Chapter 22 Materials

1/102

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

103 Terms

phase diagrams and phase transformations

central to understanding microstructure, properties, and processing paths.

metallic alloy

a mixture of a metal with other metals or non-metals (often form precipitates/inclusions).

Components

the chemical elements that make up alloys.

binary alloy

contains two components.

Alloy compositions

defined by concentration in weight % or atom %.

phase

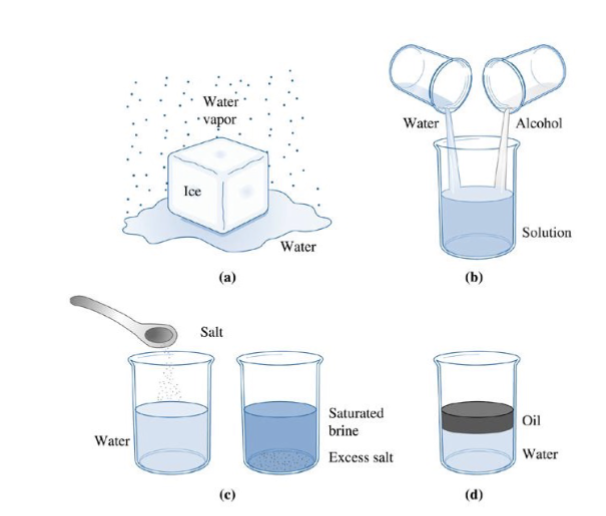

A region of a material that is structurally homogeneous (same crystal structure) and distinct (interface with surroundings)

Three forms of water (solid, liquid gas) are each one; water and alcohol have unlimited solubility (one); salt + water have limited solubility (excess salt means 2); oil and water have virtually no solubility (2)

constitution of an alloy

described by:

• The identity of phases present. (at equilibrium)

• The composition of each phase.

•The fraction of each phase

these properties are represented in a phase diagram

stable

At thermodynamic equilibrium, the constitution is _______ (no change is possible).

equilibrium constitution

the state with the lowest Gibbs free energy for a given composition, temperature, and pressure; shown in phase diagram; minimizes energy state

phase diagram

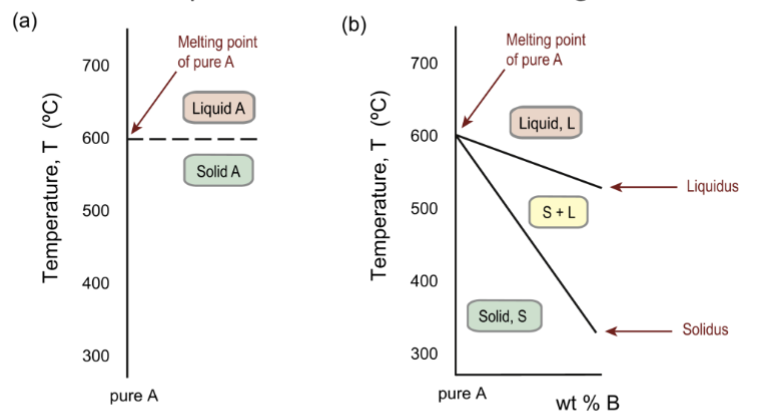

a diagram with temperature and composition as axes, showing the equilibrium constitution. It is like a map and is divided into fields or regions.

one dimensional phase diagram

for a pure substance, a temperature scale showing the phase boundary between solid and liquid – the melting point

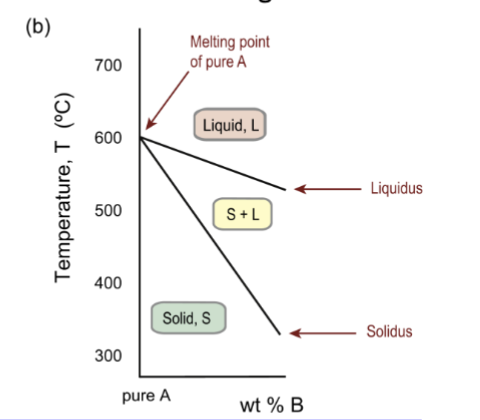

two elements in phase diagram

the A-rich end of a binary A–B phase diagram, illustrating partition of the melting point between solidus and liquidus boundaries

solid is always crystalline; S+L is the freezing range, and both solid and liquid are present

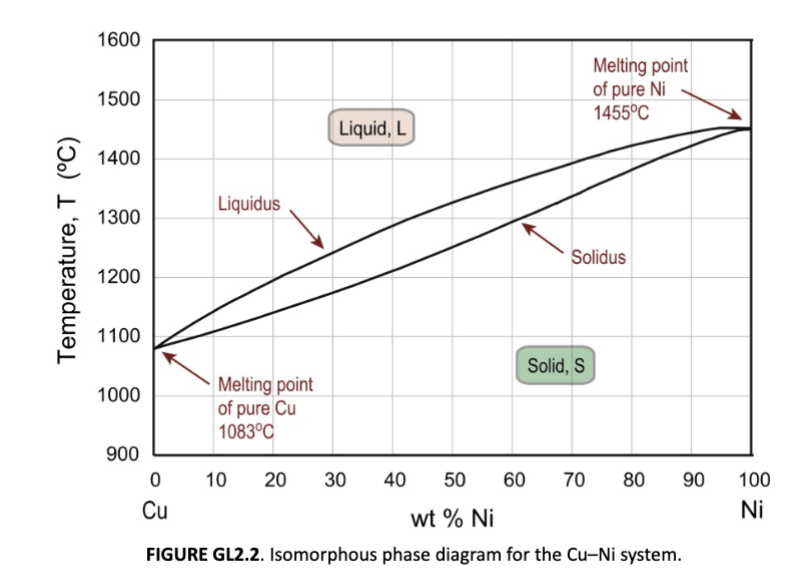

Isomorphous Phase Diagram

simplest type of phase diagram

isomorphous

For two components, we have a binary phase diagram. If there is complete solubility in the solid phase, the system is said to be…

liquidus line

boundary between liquid and L+S two-phase field

Solidus line

boundary between solid and L+S two-phase field.

Freezing range

Difference between solidus and liquidus temperatures for a given composition.

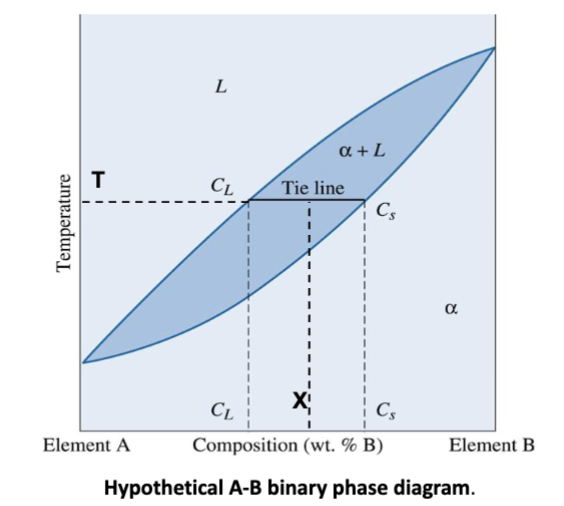

tie line

For an alloy at coordinates T-X inside a two-phase region, a _______ at the temperature of interest fixes the compositions of the two phases.

