Operations Management

1/106

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

107 Terms

What does operations management use?

resources to appropriately create outputs that fulfil defined market requirements

What is operations management?

The activity of managing the resources which are devoted to the production and delivery of products and services

The people who are responsible for managing some or all resources that comprise the operations function

Who are operations managers?

Inputs are used to transform something or themselves into outputs of services and products.

What is the transformation process model?

Resources that are treated transformed or converted in the process to produce goods or services

What are transformed resources?

What are the 4 types of operations and processes?

Volume

Variety

Variation in demand

Visibility

Can you describe what it’s like to have low volume?

The product or service is tailored to customer needs. Low repetition, each staff member performs more of each task, less systemisation and high unit costs.

Describe having a high volume?

High repeatability, specialisation, capital intensive and low unit costs

What are some examples of low volume operations?

Food chains and car manufacturing assembly lines

Explain operations that offer a low variety of products/services.

Offers a limited range of products, focuses on efficiency and standardisation, predictability and has routine tasks

Explain operations that offer a high variety of products/services.

Allows customisation and differentiation. Flexible, matches customer needs and has high unit costs.

Explain operations that have low variation in demand.

Demand is stable and there are low unit costs. It is easier to plan capacity, workforce and inventory.

Explain operations that have high variation in demand.

Changing capacity,anticipation, flexibility, in touch with demand, high unit costs.

What are examples of operations with high variation in demand?

Hotels

Ski resorts

Hospitals

Explain low visibility within an organisation.

Customers have little or no direct contact with the production process. They only see the output

Explain high visibility within an organisation.

Customers are directly involved. Satisfaction is governed by customer perception and there are high unit costs.

Examples of high-visibility operations.

Restaurants- customers expect quick service

Call centers- Customers hang up if waiting for too long

Retail checkouts- long lines reduce customer satisfaction

What are the key features of high visibility operations?

Customers experience the process in real time

Customer satisfaction depends on both service quality and interaction quality

Operations must handle short waiting tolerance

What are the key features of low visibility operations?

Customers don’t see how the work is done so efficiency and consistency matter the most

Easier to standardise processes and focus on cost reduction

Lower pressure from customers during the process itself

What are the key features of low variety operations?

Processes are routine, repetitive and standardised

Easier to forecast demand and plan resources

Operations achieve efficiency and lower costs

Limited ability to customise for individual customers

What are the key features of high variety operations?

Processes must be flexible and adaptable

More complex scheduling, planning and inventory management

Unit costs are higher (less repetition, smaller batch sizes)

Greater opportunities for customisation and differentiation

What are the examples of transformed resources?

Materials

Information

Customers

What are transforming resources?

The resources that convert the transformed resources into outputs

What is the operations function?

The part of an organisation responsible for producing the goods or providing the services a company sells in its markets.

Explain why it is important when a product is designed how choices made shape it?

Choices made at the stage of design shape how it is produced and in turn the design of the production process influences what is feasible in the product or service itself.

Should the design of products/services and the design of processes be interrelated and treated together?

Yes

What are project processes?

A one time set of coordinated activities aimed at creating a unique product or service often involving high customization complex planning and defined start and end points.

What is a jobbing process?

products are made in small quantities often as one-off items or in very low volumes

they are tailored to meet specific customer requirements.

What are some examples of jobbing processes?

Custom furniture

producing specialist machinery

tailoring clothing

In jobbing processes the focus is on what?

customisation and quality rather than speed or low cost

What is a batch process?

higher volumes but lower variety than for jobbing

What is an example of a batch process?

Bakery bakes 200 loaves in one batch stops then produces some more

Explain a mass (line) process?

standardised products are made in very large volumes but with a low variety.

What are some examples of mass production processes?

Car assembly lines

electronics manufacturing

Explain a continuous process.

Extremely high volume and low variety where production is never stopped

High volume allows them to reduce production costs which reduces the cost of the goods

What are the manufacturing process types?

Project

Jobbing

Batch

Mass

Continuous

What is professional service?

High contact customized and knowledge intensive operations where skilled professionals use their expertise to deliver tailored solutions to individual clients.

What are service shops?

service shops handle a range of services that can be partly standardised but still tailored to each customer’s situation

sits in between professional and mass services

What are mass services?

It aims to deliver the same or very similar standardised service repeatedly to many people

What are the five performance objectives ?

Quality

Speed

Dependability

Flexibility

Cost

What are the two important things you must remember for manufacturing businesses?

Volume

Variety

What happens to variety when we have a high volume and vice versa?

