Drill String Failures and Prevention

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

Types of Drill Stem Failure

❑ When a component cannot perform its function

❑ Complete separation of two members of DS (parting)

❑ Leak (washout)

Location of failures

Tube body

Tool Joint

Threads

On any drill stem component

Group 1 - Failure Mechanism

Mechanisms of failure that can be stopped:

❑ Tension

❑ Torsion

❑ Combination of Tension and Torsion

❑ Collapse Pressure

❑ Burst Pressure

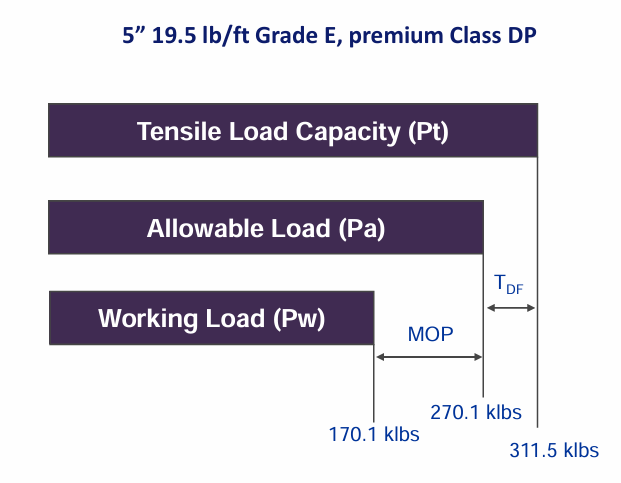

Tensile Failures

When tensile loads > capacity of the weakest component in the drill stem (drill pipe)

When connection was made up beyond recommended torque

When tensile loads > ultimate tensile strength

Surface of break at 45 degrees to axis of pipe

Mitigation method for tensile failures

Select DP that is capable of carrying the anticipated loads plus a Margin of Over-pull plus a design factor.

Use a marking system that shows tube weight and grade.

Make sure that the rig weight indicator is calibrated properly and does not exceed the allowable tensile load.

Torsional Failures

Occur in form of stretched pin or belled box

Occur in the tool joint

Mitigation method for torsional failures

Select tool joint ID and OD so that the maximum makeup torque exceeds the maximum anticipated torsion.

Check tool joints to ensure that they meet with all the dimensional requirements.

Make sure torque application device is working and calibrated properly.

Use API tool joint compound with a FF between 0.95 and 1.05 or compensate the applied torque accordingly.

Make up connections to recommended torque.

Combination of Tension and Torsion Failures

Occur while fishing or pulling on stuck pipe

Burst and Collapse Failures

If pressure loading exceeds capacity

Burst - happen high in the hole

Collapse - happen deep in the hole when pipe is evacuated for drill stem testing

Group 2 - Failure Mechanisms

Mechanisms of failure that cannot be stopped but can be controlled:

❑ Fatigue

❑ Split Box

❑ Sulfide Stress Cracking

❑ Stress Corrosion Cracking

Fatigue Failures

When cyclic stress with the peak stress higher than 40% UTS (ultimate tensile strength)

When stress concentrators raise the peak stress locally

Corrosive environment

Fracture toughness

Sources of Cyclic Loads in Fatigue Failures

Rotating pipe in a dog leg

One side in tension, one in compression

Addition and subtraction of forces create cyclic loading

Rotating BHA through a hole diameter change

Stabilizer stick/slip

Rotating pipe in a washout

Bit whirl

Bit bounce

Prevention method for fatigue failures

Early detection of Vibrations & Washouts

Starting with good materials and component design

Reducing cyclic stresses and stress concentrations

Plan the trajectory with the lowest dogleg severity

Avoid practices that create unplanned doglegs, specially in vertical holes.

Invest in straightening trips to lower Dogleg severity.

Stabilize the BHA, especially if hole enlargement around the BHA is a problem.

Keep the Neutral point below the top of the BHA.

