Lecture 5 Polymer Degradation and Design of Degradable Biomaterials

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

Degradation and Erosion

Degradation: ____ process resulting in the ____

of covalent bonds in the ___ or ____._____

______

_____

Erosion: ____ change in size, shape or mass as a

result of either ____ or simply ___Bioerosion

Water-____ being converted into water-___ under physiological condition. Including both physical (___) and chemical (____ __ _____) process.

Degradation: chemical process resulting in the cleavage

of covalent bonds in the backbone or crosslinks.Oxidative

Enzymatic

Hydrolytic

Erosion: physical change in size, shape or mass as a

result of either degradation or simply dissolutionBioerosion

Water-insoluble being converted into water-soluble under physiological condition. Including both physical (dissolution) and chemical (cleavage of backbone) process.

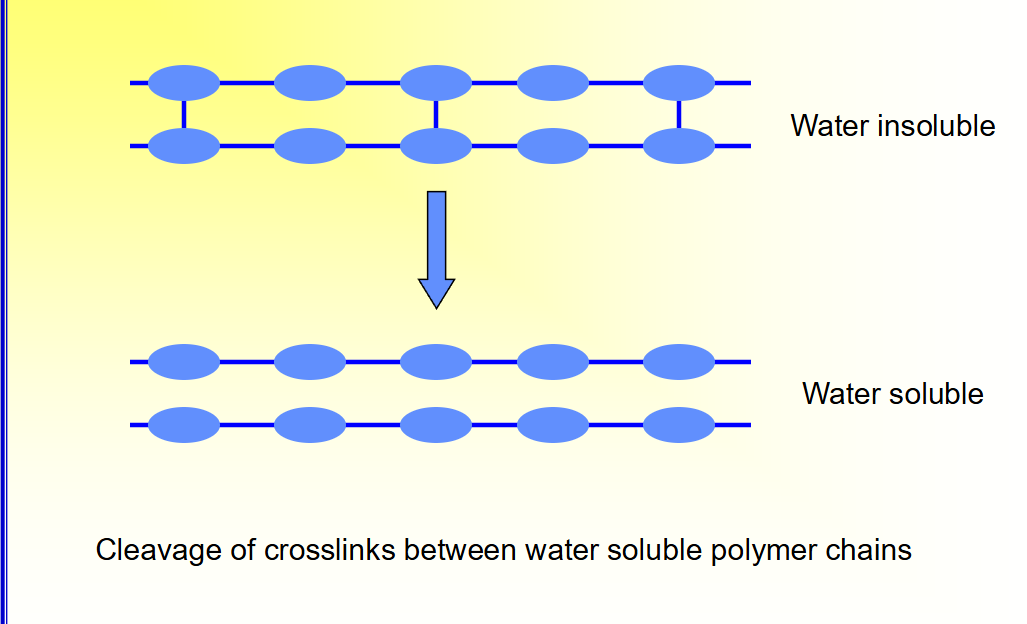

How does erosion driven by chemical processes look 1?

Cleavage of crosslinks between water soluble polymer chains

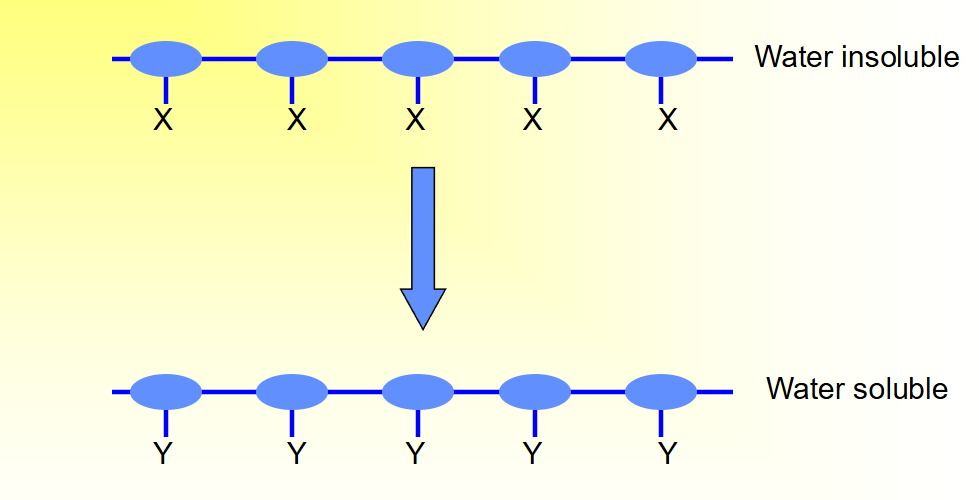

How does erosion driven by chemical processes look 2?