Constant temperature → extend line to liquidus and solidus to get composition of liquid and solid

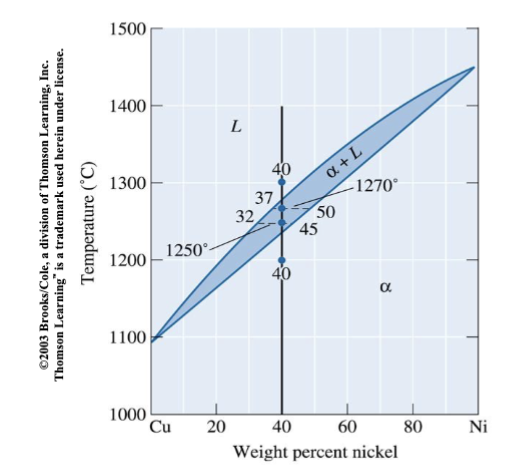

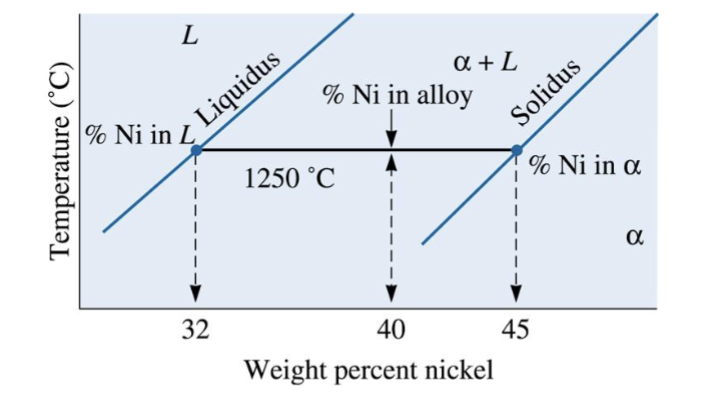

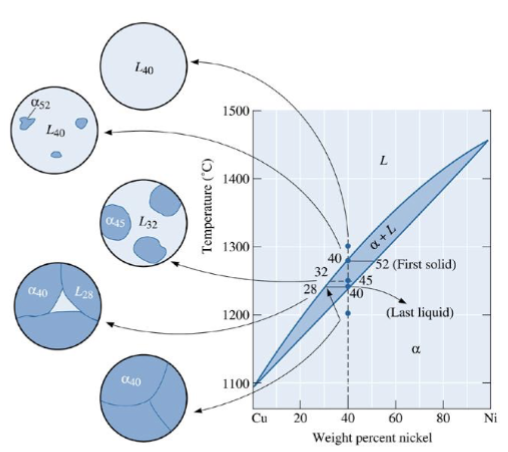

composition of phases in Cu-40% NI alloy at different temperatures

The vertical line represents overall composition of the alloy:

1300°C: Only liquid is present. The liquid must contain 40%Ni, the overall composition of the alloy.

1270°C: Two phases are present. The liquid contains 37%Ni, and the solid contains 50%Ni.

1250°C: Again, two phases are present. The tie-line drawn at this temperature shows that the liquid contains 32%Ni and the solid contains 45%Ni.

1200°C: Only solid is present, so the solid must contain 40%Ni

phase fraction

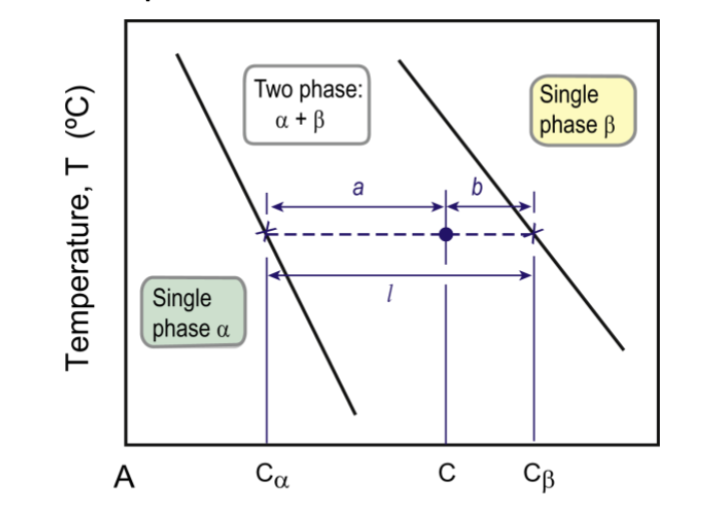

=(opposite arm of lever)/(total length of tie-line); part of the lever rule for proportion of phases

fraction α = (C-C1)/(C2-C1)

fraction L = (C2-C)/(C2-C1)

lever rule for two solids composition

fraction α = (b/l)

fraction β = (a/l)

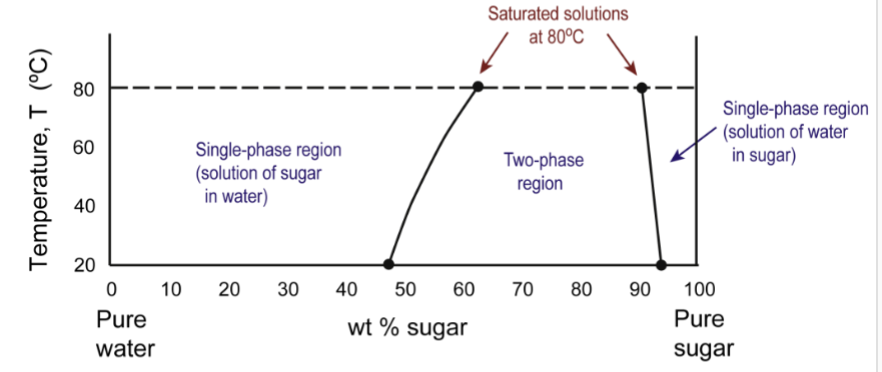

solvus line

the boundary between the single- and two-phase regions; saturation level for solutions increases with temperature

solubility

how much can we add of one material to another without producing an additional phase

unlimited solubility

soluble in all proportions; water and alcohol as liquid, Ni and Cu in both liquid and solid. In the solid (a solid solution), both Ni and Cu are FCC elements.

limited solubility

soluble up to a point where second phase begins to form (water and salt, Cu and Zn). Can also mean almost no solubility (oil and water, Cu and Pb)

Hume-Rothery Rules

necessary but not sufficient conditions for unlimited solid solubility:

