Lathe Training

5.0(3)

Card Sorting

1/26

Earn XP

Description and Tags

Last updated 4:36 AM on 10/1/22

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

27 Terms

1

New cards

Shop Safety Rules

1.) Safety Glasses

2.) Closed toed shoes

3.) Tied up hair

4.) Pants that cover your knees

5.) Roll up your sleeves

6.) Cover shoulders, midriff, and back

7.) No dangling stings or jewelry

8.) No headphone or AirPods in ears

2.) Closed toed shoes

3.) Tied up hair

4.) Pants that cover your knees

5.) Roll up your sleeves

6.) Cover shoulders, midriff, and back

7.) No dangling stings or jewelry

8.) No headphone or AirPods in ears

2

New cards

Uses of the Lathe

1.) Turning

2.) Facing

3.) Parting

4.) Drilling

5.) Slotting

6.) Tapping

2.) Facing

3.) Parting

4.) Drilling

5.) Slotting

6.) Tapping

3

New cards

Stock for the Lathe

1.) Cylindrical Rod

2.) Hexagonal Rod

3.) Square Rod (Square stock is never used on Lathe, but the video mentioned it)

2.) Hexagonal Rod

3.) Square Rod (Square stock is never used on Lathe, but the video mentioned it)

4

New cards

Dimensions of Stock

1.) Length

2.) Diameter

3.) End Face == circular face of stock

2.) Diameter

3.) End Face == circular face of stock

5

New cards

Types of Lathes

1.) Collet Lathe(Garfunkel), Collet Lathe holds on to stock with a collet of a fixed diameter

2.) Chuck Lathe(Simon), Chuck Lathe holds on to stock with its jaws to clamp it in place

2.) Chuck Lathe(Simon), Chuck Lathe holds on to stock with its jaws to clamp it in place

6

New cards

Emergency Stops

1.) Do Not use Emergency Stops unless you are in an emergency!

2.) If You Use emergency stops, alert a supervisor before turning in back on!

2.) If You Use emergency stops, alert a supervisor before turning in back on!

7

New cards

Handling Lathe Tools

1.) Tools are sharp

2.) Take your time, and make sure you are safe

3.) Use a brush not your hand to clean tools

2.) Take your time, and make sure you are safe

3.) Use a brush not your hand to clean tools

8

New cards

Chuck Lathe: Inserting Stock

1.) Put stock into the three jaws

2.) Tighten jaws using Chuck Key

3.) Once the stock is tight enough, REMEMBER TO REMOVE CHUCK KEY

4.) Pull on stock to make sure it is securely in the jaws

5.) REMEMBER: (⅓ or 6") or less of the stock should be sticking out of the jaws

2.) Tighten jaws using Chuck Key

3.) Once the stock is tight enough, REMEMBER TO REMOVE CHUCK KEY

4.) Pull on stock to make sure it is securely in the jaws

5.) REMEMBER: (⅓ or 6") or less of the stock should be sticking out of the jaws

9

New cards

Collet Lathe: Inserting Stock

1.) Choose collet

2.) Insert collet inside spindle to match alignment with the pin

3.) Turn knob clockwise to tighten stock

4.) Push tightening lever back and stop when correct tightness is found

5.) Push lock down and rotate slightly for a click

6.) REMEMBER: (½ or 6") or less of the stock should be sticking out of the collet

2.) Insert collet inside spindle to match alignment with the pin

3.) Turn knob clockwise to tighten stock

4.) Push tightening lever back and stop when correct tightness is found

5.) Push lock down and rotate slightly for a click

6.) REMEMBER: (½ or 6") or less of the stock should be sticking out of the collet

10

New cards

Lathe Operations

1.) Parting reduces the length of the stock

2.) Facing creates a smooth and even face at the end of the stock by shaving of a little bit of the end face

3.) Drilling is the process of creating a hole in the stock, remember to add 0.25 inches to the end of the hole due to the conical shape of the drill bit

4.) Tapping is the process of creating threads in a drilled hole

5.) Turning is the process of reducing the diameter of the stock

6.) Slotting is the process of creating a reduced diameter in the middle of the stock

2.) Facing creates a smooth and even face at the end of the stock by shaving of a little bit of the end face

3.) Drilling is the process of creating a hole in the stock, remember to add 0.25 inches to the end of the hole due to the conical shape of the drill bit

4.) Tapping is the process of creating threads in a drilled hole

5.) Turning is the process of reducing the diameter of the stock

6.) Slotting is the process of creating a reduced diameter in the middle of the stock