Transformation or cleavage of side chains (X) leading to

the formation of polar or charged groups (Y).

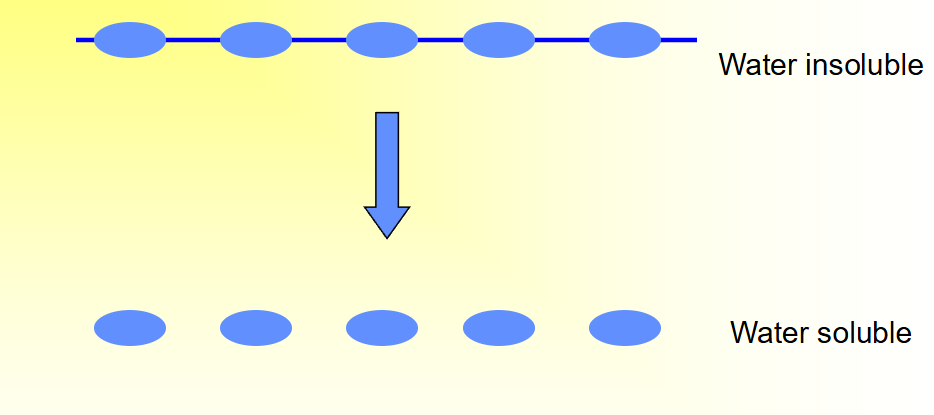

How does erosion driven by chemical processes look 3?

Cleavage of backbone linkages between polymer repeat units

What are some physical modes of Bioerosion?

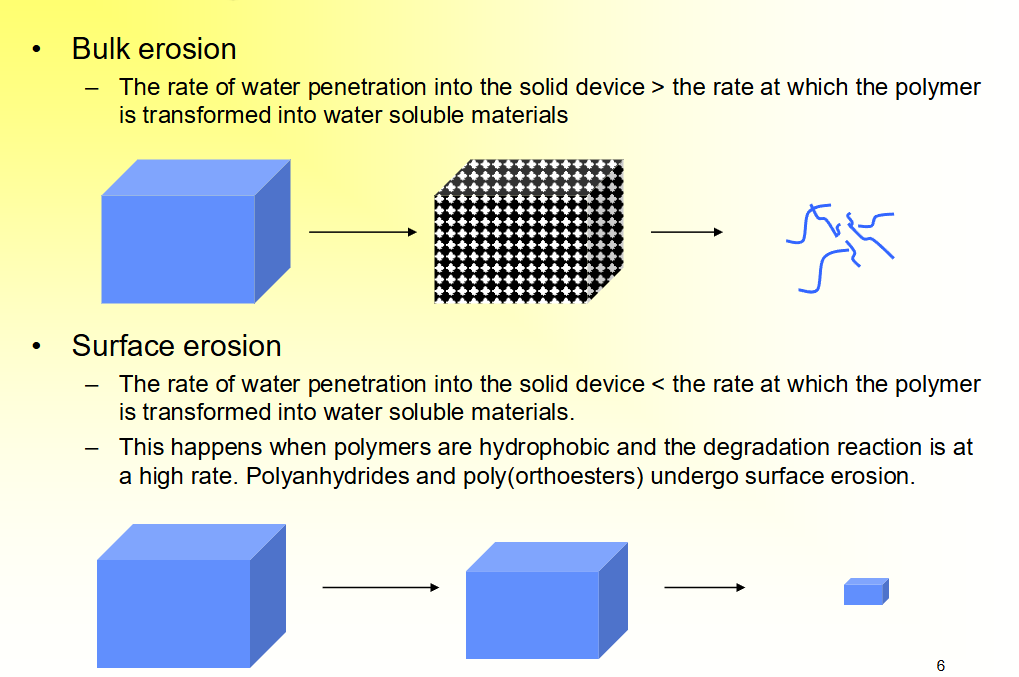

Bulk erosion

The rate of water penetration into the solid device > the rate at which the polymer

is transformed into water soluble materials

Surface erosion

The rate of water penetration into the solid device < the rate at which the polymer is transformed into water soluble materials.

