composites + timber

1/62

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

63 Terms

Definition & Basics of Composites

● Composites = materials made by embedding fibers or particles in a continuous

matrix (polymer, metal, or ceramic).

● Consist of two or more distinct phases, where the matrix phase surrounds the

dispersed phase.

● Designed to achieve better property combinations than monolithic materials

(e.g., strength, toughness, corrosion resistance).

● Trade-offs exist, but the goal is to balance properties like strength, density,

stiffness, and toughness.

Types of Composites

● Natural composites: wood, bone, nacre.

● Artificial composites: concrete, reinforced concrete, tires, GFRP, CFRP.

Technologically important composites often use …… as the dispersed phase

fibers

Design Factors Influencing Properties

● Properties of the individual phases.

● Their relative amounts.

● Geometry of dispersed phase:

○ Shape, size, orientation, and distribution.

Fiber-Reinforced Composites (FRCs)

achieve high strength and stiffness with low weight

Specific strength

tensile strength / density

Specific modulus

elastic modulus / density

Anisotropic behavior

(properties depend on direction) when fibers are aligned

Isotropic behavior

possible with random orientation.

Reinforcement efficiency

varies with fiber orientation and load direction.

Critical Fiber Length (𝑙𝑐)

Fiber must be long enough to transfer stress efficiently

Fibers are considered ……; otherwise …….

Fibers are considered continuous; otherwise short/discontinuous

Fiberglass (GFRP)

● Made from glass fibers + polymer matrix.

● Advantages:

○ High tensile strength of glass fibers.

○ Matrix provides ductility, corrosion resistance, and load-bearing

capacity.

● Forms: chopped strand mat, woven cloth, etc

Manufacturing Processes

Pultrusion

Prepregs

Pultrusion

pulling continuous fibers through resin and then a die to create

constant cross-section profiles (e.g., rods, beams).

Prepregs

fibers pre-impregnated with partially cured resin, used in lay-ups and

cured under heat and pressure

Laminar Composites (Laminates) + types

● Stacked layers (plies) of fiber-reinforced materials.

● Types:

○ Unidirectional

○ Cross-ply

○ Angle-ply

○ Multidirectional

Laminar Composites (Laminates) used in ?

Aircraft, automotive, marine, sports, and construction industries.

Carbon Fiber Reinforced Composites (CFRPs)

Carbon fibers are the most common in advanced composites due to:

1. High specific strength and modulus.

2. Retain properties at high temperatures.

3. Chemically stable at room temperature.

4. Versatile mechanical/physical characteristics.

5. Scalable fiber and composite manufacturing methods.

Structure of Wood

● Growth Rings: Indicate annual growth; water (sap) moves from roots to leaves.

● Inner Bark: Transports sugars from photosynthesis (leaves → roots/growth

areas).

● Hygroscopic Nature: Wood absorbs water, affecting its mechanical/physical

properties.

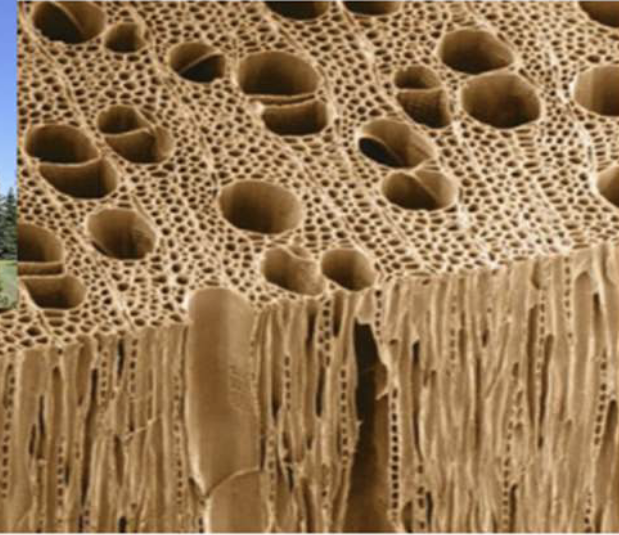

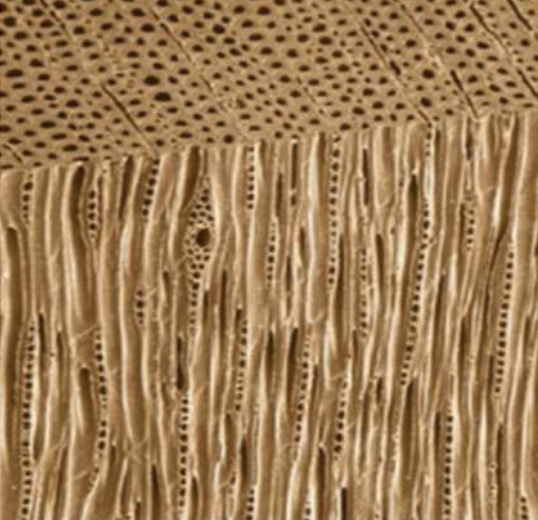

Wood Anatomy Views

● Transverse and Tangential-Longitudinal Sections:

○ Hardwood (e.g., poplar)

○ Softwood (e.g., European larch)

Hardwood

From broad-leaved, deciduous trees (e.g., oak, beech, eucalyptus)

Softwood

From coniferous, needle-bearing trees (e.g., pine, fir, cedar)

wood : Anisotropic or isotropic ?

