DESGIN TEC - Topic 3 : Modeling

1/45

Earn XP

Description and Tags

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

46 Terms

Concept modeling

Originates in the mind, primary used is to outline the principles, processes basic functions of a design or system

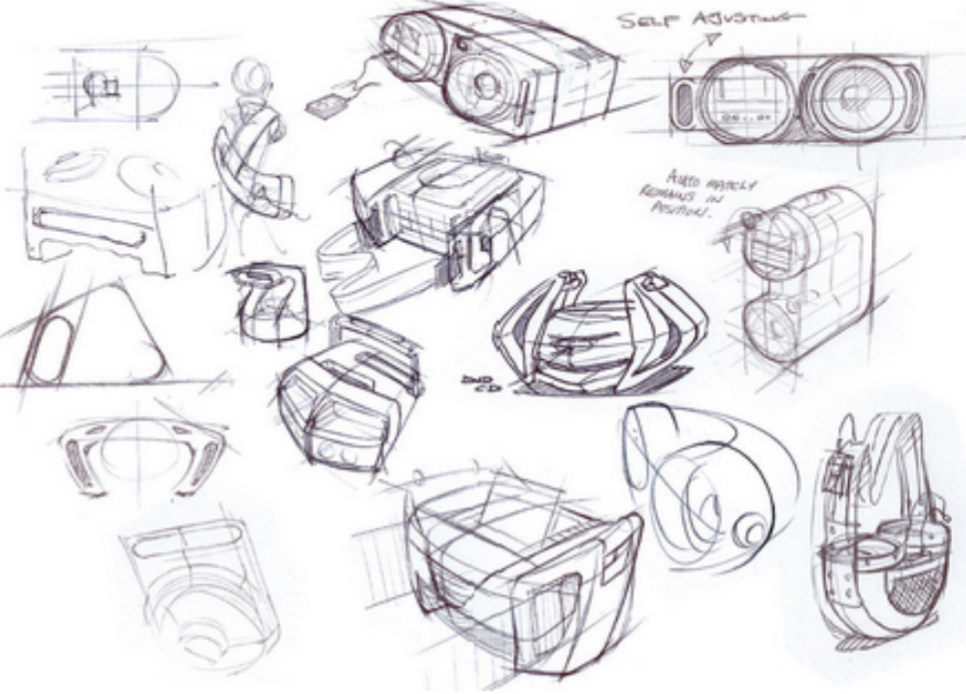

Graphical Modeling Examples

Sketches (napkin sketches), Drawings, Flow Charts

Physical Modeling Examples

Card, Clay, Rapid Prototype (3D printing), Balsa wood, Blue styrofoam

Virtual Modelling Examples

(CAD) Computer- Aided Design, Surface or Solid Modeling, FEA, DATA modeling

Service Design

The activity of planning and organizing people, infrastructure, communication and material components of a service in order to improve its quality and the interaction between service provider and customers

Advantages and Disadvantages of Concept Modeling

Advantage: Shares “big picture”, Makes it easy for non- designers and non-technical people to understand a complex idea

Disadvantage: Lacks detail, Can be misinterpreted, can be misleading if smaller or bigger than actual product