This happens when polymers are hydrophobic and the degradation reaction is at a high rate. Polyanhydrides and poly(orthoesters) undergo surface erosion.

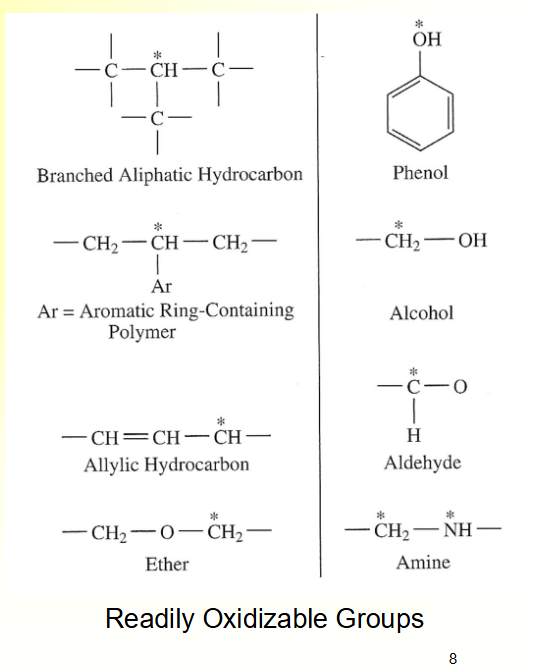

Polymer Degradation-Oxidative

Polymer chain attacked by reactive species (free radicals or oxidative ions produced by the inflammatory process or metal implant corrosion).

Initiation steps:

Homolysis

• R-R ➔2R.Heterolysis

• R-R➔R++R-

Not a common choice for designing a degradable polymer

Exception: ROS (reactive oxygen species) responsive materials

Polymer Degradation - Enzymatic

Major degradation mechanism for natural polymers

Selective: protease, esterase, lipases, glycosidase, nucleosidase

Not predictable as the levels of enzymes varies from time to time, location to location and subject to subject

Polymer may be designed to degrade by a specific cell type or specific biological condition