11

New cards

Location of Stored Stock

1.) The Bin

2.) Cat Closet

2.) Cat Closet

12

New cards

How to zero the Axis

1.) Use the X-axis knob to face

2.) Gently touch the face and press zero

3.) Move the tool back in the x direction

4.) Manually turn chuck/spindle

5.) Repeat until zeros are

2.) Gently touch the face and press zero

3.) Move the tool back in the x direction

4.) Manually turn chuck/spindle

5.) Repeat until zeros are

13

New cards

Steps for Parting

1.) Position parting tool using X-axis crank

2.) Oil and engage motor level

3.) Move parting tool halfway into stock

4.) Move away and disengage the motor control lever

2.) Oil and engage motor level

3.) Move parting tool halfway into stock

4.) Move away and disengage the motor control lever

14

New cards

Steps for Turning

1.) Move y to desired distance

2.) Oil

3.) Turn on motor level

4.) Use x axis to move into the stock

5.) Move tool away once done

6.) Turn off motor level

2.) Oil

3.) Turn on motor level

4.) Use x axis to move into the stock

5.) Move tool away once done

6.) Turn off motor level

15

New cards

Steps for Facing

1.) Move tool into needed x position for DRO

2.) Oil

3.) Engage motor control level

4.) Use y axis to move into stock halfway

5.) Move away and turn off motor control level

2.) Oil

3.) Engage motor control level

4.) Use y axis to move into stock halfway

5.) Move away and turn off motor control level

16

New cards

Steps for Tapping

1.) Set up tap guide, tap handle and tap

2.) Keep moving the tailstock into the part until there is resistance

3.) Oil tap

4.) Rotate ½ CW, ¼ CCW. Change speeds and adjust tailstock if needed.

5.) Once finished, move the tailstock back and rotate the tap out of the part.

2.) Keep moving the tailstock into the part until there is resistance

3.) Oil tap

4.) Rotate ½ CW, ¼ CCW. Change speeds and adjust tailstock if needed.

5.) Once finished, move the tailstock back and rotate the tap out of the part.

17

New cards

Steps for Slotting

1.) Move tool to needed x position

2.) Oil

3.) Engage motor control lever

4.) Move slotting tool into part using y axis knob

5.) Move slotting tool away from part using y axis knob once you are satisfied

6.) Disengage motor control lever

2.) Oil

3.) Engage motor control lever

4.) Move slotting tool into part using y axis knob

5.) Move slotting tool away from part using y axis knob once you are satisfied

6.) Disengage motor control lever

18

New cards

Chuck Lathe: Change Speeds

1.) Reference chart for correct speed of aluminum + steel

2.) Turn knobs one at a time while manually turning the chuck

3.) Make sure there is a click or change in resistance

2.) Turn knobs one at a time while manually turning the chuck

3.) Make sure there is a click or change in resistance

19

New cards

Collet Lathe: Change Speeds

1.) Reference chart for correct speed

2.) Change the letter knob while rotating the spindle manually

3.) Make sure there is a click or change in resistance

4.) Change the number knob while rotating the spindle manually

5.) Make sure there is a click or change in resistance

2.) Change the letter knob while rotating the spindle manually

3.) Make sure there is a click or change in resistance

4.) Change the number knob while rotating the spindle manually

5.) Make sure there is a click or change in resistance

20

New cards

How to find Drill Bits and Taps

1.) Go to chart by drill bits

2.) Select the drill bit size right below the tap size

2.) Select the drill bit size right below the tap size

21

New cards

When to Clean the Lathe Bed

1.) When it is full

2.) When we machine plastic or steel

2.) When we machine plastic or steel

22

New cards

Speeds for Materials on the Collet Lathe

1.) Plastics: 1000 rpm

2.) Aluminum: 730 rpm

3.) Steel: 430 rpm

2.) Aluminum: 730 rpm

3.) Steel: 430 rpm

23

New cards

Pass for Facing

0.05 inches

24

New cards

Pass for Parting

0.2 inches

25

New cards

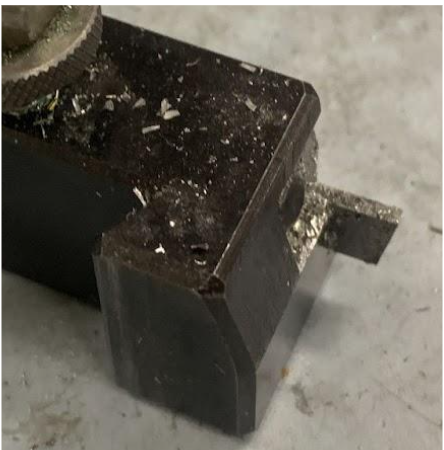

Slotting Tool

26

New cards

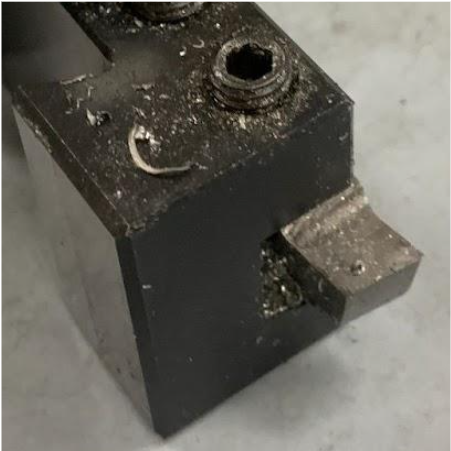

Parting Tool

27

New cards

Turning/Facing Tool