High volume- low variety

High variety- low volume

What are the 3 service process types?

Professional service

Service shop

Mass service

What is process mapping?

Understanding the journey of those goods and services

What can be done to improve that (reflecting upon the five performance objectives)

What are the seven types of waste that exist?

Transportation

Inventory

Motion

Waiting

Overproduction

Overprocessing

Defects

What are the 3 ways of categorising waste?

Value add (VA) activities

Non-value add (NVA) activities

Necessary NVA (NNVA) activities

What are value add activities (waste)?

Anything a customer is willing to pay for because it transforms the product in a meaningful way

What are non value add activities (waste)?

activities that consume resources but do not add value from the customer’s perspective

customer is not willing to pay for these activities

What are necessary NVA activities (waste)?

Essential for us to pay

What are the primary examinations of each activity?

Purpose- What is achieved

Place- Where is it done

Sequence- When is it done

Person - Who does it

Means- How is it done

What are the secondary examinations of each activity?

Purpose- What else could/should be done

Place- Where else could/should it be done

Sequence - When else could/should it be done

Person - Who else could/should do it

Means - How else could/should it be done

What are the ways in which operations differ?

volume variety variation in demand visibility of their output

What is a project?

A project is a temporary endeavor undertaken to create a unique product, service, or result, characterized by a defined beginning and end, specific objectives, and constraints such as time, budget, and resources.

What is a general characteristic of a project?

Projects are building blocks in the design and execution of organisational strategies.

What are the principal outcomes of a project?

The satisfaction of customer requirements and the delivery of project objectives on time and within budget.

When are projects terminated?

Projects are terminated upon achieving their objectives, when they are no longer viable, or when they are deemed unnecessary by stakeholders.

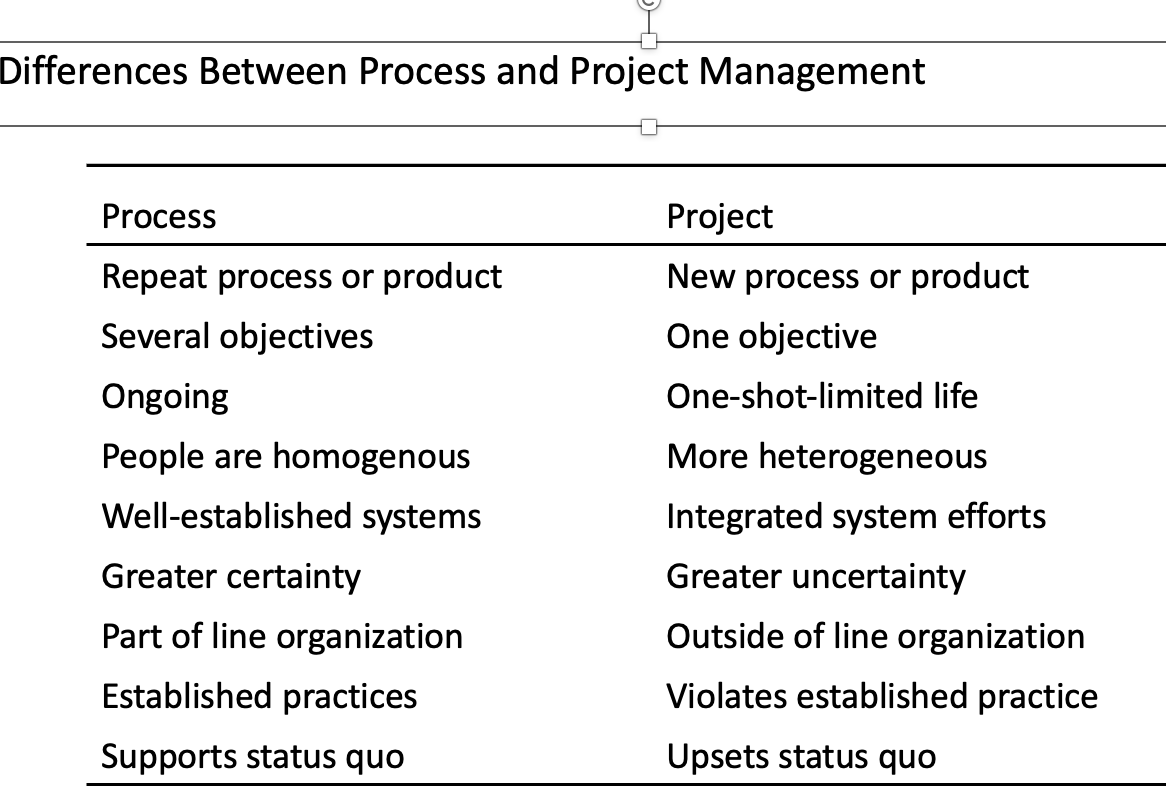

What are the differences between process and project management?