Surface erosion can be realized by enzyme-mediated degradation

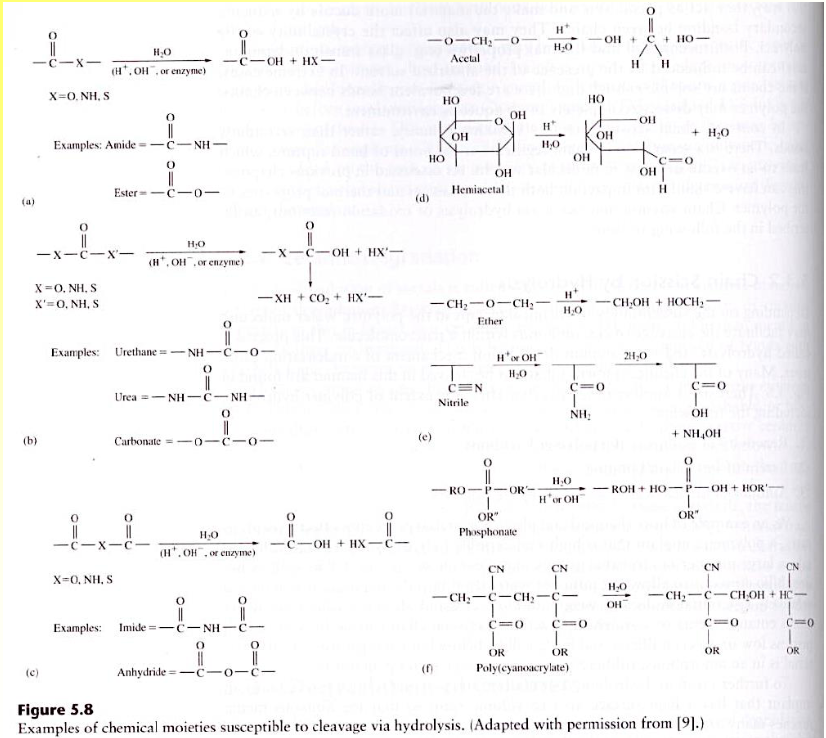

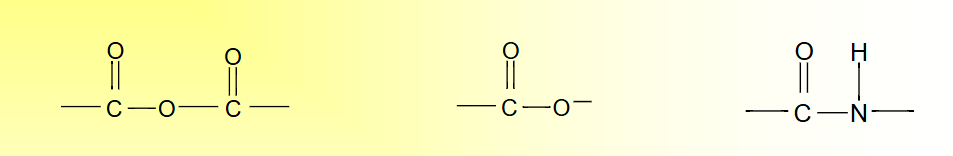

Polymer Degradation-Hydrolytic

Hydrolyzable groups: carbonyl bonded to heterochain elements (O, N, S), full list see Figure 5.8 next slide

Host induced

– Neutral water

– Ion-catalyzed

– pH-catalyzed, low pH occurs at the acute inflammation or infection site

– Enzyme-catalyzed

Factors Influencing the Hydrolytic Erosion

• Chemical stability of the linkage

Rate of degradation:

polyanhydrides > polyesters > polyamide

Factors Influencing the Hydrolytic Erosion II

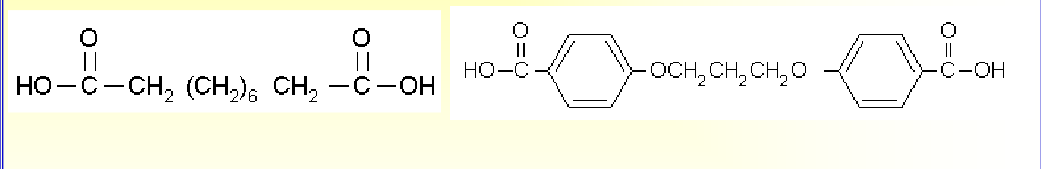

The erosion rate is strongly dependent on the ability of

water to penetrate into the polymeric matrix.Hydrophobicity of the monomer

– More polar groups, -OH, -COOH, -C=O, less hydrophobic

– More nonpolar groups, phenyl, -CH3, more hydrophobic

Polyanhydride made of hydrophilic sebacic acid erodes 3

orders of magnitude faster than that made of hydrophobic

bis(carboxy phenoxy)propane

More factors influecing the hydrolytic erosion:

Microstructure, ___ vs. ___ (glassy vs. rubbery)

____ structure is resistant to the ___ penetration. Semicrystalline PLLA vs. amorphous D,L-PLA

_____ materials degrade faster when they are above Tg (____ state) than below Tg (____ state)

____ molecular weight (molecular weight ____)

____ the initial molecular weight, quicker to break down

Geometry and morphology, more ____ area, faster erosion

Additives, catalysts, plasticizers, may ___ or ___ H2O penetration

Mechanical stress: points of ____ ___ ____ degrade more rapidly;

Processing and fabrication, ~morphology, microstructure and residual stress

Microstructure, crystalline vs. amorphous (glassy vs. rubbery)

Crystalline structure is resistant to the water penetration. Semicrystalline PLLA vs. amorphous D,L-PLA

Amorphous materials degrade faster when they are above Tg (rubbery state) than below Tg (glassy state)

Initial molecular weight (molecular weight distribution)

Lower the initial molecular weight, quicker to break down

Geometry and morphology, more surface area, faster erosion

Additives, catalysts, plasticizers, may inhibit or aid H2O penetration

Mechanical stress: points of residue stress concentration degrade more rapidly;

Processing and fabrication, ~morphology, microstructure and residual stress

Degradable Biomaterials

Advantages:

Permanent implants may cause chronic inflammation, stress shielding, etc.

Degradable materials are gradually absorbed by the body and don’t permanently

leave traces of residuals in the implantation sites.The degradation rate can be adjustable according to the application needs

Biocompatibility considerations:

Neither the polymer nor its degradation products nor the subsequent metabolites

should provoke excessive inflammation or toxicity

Storage, packaging, and sterilization stability:

Avoid moisture

Packed in air-tight aluminum-backed plastic foil, and stored at low temperature

Sterilization

Autoclaving and irradiation, bad

Ethylene oxide, OK

Applications of degradable biomaterials

Drug Delivery

Degradable polymer serves as a matrix or encapsulation.