size - within 15% difference in atomic radius

crystal structure - same for both elements

valence - same for both types of atoms

electronegativity - similar for both types of atoms

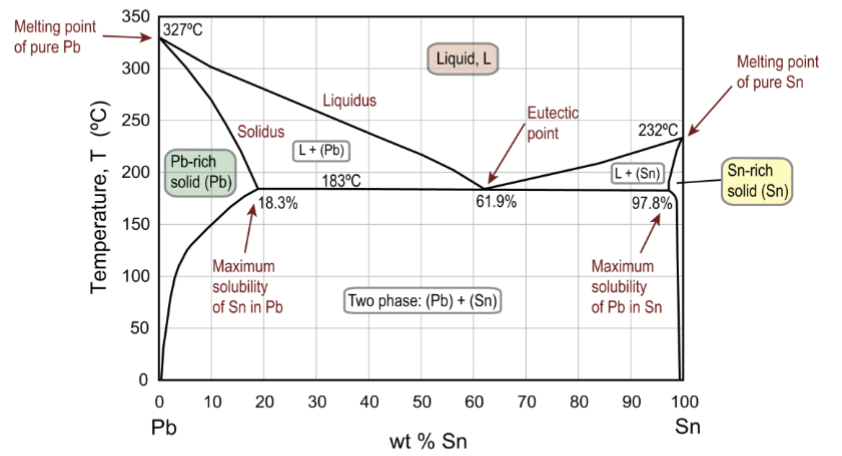

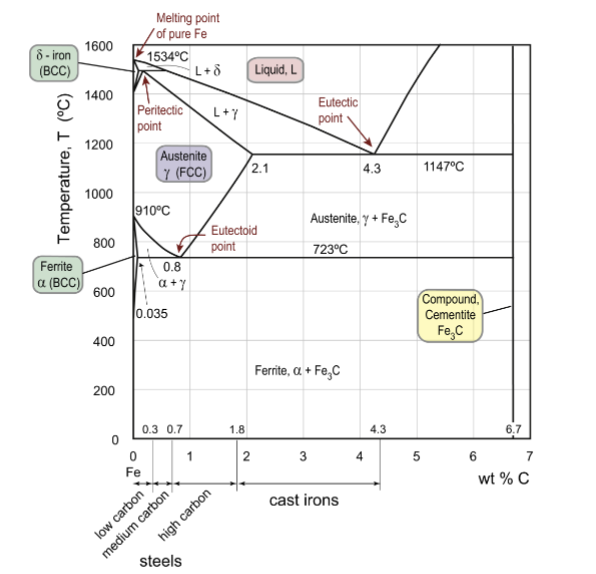

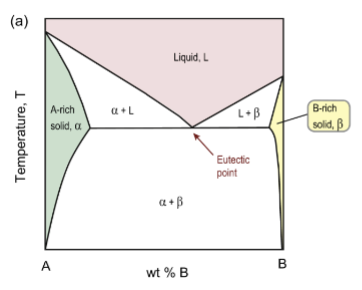

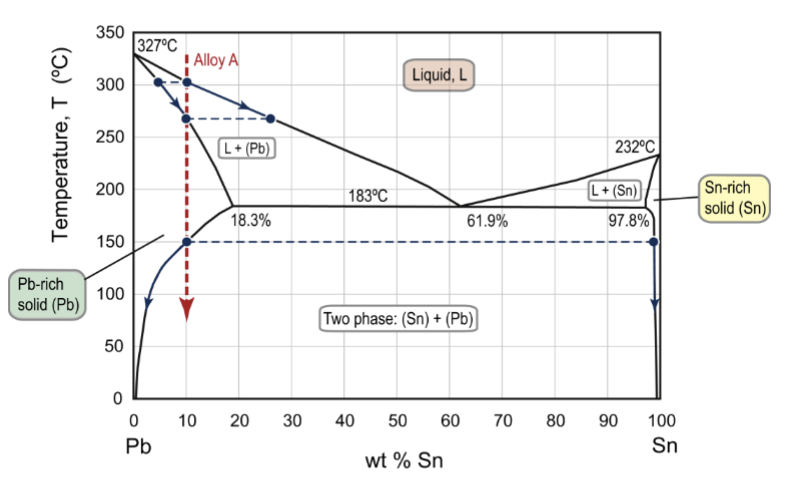

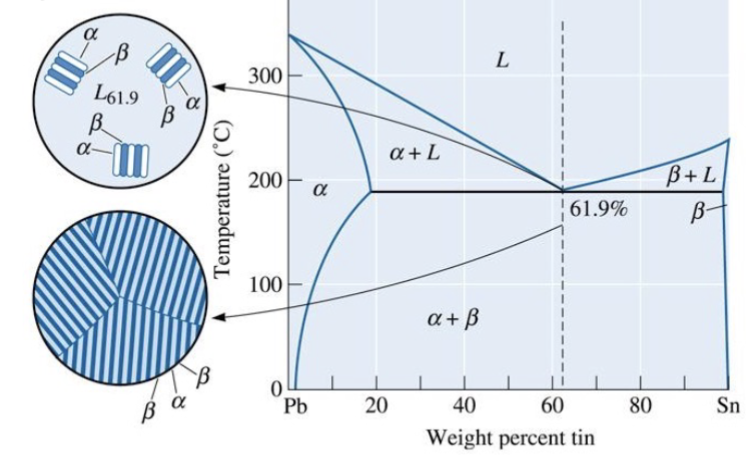

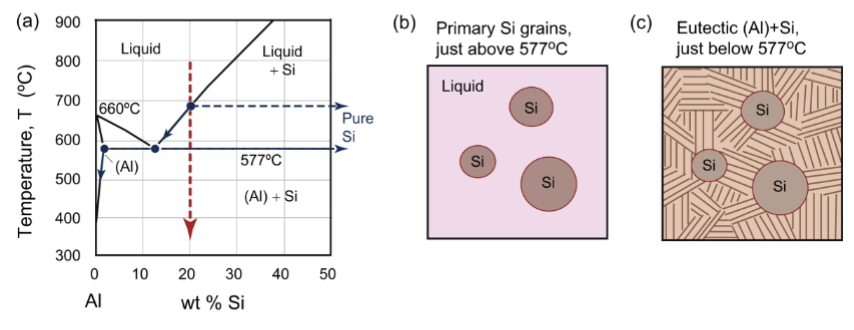

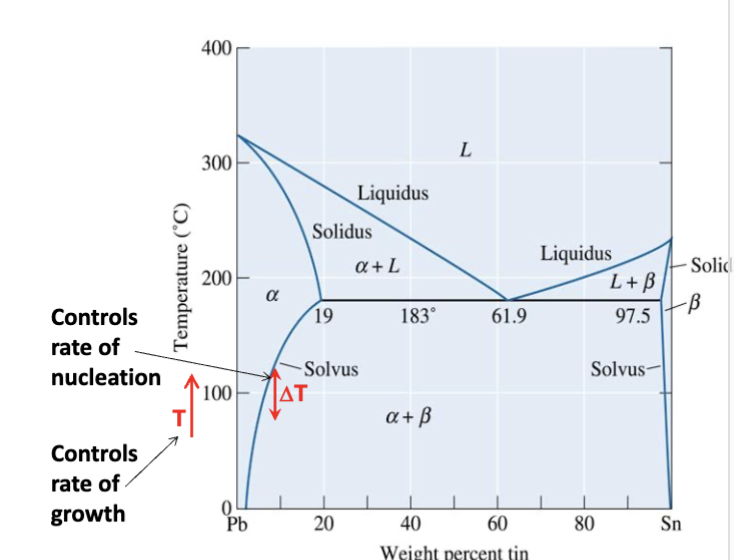

eutectic point

The lower limit of the single-phase liquid field formed by the two liquidus boundaries; example of an invariant point

eutectic reaction

at this point, this reaction occurs on cooling: Liquid → Pb-rich solid solution + Sn-rich solid solution (essentially two different solids upon cooling)

maximum solubilities

in the solid phases, usually occur at the same temperature

intermediate phases

many systems exhibit these. These compounds often have high melting points and are very stable. Ex: intermetallic compounds, where metal atoms are preferentially bonded to the other type of atom

Pretty strong and low ductility

intermetallic compounds.

If the components are both metals with stoichiometric or near-stoichiometric compositions (in atomic percent), then we call them this.

