Learning outcomes Engineering aspects of food technology

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

Why food is processed?

Lots of food is harmful to eat unprocessed. (Grain, consumption of chaff can be dangerous)

You would not get a lot of nutrition out of it.

Minimal processing

a food production process that results in minimal changes to the structure and composition of the food

Functional foods

foods that provide health benefits beyond basic nutrition due to the presence of bioactive compounds that have a positive impact on bodily functions (e.g. yakult)

Meat production

Very inefficient because for 1 Kg of meat you need 5 to 8 kg of plant protein.

Traditional reasons for food processing

Preservation by heating and drying, and fermentation.

Removal or inactivation of toxic or ‘antinutrional’ compounds, by heating or removing ocmponents by dehydrating or rinsing, and in some cases treatment by heating, but also by treatment with bases or acids.

Newer, modern era motivations for food are:

Taste, cooking or baking creates flavors, may create a texture like a crust, and will make the food much tastier

Convenience, allowing a modern lifestyle by freeing up time for other activities than the preparation of food

Health, leading to milder conditions during processing, fortification of specific ‘functional’ foods.

Development of niche markets, such as lactose and gluten free foods

Sustainability and animal welfare; leading to foods that replace meat, and other foods that require many raw materials.

Characteristics of modern food processing.

Large facilities, more efficient, safer because food safety can be checked more easily.

Development of new formulations, new treatments, and new varieties of products is easier to do if you do it for a large quantity of products being made.

On a larger scale it is easier to be efficient in the use of resources and energy. (e.g. in dairy processing, the heat that is needed for pasteurization (heating to inactivate bacteria) is reused for more than 95%. In many other factories, heat is used repeatedly.

In large factories, you can use the raw materials more completely. Raw material that would otherwise be wasted can be used to make something else.

Tea processing

Tea leaves must be dried after picking to prevent spoilage and oxidation of the phenolic components in the tea

Drying can be done in different ways:

Steam: Steam will displace the oxygen in the air, and that will prevent oxidation. The green tea leaves will remain bright green, and the infusion will be strong.

Drying in open air: slowly rollling over the leaves with a weight. Opens the cells and vacuoles that have phenolic components and exposes them to oxygen and the enzyme polyphenol oxidase. Oxidation will make the leaves and the infusion a bit more yellowish and make the taste more ‘tea-like’.

Green tea processing (Japanese tea)

By steam

Displaces Oxygen in the air.

Will prevent oxidation of leaves

Leave will remain bright green, and the infusion will also be birght green and have a rather strong grassy flavor.

Chinese tea

Leaves dry in open air

Slowly rolling over the leaves with a weight

Opens the cells and vacuoles that have the phenolic components and exposes them to oxygen and the enzyme polyphenol oxidase, present in other parts of the plant cell.

The oxidation will make the leaves and the infusion a bit more yellowish and make the taste more ‘tea-like’.

White tea

Made from the still unopened leave buds, and these buds are only dried, so not rolled.

Oxidation has hardly proceeded, but since the leaves did not yet have that many phenolics in them, white tea is less green than the ‘normal’ green tea.

Black tea

oxidation of the phenolics in tea has been maximized.

Phenolics are green in their native state, but as they are exposed to oxygen, they become browner or even black.

Rollsing is used to crush the cells and bring the phenolics into contact with oxygen and polyphenol oxidase.

What are coffee beans made out of

Berries of coffea trees

Contain a lot of caffeine

Contain phenolic components

One berry has two coffee beans. Surrounded by a soft tissue.

Processing of berries from coffea trees

Drying and sieving to get rid of debris

Berries are crushed, and then te beans are soaked in water for a few days. Which softens the soft tissue around the bean.

Soft tissue is scrubbed/washed away.

Now beans are packed in bags.

Shipped and purchased by coffee roasters. Beans at this stage are green.

Roasting of coffee beans

Beans expand by about a factor of two and make beans very porous

Much of the phenolics is lost and some of the caffeine as well.

Proteins and sugars react to form maillard products, giving more taste and flavour to the coffee.

Beans are roasted and given time to degas.

Afterwards beans are packed either under vacuum or under nitrogen since oxygen reacts with many of the flavors.

Diffusion

Caused by brownian motion

At higher temperatures, molecules will move quicker.

Diffusion is faster if the concentration difference is larger and diffusion is faster if the distance is smaller.

What happens to the volume when the size of a coffee grind is reduced by two?

23 = 8

So a particle twice as small, would have 8 times as little coffee to be extracted from it.

This is based on the fact that the amount of coffee (or any substance) available for extraction is proportional to the volume of the grind. If the volume is reduced by a factor of 8, then the total amount of coffee available to be extracted from the particle is also reduced by the same factor, meaning there's 8 times less coffee available to diffuse into the surrounding liquid.

If it is a cube; generally, a particle twice as small, will have a surface area…

That is 4 times as small.

If we have 4 times less surface area, then we also will have 4 times less coffee coming out of the particle, all other things being equal.

What happens to the concentration gradient when we decrease the size of the coffee grinds by two?