The degradation properties are tailored to achieve optimal release kinetics of the drug or active agent

Temporary Support: sutures, bone fixation devices

Provide temporary mechanical support until the nature tissue heals and regains its strength

Adjust the degradation rate to the healing process

Tissue Engineering Scaffold

The surface should permit cell adhesion and growth;

The scaffold degradation rate should match the rate of tissue regeneration by the cell type of interest

Multifunctional

Example 1: Degradable bone nails or bone screws loaded with drug

Example 2: Biodegradable and drug-eluting stents

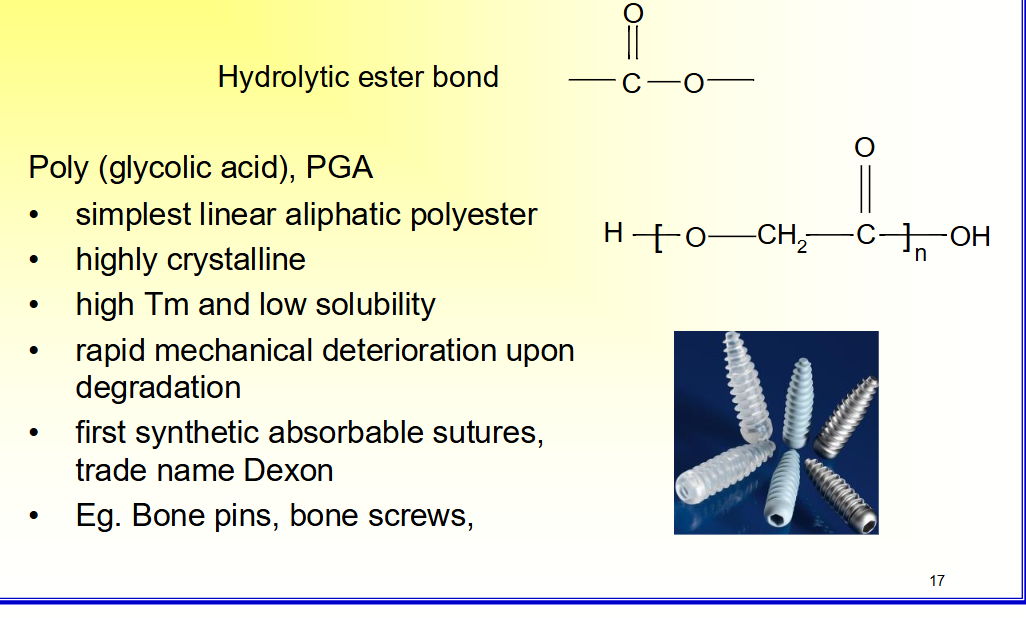

What are Polyester

Type of degradable polymer

Poly (glycolic acid), PGA

• simplest linear aliphatic polyester

• highly crystalline

• high Tm and low solubility

• rapid mechanical deterioration upon

degradation

• first synthetic absorbable sutures,

trade name Dexon

• Eg. Bone pins, bone screws

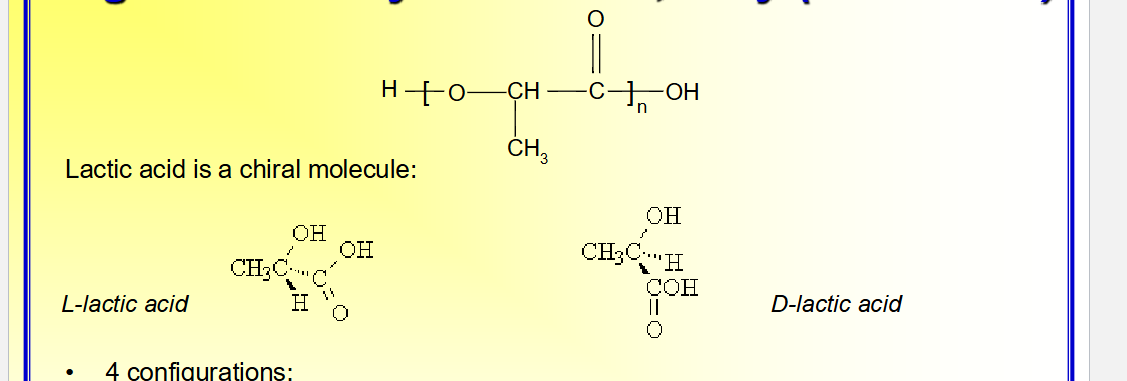

Degradable Polyester: PLA, Poly (lactic acid)