Why are projects important?

Shortened product life cycles

Narrow product launch windows

Increasingly complex and technical products

Emergence of global markets

An economic period marked by low inflation

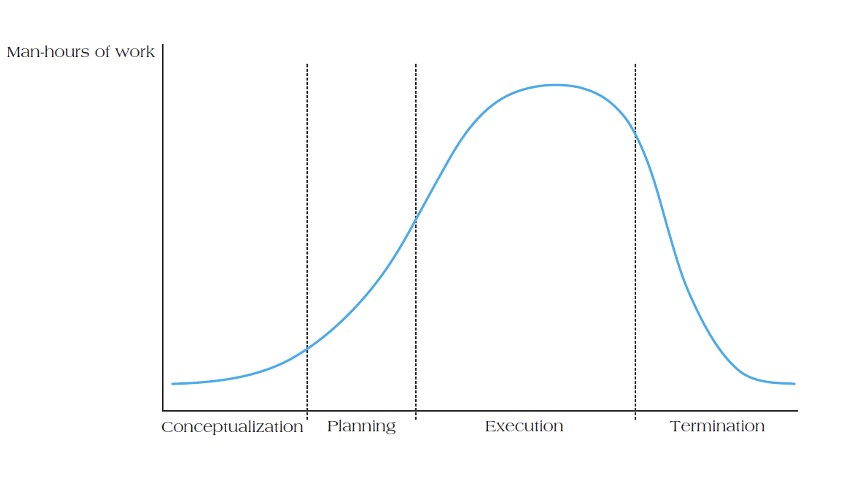

What is the diagram for project life cycle stages?

What is a project life cycle?

the stages in a project’s development

What are the four distinct phases of a project’s life cycle?

Conceptualization

Planning

Execution

Termination

Explain conceptualisation in a projects life cycle.

development of the initial goal and technical specifications of the project

Explain Planning in a projects life cycle.

All detailed specifications, schedules, schematics and plans are developed.

Explain execution in a projects life cycle.

The actual “work” of the project is performed.

Explain termination in a projects life cycle.

The project is transferred to the customer, resources reassigned and the project is closed out.

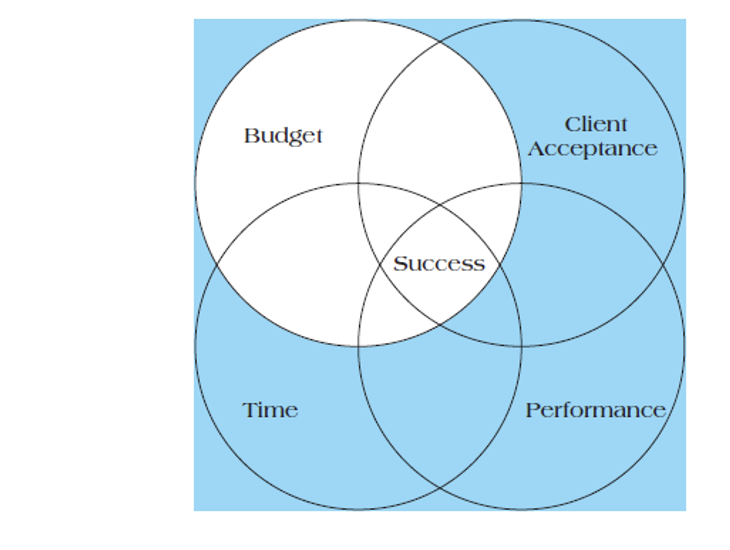

What is the quadruple constraint of project success?

What is the iron triangle when it comes to success in a project?

cost

quality (scope)

time

What must a project meet in order to be successful?

iron triangle

What is a project scope?

what is and isn’t included in a project

What is scope management?

The process of controlling all the work required within a project

What is conceptual development?

The process that addresses project objectives by identifying and evaluating the best ways to meet them.

What is a statement of work?

A formal document that contains

Introduction and background

Technical description of the project

Timeline and milestones

What is a project charter?

A document issued by the project initiator or sponsor formally sanctioning existence of the project and authorises the project manager to begin applying organisational resources to project activities.

What is included in a scope statement?

