DT Shaping

0.0(0)

Card Sorting

1/46

Earn XP

Description and Tags

Shaping

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

47 Terms

1

New cards

Hand tools

Tenon saw, Hacksaw, Coping saw, Piercing saw, Rasps, Planes, Chisels, Hand router, Gouges, Wheel brace and bit, Hand drill and twist bit, Abrasive papers

2

New cards

Tenon saw

Used for cutting straight lines when working with wood

3

New cards

Hacksaw

Used on metals and plastics for cutting straight lines

4

New cards

Coping saw

Used for cutting curved lines when working with wood or plastics

5

New cards

Piercing saw

Used to cut curved lines into metals and plastics

6

New cards

Rasps

Used to shape the edges of wood

7

New cards

Planes

Shape the edges of different types of wood

8

New cards

Chisels

Used for hollowing when working with wood

9

New cards

Hand router

Used for hollowing when working with wood

10

New cards

Gouges

Used for hollowing woods

11

New cards

Wheel brace and bit

Drills holes into wood

12

New cards

Hand drill and twist bit

Drill holes into both metals and plastics

13

New cards

Abrasive papers

Used for smoothing surfaces when working with wood, metal or plastic

14

New cards

Machine tools

Circular saw, Bandsaw, Belt sander, Pillar/bench drill, Lathe, Milling machine

15

New cards

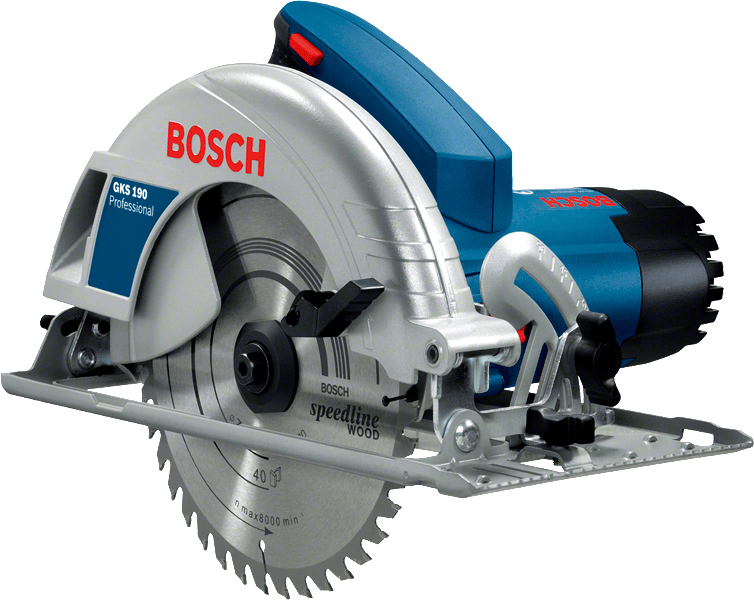

Circular saw

Cuts straight lines into woods and plastics

16

New cards

Bandsaw

Used for cutting curved lines when working with woods, metals and plastics

17

New cards

Belt sander

Used to shape the edges of woods and plastics as well as smooth the surfaces of metals and woods