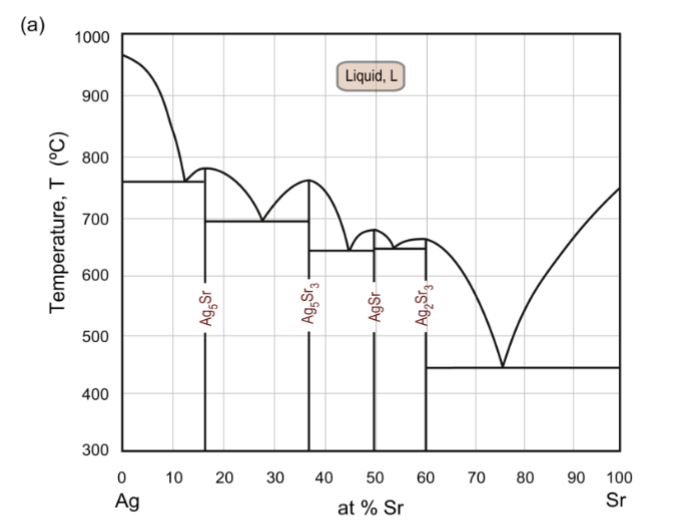

intermediate phase diagram

each intermediate phase has its own eutectic point/reaction. Straight lines mean fixed stoichiometry. This one has four distinct intermediate phases/compounds

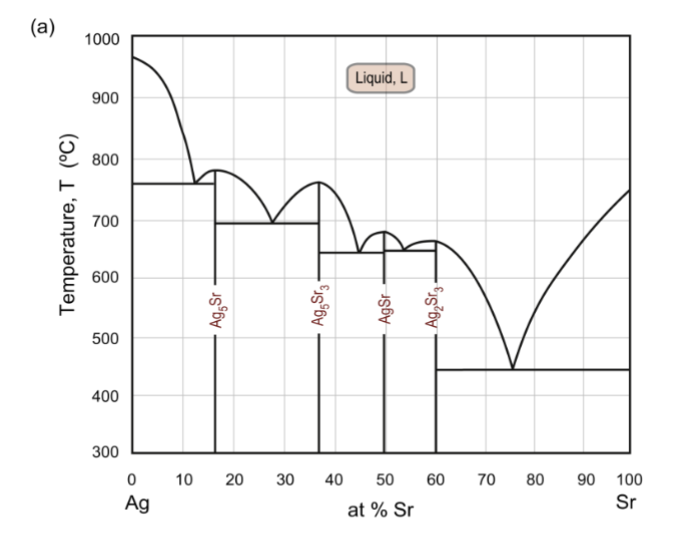

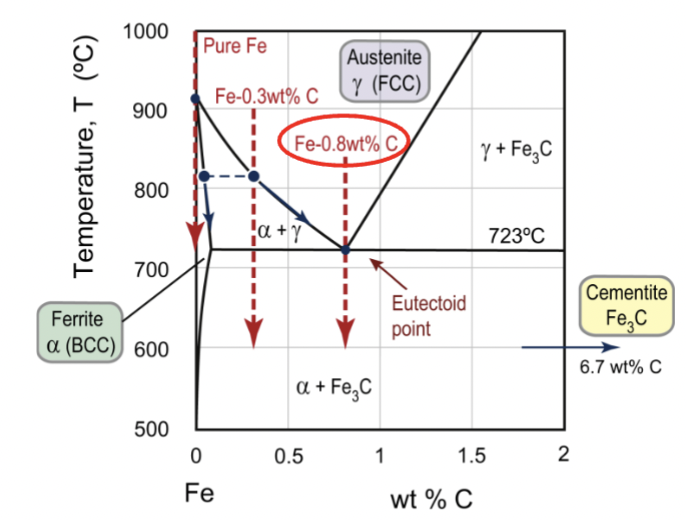

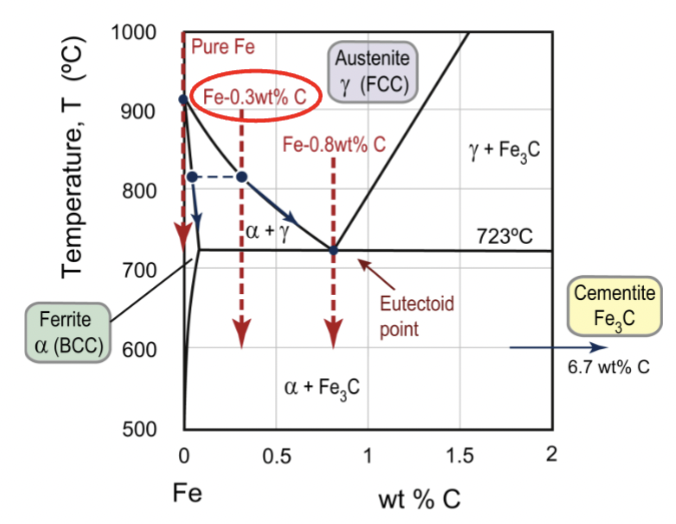

Fe-C compounds

encompasses cast irons (high wt% C) and steels (lower wt% C)

austenite

FCC iron phase, gamma; at elevated temperatures, there is a big solubility of carbon compared to BCC (wide range of properties)

up to 2.1wt% C in solid solution

ferrite

BCC iron phase, can be denoted alpha (low) or delta (high) based on temperature; unstable intermediate; same phase but just different temperatures

α: up to 0.03wt% C in solid solution

δ: up to 0.08wt% C in solid solution

cementite

Fe3C, iron carbide; about 25% atomic carbon; up to 6.7wt% C

eutectoid point for Fe-C

the lower limit of a single-phase solid field formed by two falling phase boundaries intersecting in a ‘V’. Reaction is γ → α + Fe3C.

peritectic point for Fe-C

reaction is L + δ → γ upon cooling

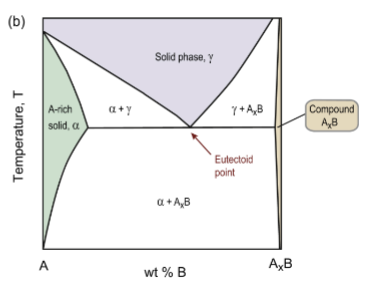

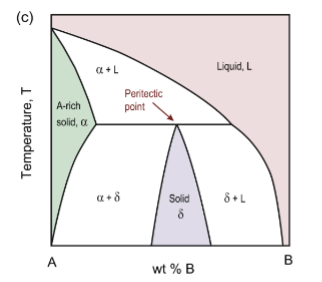

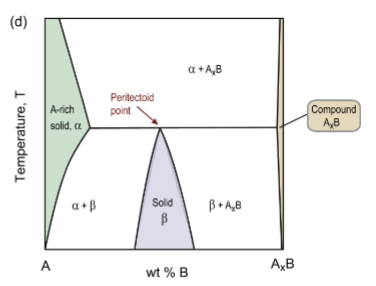

four basic types of reactions

eutectic, eutectoid, peritectic, and peritectoid

eutectic reaction

liquid → two different solids upon cooling

L → α + β

eutectoid reaction

solid → two other, different solids upon cooling

γ → α + AxB

peritectic reaction

solid + liquid → other solid upon cooling (2 phases to get 1 phase)

α + L → δ

peritectoid reaction

solid + solid → other solid upon cooling

α + AxB → β

phase transformations

driven by reduction in free energy (the “driving force”, high → low is spontaneous); usually involve diffusion; occur by a two-stage process: nucleation and growth

time temperature transition diagrams

capture the extent of isothermal transformation as a function of time and temperature