When the coffee grinds are smaller, the distance that the coffee molecules need to travel to leave the grind and diffuse into the liquid is shorter.

This smaller distance makes the concentration change happen more abruptly, which increases the steepness of the concentration gradient.

A steeper concentration gradient means that the molecules will diffuse faster because the driving force for diffusion (the gradient) is stronger.

What if we want to remove 80% of coffee in the particle during brewing

Smaller particles: If you make coffee particles half their size, they have 4 times less surface area.

Less material: Smaller particles contain 8 times less coffee to extract.

Faster diffusion: Smaller particles create a steeper concentration gradient, so diffusion happens twice as fast.

Result: You’re extracting 8 times less coffee over 4 times less surface area, but with diffusion happening 2 times faster, so the overall extraction is 2 times quicker.

Disadvantages of making the particles smaller

The smaller the particle, the more surface area the particles share with the water and the slower the water will percolate through the grounds.

Hence the coffee ground cannot be too fine. The extraction would be fine, but the water would come out of the drip cone far too slowly.

Cold-brewed coffee

At lower temperatures molecules move more slowly and therefore diffusion is slower.

For cold brewing, the times are much longer: up to 10 hours.

Has fewer undissociated acids.

Pores in tea leaves

In coffee when coffee beans are roasted, a lot of gasses are produced which crack the coffee beans open and the resulting particles are also very porous.

In tea this is not the case, in tea the caffeine and other components have to diffuse through the cell walls which are very tought.

When tea is dissolved in water it will become a little porous but nowhere compared to the porosity of coffee grounds.

This also differs per tea, the rate of diffusion in black tea is about 1.4 times higher than the diffusion in the same components from green tea leaves.

Why do we not use a drip system for making tea?

Even when we would grind tea, it would require a longer time for extraction.

Since different molecules diffuse at different rates, just forcing the tea to be extracted faster would not result in good quality tea.

Quick coffee machines

Use concentrates

The coffee is brewed in a central factory on a very large scale, after which this coffee is concentrated.

This gives a concentrated liquid, or when all water is removed, a powder.

When making a cup of coffee, the vending machine only has to release a bit of the concentrate and a greater amount of hot water.

Extraction of coffee for liquid concentrates on a large scale

On an industrial scale, it is important that you use the coffee in the beans optimally.

On an industrial scale you want to get the most out of the raw material.

Because you need much fewer beans, because coffee beans are expensive.

Less waste, companies need a permit to produce waste and getting rid of the waste is difficult.

The process of extraction of coffee for concentrate

Coffee is ground into particles of 0.5 - 1.1 mm.

The ground coffee are put in 5-8 columns, water is led through these columns under pressure and at a temperature between 155 and 180 C.

The total contact time between coffee particles and water is long between 1.5 and 4 hours, to make sure that we get every last bit of coffee out of the grounds.

A lot more components move from the coffee particles to the water compared to coffee making at home.

The concentration of coffee components in the water becomes very high. The dry matter content reaches 25 to 27%, whereas in our homemade coffee, we usually have 1 to 3%

Removal of water from the concentrate using steam

Extract is led to a column that on the inside is equipped with a bundle of tubes.

The extract is divided over the inside of these tubes and runs across the wall as a thin continuous layer downwards.

At the same time, the column is made vacuum.

On the outer sides of the tubes, steam is applied.

Which gives condensation to the tubes and the condensation heat is transferred to the tubes.

The film of the extract on the inside of the tubes is heated and the water will evaporate.

Disadvantage: Flavoring components will evaporate.

Removal of water from the concentrate using freeze-concentrating

Water is not evaporated but frozen

Extract is led in a tube that is strongly cooled on the outside, for example with liquid nitrogen.

The water in the extract will freeze on the wall and this ice will only contain water

On the inside of the tube, a rotating blade scrapes the ice from the wall and small ice crystals accumulate in the extract.

This is called a scraped surface heat exchanger.

The extract is put in a vessel, where the ice crystal can grow into larger crystals

Then the ice is separated from the extract by a washing process.

Disadvantage: Expensive

Drying of concentrate using spray drying

most common way: spray drying

Concentrate is transferred to a high column and atomized (spread in small droplets)

Droplets fall down in the column, while warm air is fed in. The water in the droplets evaporates and is taken up by the air.

Eventually all water will be evaporated, and at the bottom, the droplets can be collected as small powder particles.

Drying of concentrate using freeze drying

Concentrate is frozen and then ground into small chunks.

These chunks are then spread out in a thin layer on large plates.

The plates are slid into a large vessel.

After this vessel is closed it is made vacuum, the pressure is so low, that the ice in the chunks is directly converted into vapor.

The ice sublimates

The water vapor is carried away to a condenser. The condenser contains a cooling devise that is so cold, that the water vapor condenses and freezes.

The chunks remain cold.

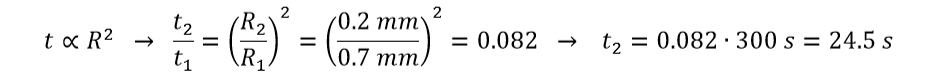

Scaling between time and particle size formula