Graphical Model

A 2D and 3D visualization of an idea, often created on paper or through software

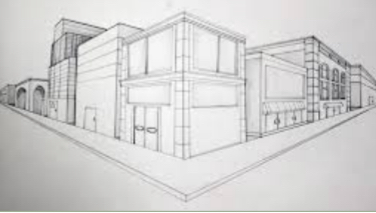

Perspective drawing

Shows what a product will look like when finished in a more lifelike way

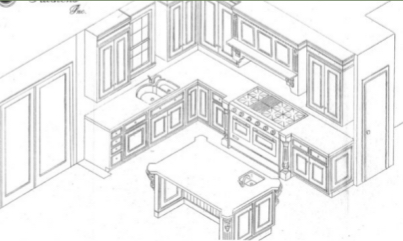

Isometric Drawing

Used to accurately show what a product will look like when it is finished

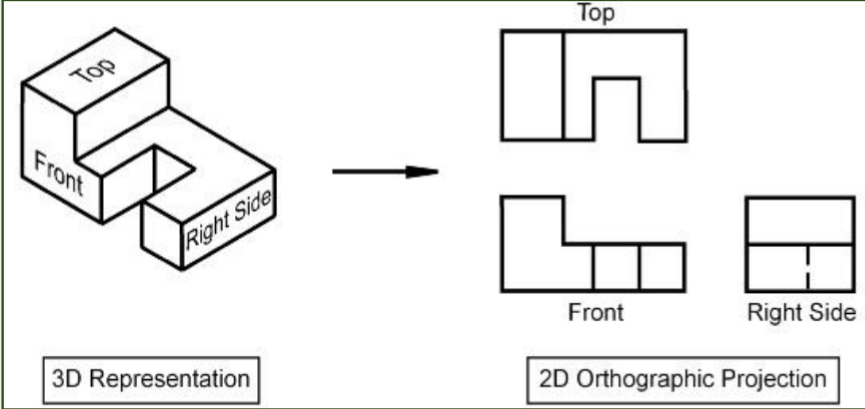

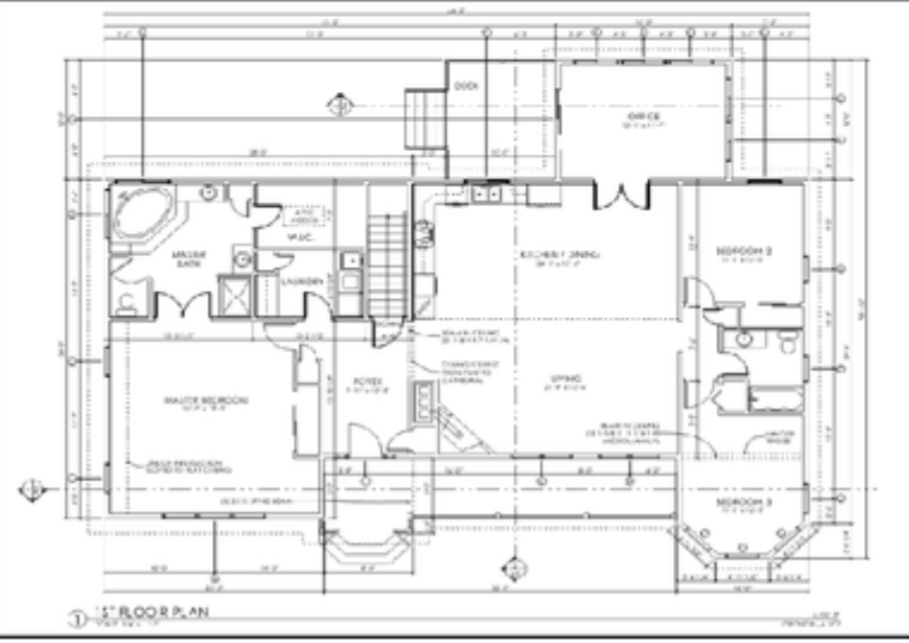

Orthographic Projection

Drawing a 3D object from different directions. ( front, side, top, bottom; must have at least 3 views)

Usually developed when its almost ready to manufacture

Scale Drawings

Show an object in proportion to its actual size. Used when something needs to be presented accurately or planning or manufacturing

Sketching

Spontaneous and free hand representation and used early in design process

Formal Drawings

Ruled out and accurate drawings, techniques tend to be use in the development phase of a design process