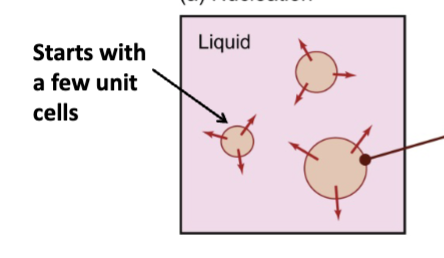

nucleation and growth

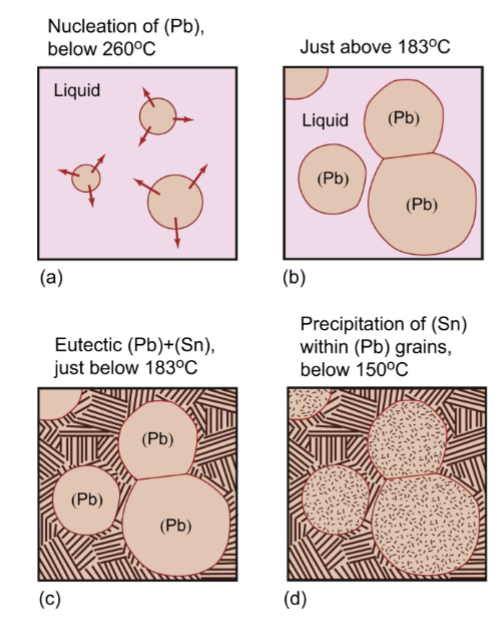

for example, in a eutectic reaction, the solid phases first have to appear/form and then the first stage of forming the initial crystal is this first step; one the microcrystal exists, it grows (step 2)

nucleation

of a crystalline solid in a liquid, atoms in a pure metal liquid; small crystal of atoms forms, once this tiny crystal forms, then it grows.

the initial process that occurs in the formation of a crystal from a solution, a liquid, or a vapour, in which a small number of ions, atoms, or molecules become arranged in a pattern characteristic of a crystalline solid, forming a site upon which additional particles are deposited as the crystal grows

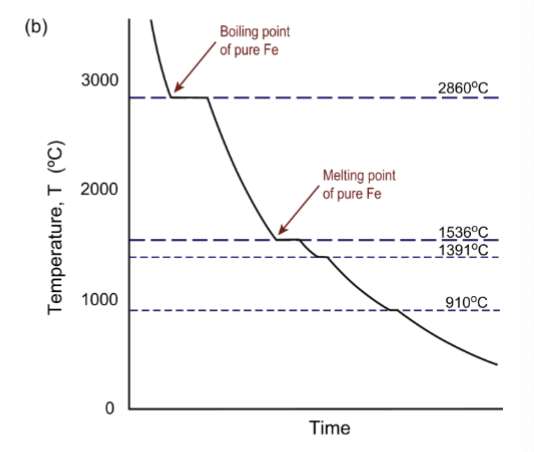

thermal arrests

occur when you remove heat in order for transformation to proceed; a large amount of heat has to be removed for the heat of vaporization or heat of fusion, so the material stays at that temperature for a while before condensing, melting, etc

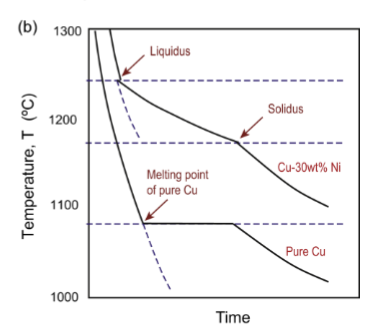

alloy cooling curve

solidify over a range of temperatures, and the plateau is replaced by a decreased cooling rate as the material gradually solidifies as temperature decreases.

no thermal arrests in alloys

because only a tiny bit of solidification occurs at each temperature and it occurs over a range of temperatures. cools more slowly due to two types of heat removal for two materials.

change of slope

in alloy cooling curve, corresponds to liquidus/solidus temperatures

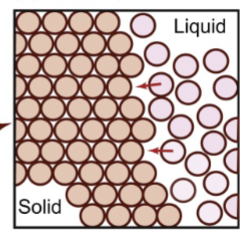

solid-liquid interface

boundary where a solid and liquid interact, with a perturbation of the liquid structure near the solid surface

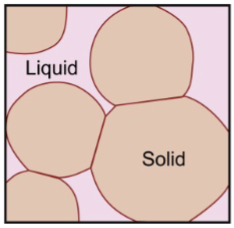

impingement

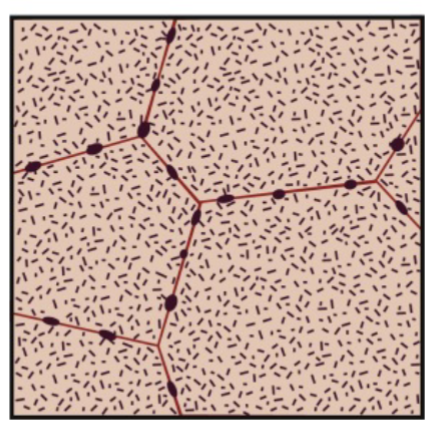

growth of nuclei and onset of this;

atoms cannot be perfectly in both crystals at the same time, leading to a disordered region or grain boundary

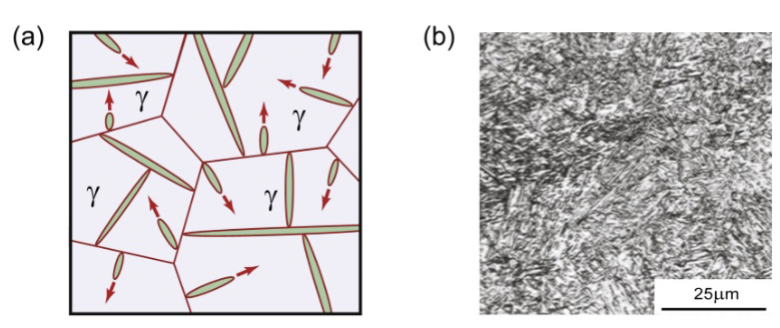

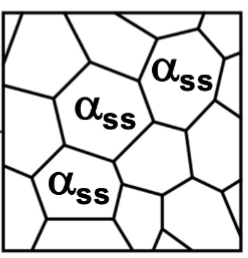

solidification of solid solution alloy

Example: Cu-40%Ni.

First solid to form: 52%Ni.

Diffusion is required so that the compositions of liquid and solid follow the liquidus and solidus curves.

Last liquid to freeze: 28%Ni.

composition changes: 52% → gives up Ni to liquid → goes down until it reaches 40% Ni

very slow cooling

in a solid solution alloy, you only can get a uniform equilibrium structure with …

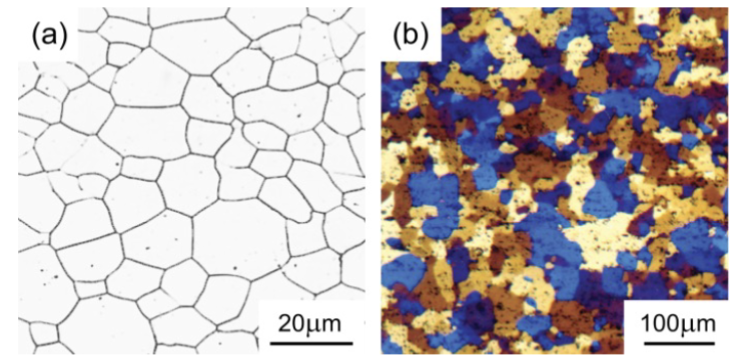

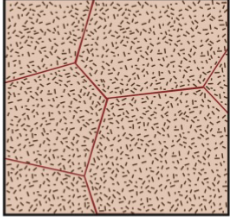

optical micrographs

(a) pure Fe and (b) pure Al. In (b) the etching technique produces color contrast between different crystal orientations – but it is still all one phase.

colors present different grains and crystal orientations

bonds

with the disorder on grain boundaries upon cooling a solid solution alloy, the _______ are not as strong on the edges as they are in the middle