Establish project goal criteria to include: cost, schedule,performace,deliverables

Develop management plan for project

Establish a work breakdown structure

Create a scope baseline

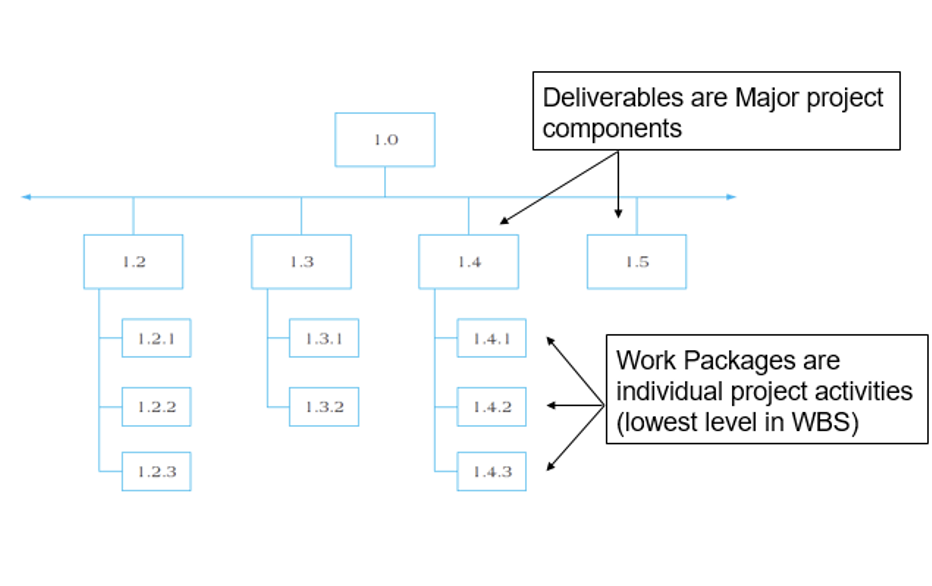

What is a work breakdown structure?

A hierarchical decomposition of the total scope of work to be carried out by the project team to accomplish the project objectives and create the project deliverables.

What is the logic of hierarchy the WBS follows?

Project

Deliverable

Subdeliverable

Work package

What is a work package?

It is the lowest level in the work breakdown structure.

Deliverable result

One owner

Miniature projects

What is the partial work breakdown structure?

What is the organizational breakdown structure?

It acts as a blueprint to project managers.

What is work authorisation?

The formal “go ahead” to begin work.

What is scope reporting?

Monitoring how well the project is staying within its defined boundaries of work, deliverables and objectives

Why may projects fail?

Poor planning

Unclear objectives

Poor communication

Inadequate resources

Unrealistic timeframes and budgets

Why may there be project changes?

Initial planning errors, either technological or human

Additional knowledge of project or environmental conditions

Uncontrollable mandates

Client requests

What does it mean if a service is standardized?

Not tailored individually

What are some examples of mass services?

Banking Airlines Retail

What is Breakeven Analysis in the context of production planning?

It addresses the decision of whether to make or buy a product.

When making a product what are the two costs involved?

Fixed costs

Variable costs

What must firms operate above to achieve profitability?

above the breakeven point

What is the formula for Breakeven point?

BEP: revenue= total cost

What are profit/loss corridors?

profit corridor- area between revenue and total cost line to right of BEP

loss corridor- area between revenue and total cost line to left of BEP

When buying a product as to making one what happens to fixed costs and variable costs?

Buying usually decreases fixed costs but increases variable costs

Breakeven analysis can be used to decide what?

Whether a business venture will succeed or not

Type and capacity of equipment needed

Whether to produce a product or outsource it

What are the steps to the decision making process?

Define problem

Identify alternatives

Determine decision making criteria

Evaluate alternatives using criteria

Choose an alternative

What are the 4 decision types?

Certain decisions

Uncertain decisions

Risky decisions

Competitive decisions

What are the 4 stages under decision making under uncertainty?

What decision alternatives do we have?

What are all the possible scenarios including future events?

What are the payoffs for each decision and state of nature?

What do I value?

What is the maximax decision rule?

Determine the best possible payoff for each scenario

Choose alternative with highest maximum payoff

What is the maximin decision rule?

Determine the worst possible payoff for each choice

Choose “best worst” alternative

What is laplace decision making rule?

Determine average payoff for each option

Choose alternative with best average benefit

What is the minimax decision making rule?

Calculate regret for each alternative under each source

Choose alternative with the smallest regret

What is the maximum likelihood decision making rule?

Choose the option with highest payoff for state of nature deemed most likely to occur