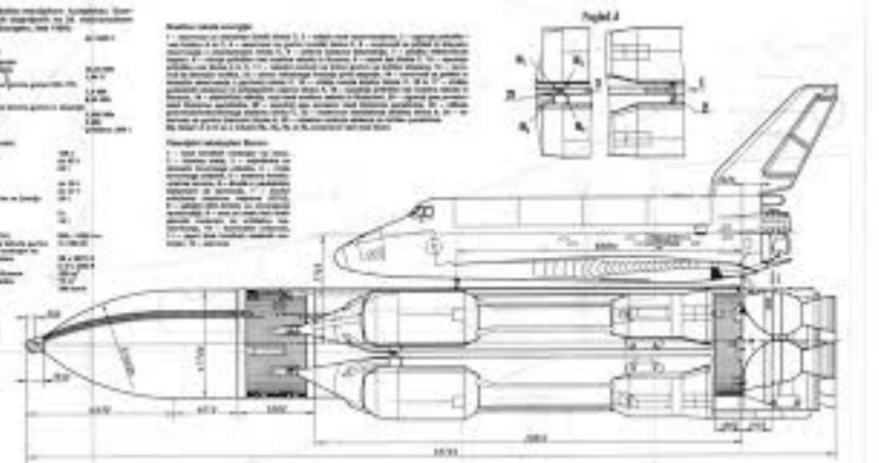

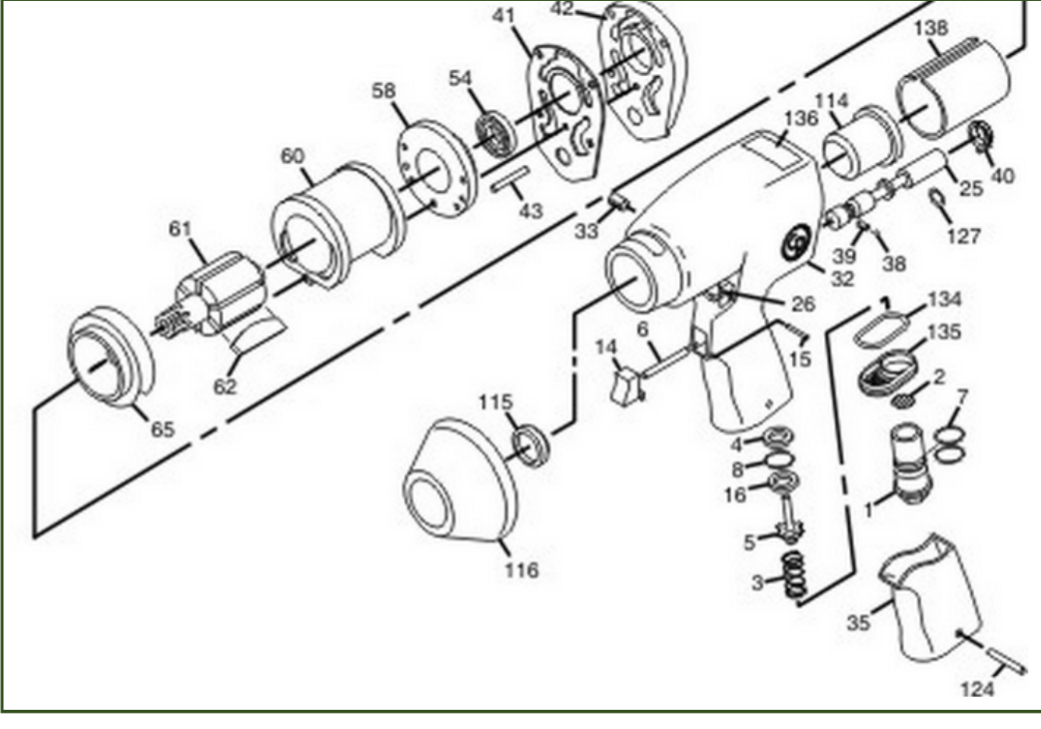

Part Drawing

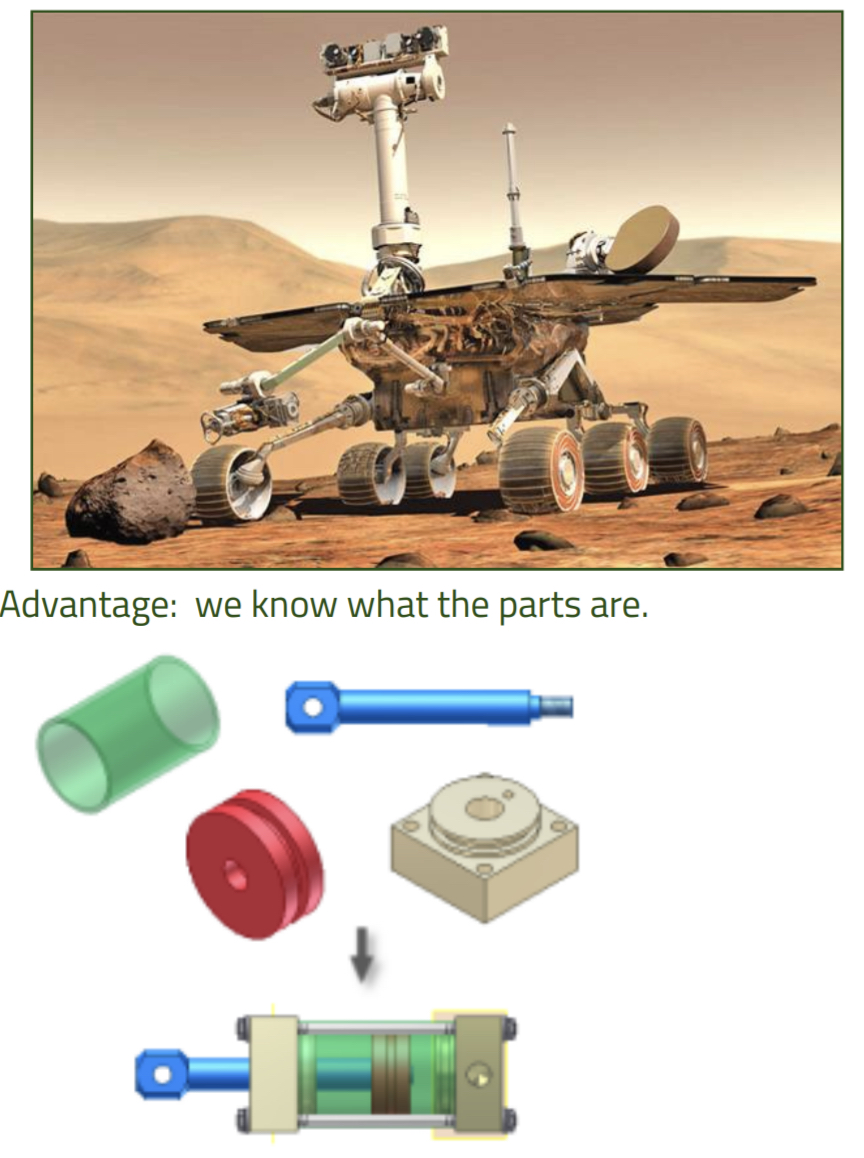

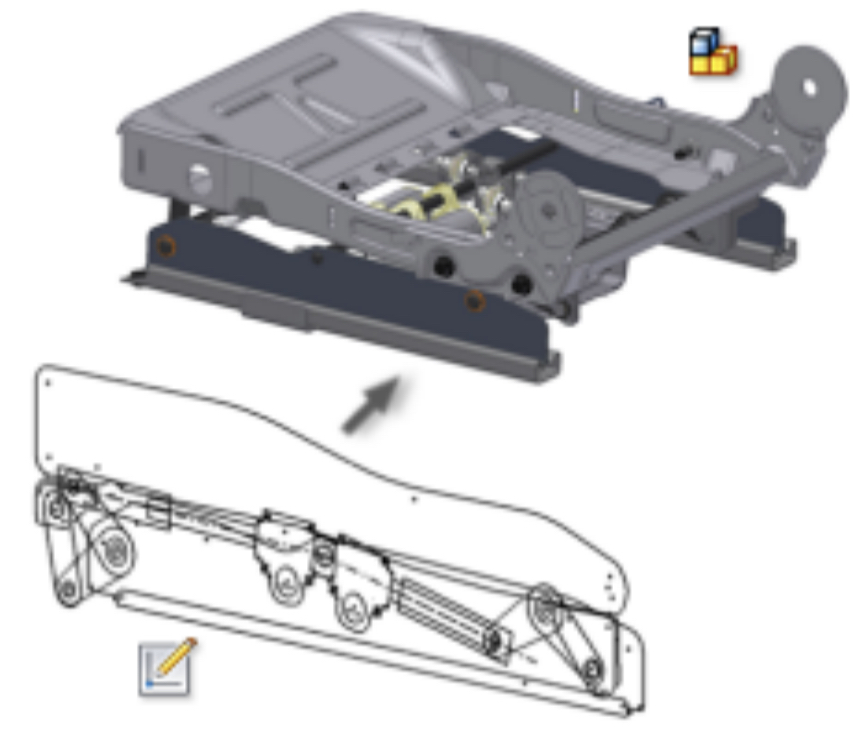

Provides information to assembly a product in a similar way that an assembly drawing does with additional benefit of having a list of parts [LOP] or Bill of Materials [BOM].

