food production (micro-organisms)

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

22 Terms

fermentation

- when microorganisms break sugars down to release energy

- usually by anaerobic respiration

process of making yoghurt

- equipment sterilised

- milk is pasteurised then cooled

- lactobacillicus bacteria added + mixture is incubated in a fermenter

- bacteria ferment the lactose sugar to form lactic acid

- lactic acid causes milk to clot + solidify into yoghurt

- flavours/colours added

why is the equip sterilised + why is the milk pasteurised

to kill off any unwanted microorganisms

how is the milk pasteurised

heated up 72C for 15 sec

how is the mixture incubated when the bacteria are added

heated to abt 40C

what are microorganisms grown in

fermenters in liquid "culture medium" (nutrient rich substance)

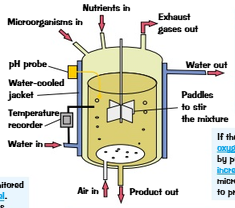

fermenter diagram

ADD DIAGRAM

how are nutrients provided for the microorganisms

liquid culture medium

how does monitoring the pH of fermenter mean highest product yield

- ensure it is kept at optimum pH level

- for microorganisms' enzymes to work efficiently

- rate of reaction as high as poss

how does monitoring the temp/ water-cooled jacket mean highest prod yield in fermenter

- optimum temp

- ensures not so hot that enzymes denature

how does paddles (agitation) mean highest prod yield in fermenter

- microorganisms kept in contact with fresh medium

- circulates the medium around the fermenter

- microorganisms always have access to nutrients needed for growth

how are fermenters sterilised between uses

with superheated steam

how does sterlising/ aseptic conditions mean highest prod yield in fermenter

- kills unwanted microbes

- microorganisms aren't competing with other organisms

- product not contaminated

how are fermenters oxygenated

by pumping in sterile air

how does oxygenation mean highest prod yield in fermenter

- microorganisms can always respire

- to provide the energy for growth

yeasts role in bread making

- enzymes break down carbohydrates in flour -> sugars

- yeast uses these sugars in aerobic resp -> produces CO2

- when O2 runs out, yeast switches to anaerobic resp (fermetation) -> produces CO2 and ethanol

- CO2 produced is trapped in bubbles in dough

- pockets of gas expand + dough begins to rise

- yeast continues to ferment in oven until dough temp is too high + it is killed

making bread

- bread dough made - yeast, flout, water, bit of sugar

- dough left in a warm place to rise

- yeast + enzymes do stuff

- CO2 trapped in bubbles in dough + these pockets expand making the dough rise

- dough baked in oven + any alcohol is boiled away

effect of changing temp on yeast CO2 production thru anaerobic resp

- mix together sugar, yeast, distilled water + add to test tube

- add a layer of oil on top

- attach a bung with tube leading to 2nd test tube of water

- place tube n water bath at certain temp

- leave tube to warm + count bubbles produced over given period

- calc rate of CO2 production

- repeat with diff temp water baths

- resp should inc (up to certain temp) bc controlled by enzymes

why is an oil layer added

to prevent oxygen getting in and create anaerobic conditions

how do u calculate CO2 production

by dividing no. of bubbles/ time taken for production

how woud u change the exp to test other conditions

do exact same but keep temp of water bath same

how could you make experiment more accurate

replace 2nd test tube with gas syringe so you'd measure gas vol and not bubbles