unit 5-6

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

two types of worker-machine relationship

1. Synchronous servicing

2. Random (Asynchronous) servicing

Synchronous Servicing

Assigning more than one machine to an operator seldom results in an ideal case where both worker and machine are occupied the entire cycle.

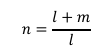

In an ideal synchronous servicing scenario, the number of machines assigned can be computed as:

Random (Asynchronous Servicing)

it is unknown when a facility needs service or how long servicing will take.

Mean values and probabilities are used to determine the number of machines to assign.

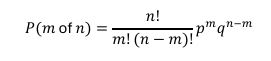

The binomial expansion gives the probability of 𝑚 out of 𝑛 machines being down:

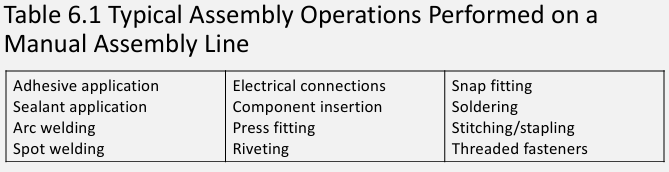

MANUAL ASSEMBLY LINES

is a production line that consists of a sequence of WORKSTATIONS where assembly tasks are performed by human workers

are work systems consisting of multiple workers who are organized to produce a single product or a limited range of products.

The common practice is to “launch” base parts onto the beginning of the line at regular intervals.

A mechanized material transport system is typically used to move the base part along the line as it is gradually transformed into the final product.

The production rate of an assembly line is determined by its slowest station.

Stations capable of working faster are ultimately limited by the slowest station (the bottleneck).

WORKSTATION

on a manual assembly line is a designated location along the work flow path at which one or more work elements are performed by one or more workers.

also includes the tools (HAND TOOLS or POWERED TOOLS) required to perform the task assigned to the station.

Work Elements

represent small portions of the total work that must be accomplished to assemble the product

two basic ways to accomplish the movement of work units along a manual assembly line

(1) manually or

(2) by a mechanized system.

The two factors that the theoretical minimum number ignores, but that exist in a real assembly line

Repositioning Losses

The Line Balancing Problem

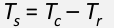

Service time

= time available each cycle for the worker to work on the product

Bottleneck

is the slowest station in a sequence.

The production rate of an assembly line is determined by its slowest station.

Stations capable of working faster are ultimately limited by the slowest station

MANUAL METHODS OF WORK TRANSPORT.

the units of product are passed from station to station by hand.

Two problems result from this mode of operation:

starving and blocking.

STARVING

occurs when the assembly operator has completed the assigned task on the current work unit, but the next unit has not yet arrived at the station. The worker is thus starved for work.

BLOCKING

occurs when the operator has completed the assigned task on the current work unit but cannot pass the unit to the downstream station because that worker is not yet ready to receive it. The operator is therefore blocked from working.

Mechanized Work Transport

Powered conveyors and other types of mechanized material-handling equipment are widely used to move units along a manual assembly line.

These systems can be designed to provide paced or unpaced operation of the line.

There are three major categories of work transport systems in production lines:

(a) continuous transport,

(b) synchronous transport, and

(c) asynchronous transport.

continuous transport system

uses a continuously moving conveyor that operates at constant velocity.

This method is common on manual assembly lines.

Continuous transport can be implemented in two ways:

(1) work units are fixed to the conveyor, and

(2) work units are removable from the conveyor.

synchronous transport systems

all work units are moved simultaneously between stations with a quick, discontinuous motion, and then positioned at their respective stations.

This type of system is also known as intermittent transport.

which describes the motion experienced by the work units

asynchronous transport system

a work unit leaves a given station when the assigned task has been completed and the worker releases the unit.

Work units move independently, rather than synchronously.

Coping with Product Variety

Because human workers are flexible in terms of the variety of tasks they can perform, manual assembly lines can be designed to deal with differences in assembled products.

Three types of assembly line can be distinguished:

single model,

batch model, and

mixed model.

single model line

produces many units of one product, and there is no variation in the product. Every work unit is identical, and so the task performed at each station is the same for all product units. This line type is intended for products with high demand.

The assembly line must be designed to achieve a production rate Rp sufficient to satisfy demand for the product.

Product demand is often expressed as an annual quantity, which can be reduced to an hourly rate.

batch model line

produces each model in batches. Workstations are set up to produce the required quantity of the first model, then the stations are reconfigured to produce the next model, and so on.

mixed model line

also produces more than one model; however, the models are not produced in batches. Instead, they are made simultaneously on the same line. Each station is equipped to perform the variety of tasks needed to produce any model that moves through it.

Repositioning losses

Some time will be lost at each station every cycle for repositioning the worker or the work unit; thus, the workers will not have the entire Tc each cycle.

occur on a production line because some time is required each cycle to reposition the worker, the work unit, or both.