masonry (stone & concrete)

1/19

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

20 Terms

commerical stone types

For commercial purposes, building stone is classified into six groups according to ASTM C199.

Granite

Limestone

Quartz-based

Slate

Marble

Other

Each group has different exposure

conditions, construction requirements

granite group

Igneous

Nonporous, strong, durable

Suitable for exposure to severe weathering, ground contact

limestone group

Sedimentary

Strength and porosity vary with density

Colors from white, to gray, to red

Normally has a textured finish; a few can be polished

quartz-based group

Sedimentary

Sandstone: from quartz deposits

Brownstone, and some varieties of bluestone are varieties of sandstone

slate group

Metamorphic

Derived from shales (mineral clays)

Dense, hard, nonabsorbent

Variety of colors

marble group

Metamorphic

Varies greatly in its physical properties and appearance

Many colors, frequently with extensive veining

Easily polished

other group

Travertine:

Partially-crystallized, patterned calcite

Chemically similar to limestone

Similar to marble in its physical properties

other types

Alabaster

Greenstone

Schist

Serpentine

Soapstone

quarrying

A long-bladed diamond saw, traveling on rails, makes deep, long cuts into the solid rock.

Closely-spaced horizontal holes are drilled into the vertical face of the rock to create a plane of weakness near the bottom of the saw cuts

Rubber bladders are inserted into the saw kerfs and inflated, causing the large slabs to fall away from the solid rock.

Steel wedges are driven into the separated slabs, to split them into smaller blocks

Blocks are labeled and stacked, ready for transporting to the mill

milling

Bandsawing & circular sawing

Planeing

And a variety of other shaping and surface finishing operations

Hand carving

stone masonry

Stone masonry: laid in mortar, self-carry all the weight of the wall

Rubble

Ashlar

Stone cladding: mechanically fasten/attached to a separate structural frame or walls.

Stones carry their own weight.

Most commonly set in mortar, like brick or CMU

Stone blocks carry own weight. CMU

backup wall with anchors provides lateral

support.

rubble masonry

Unsquared stone blocks

Random: Laid without continuous horizontal joints

Coursed: Laid with continuous horizontal joints

ashlar masonry

Squared blocks

Random or coursed

stone cladding or curtain wall

Stone panels mechanically attached to building frame

Attachment system carries the weight of the panels

concrete masonry units (cmus)

Stiff concrete mix pressed into metal molds

Steam curing in autoclaves accelerates curing

Standard nominal size: 8" x 8" x 16"

Actual size is 3/8-inch less in each dimension

Can be manufactured in a great variety of shapes and sizes

dimensioning

Like brick masonry walls, concrete masonry wall dimensions should, as much as possible, conform to the dimensional module of the block, in this case 8 inches.

This minimizes the need to cut block or work with small pieces

laying cmu

Mortar is identical to that used for brick masonry

Corner leads are laid first.

String lines and levels are used to keep walls straight, plumb, and level

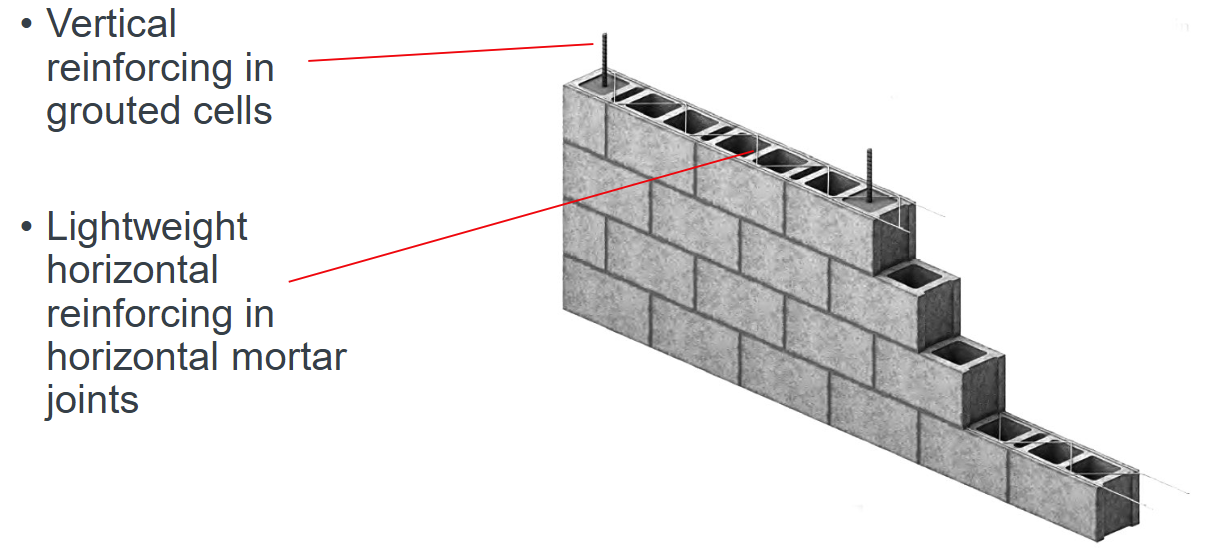

reinforcing

Reinforcing increases compressive strength, resistance to cracking and resist to lateral forces

Vertical steel reinforcing in a fully-grouted concrete block wall

Specially-shaped webs to accommodate both vertical and horizontal reinforcing bars without modification

spanning openings

Structural steel

Steel reinforced concrete block

Precast concrete

decorative or architectural units

Split-face block

Two or more blocks are cast as a single unit.

During the curing process, the blocks are split with knife-like blades

Ground-face block

After curing, block surface is ground smooth, creating a polished surface.

In any architectural block, the color of aggregates and cement can also be varied

Glazed block

Glass block