Keep drill-pipe compression less than critical buckling load in high angle wells

Monitor vibration. Optimize BHA configurations, WOB, RPM.

Consider rotating the string more slowly, by means of introducing a mud motor to the BHA, only if hole cleaning and directional objectives allow.

Reducing the corrosiveness of the environment

Ensuring good rig site operating practices

Following an inspection program

Corrosion Failures

Reduction in the wall thickness of tubulars

Occurs due to electrochemical reactions with corrosive agents

Pitting - a highly localized metal loss which penetrates the wall of the tubular

3 patterns of corrosion:

Uniform wall thickness reduction

Localized patterns of metal loss

Pitting - leads to eventual failure

Factors affecting corrosion rate

Higher temperature

Higher flow rate, especially if abrasive solids present

Higher concentration of corrosive agents (O2, H2S and CO2)

Prevention method for corrosion

Oxygen

pH

CO2 and Chlorides

H2S (Reduce or prevent H2S)

exposure of high tensile steels to partial pressure H2S > 0.05 psi can lead to catastrophic failure

metal becomes brittle and will break suddenly without warning

Inhibitors

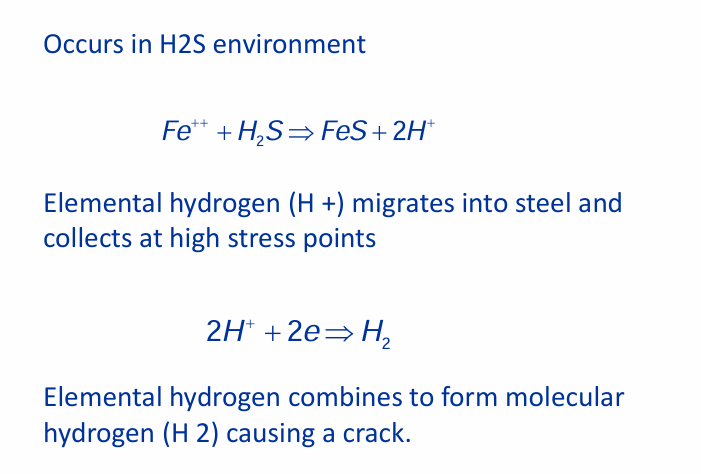

Sulfide Stress Cracking

Prevention method for sulfide stress cracking failures

Keep H2S out of the mud system

drilling overbalanced

keeping pH high

using H2S scavengers

using OBM

Control the metallurgy

use different grade pipe

Drill String Failure Prevention - ADIOS

A - Attributes: These are the metallurgical properties and dimensions that are built into each drill string component at manufacturing. E.g.: strength, toughness

D - Design: Drill stem design is selecting components and configuring assemblies to accomplish the drilling objective (to provide a drill string that will carry the loads and resist failure)

I - Inspection: Drill Stem components, unless new, have been exposed to handling damage and an unknown amount of cumulative fatigue damage.

O - Operation: The Drilling operation presents many opportunities to overload and misuse the drill stem.

S - Surroundings: The chemical and mechanical environment surrounding the drill stem can have major effect on failure probability.

Symptoms of Poor Drilling Performances

Optimization to mitigate overload and fatigue failures

Improve hydraulics

efficient cooling and lubrication of drill bit and BHA

reduces friction and heat buildup (prevent material degradation and fatigue)

enhance cutting removal (reduce stress on DS)

Reduce side loads

by optimizing well trajectory and using stabilizers (to reduce bending stress and wear)

Reduce curvature index (dogleg severity)

smoother wellbore path (reduce bending loads)

Reduce stability index

by proper bha design and weight distribution (avoid vibrations and improve stability)

Reduce torque and drag

TD leads to twisting failures

by using proper lubricants, centralizers and wellbore conditioning (to reduce mechanical resistance)

Improve hole cleaning

poor HC leads to cuttings buildups

by efficient mud programs and optimal annular velocity (to prevent excessive loads on the DS)