Helps to know which part is broken and how to repair it

![<p>Provides information to assembly a product in a similar way that an assembly drawing does with additional benefit of having a list of parts [LOP] or Bill of Materials [BOM]. </p><p>Helps to know which part is broken and how to repair it </p>](https://knowt-user-attachments.s3.amazonaws.com/33550649-eed6-4d65-9430-01f5a06bf65f.jpeg)

Assembly Drawings (Exploded isometric)

Shows how parts of a product fit together. Often used to show how to assemble parts of model kits and flat packet furniture

Algorithm

A self- contained step-by-step set of operations to be preformed

Physical Modelling

A three-dimensional, tangible representation of a design or a system. (Appearance model)

Advantages and Disadvantages of physical Modelling

Advantages: They allow the used to visualize the product and identify any problems easily on, understand how product would look it real life

Disadvantages: Can be a time consuming process, can’t be manipulated the same way a digital model can be

Scale Models

A smaller or larger physical copy of an object.

Advantages and Disadvantages of Scale Models

Advantages: Model can be overviewed easily, especially if the original design is exceptionally large. Gives an idea of how large model will be when actually built/ produced

Disadvantages: Can be time consuming to create perfect scale model. Hard to manipulate to show how it works

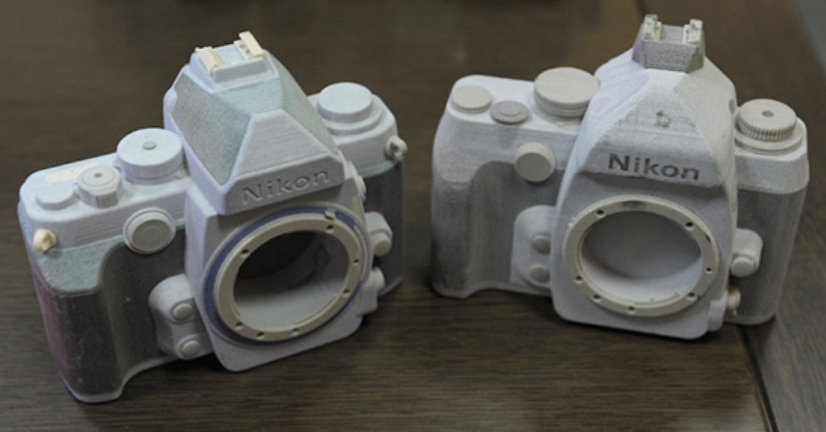

Aesthetic Models

Developed to look and feel like final product. Used for ergonomic testing and evaluation visual appeal. Do not work like final product

Advantages and Disadvantages of Aesthetic Models

Advantages: Can be used instead of digital models to give user an idea of how the product would look like in a real environment. Production engineers use data to assess the feasibility of producing the product.

Disadvantages: Are non working models and only provide a visual model of product. Fairly expensive to produce as the surface can be difficult to recreate

Mock-ups

Used to test ideas. Usually scale or full-size representation of a product used to gain feedback from users. Can be considered prototype if includes some functionality(“Work-like” and “Look-like” .

Advantages and Disadvantages of Mock-ups

Advantage: used to get feedback from the user. Models are made to a 1:1 scale and offer a full size representation of the product

Disadvantage: Does not offer as much functionality as a prototype. Can be difficult and time consuming to create

Functional Prototypes

A sample or model built to test a concept or process or to act as an object to be replicated or learned from. Used to test and validate ideas and can be used throughout design development.

