CHE 2119

1/38

Earn XP

Description and Tags

LECTURE 7

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

39 Terms

nitrogen

comprises 78% of the atmosphere

cannot be utilized by plants in atmospheric form

essential for the synthesis of amino acids, proteins, enzymes • a limiting nutrient

nitrogen cycle

the circulation or cyclic movement of nitrogen from the atmosphere to soil and back into the atmosphere

atmosphere

Nitrogen falls from the ______ to the earth by precipitation (e.g. rain or snow).

nitrogen fixation

conversion of atmospheric nitrogen into ammonia

carried out by leguminous plants and some bacteria (e.g. azotobacter, clostridium, rhizobium)

nitrification

carried out by nitrifying bacteria (e.g. nitrococcus, nitrosomonas)

ammonia is first converted to nitrites

then nitrites are converted to nitrates (by nitrobacter)

Nitrogen assimilation

the process of absorbing nitrates and ammonia into organic nitrogen

Organic nitrogen is transferred into animals when they consume plants.

ammonification

the process of converting organic nitrogen into ammonia when plants and animals die

carried out by saprophytes like fungi and bacteria

Ammonia is also produced from volcanic eruptions and excretory products of animals.

denitrification

Nitrates are converted into molecular nitrogen through nitric oxide.

carried out by denitrifying bacteria (e.g. thiobacillus denitrificans)

fixed nitrogen

manures

ammonium sulfates (by-product from coking of coal)

ammonia (recovered from coke)

Chile saltpeter (sodium nitrate)

dry distillation of nitrogenous biomaterial waste

decomposition of ammonium salts

Haber (Haber - bosch) process

Fritz Haber and Carl Bosch, 20th century

practical and large-scale synthetic ammonia process

use of abundant and inexpensive elemental H2 and N2 gas

synthetic ammonia

fertilizers (ammonium sulphate, DAP, urea)

nitric acid

explosives

fibers, synthetic rubbers, plastics (nylons and other polyamides)

refrigerants

pharmaceuticals (sulfonamide, vitamins, etc.)

pulp and paper

extractive metallurgy

soda ash

cleaning solutions

air

water

hydrocarbons

raw materials for synthetic ammonia: haber - bosh process

equilibrium

return to ______ with increase in [N2]

pressure

return to ______ upon compression

very slowly

hydrogen and nitrogen react ___________

iron

catalyst: ___ → promoted by the addition of small amounts of oxides of aluminum and potassium

space velocity

_________ → cu. ft. of exit gases in STP (0oC and 760 mmHg) that pass over 1 cu. ft. of catalyst space per hour (usually 20,000 – 40,000)

doubly promoted

13 - 14% ammonia

singly promoted

8 - 9% ammonia

pure iron

3 - 5% ammonia

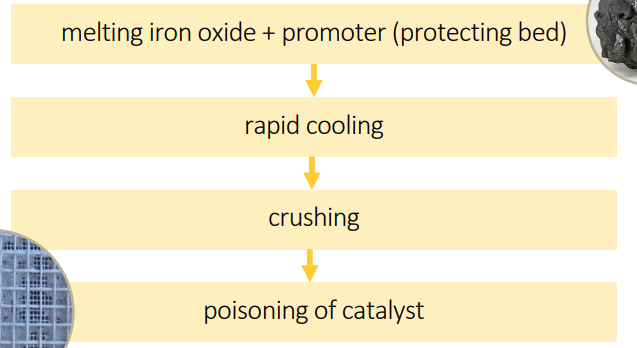

catalyst promotion

feedstock desulfurization

removal of sulfur oxide and hydrogen sulfide

R-SH + H2 → H2S + RH

H2S + ZnO → ZnS + H2

the sulfur is removed to < 0.1 ppm S in the gas feed

Zinc sulfide remains in the adsorption bed.

manufacture of hydrogen

steam-water gas process

steam-hydrogen (natural gas) process

coke-oven gas process

electrolysis of water

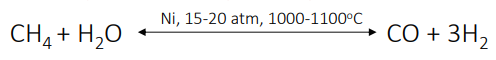

primary (steam) reforming

reformer consists of nickel - based catalyst

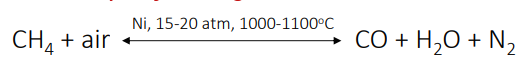

secondary reforming

only 30-40% of the hydrocarbon react

addition of air to convert the unreacted methane molecules

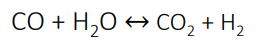

shift conversion

The process gas from the secondary reformer contains 12 – 15% CO.

The gas is passed through a bed of iron oxide/chromium catalyst around 400 – 500 degrees Celsius

Purification

CO2 Removal

scrubbing with water, amine solutions, or hot potassium carbonate solutions

methanation

CO and Further CO2 Removal

small amounts of CO and CO2 are removed by conversion to CH4 using Ni catalyst

ammonia conversion

Modern NH3 plants use centrifugal compressors for synthesis gas compression.

The synthesis of ammonia takes place on iron catalysts.

reaction is highly exothermic

Only 20 – 30% is reacted per pass in the converter due to unfavorable equilibrium conditions

ammonia

by mechanical refrigeration or adsorption/distillation

ammonia storage

urea (46% nitrogen)

ammonium nitrate (34% nitrogen)

nitric acid

used for the manufacture of ammonium nitrates (fertilizers)

intermediate in polymer industry (polyamides and polyurethanes)

oxidizing acid for the parting of gold and silver, pickling of brass, and photoengraving

nitric acid

Manufacturing Procedure: _____

evaporation of anhydrous ammonia

oxidation of ammonia gas with air (platinum gauze at 920 deg C)

cooling of nitric oxide

oxidation and hydration of nitric oxide

collection of 61 – 65% nitric acid using acid trap

waste gas treatment

evaporation of anhydrous ammonia

• anhydrous ammonia is evaporated using steam

Oxidation of Ammonia Gas with Air

NH3 gas is oxidized with air to nitric oxide by passing through a platinum gauze at 920oC

cooling of nitric oxide

Nitric oxide with excess air is cooled in two heat exchangers and a water cooler

Oxidation and Hydration of Nitric Oxide

Successive oxidations and hydrations of the nitric oxide are carried out with continuous water cooling in a stainless-steel absorption tower

2NO(g) + O2(g) → 2NO2(g)

3NO2(g) + H2O(ℓ) → 2HNO3(aq) + NO(g)

Collection of Nitric Acid using Acid Trap

61 – 65% nitric acid

water and nitric acid form an azeotrope

Waste gas treatment

The waste gas from the top of the absorption tower is heated and expanded before being exhausted to the atmosphere