Operations Management Lesson 6

1/41

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

42 Terms

capacity management

understanding the nature of demand and supply (capacity) and attempting to reduce mismatches between them

firm operations

both internal capability and partner networks

seasonality in demand forecasting

any repeating pattern of demand annual, quarterly, monthly, weekly, daily or hourly

capacity

maximum level of value-added activity over a period of time that the process or operation can achieve under normal operating conditions

impact of time on capacity

level of activity and output that may be achievable over short periods of time is not same as capacity that’s sustainable on a regular basis

capacity leakage

a reduction in capacity, caused by both predictable and unpredictable losses

design capacity

theoretical capacity of an operation that its technical designers had in mind when they commissioned it

effective capacity

the capacity of an operation after planned losses are accounted for

actual output

capacity of an operation after both planned and unplanned losses are accounted for

demand management

shaping and managing customer demand

price differentials: adjust prices based on demand

scheduled promotion: use advertising to boost demand in slow periods

constrained access: limit when customers can access services

service differentials: vary service quality with demand

alternative offerings: introduce new products/services in quiet times

factors tending to increase base level of capacity

low fixed costs

need for high levels of customer service

high perishability

inexpensive fixed capacity

factors tending to decrease base level of capacity

high fixed costs

need for high capacity utilisation

ability to store output

expensive fixed capacity

important factors to consider in setting the base level

operation’s performance objectives

perishability of outputs

variability in demand or supply

level capacity

capacity remains fixed throughout planning period, regardless of demand fluctuations

level capactiy advantages

stable employment

high utilization and productivity

low unit costs

level capacity disadvantages

excess inventory build-up

unsuitable for perishable, trendy, or customized products

risk of low utilization in services (costly)

level capacity is best suited for

high-margin industries where losing sales is expensive (jewelry, real estate)

chase capacity

adjusts capacity to closely match fluctuations in demand

involves varying staff levels, work hours, and equipment

more complex and resource-intensive than level plans

chase capacity is best suited for

perishable goods

services that can’t store output (customer processing operations)