Anisotropic Nature: Properties vary with direction (radial, tangential,

longitudinal).

Main Strength Source of wood ?

Cellulose in wood fibers

Tensile Strength of wood

○ Parallel to grain: 10–20× stronger than perpendicular.

○ Strength depends on wood density.

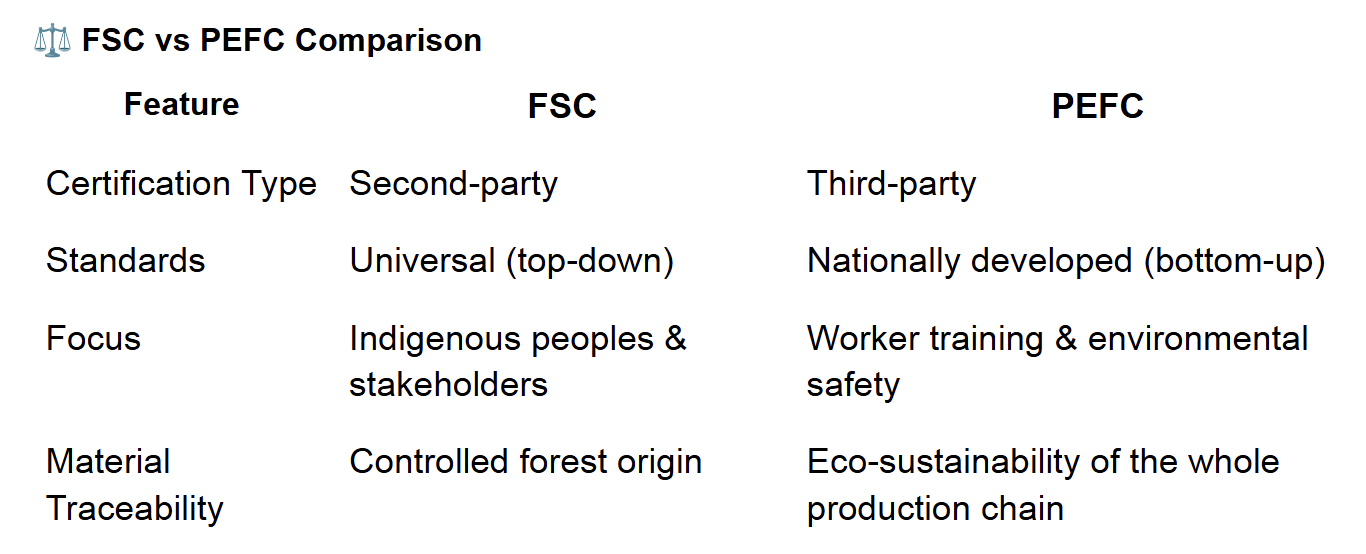

FSC (Forest Stewardship Council)

Emphasizes ecological and social responsibility

Strong protection of:

Indigenous rights

Biodiversity and high conservation value forests

Preferred by:

NGOs, green building standards (e.g., LEED), ethical brands

🔎 Ideal for: Projects needing strict environmental credibility or global recognition.

PEFC (Programme for the Endorsement of Forest Certification)

Umbrella organization that endorses national forest certification systems

Focused on making certification accessible to small forest owners

More practical for:

Family-owned forests

Regions with existing national forestry traditions

🔎 Ideal for: Large-scale sourcing, European wood, or cost-effective certifications

compare PEFC to FSC

By-products like dust, shavings, and fibers are reused for….. or…….

By-products like dust, shavings, and fibers are reused for biomass fuel or engineered timber panels.

Three main sawmill products

○ Timbers: large-cut materials used in heavy structures (beams, posts).

○ Dimensional lumber: produced by longitudinal sawing.

○ Boards: <38 mm thick, ≥38 mm wide.

Drying Methods + benefits

Air drying

Kiln drying

Benefits: reduces moisture content, increases stability, strength, and decreases transport weight/cost.

Kiln drying

Peeling and Veneering

Rotary cutting

Defect removal

Air or kiln drying

Rotary cutting

log rotated while a blade slices a continuous sheet.