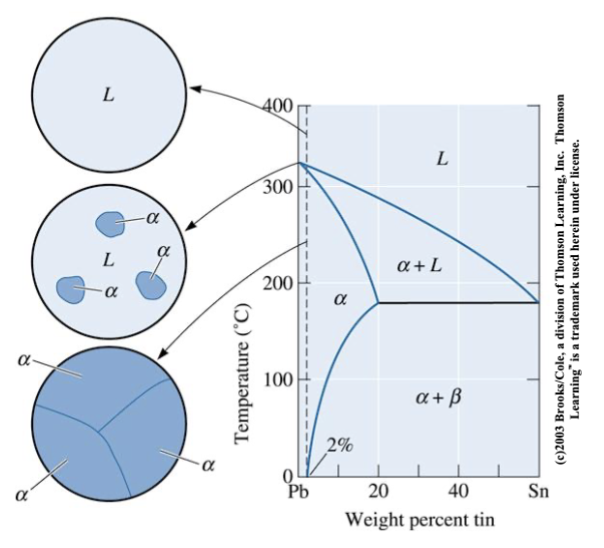

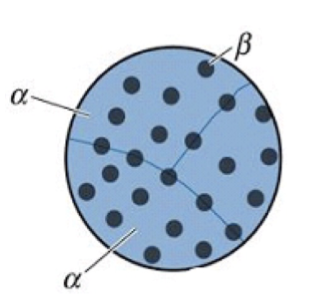

solidification with limited solubility

microstructure of a Pb-2%Sn alloy. The alloy is a single-phase solid solution

Composition Pb-2wt%Sn is special because it is the maximum solubility at room temperature; on the left side of this line, only alpha grains.

solid solution and precipitation hardening

kinds of strengthening mechanisms that could account for this alloy A composition

precipitation

of (Sn) within (Pb) grains, very fine little dots/rods → good strengthening

alloy cooled at eutectic point

the microstructure contains colonies of eutectic microconstituent instead of grains. Series of parallel layers that form colonies. Each layer is a lamella. 2D layers

proeutectic phase

phase that forms (on cooling) before the eutectoid austenite decomposes. It has a parallel with primary solids in that it is the first phase to solidify out of the austenite phase

Eutectic-like cooling but below the eutectic composition.

hypereutectic composition

those with a higher composition of species β and a lower composition of species α than the eutectic composition

Eutectic-like reaction but above the eutectic composition

kinetics

for solid-solid phase transformations, this is very important. Science of the rate at which reactions can occur — how long does something take to tranform

α → α + β (precipitation)

γ → α + β (eutectoid)

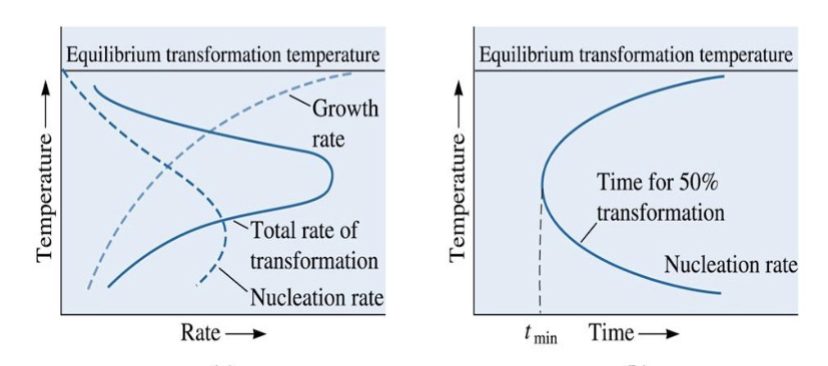

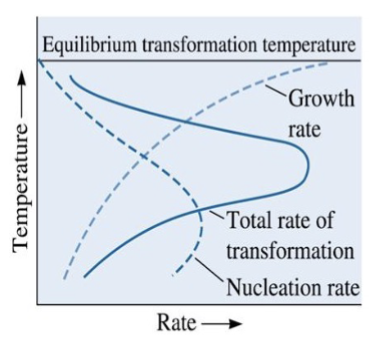

nucleation rate

is low small undercooling (ΔT) and high for large undercooling. Increases with increasing ΔT. Occurs most easily at interfaces (disorders in material that can accommodate changes)

growth rate

high for low undercooling and low for large undercooling (requires diffusion: e-Q/RT)

generally by long-range diffusion. Rate increases with increasing temperature

undercooling

difference between equilibrium temperature and actual temperature for the reaction to proceed; actual transformation occurs at temperature far from equilibrium (lower temp)

overall rate

of transformation depends on both nucleation and growth because you need nucleation in order for the reaction to begin. Growth determines the rest of the transformation.

temperature dependent

Both nucleation (N) and growth (G) are …….

N is low for small undercooling and high for large undercooling.

G is high for small undercooling and low for large undercooling (diffusion). Growth rate = A exp[-Q/(RT)]; Q is activation energy.

product of N and G rates

Overall transformation rate is a ______________. The transformation rate is usually a maximum at some intermediate temperature.

Close to equilibrium temperature → slow transformation

Start to deviate from equilibrium → larger rate

Even further from equilibrium → start to slow down again

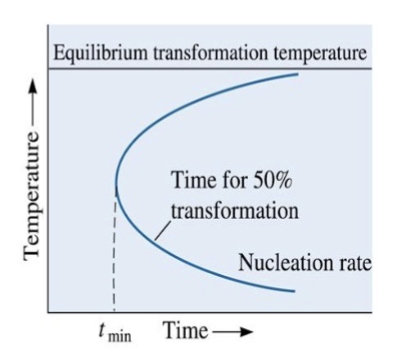

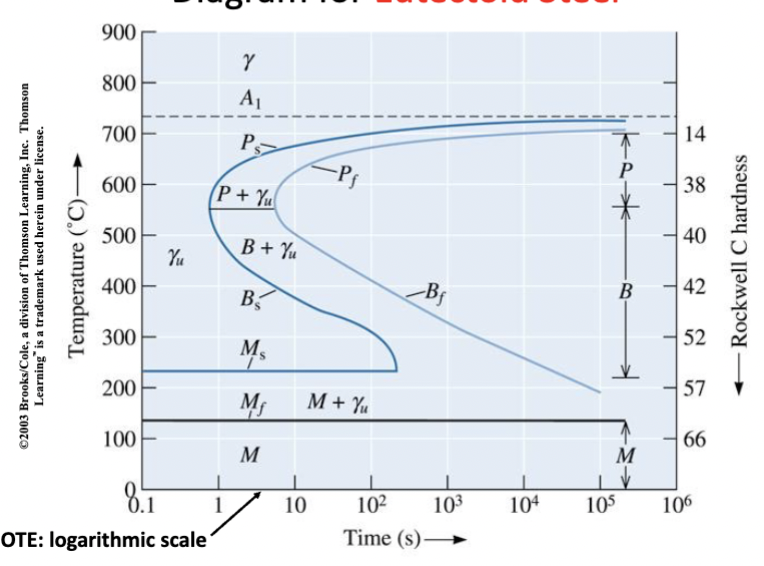

C curve

Time required for transformation is inversely related to rate of transformation. This produces a _______ in a TTT diagram

maximum transformation rate

Effect of temperature on rate of a phase transformation is the product of growth rate and nucleation rate contributions, giving a ______________ at a critical temperature

minimum time (tmin)

there is a ______ required for transformation, given by the “C-curve”