Developed from 2 perspectives, from the development team and the user

Advantages and Disadvantages for Functional Prototypes

Advantages: A semi to fully functioning model of a product a thus it can be used to test the functions of the final product out. Can provide specifications for the parts involved in a real products and how they function together

Disadvantages: can be slightly expensive to make as prototype needs to function. Does not take aesthetic into account bc primarily tests the function of product

What is Fidelity

A measure of the realism of a model or simulation

Low = just the idea, not where near real

High= mock up of the idea, as close as possible to final

Instrumented Physical Models

Equipped with the ability to take measure to to provide accurate quantitive feedback for analysis. Can be used to effectively investigate many phenomena

Ex:an instrumented model of a keyboard can record the actions of the user and provide data on how often keys are used and the number of errors a user makes

Advantages and Disadvantages of Instrumented Physical models

Advantages: Can be used to take accurate measurement related to the performance of the product, to improve the product further

Disadvantages: Can take time and be very expensive to set up

CAD

Computer Aided Design

Used for conceptual design and layout of product. Eliminates high cost of testing an manufacturing. Used in fashion construction, automotive, architecture, planning electrical or mechanical layout

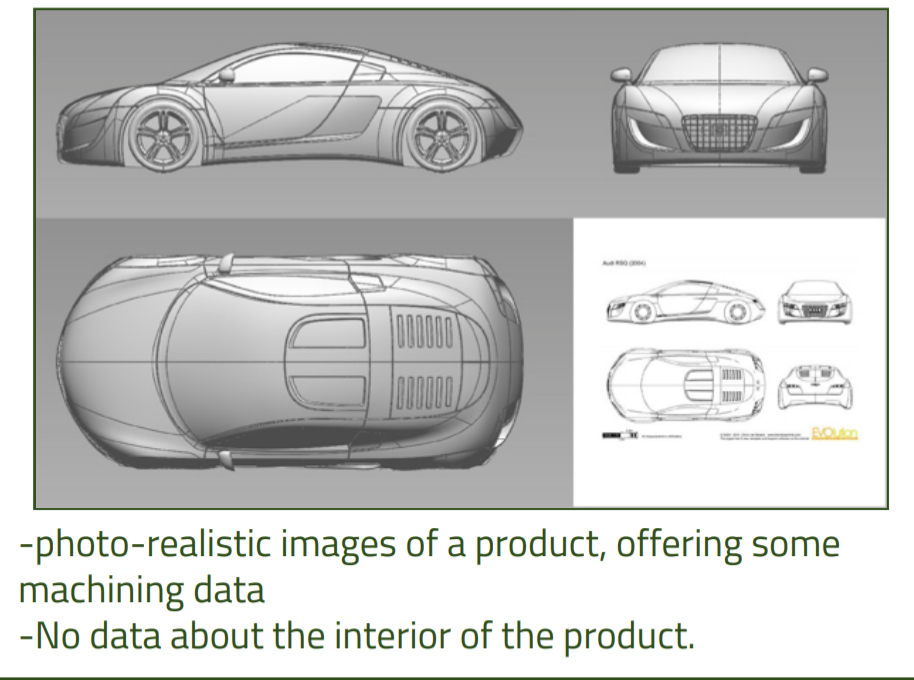

Surface Modelling

Photorealistic images of a product, offering some machining data but no data about the interior of product

