Class 10 OM 235

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

17 Terms

Dimensions of Quality

Provide a framework for evaluating a product or service for the customer’s perspective

Eight Classic Dimensions of product quality

Performance

Features

Reliability

Conformance

Durability

Serviceability

Aesthetics

Perceived Quality

Performance

Primary operating characteristics of a product or service

Features

Secondary characteristics or a “bells and whistles”

Reliability

Probability of a project functioning without failure

Durability

How long the product lasts before replacement

Serviceability

Ease, Speed, and cost of repair or maintenance

Aesthetics

How a product looks, feels, sounds, tastes, or smells

Perceived Quality

The customer’s subjective perception

FUNCTIONALITY

When the product is working, how well does it satisfy the customer?

Satisfaction usually depends on multiple product features such as performance, aesthetics, even snob appeal

RELIABILITY

Works without problems as perceived by customers?

Satisfaction usually depends on multiple product features such as performance, aesthetics, even snob appeal

CONFORMANCE

Essentially process capability. WARNING: Specification limits may not match customer wants

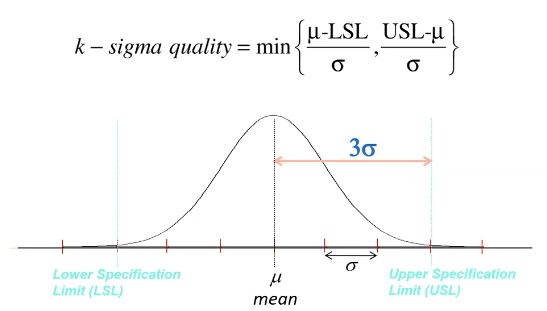

Process Capability Part 1

Quality is measured by comparing customer wants and process output

Customer wants —> design specification ( Upper and lower specification limits USL, LSL)

Tied tightly to new product development

Process Capability Part 2

Process output —> process mean and variability

Standard Deviation, also known as “sigma” or s, is the most common measure of variability in operations

Process Capability Part 3

Process capability increases with the amount of process output that falls within the design specification.

Process output that falls outside are Defects

How to get Process Capability

To get the Process Capability, we measure, in terms of std. deviations(sigma’s), how close the mean is the nearest(Customer-determined) specification, or more formally

Process Capability

There is 3-sigma quality process but 6-sigma quality is way better

6 standard deviation between the mean and the specification limit on both sides

More sigma= More control on product= less defects