18

New cards

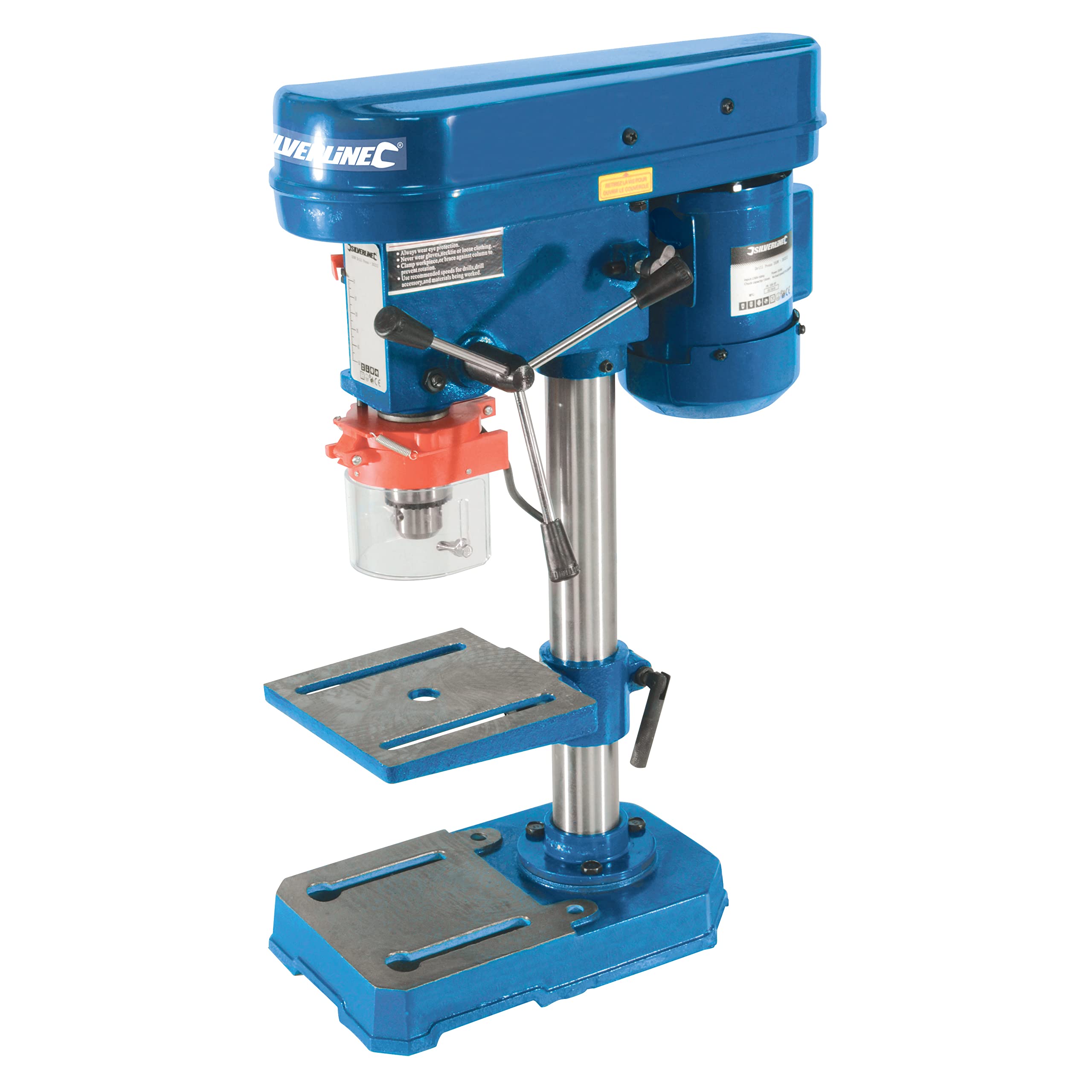

Pillar/bench drill

Drills holes into woods, metals and plastics

19

New cards

Lathe

Shapes the edges of wood

20

New cards

Milling machine

Used for hollowing metals and plastics

21

New cards

Drilling

A method used for making a hole all the way or partially through a material

22

New cards

Elements of a hole

Pilot hole, Clearance hole, Tapping, Countersunk hole, Counterbored hole

23

New cards

Pilot hole

Smaller than the screw being used, so that the thread cuts in and holds

24

New cards

Clearance hole

Larger than the thread and shank of a screw, so that the screw does not grip or ‘bite’ into the sides, allowing the two pieces to pull together

25

New cards

Tapping

Usually used with metals, where a screw-thread is added to the inside of a pilot hole, using a tool called a ‘tap’, so that it accepts a machine screw

26

New cards

Countersunk hole

An indentation at the top of a hole to accept a countersink headed screw, with the screw head being level with the surface, usually with a 90 degree inclusive angle

27

New cards

Counterbored hole

A large diameter recess at the top of a hole to accept a cheese or fillister headed screw, with the screw head being recessed below the surface

28

New cards

Deforming processes

Steam bending, Lamination, Press forming, Vacuum forming, Blow moulding

29

New cards

Steam bending

Strips of hardwood are heater in a steam chamber until the wood is pliable enough to easily bend around a former to create a specific shape

30

New cards

Lamination

Thin sheets (veneers) of hardwoods are layered with strong adhesive and pressed in a former until the adhesive cures

31

New cards

Press forming

Sheet materials are presses between a male and female former, until they cool, to take on a new shape. Some materials need to be heated to become ‘plastic’ (malleable) prior to forming, or in the case of metals they can be annealed

32

New cards

Vacuum forming

Plastic sheets are heated to their elastic state, then a former is pressed into the sheet and the air below is evacuated. The external pressure presses the plastic onto the former

33

New cards

Blow moulding

Tubes of plastic are heated and fed through a mold. The air is blown into the tube, forcing it to expand out and form against the mould.

34

New cards

Addition

The process of shaping materials by combining or joining them, for instance using screws, nails, nuts and bolts, and adhesives. Joining methods can be classified as temporary or permanent, with particular methods being used with different materials

35

New cards

Deforming

The process of subjecting a material to a stress that changes its shape. Typically heat is applied to materials to bring them into the ‘elastic’ zone, where they can be deformed

36

New cards

Reforming

The process of changing the shape of a material, typically by melting and pouring or injecting the molten material into a mould

37

New cards

Resistant material

A material that requires force in order to be worked of shaped

38

New cards

Wastage

The process of cutting away material to leave the desired shape

39

New cards

Reforming processes

Injection moulding, Extrusion, Sand casting, Die casting

40

New cards

Injection moulding

Plastic beads are heated to their plastic state and injected into a mould to form complex shapes

41

New cards

Applications of injection moulding

Toys, consumer goods (mobile phone cases)

42

New cards

Extrusion

The material is heated to its plastic state and pushed through a ‘die’ to create components or parts with a fixed cross-sectional profile

43

New cards

Applications of extrusion

Pipes, tubes, beams and rods

44

New cards

Sand casting

Non-ferrous metal (iron, brass, aluminium) is melted and poured into a mould made of a special sand

45

New cards

Applications of sand casting

Engine blocks, gas and water valves

46

New cards

Die casting

The metal is melted and forced into a hardened tool steel mould (or die)

47

New cards

Applications of die casting

Toys, brackets, engine parts