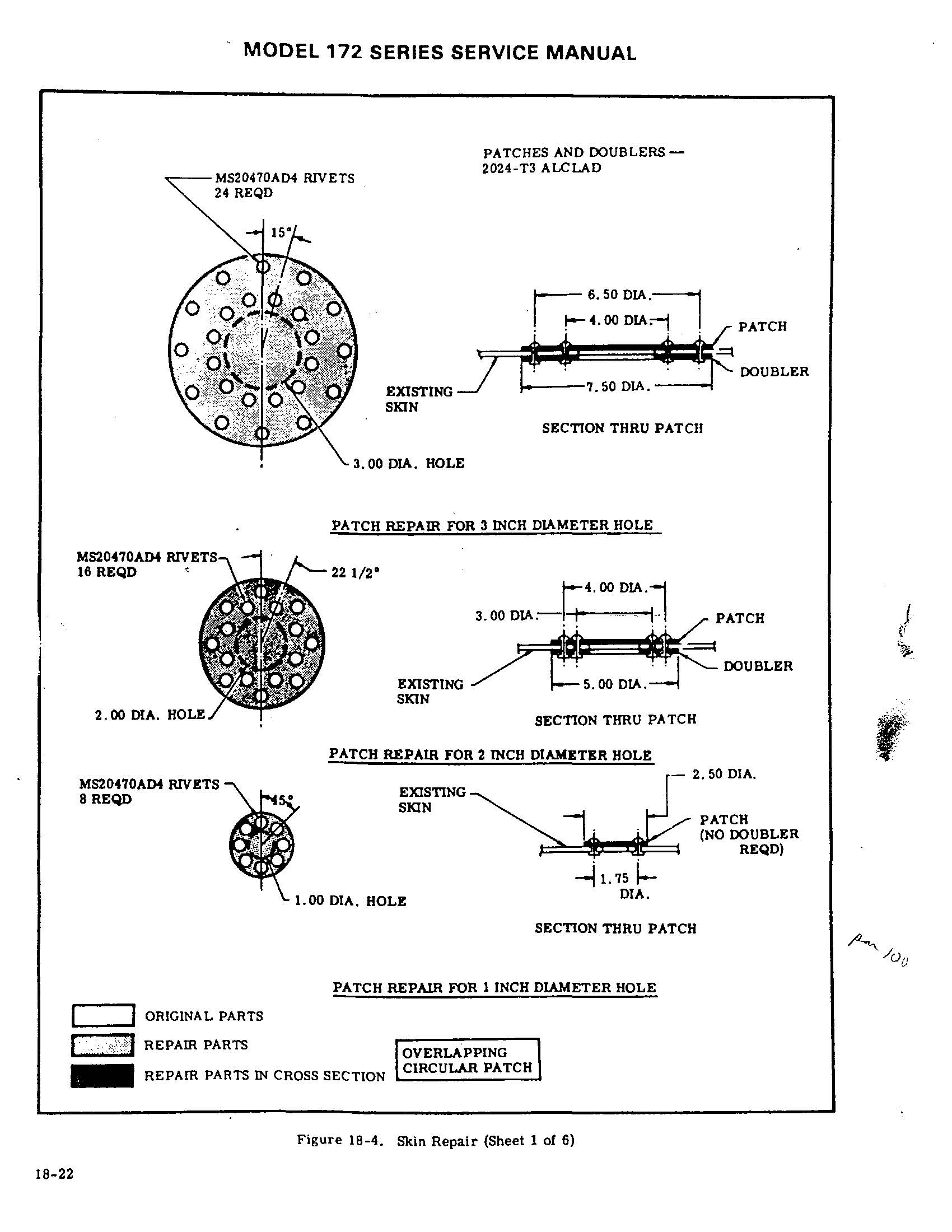

Utilizing the provided manual, 2024-T3 should be used to perform the assigned patch repair and it is Heat Treated .

2024-T3

Heat Treated

Two enthusiastic thumbs up

Why did you flip the cat over, he’s gonna fall