Defect removal

and drying (2–10% moisture) prepares veneer for gluing

Air or kiln drying

Wood-Based Products (8)

Plywood

Laminated Veneer Lumber (LVL)

Composite I-beams (LVL flanges + OSB or plywood web)

Oriented Strand Board (OSB)

Particleboard (Chipboard)

Medium-Density Fibreboard (MDF)

Natural Fiberboard (NFB)

Glue-Laminated Timber (Glulam)

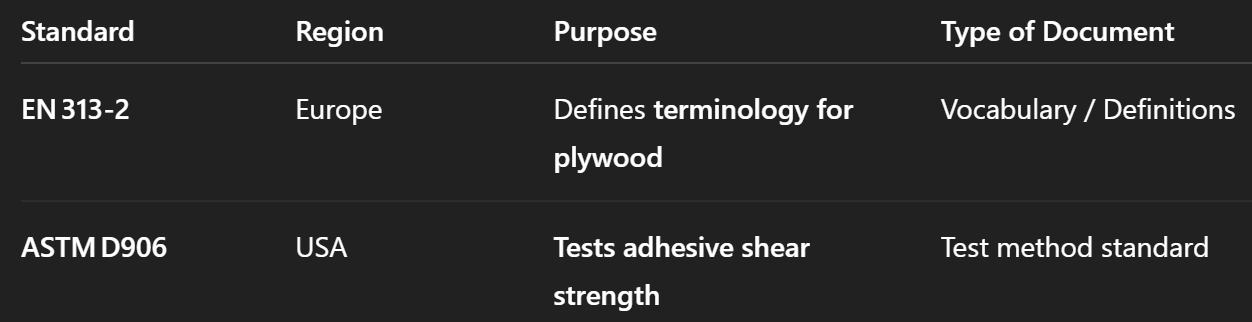

Plywood

● ASTM D906: layers (plies) glued under pressure, bond as strong as the wood

itself.

● EN 313-2: grain in adjacent layers at right angles for stability.

Laminated Veneer Lumber (LVL)

● Defined by EN 14279: veneers glued with grain parallel, forming beam-like

components.

● Used in load-bearing structures or parts of I-beams.

Composite I-Beams

● Flanges: made of LVL for tensile/compressive strength.

● Web: made of structural plywood or OSB for shear resistance

Oriented Strand Board (OSB)

● ISO 17064 & EN 300: multi-layered; outer strands aligned, core

random/perpendicular.

● Identified by large, long wood strands.

Particleboard (Chipboard)

● Wood particles/flakes mixed with polymeric adhesive, pressed with heat.

● Also includes natural fibers like flax, hemp, straw.

● Used in furniture and building.

Medium-Density Fibreboard (MDF)

● Fibers from wood + resin binder + pressure and heat.

● Denser and stronger than particleboard.

● Similar uses to plywood

Natural Fiberboard (NFB)

● No synthetic glue; lignin (natural) re-polymerized via thermo-mechanical

treatment.

● Eco-friendly: respects safety/environment standards; has certifications (F****,

CE, FSC/PEFC).

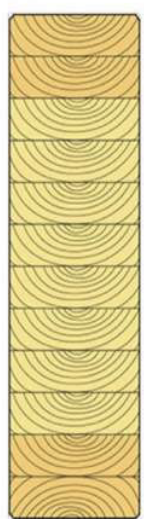

Glue-Laminated Timber (Glulam)

Definition (ISO 12578)

● Multiple timber laminations bonded with grain running parallel.

● Lamination ≤50 mm thick.

Properties of Glue-Laminated Timber (Glulam)

● Superior strength-to-weight ratio (better than steel/concrete).

● Used in beams, arches, columns.

● Excellent fire resistance, dimensional stability, and formability.

Types of Glue-Laminated Timber (Glulam)

● Homogeneous Glulam: all laminations same grade/species.

● Combined Glulam: stronger laminations in tension/compression zones; rest are

lower grade.

same strength classes, but slightly lower

mechanical properties and density due to inner/outer layer combinations.

Glue-Laminated Timber (Glulam) advantages

● Renewable and recyclable.

● Low energy use in production.

● Excellent aesthetic and durability.

● Can be crafted with simple tools.

● Fire-resistant and dimensionally stable.

Advanced Wood Products

Transparent Wood

Wood-Polymer Composites (WPC)

Wood-Polymer Composites (WPC)

● Blend of natural fibers/flour (e.g., wood powder, agri-residue) + polymers

(PVC, PP, PE).

● Processing: extrusion, calendaring, injection, compression molding.

● Used in decking, cladding, fencing, furniture.

Transparent Wood

● Natural wood is opaque due to light scattering and lignin absorption.

● 80–95% of absorption due to chromophores in lignin and extractives.

● Research (Chutturi et al., 2023) explores transparent wood for potential

applications.

hardwood

softwood

plywood

LVL composite I beam

LVL

oriented strand board (OSB)

particle board

medium density fiber board

natural fiber board

glulam