chase capacity advantages

reduces waste from overstaffing

minimizes inventory when demand is unpredictable

chase capacity challenges

operational complexity

may not be feasible in all environments

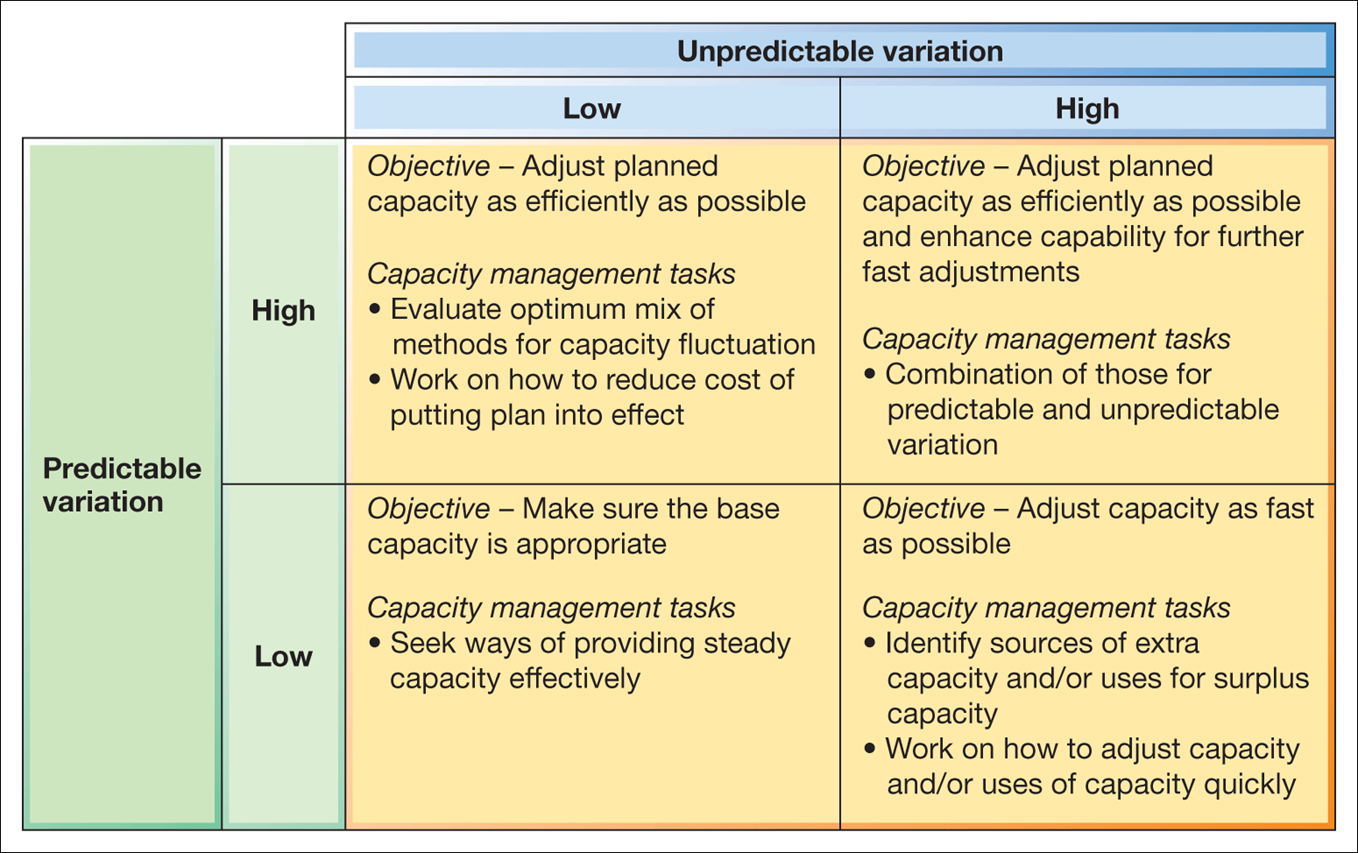

factors to consider for capacity management plans (demand management, level capacity or chase capacity)

predictable vs unpredictable demand variation

cumulative representations of demand and capacity

queuing principles to make capacity management decisions

longitudinal perspective that considers short- and long-term outlooks

inventory

accumulation of materials, customers or information as they flow through processes or networks

equipment effectiveness key indicators

availability rate

performance rate

quality rate

yield management

collection of methods used to maximize revenue from existing demand, especially useful when

capacity is relatively fixed

market can be clearly segmented

service cannot be stored in any way

service is sold in advance

marginal cost of making a sale is relatively low

the higher the base level of capacity

the less capacity fluctuation is needed to satisfy demand

nature of capacity management

inventory turnover rate

= COGS / Average inventory

A relatively low inventory turnover ratio may be a sign of

weak sales or excess inventory

a higher ratio signals

strong sales or effective inventory management, but may also indicate inadequate inventory stockingthat inventory is sold quickly and efficiently.

cycle inventory / working inventory

the stock a business holds to meet expected demand during a regular sales or production cycle

cycle inventory components

raw materials, work-in-progress, and finished goods ready for sale

cycle inventory replenishment

typically ordered in batches to balance ordering costs with storage expenses

return on assets

(revenue - costs) / (working capital + fixed assets)

holding costs / carrying costs

expenses a business incurs for keeping unsold inventory in storage

order costs

expenses associated with placing and receiving new inventory from suppliers and can be fixed or variable (i.e. warehouse capita costs, delivery of single order to location,…)

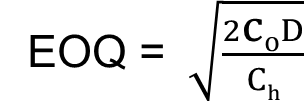

economic order quantity (EOQ) formula

co = Order cost per order

D = Demand

ch = Inventory holding cost per unit

Q = ordered quantity

re-order point (ROP)

stock level trigger for replenishing inventory. it helps businesses avoid stockouts and optimize their ordering cycles. 2 main factors that influence the reorder point

lead time

demand rate

key elements of capacity

scale

processing capability

inventory occurs in operations because of

the timing of supply and the timing of demand don’t always match —> needed to smooth the differences between supply and demand

five main reasons for keeping physical inventory

buffer inventory

cycle inventory (cope with an operation’s inability to make all products simultaneously)

allow different stages of processing to operate at different speeds and with different schedules

cope with planned fluctuations in supply or demand (anticipation inventory)

cope with transportation delays in the supply network (pipeline inventory)