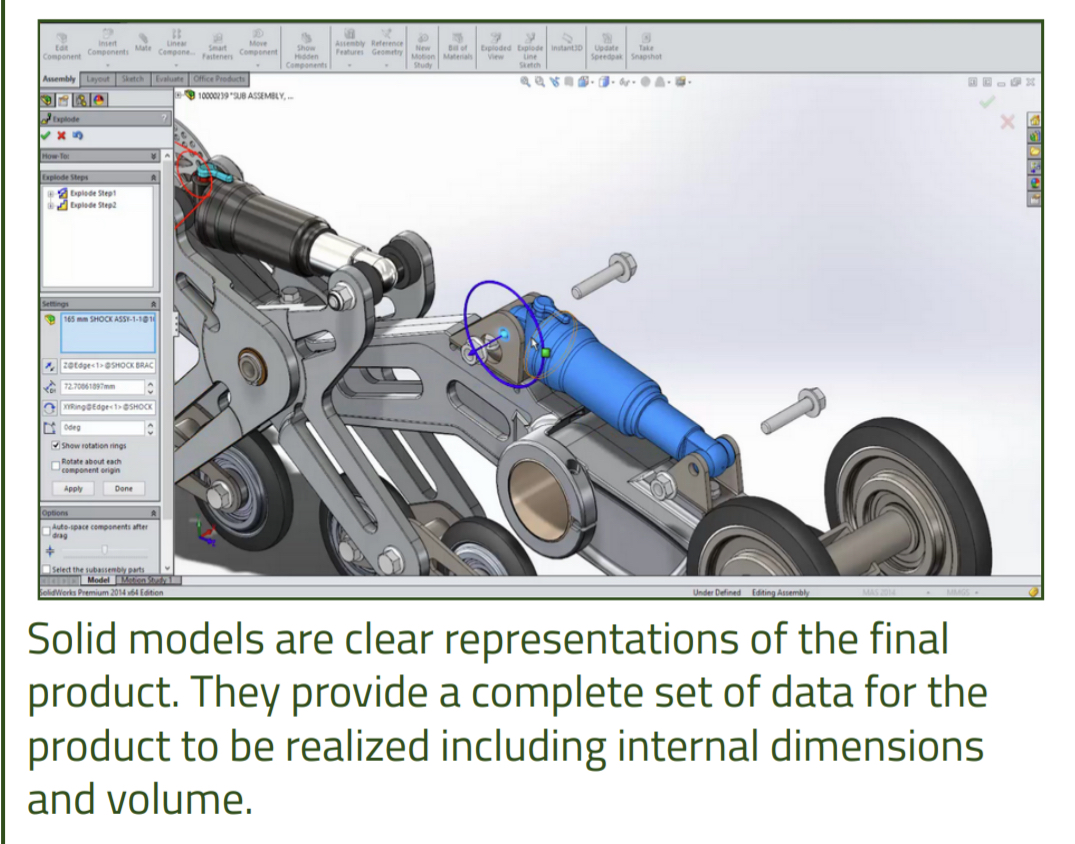

Solid Modelling

Clear representations of final product. Provide a complete set of data for the product to be realized including internal dimensions and volume

Data Modelling

Explicitly determines the structure of data or structured data including statistical modelling

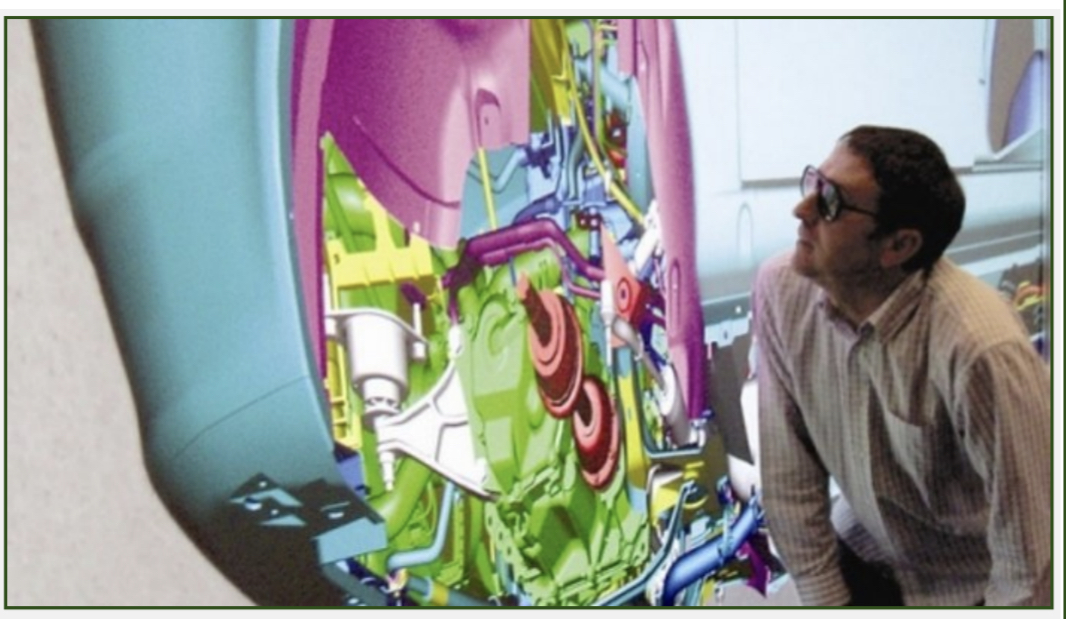

Virtual prototyping

Involves the use of surface and solid modelling to develop photo-realistic interactive models, can be considered digital mock-up

Bottom up Modelling

Designed creates part geometry independent of assembly or any other component. Some design criteria often established before modeling the part this information is not shared between models. Once all part models complete they are brought together in assembly.

