Pre Q Graphics - 1.3d Plastic forming processes

1/13

Earn XP

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

14 Terms

Image_

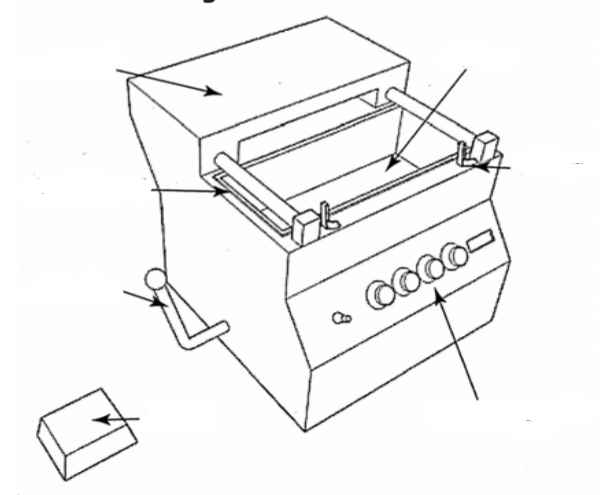

Line bender

Image_

Vacuum former

Image_

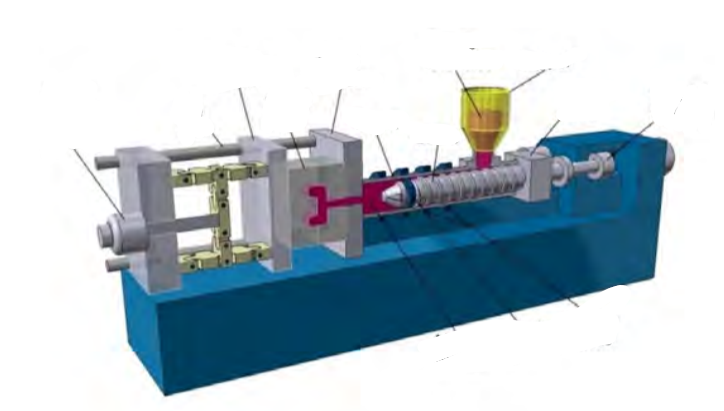

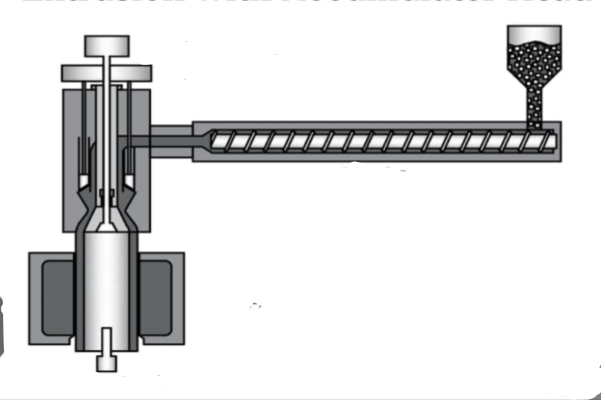

Injection moulder

Image_

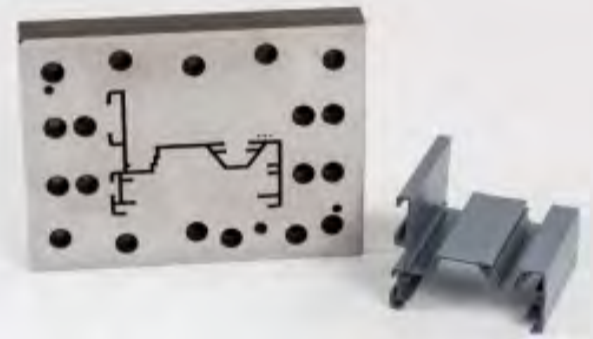

Extrusion mould

Image_

Blow moulder

Line bender process

1. Use a marker pen or chinagraph pencil to mark out where the bend lines will be

2. Turn on the ____ so that it comes up to a working temperature

3. Put on heat-proof gloves and have a tray of water ready to cool the workpiece

4. Place the marked line of the workpiece across the heating strip

5. Allow the plastic to heat through (the time needed will depend on the thickness of the material, thicker materials may need to be turned over to heat from both sides)

6. Test for flexibility as the workpiece approaches the right temperature (too cool can lead to it cracking, too hot can lead to scorching and blistering)

7. Bend the workpiece to the required angle (a jig or former may be used to ensure accuracy)

8. Once the workpiece has set it can be cooled in the water tray.

Vacuum Forming Process

1. The mould is placed on the platen.

2. A thermoplastic sheet is placed over the airtight seal and clamped above the platen.

3. The heater is pulled accross.

4. The platen is raised so the mould is sitting underneath the plastic.

5. The ___ is turned on and the plastic is sucked over the mould

Injection Moulding Process

1. Granules of the chosen plastic are fed into the hopper 2. The hopper feeds the Archimedes screw that drags the granules past a heater, where they are softened and become plasticised as they travel forward 3. The plastic is in a soft, pliable form as it reaches the end of the screw, where it collects until there is enough to fill the mould 4. At this point a hydraulic piston forces the softened plastic into the mould under pressure, filling it up 5. The plastic sets quickly, the mould is separated and ejector pins release the moulding 6. The process is repeated.

Blow moulding process

Heated plastic is poured into the mould

The mould is closed and gripped in place

Compressed air is blown into the mould which inflates the plastic

The plastic fills the mould

Product gets trimmed and is removed from the mould

Glass Reinforced plastics process

Apply a layer of release agent on mould

add layer of coloured gellcoat resin

add sheet of glassfibre

add layer of polyester resin

set and release from mould

Rotational moulding process

Powered plastic is inserted in the mould

The mould is closed and heated

The mould slowly rotates to evenly coat walls of the mould

The rotating mould is cooled with a water spray to make the plastic set. The mould is then opened.

Image_

Rotational moulding

Image_

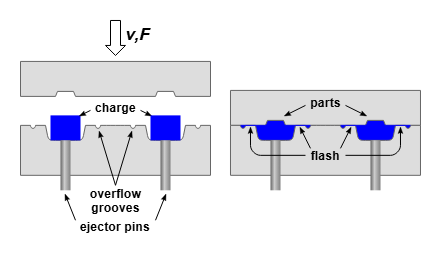

Compression moulding

Compression moulding process

Granular plastic is being poured into the mould

The two halves of the heated mould closes and squeezes the plastic

Plastic melts and fills the shape of the mould

Mould opens and ejector pin removes the product