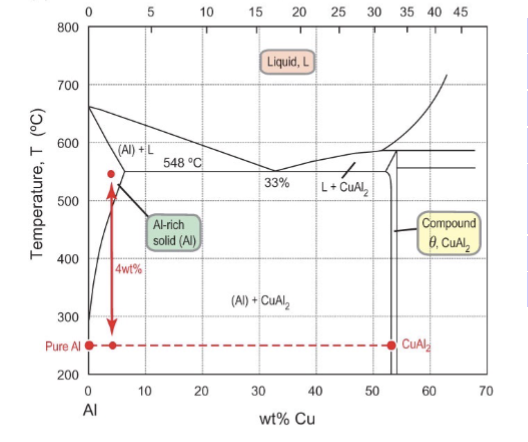

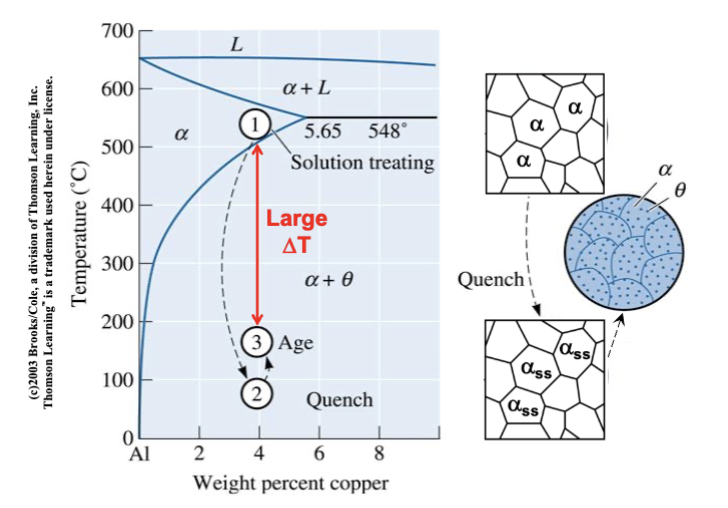

precipitation reactions

When we cross from Al solid solution to the two-phase region, the solubility of Cu in Al decreases and CuAl2 begins to form in the pre-existing grain structure.

Further from the solvus boundary, the nucleation rate increases

Compositional range for CuAl2 in (Al): between 0wt% CU and max solubility of copper in aluminum (5-6%)

precipitates of CuAl2 in (Al)

cool slowly.

initially, CuAl2 precipitates tend to form on grain boundaries first (from there more rapidly). Diffusion is faster along grain boundaries leading to larger precipitates.

In the bulk of the grains, there is a much lower diffusion rate and nucleation occurs later because there is a barrier towards formation more inside the grains than elsewhere. Nucleation rate will be high and the growth rate slow, leading to widely dispersed, very small precipitates

low ΔT and slow cooling

slow nucleation, fast growth = slow overall reaction. Probably heterogenous → form on defects, boundaries, surfaces, etc.

A few nuclei grow large (widely spaced large precipitates)

high ΔT and faster cooling

fast nucleation, slow growth = slow overall reaction. Probably homogeneous → not enough places for heterogeneous nucleation to occur.

Many nuclei that grow slowly (closely spaced fine precipitates). Good precipitation hardening.

very rapid cooling

supersaturated solid solution. No precipitation occurs, even though there is a high driving force, nucleating and growth don’t have a chance to get started. Don’t see a transformation occurring

age or precipitation hardening

produces a uniform dispersion of fine, hard precipitates in a softer, more ductile matrix. Three steps: solution anneal, quenching, and aging

Extremely slow process at room temperature but allows the strength and ductility to be retained for practical use

solution anneal

step one of age/precipitation hardening: goal is to dissolve any existing second phase by heating above the solvus boundary and entering a single phase region where all of the 2nd element is soluble in the Al-rich phase.

Homogenize the solid solution → allow diffusion to make composition uniform

quenching

step two of age/precipitation hardening: Rapidly cool to retain supersaturated solid solution (not at equilibrium). Prevent precipitation (no nucleation or growth)

aging

step three of age/precipitation hardening: heat supersaturated solution below the solvus boundary and precipitates nucleate and grow → get very fine dispersion → much higher strength → extremely fine spacing and very small precipitates

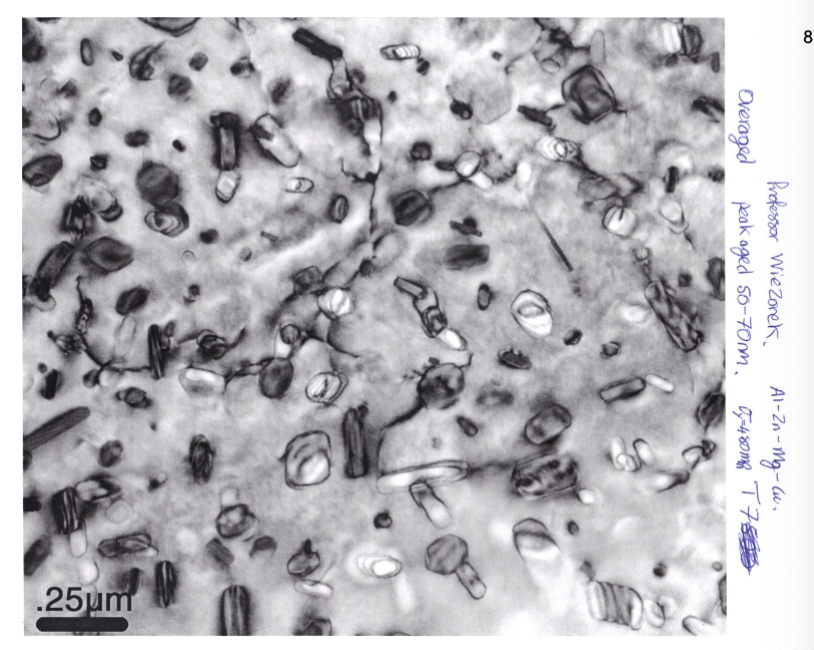

overaged

heated longer or at a higher temperature than to get peak strength (leading to larger particles). slightly weaker than the peak aging, but still with extremely small spacing.

phase transformation in carbon steels

includes eutectoid point, where austenite transforms to ferrite and iron carbide

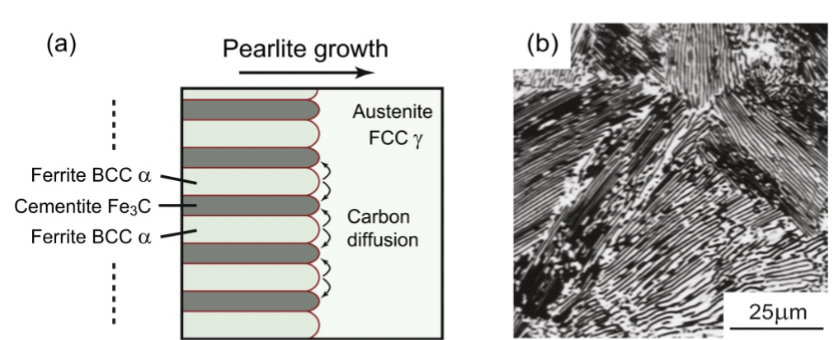

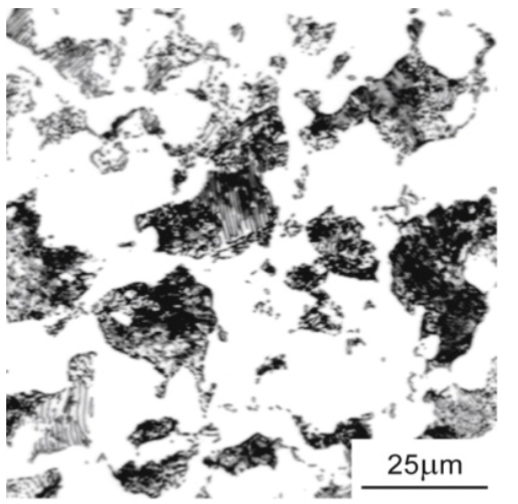

pearlite

carbon must diffuse to the growing cementite phase as the two-phase _______ grows (α-Fe is almost pure Fe)

a two-phase lamellar (parallel layers) mixture of ferrite and cementite. Eutectoid transformation. Not on phase diagram → α + Fe3C but can have different morphology.

low undercooling and slow cooling

Slow nucleation, fast growth = slow overall reaction.