4 configurations:

stereoregular D-PLA (PDLA) and L-PLA (PLLA). Usually PLLA is used because the hydrolysis product L-lactic acid is the naturally occurring lactic acid

racemic D,L-PLA

meso-PLA obtained from D,L lactide

Semi-crystalline PDLA and PLLA; amorphous D,L-PLA

amorphous D,L-PLA is used in drug delivery where monophasic matrix is important;

semi-crystalline PLLA is good for applications requiring high mechanical strength and

toughness, such as sutures and orthopedic devices

Copolymer of LA and GA (PLGA)

PLLA is more hydrophobic than PGA, limits the

water uptake and reduce the backbone hydrolysisAddition of PLA component to PGA helps to reduce the hydrolysis rate

GA:LA 90:10 is used as suture materials (Vicryl and Polyglactin 910)

There is no simple linear relationship between the ratio of GA:LA and the mechanical and degradation properties of the corresponding copolymers (see homework 2)

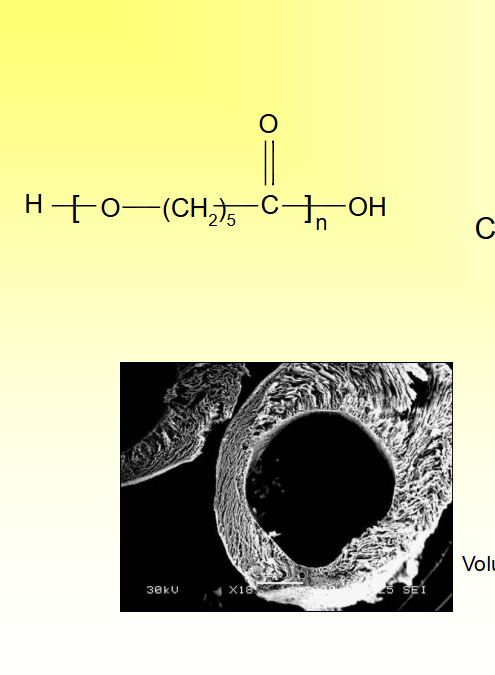

Poly (-caprolactone)

Sutures and drug release

Slower degradation than PLA

Semi-crystalline

Copolymers have been made with PGA

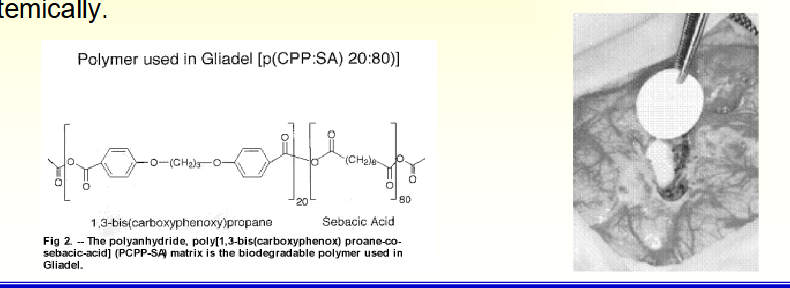

Polyanhydride

• Among the most reactive and hydrolytically unstable polymers used as biomaterials

• Fast degradation, excellent in vivo biocompatibility

• React with drugs having free amino groups or other nucleophilic

functionalities → limit the types of drugs that can be successfully

incorporated.

• Predominantly used in drug delivery prepared by compression molding or

microencapsulation.

• Gliadel Wafer: used for intracranial delivery of bis-chloroethylnitrosourea (BCNU) for brain cancer. The wafers are implanted directly into the brain to deliver BCNU that has deleterious side effects when administered

systemically.