Demand/Supply Integration: Forecasting and S&OP

1/28

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

29 Terms

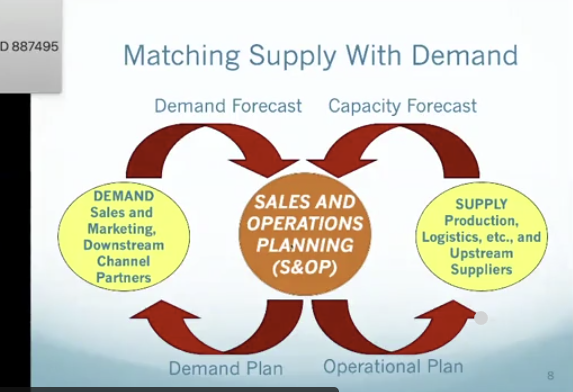

Matching supply with demand

forecast are inputs, outputs of plans

S&OP stands for

sales and operations planning

Demand

is what customers would buy from us if they could. This is unconstrained demand (by firms ability to supply)

The demand forecast

is a projection into the future of expected demand, given a stated set of assumptions. Unconstrained forecast- not infulenced by ability to supply.

Plans

are the managerial actions that result from the demand/supply integration process.

Supply (ordering & manufacturing) , Inventory (buildering inv buffer), Demand (adjust marketing effort to bring into valance) , Financial (working capital, telling wall street)

Forecast are ______________. Plans are ___________

Forecast are best guessed about what we think will happen. Plans are decisions we make about what we will actually do.

How do companies manage this forecasting process?

techniques (statistical and qualitative), systems (keep track of data), management

Measure performance at center

The nature of the business determines the nature of the process

nature of customer base

Nature of the date

nature of products

nature of the people

Nature of the customer base

narrow: boeing, small- forecasting demand is easy just go ask the 100 customers

broad: think coca-cola, billions of customers in thousands of retailers. Need to use alot of statical

regional differences

Nature of data

age

detail

quality

previous purchase data

Nature of the products

new products- harder to forecast, don’ have any past history

seasonal demand: christmas vs toliet paper

shelf life:

Nature of the people

resources

education/training- many SC people start in demand planning

Two Categories of Demand Forecasting Techniques

quantitative or statistical: time series, regression & casual models

Qualitative: includes salesforce composite

Statistical forecasting

looks in rear view mirror, looking for patterns in historical data and project them into the future to get foercast

some patterns are function of time (demand for christmas trees going up and down), try to idenfiy using time series techniques

some patterns are a function of the way that other factors affect demand, and we try to identify patterns with regression analysis

Components of Time Series (3)

Trend: continuing pattern of demand increase or decrease, can be straight line or curve

Seasonality: repeating pattern of demand increases or decreases. Normally think of seasonality as occurring within a single year, and cycles as occurring over longer than one-year periods

Noise: random fluctuation, that part of demand history which the other time series components cannot explain

Regression Analysis

is useful when you think there are measurable factors that affect demand. Demand is always your dependent variable (y axis). The measurable factors are you independent variables (are measurable and can be internal or external)-

spendiny money in adversting hope will increase demand, regession can give insight into how much

Demand Forecasting Tecniques

statiscal forecasting -lookinng in review mirror, may get hit by truck. Need insight about how the future is likely to look different from the past. Need qualtiative forcasting

Qualitative forecasting

subjective or judgmental forecasting

process of turning the experience, judgements, and intuition of experienced people into formal forecasts

When would you use it?: when you have reason to believe that the future will not necessarily look exactly like the past. New products with no historical data, new conditions will change previous patterns- effectiveness of TV adversting has gone down

Salesforce Composite

The most common example of qualitative forecasting

salesforce composite

Salesforce Composite forecasting

when does it make sense for salespeople to forecast? When they have insight into changing demand patterns at their large customers- P&G changing shelf space at Walmart. When they have insights into probabilities of securing large orders (IBM asked him are we likely to win the business, have to prepare the supply chain)

What gets measured gets _____. and what gets ______ gets done

measured, example course evaluation incentive.

Dimensions of demand forecasting performance (4)

Bias: is the forecast systematically to high or low

Accuracy: How close was the forecast to the actual demand? (always going to be wrong)

Bias & Accuracy how measure forcasting performance

Cost Reduction: inventory, expedited freight, purchasing cost

Customer Satisfaction: improved fill rates, have enough product available when need it

Cost reduction and customer satisfaction- result of forecasting excellence

How we measure forecasting performance

bias & accuracy

Result of forecasting excellence

cost reduction & customer satisfaction

What is S&OP

the process by which a company matches its demand in the marketplace with its supply capabilities

Why do companies do S&OP

so that marketing will create demand for products that can be produced. So that operations will supply products for which there is demand. Bottom line-so both sides of a company will be singing out of the same hymnal. One the same page

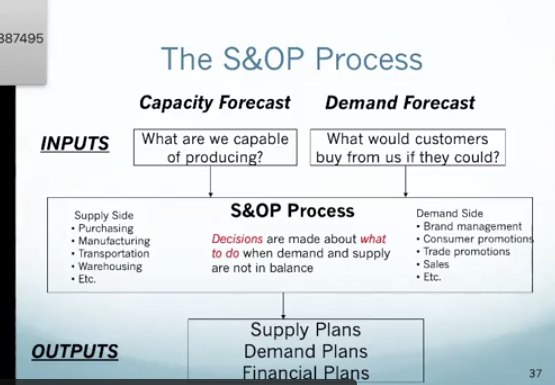

S&OP process

inputs: capacity forecast (what are we capable of producing) & demand forecast (what would customers buy from us if they could?)

process: decision about what to do when demand and supply are not in balance, both demand and supply side of business

outputs: supply plans, demand plans, financial plans

S&OP regularly scheduled meetings

normally monthly process,

demand meeting: forecaster, marketers and sales- consensus demand forecast

supply meeting: operations, purchasing, and logistics, consensus capacity forecast

Partnership meeting: executives from both sides & finance, balancing demand with supply, outcome: agreed-upon demand & supply plans

S&OP should be both tactical and strategic in nature

Tactical: What should we make, and what should we sell over the next 1-6 months (short-term)

Strategic: What are the longer term trends that will affect both demand and supply over the next 6-24 months, and beyond? make big investments in building or shutting down capacity