A few nuclei grow large (widely spaced large lamellae).

Close to equilibrium. Fast diffusion. Coarse Pearlite. thicker layers.

high undercooling and faster cooling

Fast nucleation, slow growth = slow overall reaction.

Many nuclei that grow slowly (closely spaced fine lamellae)

very fine pearlite. Layers very close together

rapid cooling (water quench)

Supersaturated solid solution which forms martensite at lower temperature. Unstable austenite solid solution which forms martensite at lower temperature.

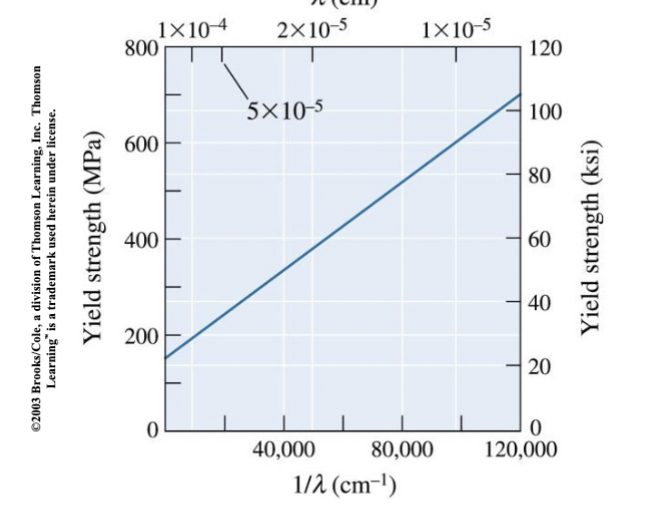

lamellar spacing

of pearlite, depends on how far carbon can diffuse in the time available during cooling.

Graph shows yield strength vs inverse of this in pearlite.

decreased ________ → higher yield strength

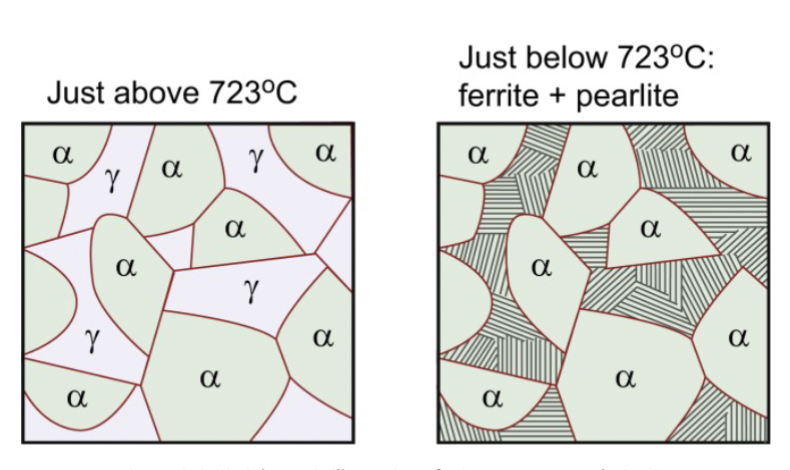

fraction pearlite

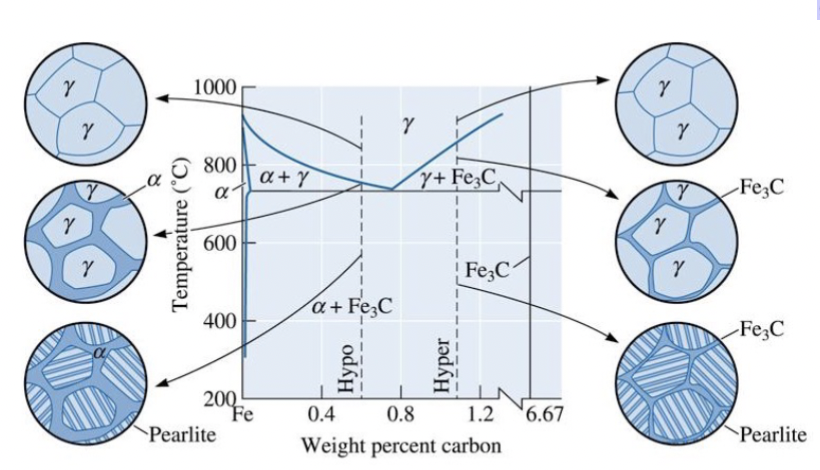

equal to the fraction of austenite (g) before the transformation when cooling at Fe-0.3wt%C alloy.

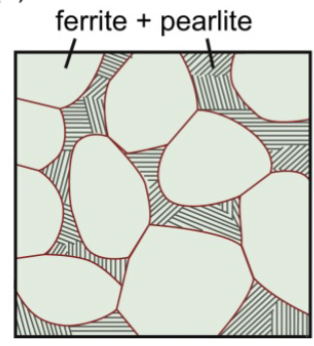

hypoeutectoid steel

from ferrite and austenite to ferrite and pearlite

microstructure in hypoeutectoid steel

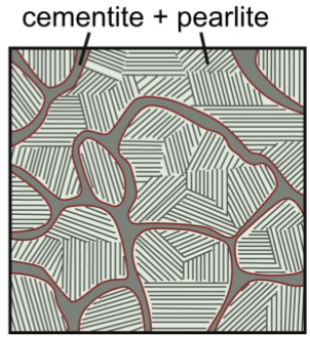

hypereutectoid steel

microstructure composition constists mainly of colonies of pearlite with some proeutectoid cementite; means at a higher composition of carbon than a regular eutectoid reaction

hypo

0.2wt%C - ferrite + pearlite

microstructure gives a higher ductility; almost all ferrite. <0.8%. Good ductility and strength

hyper

1.0wt% C: cementite and pearlite. >0.8%. microstructure contains more cementite, which is a brittle phase. Very strong but not as ductile. more Fe3C → network causes to be more brittle

evolution of the microstructures

The ____________________ of hypoeutectoid and hypereutectoid steels during cooling in relationship to the Fe3C phase diagram.

Increasing pearlite amounts converge at the eutectoid point.

composition (wt%C)

Controlling Amount of Eutectoid Microconstituent: By changing this, we change the amount of pearlite

cooling rates

Controlling the Lamellar Spacing and Strength: Lamellar spacing and strength are controlled by this. Higher ________ lead to finer lamellae and greater strength

time-temperature-transformation (TTT)

diagram for eutectoid steel. Logarithmic scale. PS: start of pearlite formation. Pf: finish of transformation to pearlite (consume all austenite).

Below 550 ℃ → avoid forming pearlite.

γu : unstable → will transform, depending on temperature.

martensite

formation occurs without diffusion. Function of temperature only (not time). very hard and strong. Quite brittle. All carbon is in solution. Not at equilibrium so not on phase diagram.

Nucleation from austenite grain boundaries. Athermal transformation - no diffusion!