“Assembly line”

Top- Down Modelling

A product- development process obtained through 3D. Main feature is that the design originates as a concept and gradually evolves into a complete product consisting of components and sub-assemblies. Begins with design criteria and create components that meet those criteria. List known parameters and create engineering layout. Layout can be 2D deign that evolves throughout design process

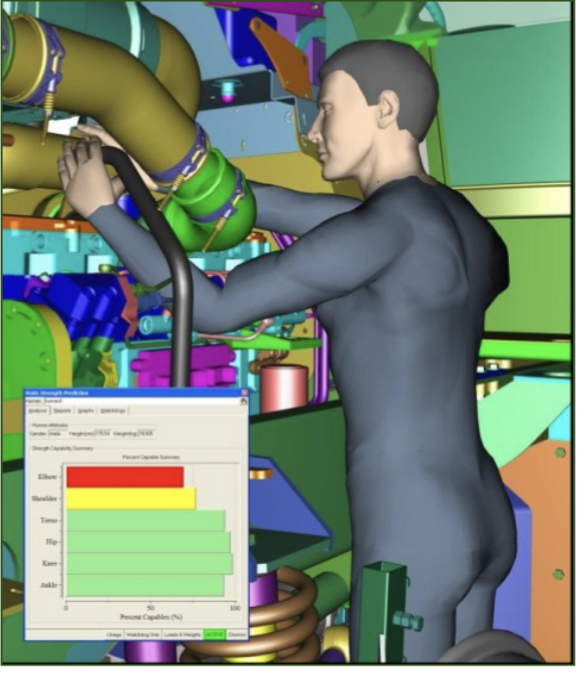

Digital Humans

Computer simulations of a variety of mechanical and biological aspects of human body. Can be used to interact with a virtual prototype. Enables product to be developed more quickly. Results in higher product quality that meets human requirements more accurately

Motion Capture

the recording of human and animal movement by any means, for example, by video, magnetic or electro-mechanical devices. A person wears a set of acoustic, inertial, LED, magnetic or reflective markers at each joint. Sensors track the position of the markers as the person moves to develop a digital representation of the motion. Motion capture can reduce the cost of animation, which otherwise requires the animator to draw either each frame or key frames that are then interpolated. Motion capture saves time and creates more natural movements than manual animation but is limited to motions that are anatomically possible.

Haptic Technology

a technology that interfaces the user via a sense of touch. Also known as force feedback technology, haptic technology works by using mechanical actuators (motor) to apply forces to the user. By simulating the physics of the user’s virtual world, it is possible to compute these forces into real time. Haptic technology allows the user to become part of a computer simulation and to interact with it, enabling the designer to observe the user’s performance and to design a better outcome. ,t can also be used in situations where it is difficult to train in the real environment. Haptic technology is also used in feedback devices used in home entertainment consoles.

Virtual Reality

The ability to simulate a real situation on the screen and interact with it in a near-natural way

Animation

The ability to link graphic screens together in such a way as to simulate motion to a process

Finite element analysis

Involves the calculation and simulation of unknown factors in products using CAD systems

Uses color indication to show ;

Structural load

Aerodynamics

Thermodynamics

Stereolithography

It is a form of 3D printing using a liquid bath of resin combined with an ultraviolet laser. The ultraviolet light hits the liquid Kardening it to form the structure of the object being printed. The Ease plate of the bath then moves down allowing more liTuid to flow over the previously hardened liquid so the same process can be repeated until the object being printed has been completed. The ‘Sweeper’ seen in the image to the right just helps even out the height of the bath every time the laser fires.

Laminated Object Manufacturing

Takes the sliced CAD data from a 3D model and cuts out each layer from a roll of material, using a laser to plotter cutter. Layers are glued together to form model

Fused deposition modelling

Uses additive principle by layering down material in layers. Uses Plastic/ metal from a coil and sent to an extrusion nozzle that can turn the flow on and off. Nozzle heated to melt material and moves horizontally and vertically

Selective Laser Sintering

An additive manufacturing technique that uses a high-power laser to fuse small particles of materials such as plastic, glass, metal